2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2024-01-02 13:55

vuam thev naus laus zis yog siv hauv ntau ceg ntawm tib neeg kev ua haujlwm. Nws versatility tau ua gas-shielded welding ib feem tseem ceeb ntawm kev tsim khoom.

Qhov ntau yam no ua rau nws yooj yim los txuas cov hlau nrog lub thickness ntawm 1 hli mus rau ob peb centimeters nyob rau hauv txhua txoj hauj lwm nyob rau hauv qhov chaw. Vuam nyob rau hauv qhov chaw tiv thaiv yog maj mam hloov cov tsoos electrode vuam.

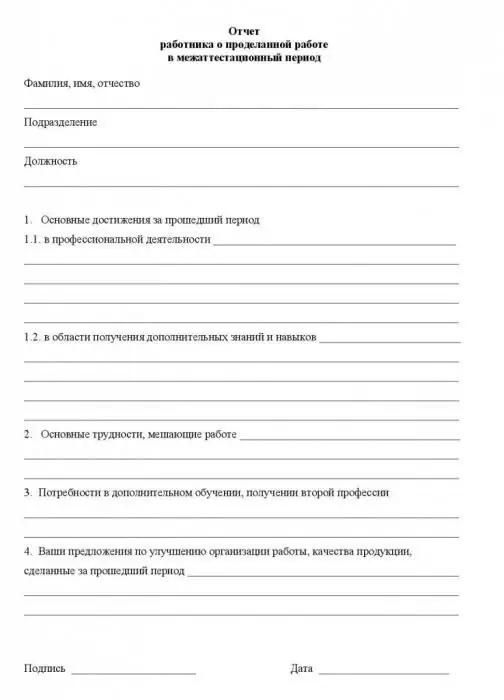

Lub ntsiab ntawm cov txheej txheem vuam hauv kev tiv thaiv roj

Cov txheej txheem vuam yog siv los tsim kev sib txuas mus tas li ntawm cov hlau sib txawv. Nws yog ua tiav los ntawm cua sov cov ntsiab lus txuas mus rau qhov kub thiab txias ze rau lub melting point. Cov cua sov tshwm sim nrog kev pab los ntawm hluav taws xob arc, uas muaj qhov kub thiab txias ntawm 7,000 txog 18,000 ° C. Qhov no tso cai rau koj kom sov cov hlau raug welded thiab tsim ib tug weld pas dej ua ke, uas yog sau nrogmolten electrode.

Yuav kom cov hluav taws xob arc hlawv kom ruaj khov, thiab kom cov huab cua tsis cuam tshuam rau vuam, cov roj tiv thaiv tau muab rau thaj tsam combustion, uas tsim lub dome uas tiv thaiv oxidation.

Gas-shielded welding yog siv qhov yooj yim welding nrog coated electrode tsis ua hauj lwm. Qhov no yog ib qho kev sib xyaw ntawm cov hlau xws li:

- tooj;

- bronze;

- titanium;

- molybdenum;

- chrome thiab lwm yam

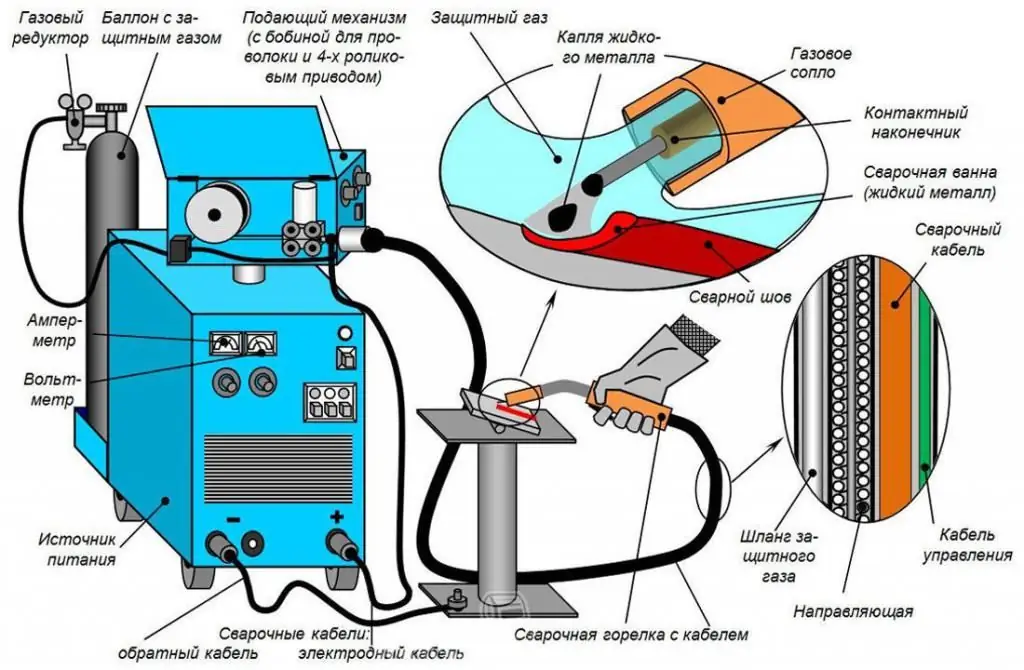

Niaj hnub nimno tsis siv neeg ntau lawm siv tshuab vuam hauv kev tiv thaiv roj. Nrog nws cov kev pab, tsis tsuas yog cov hlau tsis yog ferrous yog brewed, tab sis kuj ferrous sawv daws yuav (ntau hom hlau).

Txoj kev txiaj ntsig

hom vuam no muaj ntau yam zoo.

- Tso cai vuam ntawm cov hlau tsis muaj hlau. Qhov nyuaj ntawm lawv cov vuam yog nyob rau hauv qhov tseeb hais tias lawv muaj ib tug tsawg melting point nrog high oxidization, uas pollutes lub vuam cheeb tsam nrog oxides thiab ua rau nws nyuaj rau tau ib tug zoo seam.

- Kub kub cua sov. Qhov no ua rau nws muaj peev xwm ua kom thaj chaw vuam tsis pub dhau qhov txwv me me. Raws li qhov tshwm sim, cov hlau welded tsis hloov nws cov khoom siv vim yog overheating.

- Kev ua haujlwm siab. Vuam nyob rau hauv ib puag ncig tiv thaiv roj ua rau nws muaj peev xwm automate cov txheej txheem los ntawm kev siv cov hlau qhov txhab ntawm lub kauj thiab nws tsis siv neeg pub.

- No slag. Tsis muaj sij hawm nkim rho tawm.

Qhov tsis zoo ntawm kev tiv thaiv vuam

Txog qhov tsis zoo ntawm hom nowelding tuaj yeem raug ntaus nqi los ntawm qhov loj ntawm cov khoom siv. Ntxiv nrog rau lub tshuab vuam nws tus kheej, cov khoom siv suav nrog lub tog raj kheej roj, reducers, roj fittings.

Cov khoom siv tau kim dua li cov pa arc vuam.

Nyob rau hauv kev lag luam niaj hnub no, lub ntsiab lus tseem ceeb rau kev muaj peev xwm ua tau nyiaj txiag yog lub sijhawm siv rau kev tsim khoom. Lawv qhia tsis siv neeg vuam tshuab nyob rau hauv shielding gases. Yog li ntawd, tus nqi siab ntawm cov ntaub ntawv yog offset los ntawm high productivity.

Yuav muaj zog npaum li cas

vuam hlau tsim kom muaj kev sib raug zoo. Nws muaj zog ntau dua li bolted los yog riveted pob qij txha. Tsis tas li ntawd, qhov twg nws yog qhov tsim nyog los tsim kom nruj, vuam yog qhov tseem ceeb. Qhov kev txwv tseem ceeb hauv nws daim ntawv thov yog qhov tsis muaj peev xwm tiv taus dynamic loads uas sib txawv ntawm qhov loj thiab hauv vector ntawm kev cuam tshuam. Nws yog vim li no tias rivets tau siv hauv kev tsim dav hlau es tsis txhob siv cov pob qij txha.

Lub zog ntawm qhov vuam yog nyob ntawm cov ntaub ntawv siv, ua raws li cov thev naus laus zis thiab kev npaj kom raug ntawm cov npoo kom welded.

Ntau yam khoom siv

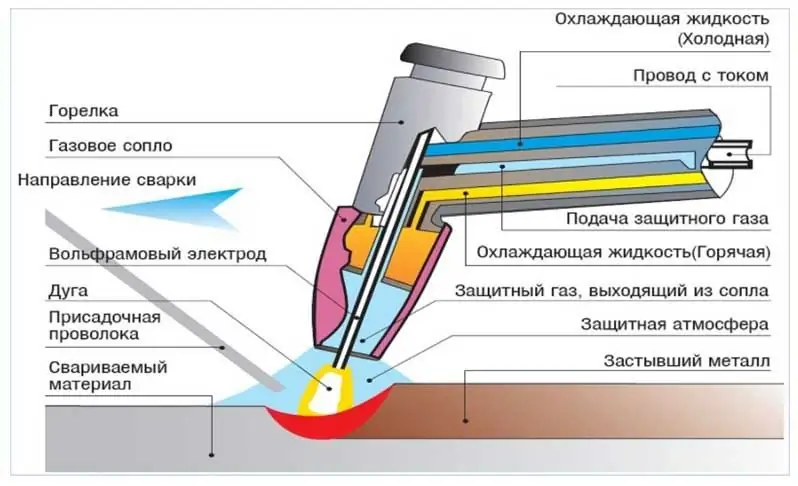

Gas shielded welding muaj ob hom:

- Tsis siv tau electrode. Cov hluav taws xob arc yog tsim los ntawm tungsten pas nrig uas tsis yaj hauv cov txheej txheem. Cov khoom siv los sau cov pas dej vuam yog pub manually hauv daim ntawv ntawm ib daim hlau.

- khoom siv hluav taws xob. Ntawm no cov hluav taws xob arc yog tsimtsis siv neeg pub hlau, uas tau txais hluav taws xob tam sim no. Cov hlau no melts thiab puv lub pas dej ua ke, ua ib qho seam.

Raws li qhov no, cov cuab yeej siv hluav taws xob tiv thaiv vuam tau muab faib ua ob hom:

- Vuam transformers thiab inverters nruab nrog tungsten tip torch.

- Semi-automatic vuam. Tam sim no hom khoom siv no feem ntau siv dav. Nrog lawv cov kev pab, koj tuaj yeem welding tag nrho cov hlau. Lawv yog mobile thiab muaj kev ua tau zoo heev. Semi-automatic vuam nyob rau hauv ib puag ncig tiv thaiv roj yog siv ob qho tib si hauv chaw nres tsheb thiab tsev neeg ntiag tug, nrog rau hauv kev lag luam loj.

- Laser-arc vuam. Qhov no yog ib hom khoom siv hybrid, qhov twg ntxiv rau qhov vuam arc los ntawm tungsten electrode, sib sib zog nqus melting yog tsim los ntawm laser beam. Nyob rau hauv cov ntaub ntawv no, ib tug ntaus ntawv yog siv uas combines laser optics thiab ib tug tungsten-tipped torch.

Cov pa roj twg siv

Muaj ntau hom roj siv, uas tuaj yeem muab faib ua 3 pawg: inert, nquag thiab ua ke.

Inert gases suav nrog: helium, argon. Helium yog sib dua li huab cua, kim dua los tsim, thiab siv tsawg dua. Tab sis lub arc nyob rau hauv nws khaws qhov kub siab tshaj nyob rau hauv argon, yog li welding nyob rau hauv ib puag ncig helium muaj ntau dua productivity. Nws yog siv rau vuam aluminium thiab magnesium alloys.

Argon muaj qhov dav duadaim ntawv thov. Nws yog siv rau vuam qhov tseem ceeb, nrog rau cov hlau tsis tshua muaj thiab tsis muaj hlau.

Nitrogen tuaj yeem raug cais raws li cov pa roj ntsha tsis zoo. Nws tsuas yog siv rau vuam tooj liab thiab nws cov alloys, nyob rau hauv kev sib raug zoo uas nws tsis active.

Cov pa roj carbon monoxide, txawm hais tias lawv tiv thaiv thaj chaw vuam, txawm li cas los xij lawv yaj lawv tus kheej hauv cov hlau welding, hloov nws cov muaj pes tsawg leeg. Cov no suav nrog carbon dioxide thiab oxygen. CO2 yog siv rau vuam ferrous hlau: qis thiab nruab nrab carbon steels, cam khwb cia hlau, tsawg alloy steels, thiab lwm yam.

Oxygen los tsuas yog tov nrog cov roj inert.

Kev sib xyaw ntawm cov roj sib xyaw yog siv ntau qhov sib txawv kom muaj kev ruaj ntseg ntawm cov txheej txheem vuam thiab txhim kho cov yam ntxwv ntawm cov vuam.

Rau ib nrab tsis siv neeg vuam nyob rau hauv ib puag ncig tiv thaiv roj, siv cov hlau dov rau hauv coils. Nws muaj ntau tshaj 80 ntau yam. Nws txoj kab uas hla yog los ntawm 0.3 mus rau 12 mm. Cov coils uas nws yog folded hnyav los ntawm 1.5 mus rau 40 kg. Cov hlau raug xaiv nrog tib yam muaj pes tsawg leeg raws li cov khoom yuav tsum tau welded.

Tsis siv hluav taws xob tuaj yeem yog tungsten lossis carbon. Lub tungsten electrode yog ib tug hlau nrog ib txoj kab uas hla ntawm 0.5-3 hli los yog rods nrog ib txoj kab uas hla ntawm 5-8 hli. Cov khoom siv rau cov khoom ntxiv yog cov hlau uas muaj txoj kab uas hla ntawm 1.6-5 mm.

Npaj rau kev ua haujlwm vuam

Vuam nyob rau hauv ib puag ncig tiv thaiv yog ua tsuas yog rau vuam qhov tseem ceeb. Yog li ntawd, thawj qhov yuav tsum tau muaj yog kev tsim nyog ntawm cov neeg ua haujlwm. Yuav ua li casua hauj lwm raug tso cai vuam yam tsawg kawg yog qib 5, uas tau kawm thiab tau txais daim ntawv tso cai.

Ua ntej pib ua haujlwm, tsis hais daim ntawv pov thawj, tus welder raug yuam kom pob tw-weld tus qauv uas yuav raug kuaj kom muaj zog. GOST gas-shielded vuam txiav txim siab npaum li cas tensile quab yuam cov qauv no yuav tsum tau tiv taus.

chav vuam yuav tsum muaj cov hmoov av tsawg kawg nkaus. Txhua hom kev ua haujlwm nrog nws tsim yog txwv tsis pub (txiav, sib tsoo, sib tsoo ua haujlwm).

Huab cua sab hauv tsev yuav tsum sov thiab qhuav. Rau qhov no, ntsuas kub thiab hygrometers raug teeb tsa. Qhov kub yuav tsum yog tsawg kawg 16 ° C.

teeb pom kev zoo yuav tsum muab cov ntsiab lus ntawm thaj chaw vuam thiab tso cai rau lub sijhawm tshawb pom qhov tsis xws luag uas tshwm sim hauv cov vuam sib txawv hauv qhov chaw tiv thaiv roj.

Drafts tsis pub nyob hauv chav. Huab cua khiav ceev yuav tsum tsis pub tshaj 0.5 m/s.

Tips & Tricks

Yuav kom tau txais kev sib txuas zoo, koj yuav tsum ua qee yam kev npaj ua haujlwm.

- Txiav cov npoo ntawm cov khoom kom raug welded. Kev nkag mus thiab txhaws ntawm lub pas dej ua ke nrog hlau nyob ntawm qhov no.

- Ua kom huv si saum npoo kom welded los ntawm av, xeb.

- Kho qhov tiv thaiv roj siab. Yog tias qhov siab siab, yuav muaj cua txias ntau dhau ntawm qhov chaw vuam. Tsis tshua muaj siab yuav ua rau pores tsim nyob rau hauv lub vuam.

- Xaiv lub zog tam sim no. Nws raug xaiv raws li lub thickness ntawm cov hlau yuav tsum tau welded. Cov hlau pub yog kho raws li qhov amperage.

- Tau txaisLub tshuab hluav taws xob zoo seam yuav tsum tau ntxuav txhua lub sijhawm. Yog tias qhov no tsis ua tiav, tom qab ntawd maj mam ntsuas qhov ntsuas yuav txo qis sab hauv txoj kab uas hla ntawm lub qhov cub, thiab cov roj tiv thaiv yuav muab nkag rau thaj tsam combustion nrog lub teeb tsis raug. Tsis tas li ntawd, qhov ntsuas yuav ua rau nws nyuaj rau noj cov hlau. Silicone tuaj yeem siv los txo qhov tsim ntawm soot ntawm lub qhov cub. Lawv lubricate sab hauv ntawm lub burner. Siv tau zoo heev aerosol cov kaus poom rau vuam.

Gas-shielded welding yog lub luag haujlwm txheej txheem uas feem ntau nyob ntawm tib neeg yam. Kev ua raws li kev ntsuas kev nyab xeeb, kev siv cov cuab yeej tiv thaiv yuav pab tsis tau tsuas yog ua haujlwm kom zoo, tab sis kuj ua kom muaj kev noj qab haus huv.

Pom zoo:

Loj hlob nceb hauv tsev cog khoom: thev naus laus zis, yam ntxwv ntawm kev ua haujlwm, cov xwm txheej tsim nyog thiab cov kws tshaj lij cov lus qhia

Kev cog nceb hauv tsev cog khoom yog ib txoj hauv kev zoo kom tau cov qoob loo huv si rau koj tus kheej lossis muag. Nws tsis tuaj yeem hais tias thev naus laus zis ntawm cov txheej txheem no nyuaj heev, tab sis ntau txoj haujlwm yuav tsum tau nqis peev

Dab tsi yog kev lag luam cuab yeej? Cov cuab yeej siv thev naus laus zis thiab cov cuab yeej siv

Cov kab lus no mob siab rau cov cuab yeej siv thev naus laus zis. Cov khoom siv, cov nuances ntawm kev tsim thiab kev tsim khoom, kev ua haujlwm, thiab lwm yam raug txiav txim siab

Forge vuam: piav qhia, ua haujlwm thev naus laus zis thiab cov cuab yeej tsim nyog

Forge welding yog kab tias txoj kev qub tshaj plaws ntawm kev sib txuas hlau. Blacksmithing yog tib txoj kev ua cov hlau rau ntau txhiab xyoo, kom txog rau thaum xyoo 19th cov kws tshaj lij tau paub txog kev lag luam foundry. Thiab nyob rau hauv lub xyoo pua 20th, thev naus laus zis kev vam meej tau tsim, vim tias lwm yam kev sib txuas ntawm cov hlau tau dhau los ua rau noob neej. Vim li no, forging tau poob nws qhov tseeb

Kev sib tsoo ncej: txheej txheem, cov ntaub ntawv tsim nyog thiab cov cuab yeej, cov lus qhia ua haujlwm ib kauj ruam thiab cov lus qhia kws tshaj lij

Hnub no, kev sib tsoo ncej yog siv dav hauv kev lag luam xws li kev tsim kho tshuab. Qhov kev ua haujlwm no tso cai rau kev npaj cov khoom uas yuav muaj me me roughness, me ntsis sib txawv ntawm cov duab, thiab lwm yam

Kev kho dua tshiab ntawm qhov chaw los ntawm vuam thiab ntog: cov txheej txheem thiab cov txheej txheem ntawm kev kho dua tshiab, nta, txheej txheem thev naus laus zis

Vuam thiab surfacing thev naus laus zis ua rau nws ua tau zoo los kho cov hlau seem, muab cov qib siab ntawm kev ntseeg siab thiab ua haujlwm ntev ntawm cov khoom. Qhov no tau lees paub los ntawm kev xyaum siv cov txheej txheem no thaum ua haujlwm kho hauv ntau qhov chaw - los ntawm kev kho tsheb mus rau kev tsim cov hlau dov. Hauv tag nrho cov nyiaj ua haujlwm ntawm kev kho cov qauv hlau, kev kho dua tshiab ntawm qhov chaw los ntawm kev vuam thiab surfacing yuav siv li 60-70%