2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2024-01-02 13:55

Forge welding yog kab tias txoj kev qub tshaj plaws ntawm kev sib txuas hlau. Blacksmithing yog tib txoj kev ua cov hlau rau ntau txhiab xyoo, kom txog rau thaum xyoo 19th cov kws tshaj lij tau paub txog kev tsim cov khoom tsim. Thiab nyob rau hauv lub xyoo pua 20th, thev naus laus zis tau tsim, vim tias lwm txoj hauv kev zoo ntawm kev sib txuas ntawm hlau tau los rau noob neej. Vim li no, forging tau poob nws qhov tseeb. Niaj hnub no, cov khoom siv tes ua no tsuas yog tsim nyog, raws li qhov kev thov ntawm qee tus kws tshaj lij khoom siv tes ua.

Cov lus qhia

Forge welding yog txheej txheem tsim khoom uas tsim kev sib cais tsis sib xws ntawm cov khoom siv hlau siv qhov kub thiab txias thiab cuam tshuam. Nyob rau hauv lwm yam lus, hlau fragments yog rhuab nyob rau hauv ib tug tshwj xeeb rauv rau lub xeev cov kua thiab, siv percussion instruments, nyob rauhlau puag nqa tawm lawv cov kev sib txuas. Tag nrho cov txheej txheem muaj cov kauj ruam hauv qab no:

- npaj ua ntej ntawm qhov chaw yuav koom nrog;

- cua sov rau qhov kub thiab txias;

- kev sib txuas nrog cov cuab yeej percussion;

- kawg forging, tso cai rau koj los teeb tsa qhov xav tau.

Qhov tseem ceeb tshaj plaws nyob rau hauv rooj plaub no yog cov cua sov ntawm cov hlau uas siv qhov kub thiab txias. Nqa cov hlau mus rau qhov ntsuas kub yuav tsum tau tswj los ntawm kev hloov xim ntawm qhov kub. Yog li, ncav cuag qhov kub ntawm 1300 degrees, cov hlau yuav ci daj. Thaum tshav kub kub nce mus txog 1400 degrees, nws pib ci dawb. Thaum qhov ntsuas kub yuav tsum tau mus txog, qhov kev sib txuas yuav tsum tau ua tam sim ntawd. Txwv tsis pub, qhov zoo ntawm cov khoom yuav raug kev txom nyem vim overburning ntawm cov khoom, uas yog nrog los ntawm kev tsim ntawm ib tug ntau txheej ntawm scale.

Ntse

Kev ntseeg siab rau cov tebchaw, vim yog thermal diffusion, siv lub zog siab, thaum nqa cov khoom mus rau lub xeev cov yas mos, raws li txoj cai, rau ntau hom hlau thiab cov khoom muaj qhov sib txawv loj. Yog li, cov hlau tsis muaj cov pa roj carbon tsawg nrog qhov feem pua ntawm cov pa roj carbon tsis ntau tshaj 0.6% yog suav tias yog malleable rau pob qij txha. Raws li qhov feem pua nce ntxiv, tag nrho lub peev xwm los ua ke tsis muaj zog.

Alloy steels nyuaj rau forge, nrog rau cov hlau tsis muaj hlau, suav nrog lawvalloys. Tsis tas li ntawd, txhua hom cam khwb cia hlau tsis tuaj yeem txuas rau hauv txoj kev no. Qhov teeb meem tseem ceeb rau kev sib koom ua ke hauv cov txheej txheem ntawm thermal diffusion yog tsim ntawm txheej txheej ntawm cov rhuab saum npoo. Cov txheej no yog tsim los ntawm refractory oxides hu ua FeO thiab Fe3O4, uas muaj peev xwm yaj thaum raug kub uas txaus. kom tsis muaj zog ntawm lub ntsiab ntawm cov hlau.

txhawm rau txo qhov cuam tshuam ntawm oxides uas tsim kev cuam tshuam, qhov chaw yuav tsum tau kho yog coated nrog tshwj xeeb fluxes rau forge vuam. Lawv yog cov acidic. Feem ntau, lub rooj ntsev los yog boric acid yog siv rau lub hom phiaj no. Ib qho calcined laum rau forge welding kuj tseem tsim nyog. Hauv lwm qhov xwm txheej, kev siv flux yog hloov los ntawm qee cov ntaub ntawv improvised. Qhov no, piv txwv li, tuaj yeem yog iav cullet, nrog rau cov xuab zeb zoo los ntawm tus dej ntug dej, uas tuaj yeem hloov cov kws ua hlau vuam nrog xim av.

vuam no yog suav tias yog ib qho ntawm cov txheej txheem nyuaj tshaj plaws ntawm kev siv thev naus laus zis, vim nws xav tau ntau yam kev paub thiab kev txawj ntse los ntawm tus kws tshaj lij. Piv txwv li, nws yuav tsum to taub tias lub peev xwm los koom nrog cov hlau tshwm tsuas yog thaum muaj qhov kub thiab txias. Nyob rau hauv cov ntaub ntawv ntawm cov cua kub tsis txaus ntawm qhov chaw, ib qho kev tsis xws luag hu ua tsis muaj kev nkag mus yuav tshwm sim. Thiab yog hais tias cov hlau yog overheated, ces ib tug hlawv yog tsim, uas kuj yuav tsis coj cov khoom mus rau ib tug high-zoo daim ntawv.

Txoj kev

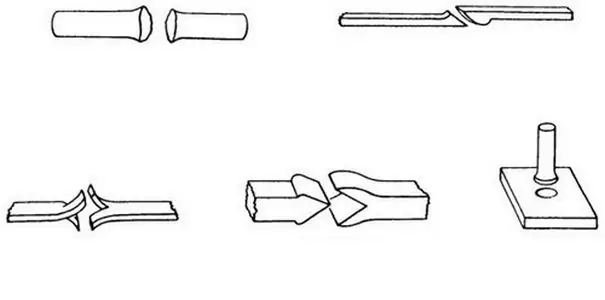

Muaj ntau txoj hauv kev sib txuas yooj yim uas tsis xav tau ntevkev npaj ua thaum lub sij hawm forge welding. Cov npe txheej txheem hauv qab no yog siv:

- overlapping;

- pob;

Txoj Cai

Yuav ua li cas siv cov tswv yim no, koj yuav tsum ua raws li ib txoj cai uas yuav tsum tau ua - qhov kawg ntawm lub workpieces yuav tsum muaj cov duab convex, thiab kuj muaj thickenings ntawm lawv qhov kawg. Cov xwm txheej no yuav tsum raug soj ntsuam vim tias nyob rau hauv tus txheej txheem ntawm kev sib txuas los ntawm forge welding txoj kev, thaum lub sij hawm cua sov ntawm lub workpiece, ib tug slag zaj duab xis yog tsim nyob rau hauv cov hlau nto. Thiab yog tias qhov chaw muaj bulges, ces slag hais tuaj yeem raug nyem tawm. Thickenings tsim nyob rau ntawm qhov kawg ntawm qhov khoob uas npaj rau forging ua ib qho cuab yeej cuab tam hauv cov txheej txheem kom tau txais cov duab uas xav tau.

Lwm technologies

Tseem muaj ntau txoj kev forge vuam thev naus laus zis uas tso cai rau koj los tsim cov khoom lag luam uas ua lub luag haujlwm ntawm cov khoom siv hauv cov txheej txheem nyuaj lossis sawv cev cov khoom zoo nkauj hauv ntau cov qauv tsim:

- Ib qho ntawm cov txheej txheem no yog pov thawj phua vuam. Cov txheej txheem no tau siv yav dhau los, koom nrog cov hlua hlau hauv cov txheej txheem ntawm kev ua cov log tsheb hlau uas xav tau los ntawm cov tsheb hauv zos.

- Txoj kev tom ntej yog vuam siv cov checkers. Cov txheej txheem no muaj txiaj ntsig zoo thaum txuas cov khoom siv tag nrho.

Rau kev sib cais vuam, cov txheej txheem ntawm cov strips dhaukev cob qhia tshwj xeeb. Lawv yog thawj zaug rub thiab ces txiav nyob rau hauv xws li ib tug txoj kev uas ua ntej welding, nws yuav ua tau mus cuag los ntawm overlapping. Tsuas yog tom qab ntawd qhov tawg yog rhuab mus rau qhov kub thiab txias thiab welded los ntawm forging. Qhov thib ob txoj kev ntawm forge welding ntawm steel yog siv los ntawm ib qho ntxiv. Cov ntsiab lus no hu ua checkers.

Scope of application

Forge welding hnub no tsis yog txoj hauv kev tseem ceeb ntawm kev koom nrog cov hlau. Nws yog siv tsuas yog rau kev tsim khoom ntawm complex hlau Cheebtsam nyob rau hauv intricate qauv ntawm artistic forging masters. Kev kos duab vuam ntawm cov hlau tawg tso cai rau koj los tsim cov ntaub ntawv zoo kawg uas kho ntau yam facades.

Tsis tas li ntawd, txoj kev vuam no qee zaum siv rau kev tsim cov cuab yeej tes uas xav tau hauv lub neej txhua hnub. Thiab nws tau poob nws qhov tseem ceeb hauv kev lag luam vim tias tsis muaj cov khoom lag luam tawm tsam keeb kwm yav dhau los ntawm lwm txoj kev sib txuas.

Cons

Qhov tsis zoo ntawm cov thev naus laus zis no suav nrog:

- qis cua sov;

- tsis txaus lub zog ntawm cov pob qij txha tshwm sim;

- qhov tseem ceeb heterogeneity nyob rau hauv nqe lus ntawm kev chim siab;

- kev tsim nyog tau txais los ntawm cov neeg ua yeeb yam.

Tsuas yog ob peb qhov kev lag luam txuas ntxiv siv forge vuam. Tam sim no, siv cov cuab yeej no, lawv txuas ntxiv tsim cov kav dej hlau, txoj kab uas hla tsis tshaj 100 mm. Tsim tej yam kev mobTxhawm rau ua tiav cov txheej txheem no, cov hlua hlau yog rhuab rau hauv qhov cub tshwj xeeb, thiab tom qab ntawd dov linearly los ntawm cov yob. Ces nws yog dragged los ntawm lub mandrels ntawm kev kub ceev. Nyob rau hauv txoj kev no, qhov dav dav seam vuam ntawm cov yeeb nkab dej tshwm sim nyob rau hauv lub zog siab.

Kuj ntawm kev lag luam nplai, forge welding tseem siv nyob rau hauv kev tsim cov phaj bimetallic complex. Feem ntau, rau qhov no, kev sib koom ua ke ntawm cov ntawv kub kub los ntawm cov chais tshwj xeeb yog siv, lossis siv txoj kev nias, siv cov cua sov cua sov, nrog rau lub tshuab nqus tsev. Forge welding tso cai rau koj muab cov txheej txheem ntau txheej rau cov khoom, uas qee zaum tseem ceeb heev.

khoom siv thiab khoom siv

Nws tsis siv ntau los teeb tsa me me rau kev tsim khoom siv tes ua ntawm qee yam khoom lossis kos duab kos duab.

Nrog qee yam khoom siv thiab ob peb yam cuab yeej, koj tuaj yeem teeb tsa koj tus kheej tsim cov hlau forge vuam:

- Ua ntej tshaj plaws, koj xav tau ib lub bugle nyob ruaj khov thiab ib qho nqa tau. Qhov no yog ib qho cuab yeej tshwj xeeb tsim nyog rau cua sov ntawm qhov chaw yuav tsum tau welded. Ib qho roj av autogenerator zoo tib yam tuaj yeem dhau los ua cov khoom siv tau yooj yim.

- Tom ntej no koj xav tau ib pab pawg ntawm anvils. Nws yog ib qho tseem ceeb uas nws yuav tsum yog ob qho tib si loj thiab me. Tsis tas li ntawd xwb, nws tsis yog txaus kom muaj ob lub hneev taw nkaus xwb. Ib-horned kuj yuav tsum muaj.

- Tshuaj ntawm tus kws kho hniav,ua los ntawm ntau qhov ntau thiab tsawg li ntau tau.

- Ib txheej ntawm cov hammers uas yuav tso cai rau koj ua tiav cov txheej txheem forging.

- Ob lub thawv tsim los rau cov khoom txias. Ib tug ntawm lawv yuav tsum tau ntim nrog dej thiab lwm yam muaj roj.

tseem ceeb

Nws yog qhov tsim nyog los muab lub forge nrog tag nrho cov khoom siv kev nyab xeeb tsim nyog. Tsis tas li ntawd, cov khoom siv yuav tsum muaj cov khoom siv tiv thaiv tus kheej - iav tsom iav, tawv tawv apron, cov hnab looj tes tuab tuab.

Pom zoo:

Loj hlob nceb hauv tsev cog khoom: thev naus laus zis, yam ntxwv ntawm kev ua haujlwm, cov xwm txheej tsim nyog thiab cov kws tshaj lij cov lus qhia

Kev cog nceb hauv tsev cog khoom yog ib txoj hauv kev zoo kom tau cov qoob loo huv si rau koj tus kheej lossis muag. Nws tsis tuaj yeem hais tias thev naus laus zis ntawm cov txheej txheem no nyuaj heev, tab sis ntau txoj haujlwm yuav tsum tau nqis peev

Kev ua haujlwm ntawm kev lag luam: cov cuab yeej thiab thev naus laus zis

CRM-systems, ERP-solutions, WEB-cov cuab yeej thiab BPM-cov tswv yim - tag nrho cov ntsiab lus no poob rau cov neeg ua lag luam niaj hnub no uas tau mob siab rau kev ua lag luam tshiab. Qhov no yog dab tsi?

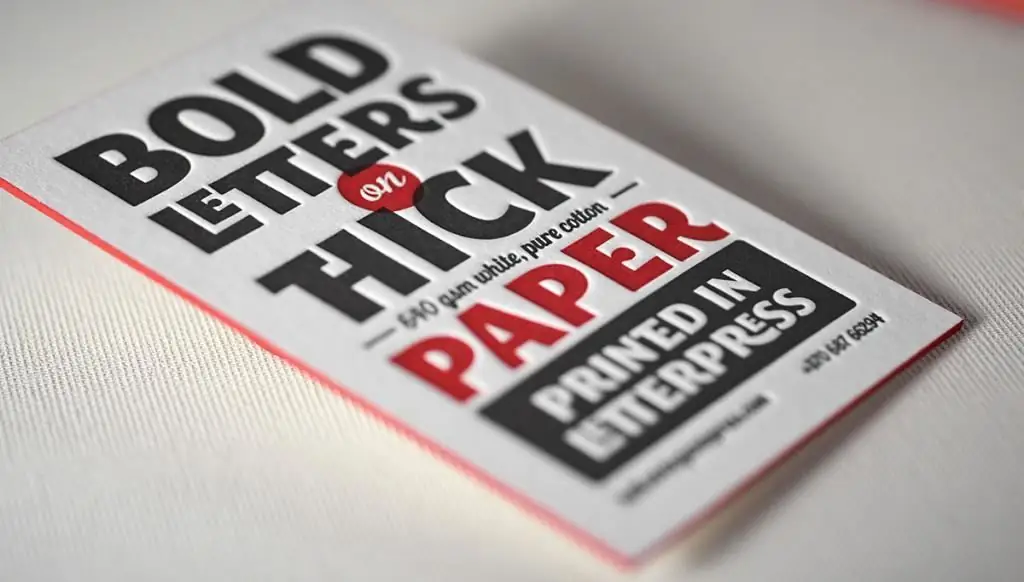

Letterpress yog Letterpress luam ntawv thev naus laus zis, theem niaj hnub ntawm kev txhim kho, cov cuab yeej tsim nyog, qhov zoo thiab qhov tsis zoo ntawm hom luam ntawv no

Letterpress yog ib txoj hauv kev siv cov ntaub ntawv siv cov matrix nyem. Cov ntsiab lus uas protrude yog them nrog xim nyob rau hauv daim ntawv ntawm ib tug muab tshuaj txhuam, thiab ces nias rau ntawm daim ntawv. Yog li, ntau yam huab hwm coj, cov phau ntawv siv, cov phau ntawv thiab cov ntawv xov xwm tau luam tawm

Dab tsi yog kev lag luam cuab yeej? Cov cuab yeej siv thev naus laus zis thiab cov cuab yeej siv

Cov kab lus no mob siab rau cov cuab yeej siv thev naus laus zis. Cov khoom siv, cov nuances ntawm kev tsim thiab kev tsim khoom, kev ua haujlwm, thiab lwm yam raug txiav txim siab

Vuam hauv qhov chaw tiv thaiv roj: ua haujlwm thev naus laus zis, txheej txheem piav qhia, cov txheej txheem ua tiav, cov khoom tsim nyog thiab cov cuab yeej, cov lus qhia ua haujlwm ib ntus thiab cov lus qhia kws tshaj lij

Vuam thev naus laus zis yog siv hauv ntau ceg ntawm tib neeg kev ua haujlwm. Versatility tau ua vuam nyob rau hauv ib puag ncig tiv thaiv roj ib qho tseem ceeb ntawm kev tsim khoom. Qhov ntau yam no ua rau nws yooj yim los txuas cov hlau nrog lub thickness ntawm 1 hli mus rau ob peb centimeters nyob rau hauv txhua txoj hauj lwm nyob rau hauv qhov chaw. Vuam nyob rau hauv ib puag ncig tiv thaiv yog maj mam hloov cov tsoos electrode vuam