2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Ntau tus neeg paub tias hlau yog cov khoom tau txais los ntawm cov txheej txheem smelting lwm yam. Tab sis dab tsi? Dab tsi yog hauv steel? Niaj hnub no, cov khoom no yog deformable alloy ntawm hlau nrog carbon (nws tus nqi yog 2.14%), nrog rau ib tug me me feem ntawm lwm yam ntsiab.

cov ntaub ntawv dav dav

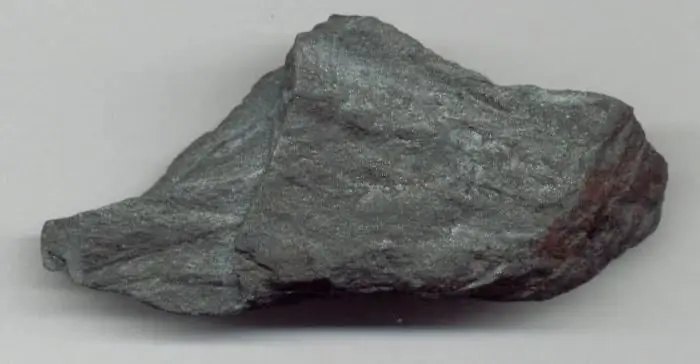

Nws yog ib qho tsim nyog sau cia tias cov hlau yog cov hlau alloy uas muaj raws nraim li 2, 14% carbon hauv nws cov muaj pes tsawg leeg. Ib qho hlau uas muaj ntau tshaj 2.14% carbon twb hu ua cam khwb cia hlau.

Nws paub tias cov pa roj carbon steel thiab cov hlau zoo tib yam tsis zoo ib yam. Yog hais tias lub substrate ib txwm muaj xws li carbon thiab lwm yam alloying (kev txhim kho) Cheebtsam, ces tsis muaj alloying ntsiab nyob rau hauv cov khoom carbonaceous. Yog hais tias peb tham txog alloy steel, ces nws muaj pes tsawg leeg yog ntau nplua nuj. Txhawm rau txhim kho kev ua haujlwm ntawm cov khoom siv no, cov ntsiab lus xws li Cr, Ni, Mo, Wo, V, Al, B, Ti, thiab lwm yam ntxiv rau nws cov muaj pes tsawg leeg. muab precisely los ntawm kev ntxiv alloyed complexes, tsis yog ib los yog ob yam.

Kev faib tawm

SivKev faib tawm ntawm cov khoom peb tab tom txiav txim siab tuaj yeem ua raws li ntau qhov ntsuas:

- thawj qhov taw qhia yog cov tshuaj muaj pes tsawg leeg ntawm cov hlau.

- Qhov thib ob yog microstructure, uas tseem ceeb heev.

- Tau kawg, steels txawv ntawm lawv txoj kev ua tau zoo thiab kev tsim khoom.

- Tsis tas li, txhua hom hlau muaj nws tus kheej daim ntawv thov.

Hauv kev nthuav dav ntxiv, qhov muaj pes tsawg leeg tuaj yeem txiav txim siab siv qhov piv txwv ntawm cov tshuaj muaj pes tsawg leeg. Raws li lub hauv paus no, ob hom ntau yam txawv - cov no yog alloyed thiab carbon steels.

Ntawm cov pa roj carbon steel, muaj peb hom, qhov sib txawv ntawm qhov tseem ceeb yog cov ntsiab lus ntawm cov pa roj carbon ntau. Yog tias cov khoom muaj tsawg dua 0.3% carbon, ces nws raug cais raws li cov pa roj carbon tsawg. Cov ntsiab lus ntawm cov khoom no hauv cheeb tsam los ntawm 0.3% mus rau 0.7% txhais cov khoom kawg rau hauv qeb ntawm nruab nrab carbon steels. Yog hais tias cov hlau muaj ntau tshaj 0.7% carbon, ces cov hlau yog cais raws li high-carbon.

Nrog cov hlau alloy, yam khoom zoo ib yam. Yog hais tias muaj pes tsawg leeg ntawm cov khoom muaj tsawg tshaj li 2.5% alloying ntsiab, ces nws yog xam tias yog tsawg-alloyed, los ntawm 2.5% mus rau 10% - nruab nrab-alloyed, thiab los ntawm 10% thiab siab dua - high-alloyed.

Microstructure

Lub microstructure ntawm steel txawv nyob ntawm nws tus mob. Yog hais tias lub alloy yog annealed, ces nws cov qauv yuav muab faib ua carbide, ferritic, austenitic, thiab hais txog. Nrog rau qhov normalized microstructure ntawm cov khoom, cov khoom yuav ua pearlitic, martensitic los yog austenitic.

Cov khoom sib xyaw thiab cov khoom ntawm cov hlau txiav txim siab seb cov khoom puas yog ib qho ntawm peb chav kawm. Qhov tsawg tshaj plaws alloyed thiab carbon steels yog cov chav kawm pearlitic, cov nruab nrab yog martensitic, thiab cov ntsiab lus siab ntawm cov ntsiab lus alloying los yog carbon txhais rau hauv qeb ntawm austenitic steels.

Production and quality

Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias cov hlau xws li hlau yuav suav nrog qee cov ntsiab lus tsis zoo, cov ntsiab lus siab uas ua rau qhov ua tau zoo ntawm cov khoom. Cov tshuaj no suav nrog sulfur thiab phosphorus. Nyob ntawm cov ntsiab lus ntawm ob lub ntsiab lus no, cov muaj pes tsawg leeg thiab hom hlau tau muab faib ua plaub pawg hauv qab no:

- Private steel. Qhov no yog cov hlau zoo tib yam, muaj txog li 0.06% sulfur thiab mus txog 0.07% phosphorus.

- Quality. Cov ntsiab lus ntawm cov khoom saum toj no hauv cov hlau no txo qis rau 0.04% sulfur thiab 0.035% phosphorus.

- zoo heev. Tsuas muaj txog li 0.025% ntawm leej faj thiab phosphorus.

- Qhov zoo tshaj plaws alloy yog muab yog tias feem pua ntawm cov leej faj tsis ntau tshaj 0.015, thiab phosphorus tsis ntau tshaj 0.025%.

Yog tias peb tham txog cov txheej txheem tsim khoom ntawm cov hlau zoo tib yam, feem ntau nws tau txais hauv qhov qhib-hearth furnaces lossis hauv Bessmerov, Thomas converters. Cov khoom no yog poured rau hauv loj ingots. Nws yog ib qho tseem ceeb kom nkag siab tias muaj pes tsawg leeg ntawm cov hlau, nws cov qauv, nrog rau nws cov yam ntxwv zoo thiab cov khoom raug txiav txim siab los ntawm cov txheej txheem ntawm nws cov khoom siv.

kom tau txais cov hlau zoo kuj sivqhib hearth furnaces, txawm li cas los xij, cov txheej txheem smelting yog nruj dua kom tau txais cov khoom zoo.

Lub melting ntawm high-zoo steels yog nqa tawm tsuas yog nyob rau hauv hluav taws xob furnaces. Qhov no yog vim qhov tseeb tias kev siv cov cuab yeej siv no tau lees paub yuav luag yam tsawg kawg nkaus ntawm cov khoom siv tsis yog xim hlau, uas yog, nws txo qhov feem pua ntawm leej faj thiab phosphorus.

Yuav kom tau txais cov hlau tshwj xeeb ntawm cov khoom zoo, lawv siv cov txheej txheem ntawm electroslag remelting. Kev tsim cov khoom no tsuas yog ua tau nyob rau hauv hluav taws xob furnaces. Tom qab qhov kawg ntawm kev tsim khoom, cov hlau no ib txwm tau txais tsuas yog alloyed.

Hom alloys los ntawm daim ntawv thov

Ib txwm, qhov kev hloov pauv ntawm cov hlau muaj txiaj ntsig zoo rau kev ua haujlwm ntawm cov khoom siv no, uas txhais tau hais tias qhov kev siv ntawm nws kuj hloov pauv. Muaj cov qauv hlau uas tuaj yeem siv rau hauv kev tsim kho, kev sib sau txias, rooj plaub tawv, temperable, siab zog, thiab lwm yam.

Yog tias peb tham txog kev tsim cov hlau, ces lawv feem ntau suav nrog nruab nrab-carbon, nrog rau cov alloys qis. Txij li thaum lawv tsuas yog siv rau kev tsim kho vaj tse, cov yam ntxwv tseem ceeb tshaj plaws rau lawv yog weldability zoo. Case-hardened steel feem ntau yog siv rau ntau qhov chaw, lub hom phiaj tseem ceeb ntawm kev ua haujlwm nyob rau hauv cov xwm txheej ntawm qhov chaw hnav thiab dynamic loading.

Lwm yam steels

Rau lwm hom hlau tuaj yeem raug ntaus nqi txhim kho. Hom alloy no tsuas yog siv tom qab kev kho cua sov. Cov hlau yog raug kub siab rau quenching, thiab tom qab ntawd raug tempering nyob rau hauv ib puag ncig.

Hom steels muaj zog muaj xws li cov uas, tom qab xaiv cov tshuaj muaj pes tsawg leeg, nrog rau tom qab kev kho cua sov, lub zog nce mus txog qhov siab tshaj plaws, uas yog, kwv yees li ob zaug ntau npaum li qhov qub. hom khoom no.

Caij nplooj ntoos hlav steels tuaj yeem paub qhov txawv. Qhov no yog ib qho alloy uas, raws li qhov tshwm sim ntawm nws cov khoom, tau txais qhov zoo tshaj plaws nyob rau hauv cov nqe lus ntawm elastic txwv, load kuj, thiab qaug zog.

Stainless hlau muaj pes tsawg leeg

Stainless hlau yog hom alloy. Nws cov cuab yeej tseem ceeb yog kev tiv thaiv corrosion siab, uas yog ua tiav los ntawm kev ntxiv cov khoom xws li chromium rau cov ntsiab lus ntawm cov hlau. Hauv qee qhov xwm txheej nickel, vanadium lossis manganese tuaj yeem siv los hloov chromium. Nws yog ib qho tsim nyog sau cia tias los ntawm melting cov khoom thiab ntxiv cov khoom tsim nyog rau nws, nws tuaj yeem tau txais cov khoom ntawm ib qho ntawm peb qib stainless hlau.

Qhov muaj pes tsawg leeg ntawm cov hom hlau no, tau kawg, txawv. Qhov yooj yim tshaj plaws yog cov pa roj carbon monoxide uas muaj zog corrosion kuj 08 X 13 thiab 12 X 13. Ob hom tom ntej no corrosion-resistant alloy yuav tsum muaj kev ua haujlwm siab tsis yog ntawm qhov qub, tab sis kuj nyob rau qhov kub siab.

Pom zoo:

Sib xyaw pub: hom, muaj pes tsawg leeg, daim ntawv thov

Qhov tsis txaus ntseeg yog qhov kev loj hlob tag nrho thiab kev loj hlob ntawm cov tsiaj ua liaj ua teb thiab cov noog, lub hauv paus ntawm kev noj haus yuav tsum tau muab sib xyaw pub (sib xyaw). Nws yuav tsum tau muab sau tseg tias ntau yam zaub mov txawv tau tsim rau txhua hom tsiaj hauv tsev. Peb yuav tham txog hom hauv peb tsab xov xwm

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

Hom cam khwb cia hlau, kev faib tawm, muaj pes tsawg leeg, khoom, cim thiab daim ntawv thov

Cov hom cam khwb cia uas muaj nyob niaj hnub no tso cai rau ib tus neeg los tsim ntau yam khoom. Yog li ntawd, peb yuav tham txog cov ntaub ntawv no nyob rau hauv kom meej ntxiv nyob rau hauv tsab xov xwm no

Flux rau vuam: lub hom phiaj, hom vuam, flux muaj pes tsawg leeg, cov cai ntawm kev siv, GOST cov cai, qhov zoo thiab qhov tsis zoo ntawm daim ntawv thov

Qhov zoo ntawm cov vuam yog txiav txim siab tsis yog los ntawm lub peev xwm ntawm tus tswv los npaj lub arc kom raug, tab sis kuj los ntawm kev tiv thaiv tshwj xeeb ntawm thaj chaw ua haujlwm los ntawm kev cuam tshuam sab nraud. Tus yeeb ncuab tseem ceeb ntawm txoj hauv kev los tsim kom muaj kev sib txuas ntawm cov hlau uas muaj zog thiab ruaj khov yog cov huab cua puag ncig ntuj. Lub vuam yog cais tawm los ntawm cov pa oxygen los ntawm cov flux rau vuam, tab sis qhov no tsis yog nws txoj haujlwm xwb

Pob zeb sib xyaw: cov khoom, muaj pes tsawg leeg, hom, qib ntawm pob zeb, yam ntxwv, ua raws li GOST cov qauv thiab daim ntawv thov

Ntawm cov khoom tseem ceeb ntawm cov pob zeb sib tov, uas tseem hu ua hydrotechnical pob zeb, nws yog ib qho tsim nyog los qhia txog qhov ua kom muaj dej ntau ntxiv. Cov vaj tse raug tsim los ntawm cov khoom siv no los siv rau hauv thaj chaw swampy lossis hauv cheeb tsam uas muaj dej nyab