2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Hnub no yuav luag tsis muaj ib cheeb tsam ntawm tib neeg lub neej uas cam khwb cia hlau tsis siv. Cov ntaub ntawv no tau paub los ntawm noob neej ntev heev thiab tau ua pov thawj nws tus kheej zoo heev los ntawm kev pom zoo. Cam khwb cia hlau yog lub hauv paus ntawm ntau yam ntawm cov khoom, cov rooj sib txoos thiab cov txheej txheem, thiab qee zaum txawm tias cov khoom siv tus kheej muaj peev xwm ua tau raws li cov haujlwm tau muab rau nws. Yog li ntawd, nyob rau hauv tsab xov xwm no peb yuav xyuam xim rau qhov no hlau-muaj compound. Peb tseem yuav paub seb cov hlau cam khwb cia yog dab tsi, lawv lub cev thiab tshuaj lom neeg.

Definition

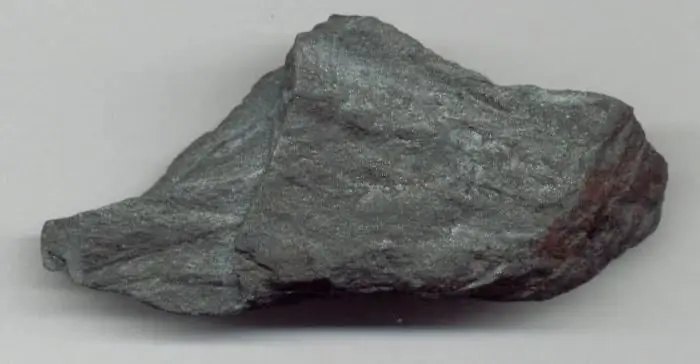

cam khwb cia hlau yog ib qho tshwj xeeb alloy ntawm hlau thiab carbon, uas Fe yog ntau tshaj 90%, thiab C tsis ntau tshaj 6.67%, tab sis tsis tsawg dua 2.14%. Tsis tas li ntawd, carbon tuaj yeem pom nyob rau hauv cam khwb cia hlau hauv daim ntawv ntawm cementite lossis graphite.

Carbon muab cov alloy kom txaus siab hardness, txawm li cas los xij, tib lub sijhawm, nws txo cov khoom zoo thiab ductility. Raws li qhov tshwm sim, cam khwb cia hlau yog cov khoom siv nkig. Tsis tas li ntawd, cov khoom siv tshwj xeeb tau ntxiv rau qee qib ntawm cov hlau cam khwb cia, uas tuaj yeem muab cov khoom sib xyaw ua ke. Lub luag haujlwm ntawm alloying ntsiab yuav yog: npib tsib xee, chromium, vanadium, txhuas. Qhov ntom ntom ntawm cov hlau cam khwb cia yog 7200 kilograms ib cubic meter. Los ntawm qhov nws tuaj yeem xaus qhov ntawdqhov hnyav ntawm cam khwb cia hlau yog qhov taw qhia uas tsis tuaj yeem hu ua me me.

keeb kwm keeb kwm

Smelting hlau tau ntev tau paub rau txiv neej. Thawj qhov hais txog cov alloy hnub rov qab mus rau xyoo pua BC.

Nyob rau hauv ancient sij hawm, Tuam Tshoj tsim hlau cam khwb cia hlau nrog ib tug tsawg melting point. Cam khwb cia hlau pib tsim nyob rau hauv cov teb chaws Europe nyob ib ncig ntawm lub xyoo pua 14th, thaum blast furnaces thawj zaug siv. Thaum lub sij hawm ntawd, xws li hlau casting yog siv los tsim riam phom, plhaub, tsim qhov chaw.

Nyob rau hauv Russia, kev tsim cov hlau cam khwb cia tau pib nyob rau xyoo pua 16th thiab tom qab ntawd nthuav dav sai. Thaum lub sij hawm ntawm Peter kuv, Lavxias teb sab faj tim teb chaws muaj peev xwm bypass tag nrho cov teb chaws ntawm lub ntiaj teb no nyob rau hauv cov nqe lus ntawm hlau ntau lawm, tab sis ib puas xyoo tom qab nws pib poob av dua nyob rau hauv lub ferrous metallurgy lag luam.

Cam khwb cia hlau tau siv los tsim ntau yam kev kos duab txij li Hnub Nyoog Nruab Nrab. Tshwj xeeb, nyob rau hauv lub xyoo pua 10th, Suav masters pov ib tug tiag tiag daim duab ntawm ib tug tsov ntxhuav, qhov hnyav ntawm uas tshaj 100 tons. Pib los ntawm lub xyoo pua 15th nyob rau hauv lub teb chaws Yelemees, thiab tom qab ntawd nyob rau hauv lwm lub teb chaws, cam khwb cia hlau casting tau dav. laj kab, lattices, chaw ua si sculptures, vaj rooj tog, tombstones tau ua los ntawm nws.

Nyob rau xyoo tas los ntawm lub xyoo pua 18th, hlau casting feem ntau koom nrog hauv architecture ntawm Russia. Thiab lub xyoo pua 19th feem ntau hu ua "lub hnub nyoog ntawm cov hlau", txij li cov hlau tau nquag siv hauv architecture.

Ntse

Muaj ntau homcam khwb cia hlau, txawm li cas los xij, qhov nruab nrab melting point ntawm no hlau compound yog hais txog 1200 degrees Celsius. Daim duab no yog 250-300 degrees tsawg tshaj li qhov xav tau rau kev tsim steel. Qhov sib txawv no muaj feem xyuam nrog cov ntsiab lus carbon ntau, uas ua rau nws tsis tshua muaj kev sib raug zoo nrog cov hlau atoms ntawm qib molecular.

Thaum lub sijhawm smelting thiab tom qab crystallization, cov pa roj carbon uas muaj nyob rau hauv cam khwb cia hlau tsis muaj sij hawm los nkag mus rau hauv lub molecular lattice ntawm hlau, thiab yog li ntawd cam khwb cia hlau nws thiaj li hloov mus ua nkig heev. Nyob rau hauv no hais txog, nws tsis yog siv nyob rau hauv qhov chaw uas muaj tas li dynamic loads. Tab sis tib lub sijhawm, nws yog qhov zoo heev rau cov khoom uas muaj kev xav tau ntxiv rau lub zog.

Tsev tsim khoom

Txhua yam ntawm cov hlau cam yog tsim nyob rau hauv qhov cub tawg. Qhov tseeb, cov txheej txheem smelting nws tus kheej yog ib qho kev ua haujlwm nyuaj uas yuav tsum tau siv cov khoom siv loj. Ib tuj npua hlau yuav tsum tau txog 550 kilograms ntawm coke thiab yuav luag ib tuj dej. Lub ntim ntawm ore loaded rau hauv lub cub tawg yuav nyob ntawm seb cov ntsiab lus hlau. Feem ntau, ore yog siv, nyob rau hauv uas hlau yog tsawg kawg yog 70%. Qhov qis dua ntawm lub caij yog qhov tsis xav tau, vim tias nws yuav siv tsis tau.

thawj theem tsim khoom

Smelting hlau yog raws li nram no. Ua ntej tshaj plaws, cov ore yog nchuav rau hauv lub qhov cub, nrog rau cov qib coking thee, uas ua hauj lwm kom siab thiab tswj qhov kub thiab txias hauv qhov cub. Tsis tas li ntawd, cov khoom no thaum lub sij hawm combustion txheej txheem yog nquag koom nyob rau hauv cov tshuaj tiv thaiv tsis tu ncua nyob rau hauvLub luag haujlwm ntawm cov tshuaj txo cov hlau.

Tib lub sijhawm, cov flux tau ntim rau hauv lub qhov cub, uas ua haujlwm raws li cov khoom siv hluav taws xob. Nws pab cov pob zeb kom yaj sai dua, uas txhawb kev tso tawm hlau.

Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias cov ore tau txais kev kho mob tshwj xeeb ua ntej muab tso rau hauv qhov cub. Nws yog crushed nyob rau hauv ib tug crushing nroj tsuag (me me hais yaj sai dua). Nws yog tom qab ntawd ntxuav kom tshem tawm cov khoom tsis muaj hlau. Tom qab ntawd, cov khoom siv raw raug rho tawm haujlwm, vim qhov no, sulfur thiab lwm yam khoom txawv teb chaws raug tshem tawm ntawm nws.

theem ob ntawm kev tsim khoom

Natural gas yog muab rau lub cub tawg loaded thiab npaj rau kev khiav hauj lwm los ntawm tshwj xeeb burners. Lub coke heats li raw khoom. Nyob rau hauv cov ntaub ntawv no, carbon yog tso tawm, uas ua ke nrog oxygen thiab tsim ib tug oxide. Qhov no oxide tom qab koom nrog hauv kev rov qab los ntawm cov hlau los ntawm cov ore. Nco ntsoov tias nrog qhov nce ntawm cov pa roj hauv qhov cub, tus nqi ntawm cov tshuaj tiv thaiv txo qis, thiab thaum muaj qee qhov sib piv, nws nres tag nrho.

Cov pa roj carbon ntau nkag mus rau hauv cov yaj thiab koom nrog cov hlau, thaum kawg ua cov hlau cam khwb cia. Tag nrho cov ntsiab lus uas tsis tau yaj yog nyob rau saum npoo thiab raug tshem tawm thaum kawg. Cov khib nyiab no hu ua slag. Nws tseem tuaj yeem siv los tsim lwm yam ntaub ntawv. Hom cam khwb cia hlau tau nyob rau hauv txoj kev no hu ua foundry thiab npua hlau.

Differentiation

Kev faib tawm niaj hnub ntawm cam khwb cia hlau muab rau kev faib cov alloys rau hauv hom hauv qab no:

- White.

- Ib nrab.

- Grey nrog flake graphite.

- High lub zog nodular graphite.

- Ductile.

Cia peb saib nyias nyias.

cam khwb cia hlau

Cov cam khwb cia hlau no yog ib qho uas yuav luag tag nrho cov pa roj carbon monoxide sib raug zoo. Hauv kev tsim kho tshuab, cov hlau no tsis siv ntau zaus, vim tias nws nyuaj, tab sis nkig heev. Tsis tas li ntawd, nws tsis tuaj yeem machined nrog ntau yam cuab yeej txiav, thiab yog li ntawd yog siv rau casting qhov chaw uas tsis tas yuav tsum tau ua. Txawm hais tias hom cam khwb cia hlau no tso cai rau kev sib tsoo nrog lub log abrasive. Dawb cam khwb cia hlau tuaj yeem ua tau ob qho tib si thiab alloyed. Nyob rau tib lub sijhawm, vuam nws ua rau muaj teeb meem, vim tias nws tau ua ke los ntawm kev tsim ntau yam kab nrib pleb thaum lub caij txias lossis cua sov, thiab kuj yog vim muaj qhov sib txawv ntawm cov qauv uas ua rau ntawm qhov chaw vuam.

Dawb hnav-resistant cam khwb cia hlau yog tau los ntawm thawj crystallization ntawm cov kua alloy thaum lub sij hawm ceev txias. Lawv feem ntau yog siv rau cov ntawv thov kev sib txhuam qhuav (xws li cov pawm nres) lossis rau kev tsim cov khoom uas muaj zog hnav thiab kub tsis kam (rolling mill rolls).

Los ntawm txoj kev, dawb cam khwb cia hlau tau txais nws lub npe vim qhov tseeb tias cov tsos ntawm nws cov pob txha yog lub teeb-crystalline, radiant nto. Cov qauv ntawm cov cam khwb cia hlau no yog kev sib xyaw ua ke ntawm ledeburite, perlite thiab lwm yam cementite. Yog hais tias qhov no cam khwb cia hlau yog alloyed, ces pearlite yog hloov mus rau hauvtroostite, austenite lossis martensite.

Ib nrab cam khwb cia hlau

Kev faib tawm ntawm cov hlau cam yuav ua tsis tiav yam tsis tau hais txog ntau hom hlau alloy.

Cov cam khwb cia hlau no yog tus cwj pwm los ntawm kev sib xyaw ntawm carbide eutectics thiab graphite hauv nws cov qauv. Feem ntau, tag nrho cov qauv muaj cov hauv qab no: graphite, pearlite, ledeburite. Yog hais tias cov cam khwb cia hlau raug kev kho cua sov los yog alloying, qhov no yuav ua rau tsim austenite, martensite los yog acicular troostite.

hom cam khwb cia hlau no yog nkig heev, yog li nws siv tsawg heev. Cov hlau nws tus kheej tau txais nws lub npe vim tias nws cov pob txha tawg yog kev sib xyaw ntawm qhov tsaus ntuj thiab lub teeb ntawm cov qauv crystalline.

Cov khoom siv engineering feem ntau

Grey cam khwb cia hlau GOST 1412-85 muaj txog 3.5% carbon, los ntawm 1.9 mus rau 2.5% silicon, mus txog 0.8% manganese, mus txog 0.3% phosphorus thiab tsawg dua 0, 12% sulfur.

Graphite hauv cov hlau cam no muaj cov duab lamellar. Nws tsis tas yuav hloov kho tshwj xeeb.

Graphite daim hlau muaj qhov ua kom tsis muaj zog thiab yog li grey cam khwb cia hlau yog tus cwj pwm los ntawm kev cuam tshuam lub zog qis heev thiab yuav luag tsis tiav ntawm elongation (tsawg dua 0.5%).

Grey cam khwb cia hlau yog machined zoo. Cov qauv hlau tuaj yeem ua raws li hauv qab no:

- Ferrite-graphite.

- Ferrite-pearlite-graphite.

- YPerlite-graphite.

Grey cam khwb cia hlau ua haujlwm zoo dua hauv compression dua li qhov nro. Nws kujwelds zoo heev, tab sis qhov no yuav tsum tau preheating, thiab tshwj xeeb cam khwb cia hlau pas nrig nrog cov ntsiab lus siab ntawm silicon thiab carbon yuav tsum tau siv los ua cov khoom muab tub lim. Yog tsis muaj preheating, vuam yuav nyuaj vim cov cam khwb cia hlau yuav bleach nyob rau hauv lub vuam cheeb tsam.

Grey cam khwb cia hlau yog siv los tsim cov khoom lag luam uas tsis muaj kev poob siab (pulleys, npog, txaj).

Kev xaiv ntawm cov cam khwb cia no tshwm sim raws li cov hauv qab no: SCH 25-52. Ob tsab ntawv qhia tias qhov no yog grey cam khwb cia hlau, tus naj npawb 25 yog qhov taw qhia ntawm lub zog tensile (hauv MPa lossis kgf / mm 2), tus lej 52 yog lub zog tensile tam sim no ntawm khoov.

Cov hlau nplaum

Nodular cam khwb cia hlau yog qhov txawv ntawm nws lwm "kwv tij" nyob rau hauv uas nws muaj nodular graphite. Nws yog tau los ntawm kev qhia tshwj xeeb modifiers (Mg, Ce) rau hauv cov kua alloy. Tus naj npawb ntawm cov graphite suav nrog thiab lawv cov kab sib txawv tuaj yeem sib txawv.

Dab tsi yog qhov zoo ntawm spheroidal graphite? Qhov tseeb tias daim ntawv zoo li no ua rau cov hlau tsis muaj zog, uas, dhau los, tuaj yeem yog pearlitic, ferritic lossis pearlitic-ferritic.

Vim siv cov kev kho cua sov los yog alloying, cam khwb cia hlau puag tuaj yeem ua acicular-troostite, martensitic, austenitic.

Qib ntawm cov hlau nplaum sib txawv, tab sis feem ntau, nws qhov kev xaiv yog raws li hauv qab no: VCh 40-5. Nws yog ib qho yooj yim los twv tias HF yog high-strength cam khwb cia hlau, tus naj npawb 40 yog qhov taw qhiatensile zog (kgf/mm2), tus naj npawb 5 yog txheeb ze rau elongation, qhia raws li feem pua.

Cov hlau nplaum

Cov qauv ntawm cov hlau ductile yog muaj cov graphite hauv nws hauv daim ntawv flaky lossis kheej kheej. Nyob rau tib lub sijhawm, flaky graphite tuaj yeem muaj qhov sib txawv thiab qhov sib txawv, uas, dhau los, muaj kev cuam tshuam ncaj qha rau cov khoom siv hluav taws xob ntawm cam khwb cia hlau.

Kev lag luam ductile hlau feem ntau tsim nrog lub hauv paus ferritic, uas muab ntau dua ductility.

Cov pob txha zoo li ntawm ferritic ductile hlau muaj qhov zoo li dub velvety. Qhov siab dua tus nqi ntawm perlite hauv cov qauv, qhov sib dua qhov tawg yuav dhau los.

Feem ntau, cov hlau nplaum yog tau los ntawm cov hlau dawb vim yog qhov ntev ntev hauv cov cub tawg rhuab mus rau qhov kub ntawm 800-950 degrees Celsius.

Hnub no, muaj ob txoj hauv kev los ua cov hlau nplaum: European thiab Asmeskas.

Asmeskas txoj kev yog languish cov hlau hauv cov xuab zeb ntawm qhov kub ntawm 800-850 degrees. Hauv cov txheej txheem no, graphite nyob nruab nrab ntawm cov nplej ntawm cov hlau purest. Yog li ntawd, cam khwb cia hlau ua viscous.

Nyob rau hauv European txoj kev, castings yog languishing nyob rau hauv hlau ore. Qhov kub ntawm tib lub sijhawm yog li 850-950 degrees Celsius. Cov pa roj carbon monoxide nkag mus rau hauv cov hlau ore, vim qhov txheej txheej ntawm cov castings yog decarburized thiab ua mos. cam khwb cia hlau ua malleable, thaum lub hauv paus tseem nkig.

Kos npe ntawm cov hlau tsis muaj hlau: KCh 40-6, qhov twg KCh yog, tau kawg, cov hlau tsis tuaj yeem; 40 - tensile zog Performance index;6 – elongation, %.

Lwm yam ntsuas

Raws li kev faib cov cam khwb cia hlau los ntawm lub zog, kev faib tawm hauv qab no yog siv ntawm no:

- Lub zog muaj zog: σv txog 20 kg / mm 2.

- Nyob zog: σv=20 - 38 kg/mm2.

- High zog: σv=40 kg/mm2 thiab siab dua.

Raws li ductility, cam khwb cia hlau muab faib ua:

- Inflexible - tsawg dua 1% elongation.

- Cov yas qis - los ntawm 1% mus rau 5%.

- YPlastic - los ntawm 5% mus rau 10%.

- Txhim plasticity - ntau dua 10%.

Nyob rau hauv xaus, kuv kuj xav kom nco ntsoov tias cov khoom ntawm tej cam khwb cia hlau yog heev cuam tshuam txawm los ntawm cov duab thiab qhov xwm ntawm lub ncuav.

Pom zoo:

Pyrotechnic muaj pes tsawg leeg: kev faib tawm, cov khoom siv, daim ntawv thov

Ib pyrotechnic muaj pes tsawg leeg yog ib yam khoom los yog sib tov ntawm cov khoom tsim los tsim cov nyhuv ntawm cov cua sov, lub teeb, suab, roj, pa luam yeeb, los yog ib qho kev sib xyaw ua ke, raws li nws tus kheej txhawb nqa exothermic tshuaj tiv thaiv uas. coj qhov chaw tsis muaj detonation. Cov txheej txheem zoo sib xws tsis yog nyob ntawm cov pa oxygen los ntawm lwm qhov chaw

Hlau sulphate: muaj pes tsawg leeg, mis, khoom, lub hom phiaj thiab daim ntawv thov

Vim hlau sulphate yog ib qho yooj yim-rau-ua thiab yooj yim muaj tshuaj, nws yog dav siv nyob rau hauv ntau yam kev siv. Nyob rau hauv lub neej txhua hnub, nws yog ib tug zoo-paub hlau sulphate, feem ntau nyob rau hauv vaj. Yog hais tias peb tham txog kev siv ntawm ib tug loj scale, ces nws yog siv tsis tau tsuas yog nyob rau hauv kev ua liaj ua teb sector, tab sis kuj nyob rau hauv kev lag luam

Cov khoom noj muaj zog: lub hom phiaj, muaj pes tsawg leeg, khoom noj muaj txiaj ntsig, hom thiab kev xav tau zoo

Ntxiv rau cov kua dej thiab ntxhib, cov khoom noj muaj zog kuj tau qhia rau hauv kev noj zaub mov ntawm cov tsiaj txhu ua liaj ua teb thiab nqaij qaib. Muaj tsuas yog ob hom tseem ceeb ntawm lawv - carbohydrate thiab protein

Steel: muaj pes tsawg leeg, khoom, hom thiab daim ntawv thov. Kev sib xyaw ntawm stainless hlau

Hnub no, hlau yog siv nyob rau hauv feem ntau ntawm kev lag luam. Txawm li cas los xij, tsis yog txhua tus paub tias muaj pes tsawg leeg ntawm cov hlau, nws cov khoom, hom thiab daim ntawv thov txawv ntawm cov txheej txheem tsim khoom ntawm cov khoom no

Ua npuas ncauj vapor permeability: muaj pes tsawg leeg, khoom, qauv, kev faib tawm, daim ntawv thov thiab kev nyab xeeb

Lub thickness thiab vapor permeability ntawm npuas - qhov no tsis yog txhua yam koj yuav tsum paub thaum yuav khoom. Nws yog ib qho tseem ceeb kom tau txais kev txaus siab rau lub suab thiab windproof zog. Yog tias cov phab ntsa yog insulated nrog npuas, lawv yuav tsis xav tau cua tiv thaiv. Lub suab pov thawj ntawm lub tsev yuav raug txhim kho. Yog li, cov khoom pov thawj suab tau piav qhia los ntawm cov qauv cellular