2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Cov txheej txheem thev naus laus zis uas cov khoom ua haujlwm tau ua tiav, uas ua rau nws tuaj yeem tau txais cov khoom tiav lossis cov khoom tiav ntawm ntau cov duab thiab ntau thiab tsawg, yog stamping. Cov cuab yeej ua haujlwm rau lub hom phiaj no yog lub thwj cim, uas yog tsau rau ntawm lub xovxwm lossis lwm yam khoom siv. Stamping yog ob hom thev naus laus zis uas, nyob ntawm qhov xwm txheej, tau ua hauv txoj kev kub lossis txias, thiab yog li ob qho tib si cov cuab yeej siv thiab cov qauv thev naus laus zis txawv ntawm ib leeg.

Qeb

Ntxiv rau kev faib cov thev naus laus zis rau hauv txoj kev txias thiab kub, stamping yog tag nrho cov pawg rau hauv cov txheej txheem ua cov khoom sib faib. Txoj kev xaiv feem ntau yog nyob ntawm lub hom phiaj ntawm cov khoom, tab sis cov txheej txheem thev naus laus zis kuj cuam tshuam rau nws. Piv txwv li, muaj ib txoj kev uas ib feem ntawm lub workpiece yog sib cais, thiab qhov no yog sib cais stamping. Qhov no kuj muaj xws li xuas nrig ntaus, txiav, txiav qhov chaw. Muaj ib pawg ntawm kev ua haujlwm thaum siv kub stamping, los ntawm cov ntawv ntawm cov hlau hloov cov duab. Lawv kuj hu ua shaping. Raws li qhov tshwm sim, qhov chaw raug khoov, kos duab thiab lwm yam txheej txheem.

Txias thiab kub forging yog siv tib lub hauv paus ntsiab lus, uas cuam tshuam cov khoom deformation, tab sis txwv tsis pub cov khoom tsim los ntawm cov txheej txheem no muaj ntau qhov sib txawv. Ua ntej cua sov ntawm qhov chaw rau qee qhov (thiab siab dua) qhov kub thiab txias yog suav tias yog nyob rau hauv cov chaw lag luam loj, xws li, piv txwv li, cov khoom siv hlau. Qhov no yog vim qhov nyuaj ntawm cov txheej txheem thev naus laus zis, kev ua haujlwm ntau, uas tuaj yeem ua tau zoo tsuas yog nrog kev suav ua ntej kom raug thiab ua raws li qhov tseeb ntawm qib cua sov ntawm lub workpiece.

Hot way

Forged qhov chaw ua tiav siv tshuab kub yuav tsum yog qhov zoo heev, vim, piv txwv li, xws li cov khoom tseem ceeb xws li boiler bottoms thiab lwm yam khoom hemispherical, suav nrog cov ntsiab lus tseem ceeb hauv kev tsim nkoj, yog tsim los ntawm cov ntawv hlau sib txawv. Txhawm rau kom sov ib feem ntawm cov hlau, siv cov cuab yeej uas muab qhov kub thiab txias.

Cov khoom siv thiab cov cub tawg no tuaj yeem ua ntshav, hluav taws xob lossis lwm yam, muaj ntau hom. Ua ntej muab qhov kub kub rau cov xovxwm stamping, nws yog ib qho tsim nyog tsis yog tsuas yog suav cov cua sov, tab sis kuj tsim cov duab kos duab ntawm cov khoom tiav lawm, qhov twg nws yog qhov tsim nyog.coj mus rau hauv tus account lub shrinkage ntawm hlau tom qab txias.

Cold forming

Txias stamping cuam tshuam nrog kev tsim cov khoom lag luam los ntawm kev siv lub zog ua haujlwm los ntawm kev ua haujlwm ntawm cov xovxwm. Cov khoom zoo li no tsis raug shrinkage, vim lawv tsis preheated. Kev kho kom zoo ntxiv ntawm cov khoom siv no kuj tsis xav tau tom qab stamping tiav. Stamping txoj kev yuav txawv, tab sis txias stamping yog ob qho tib si yooj yim dua thiab raug nqi.

Cov ntaub ntawv uas qiv lawv tus kheej zoo rau qhov txias txias tsis txwv rau cov pa roj carbon lossis hlau alloy. Stamping ntau lawm ua haujlwm tau zoo ntawm txhuas thiab tooj liab alloys. Txoj kev txias yog nqa tawm tsuas yog nrog kev pab los ntawm hydraulic presses, thiab lawv cov ntau lawm yog tswj los ntawm GOST. Serial qauv yog ntau haiv neeg, thiab yog li ntawd nws yuav ua tau los xaiv ib tug tsim lub tshuab rau zus tau tej cov configurations thiab qhov ntau thiab tsawg ntawm cov khoom. Tuag rau stamping hlau yog txawv heev nyob rau hauv lawv cov khoom los ntawm cov uas ua hauj lwm nrog cov ntaub ntawv xws li tawv, roj hmab, cardboard, polymer alloys, thiab cov zoo li.

Sib cais stamping

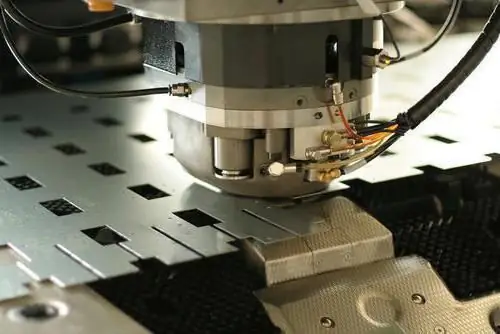

Ib qho kev ua haujlwm thev naus laus zis feem ntau yog kev sib cais stamping, uas cais ib feem ntawm cov hlau los ntawm cov khoom ua haujlwm. Txoj kev no yog siv nyob rau hauv yuav luag tag nrho cov chaw tsim khoom lag luam. Cov cuab yeej tshwj xeeb raug ntsia rau ntawm cov xovxwm stamping, uas ua rau txiav, xuas nrig ntaus thiab xuas nrig ntaus ntawm cov khoom. Los ntawm cov txheej txheem nokoj tuaj yeem cais cov khoom hlau txawm tias nyob ntawm qhov nkhaus, txawm tias nyob ntawm txoj kab ncaj nraim. Kev txiav yog ua los ntawm ntau yam khoom siv: guillotine shears, vibrating thiab disk tshuab, thiab lwm yam. Txiav yog siv los txiav qhov khoob rau kev ua haujlwm ntxiv.

Punching yog lwm txoj haujlwm thev naus laus zis. Piv txwv li, ib daim ntawv hlau stainless yuav tsum tau tig mus rau hauv qhov chaw nrog kaw contours. Cov ntawv hlau yog muab nrog lub qhov ntawm txhua qhov kev teeb tsa siv xuas nrig ntaus. Nws yuav tsum tau hais tias cov txheej txheem thev naus laus zis no tseem yuav tsum tau ua tib zoo npaj ua ntej thiab cov phiaj xwm ntxaws, nrog rau kev suav cov geometric tsis ntawm cov cuab yeej siv. Txwv tsis pub, cov khoom zoo yuav tsis ua haujlwm. Muaj ntau yam kev ua haujlwm thev naus laus zis ntsig txog stamping, vim nws yuav tsum tau hloov qhov kev teeb tsa thawj zaug ntawm cov khoom. Cov no yog khoov, sib sau, flanging, kos duab thiab crimping.

Technological operations

Kev ua haujlwm ntau tshaj plaws uas hloov cov duab ntawm ib feem yog dabtsi yog khoov, uas tsim cov seem uas tau npaj nrog khoov rau saum npoo ntawm cov hlau ua haujlwm. Lub hood hu ua volumetric stamping. Qhov no yog ib qho kev ua haujlwm los ntawm cov khoom peb-dimensional yog tau los ntawm xws li ib tug ca hlau nto, xws li, piv txwv li, ib tug stainless hlau ntawv. Nws yog nrog kev pab los ntawm lub hood uas nws hloov mus rau hauv lub tog raj kheej, lub khob hliav qab, hemisphere los yog siv lub thawv-zoo li tus configuration. Sheet hlau cov khoom yuav tsum muaj ib tug ntug raws ntug thiab ib ncig ntawm lub qhov, yog hais tias lawv yog ua nyob rau hauv lub workpiece. Piv txwv li, flanging yuav tsum ua kom tiavkawg ntawm cov yeeb nkab rau nruab ib lub flange rau nws. Txoj haujlwm no yuav tsum muaj cov cuab yeej tshwj xeeb.

Nrog crimping, qhov thim rov qab tshwm sim. Flanging nthuav qhov kawg ntawm cov ntawv hlau blanks, thiab crimp narrows. Tib qhov kawg ntawm cov kav dej los yog ntug ntawm cov kab noj hniav yuav tsum tau ua haujlwm, uas yog nqa tawm sab nraud los ntawm kev siv lub conical matrix. Moulding kuj yog ib qho ntawm cov haujlwm tseem ceeb ntsig txog stamping. Nws pab hloov cov duab ntawm tus kheej cov ntsiab lus ntawm qhov chaw stamped, thiab cov contour sab nrauv tseem tsis hloov. Volumetric stamping yuav tsum tau ua haujlwm ntawm cov cuab yeej tshwj xeeb thiab cov duab kos ua ntej, thiab yog li ntawd yuav luag tsis tau siv hauv tsev.

Xaiv Abs

Rau kev ua cov hlau, txawm tias qhov softest (piv txwv li, rau stamping aluminium), yuav tsum muaj cov cuab yeej tshwj xeeb: hydraulic lossis crank xovxwm lossis guillotine txiab. Thiab ntawm chav kawm, xav tau ntau yam kev paub. Piv txwv li, yuav ua li cas xam cov khoom siv thiab ua tiav cov duab kos duab. Cov kev cai ntawm GOST yuav tsum tau coj mus rau hauv tus account.

Xaiv txoj cai stamping xovxwm, koj yuav tsum xub xav kom meej txog txoj haujlwm uas nws yuav tsum tau daws. Kev khiav hauj lwm xws li xuas nrig ntaus los yog xuas nrig ntaus yuav tsum tau siv cov cuab yeej xuas nrig ntaus ib leeg nrog kev mus ncig me ntsis ntawm cov slider thiab cov ntxhua khaub ncaws thaum ua haujlwm. Tab sis twb yog rau lub hood, qhov sib txawv kiag li, xav tau cov cuab yeej muaj zog dua, qhov twg cov slider thiab cov ntxhua khaub ncaws ua rau cov hlab ntsha loj dua. Qhov peev xwm no muajob chav ua yeeb yam.

GOST khoom

Punching, nyob ntawm cov xwm txheej ntawm txoj haujlwm, tuaj yeem ua tau ntawm cov khoom siv hauv qab no: ib-, ob- thiab plaub-crank. Lub tom kawg - nrog rau installation ntawm loj sliders. Txawm li cas los xij, cov cuab yeej ntawm stamping xovxwm nrog lub matrix tsis nyob ntawm tus qauv tsim. Lub luag haujlwm tseem ceeb los ntawm kev txav mus los yog ua los ntawm cov slider txuas nrog nws sab qis mus rau lub thwj cim txav. Thiab nyob rau hauv thiaj li yuav kom cov xovxwm slider txav mus, lub tsav tsav yog nruab nrog kinematic saw ntsiab: ib tug V-siv tsav, pib clutch, washers, ib tug crankshaft, ib tug txuas pas nrig uas tswj cov hlab ntsha ntawm lub slider.

Lub slider yog pib siv ko taw nias pedal, uas txuas nrog lub clutch pib, tom qab uas nws reciprocating txav pib, qhia rau lub rooj ua haujlwm ntawm cov xovxwm. Plaub-rod xovxwm muaj lub hauv paus ntsiab lus ntawm kev ua haujlwm. Nws lub cev ua haujlwm tau coj tag nrho cov kev siv zog mus rau hauv nruab nrab ntawm lub quadrangle, uas yog tsim los ntawm plaub txoj hlua txuas. Xws li cov cuab yeej siv tau zoo rau kev tsim cov khoom ntawm cov kev teeb tsa nyuaj tshaj plaws: asymmetric lossis tag nrho.

Rau cov khoom nyuaj

Kom tau txais cov khoom lag luam zoo ntawm kev teeb tsa nyuaj, pneumatic hom xovxwm nrog ob lossis peb lub sliders yog siv dav heev. Cov xovxwm ob leeg ua haujlwm nrog ob lub sliders ib txhij: lub sab nrauv kho lub workpiece, thiab sab hauv yog rub lub npoo ntawm cov ntawv hlau. Cov ntawv nyias nyias ntawm cov hlau yog stamped nrog kev sib txhuam tshwj xeeb,thiab cov tuab - hydraulic, uas muaj ntau txhim khu kev qha washers.

Ib pawg ntawm cov khoom siv stamping - stamping, tswj kev tawg. Cov khoom siv zoo li no coj lub zog ntawm qhov tawg mus rau qhov sib cais ntawm cov hlau ua haujlwm (feem ntau ntawm cov tuab tuab). Qhov no yog cov cuab yeej tshiab, kev ua haujlwm uas txawm nyob hauv video zoo li zoo nkauj heev. Cov folds thiab kev teeb tsa dav dav ntawm cov khoom lag luam yog ua tiav los ntawm kev siv cov vibrating shear built-in.

Daim ntawv stamping

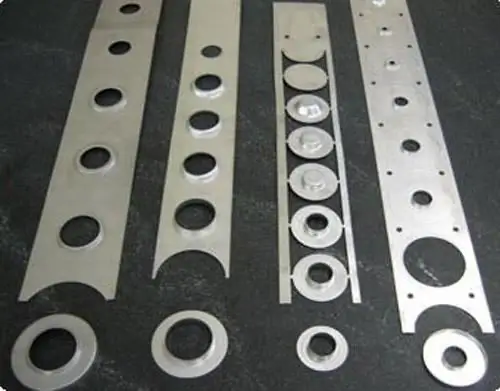

Daim ntawv xuas nrig (piv txwv li, kev tsim cov ntawv perforated) koom nrog cov txheej txheem ntawm xuas nrig ntaus ntawv hlau. Qhov seem ntawm stamping yog volumetric. Cov cuab yeej siv rau cov khoom siv stamping yog muab faib ua hom. Nws tuaj yeem yog instrumental, impulse (tawg, sib nqus los yog hydraulic impulse), yob los yog stamping nrog elastic media. Daim ntawv stamping tuaj yeem tsim qhov chaw thiab tiaj tus ntawm ntau qhov hnyav - los ntawm feem ntawm ib gram, thiab ntau qhov ntau thiab tsawg - los ntawm feem ntawm ib millimeter (ntawm no koj tuaj yeem saib ntawm ob txhais tes ntawm lub dab teg). Sheet hlau stamping kuj tsim qhov hnyav ntau kaum kilograms thiab ob peb meters hauv qhov loj (automotive cladding, foob pob hluav taws thiab aircraft).

Lawv siv cov pa roj carbon tsawg feem ntau rau qhov no, nrog rau cov hlau alloy - nrog cov khoom tshwj xeeb, tooj dag, tooj liab, txhuas thiab magnesium nrog alloys, titanium thiab ntau ntxiv. Sheet stamping yog yuav luag txhua qhov kev lag luam: foob pob hluav taws, dav hlau, tsheb laij teb, pib, ntsuas, hluav taws xob kev lag luam, thiab lwm yam, koj tuaj yeem sau txhua yam. Nws cov txiaj ntsig zoo heev.

3D stamping

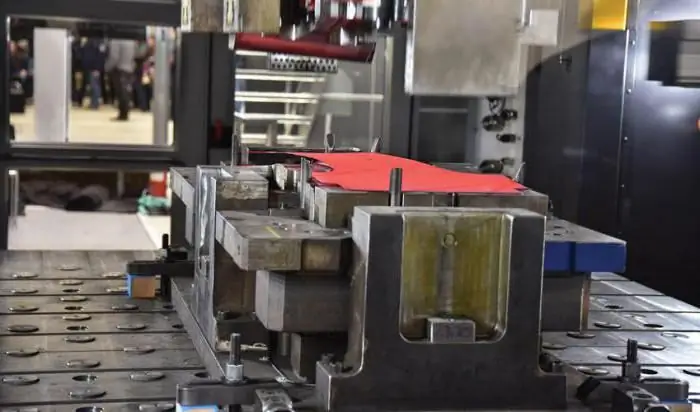

Forging tuaj yeem ua tau ob qho tib si txias thiab kub. Kub - kev kho mob siab, qhov twg lub shaping ntawm forging yog nqa tawm siv lub stamp. Cov blanks yog dov cov duab plaub, puag ncig, square profile, uas yog txiav mus rau hauv seem seem (qee zaum tsis txiav, tab sis stamped ncaj qha los ntawm lub bar, ces cais lub forging ncaj qha nrog lub tshuab stamping).

Forging yog siv rau hauv ntau lawm thiab serial ntau lawm, uas ua rau kom cov khoom tsim tau thiab txo cov hlau pov tseg. Cov khoom zoo kuj ua tau raws li cov qauv siab. Cov stamping zoo li no tsim cov khoom lag luam uas tsis tshua muaj kev sib tw, uas tsis tuaj yeem tau txais txawm tias dawb forging.

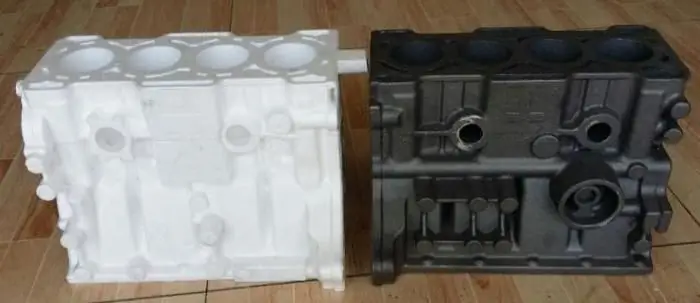

Dies qhib thiab kaw

Qhib tuag tso cai rau koj saib qhov sib txawv ntawm qhov chaw ruaj khov thiab txav ntawm lub tshuab. Thaum lub sij hawm kub stamping, flash ntws mus rau hauv qhov sib txawv - hlau, kaw qhov tawm ntawm cov kab noj hniav thiab yuam kom tag nrho cov khoom ntim rau hauv cov kab noj hniav kom tiav. Nyob rau hauv tus txheej txheem ntawm deformation, cov hlau ntau dhau mus rau hauv lub teeb. Tab sis tshem flash yog nyuaj.

Cov nyiaj kaw tsis tso cai rau koj saib sab hauv thiab saib cov txheej txheem - kab noj hniav raug kaw. Lub npog kuj tsis muab. Cov cuab yeej ntawm xws li lub thwj cim nyob ntawm seb hom tshuab. Ntawm no nws yog ib qho tsim nyog yuav tsum tau ua tib zoo saib xyuas qhov tseeb ntawm qhov ntim thiab lawv qhov sib npaug ntawm qhov khoob thiab forgings: tsis muaj hlau yuav tawm hauv cov ces kaum ntawm cov kab noj hniav, thiab qhov ntau dhau ntawm nws yuav ua rau forging ntau tshaj qhov siab xav tau.

Pom zoo:

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

Kev tsim cov khoom siv roj: cov txheej txheem thev naus laus zis, khoom siv thiab khoom siv

Hnub no, muaj ntau yam khoom siv hauv tsev uas nrov. Ib qho kev tsim kho tshiab yog kev tsim cov khoom siv roj av, uas yog cov pob zeb ntawm tes. Ntawm cov no, nws muaj txiaj ntsig tsis yog los tsim ib lub tsev ntiag tug xwb, tab sis kuj tsim khoom muag

Hlau casting: txheej txheem, txheej txheem, txheej txheem

Hlau yog lub hauv paus ntawm txhua qhov kev vam meej niaj hnub no. Hauv ib xyoos, tib neeg niaj hnub mines thiab cov txheej txheem xws li cov hlau ib leeg ua ntej tag nrho lub ntiaj teb yuav tau khawb nws tsawg kawg ob peb centuries

Vuam hauv qhov chaw tiv thaiv roj: ua haujlwm thev naus laus zis, txheej txheem piav qhia, cov txheej txheem ua tiav, cov khoom tsim nyog thiab cov cuab yeej, cov lus qhia ua haujlwm ib ntus thiab cov lus qhia kws tshaj lij

Vuam thev naus laus zis yog siv hauv ntau ceg ntawm tib neeg kev ua haujlwm. Versatility tau ua vuam nyob rau hauv ib puag ncig tiv thaiv roj ib qho tseem ceeb ntawm kev tsim khoom. Qhov ntau yam no ua rau nws yooj yim los txuas cov hlau nrog lub thickness ntawm 1 hli mus rau ob peb centimeters nyob rau hauv txhua txoj hauj lwm nyob rau hauv qhov chaw. Vuam nyob rau hauv ib puag ncig tiv thaiv yog maj mam hloov cov tsoos electrode vuam

Kev kho dua tshiab ntawm qhov chaw los ntawm vuam thiab ntog: cov txheej txheem thiab cov txheej txheem ntawm kev kho dua tshiab, nta, txheej txheem thev naus laus zis

Vuam thiab surfacing thev naus laus zis ua rau nws ua tau zoo los kho cov hlau seem, muab cov qib siab ntawm kev ntseeg siab thiab ua haujlwm ntev ntawm cov khoom. Qhov no tau lees paub los ntawm kev xyaum siv cov txheej txheem no thaum ua haujlwm kho hauv ntau qhov chaw - los ntawm kev kho tsheb mus rau kev tsim cov hlau dov. Hauv tag nrho cov nyiaj ua haujlwm ntawm kev kho cov qauv hlau, kev kho dua tshiab ntawm qhov chaw los ntawm kev vuam thiab surfacing yuav siv li 60-70%