2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Vuam thiab surfacing thev naus laus zis ua rau nws ua tau zoo los kho cov hlau seem, muab cov qib siab ntawm kev ntseeg siab thiab ua haujlwm ntev ntawm cov khoom. Qhov no tau lees paub los ntawm kev xyaum siv cov txheej txheem no thaum ua haujlwm kho hauv ntau qhov chaw - los ntawm kev kho tsheb mus rau kev tsim cov hlau dov. Nyob rau hauv tag nrho cov nqi ntawm kev ua hauj lwm ntawm kev kho cov qauv hlau, kev kho dua tshiab ntawm qhov chaw los ntawm vuam thiab surfacing yuav siv li 60-70%. Kev kho ntau tshaj plaws ntawm steel lub tog raj kheej blocks, lub cev muaj zog shafts, crankcases, saw txuas, hniav, thiab lwm yam.

Vuam thiab surfacing hauv kev kho thiab kho dua tshiab

Ob txoj kev yog ua raws li cov txheej txheem kho cua sov uas muaj qhov sib txawvkev ua haujlwm ntawm cov khoom siv txuas nrog. Vuam yog to taub raws li cov txheej txheem ntawm kev tsim cov interatomic bonds, uas yuav siv tau los txuas cov ntsiab lus sib txawv ntawm ib feem, kaw cov cuab yeej cuab tam thiab tshem tawm cov teeb meem me me ntawm qhov chaw. Lub zog muaj peev xwm rau cov txheej txheem vuam yog muab los ntawm cov cua sov hauv zos lossis hauv zos ntawm cov khoom ua haujlwm.

Kev ua haujlwm ib txwm ntawm hom no suav nrog kho ntxiv lossis tawg qhov chaw ntawm daim hlau, rims thiab bushings. Ntxiv nrog rau kev kho cov khoom nrog cov duab geometric yooj yim, ntau txoj haujlwm kho dua tshiab kuj tuaj yeem ua tau, tab sis ua ib feem ntawm lwm yam kev ua haujlwm thev naus laus zis. Piv txwv li, xov rov qab los ntawm kev vuam yuav ntxiv los ntawm cov txheej txheem kev sib dhos thiab tig. Tsis tas li ntawd, nyob rau hauv xws li kev ua hauj lwm, yuav tsum tau ua kom overheating ntawm ib tug auxiliary cuab tam xws li tuag, uas yog ncaj qha koom nyob rau hauv kev kho cov xov, yuav tsum tau soj ntsuam.

Raws li kev surfacing, txoj kev no yuav tsum siv cov txheej txheem hlau ntxiv rau saum npoo kom rov qab los. Cov txheej txheem thev naus laus zis tshiab tuaj yeem siv tau thaum kho cov khoom hnav lossis ua kom muaj zog ntawm qhov chaw ntawm kev sib txhuam.

Khoom siv siv

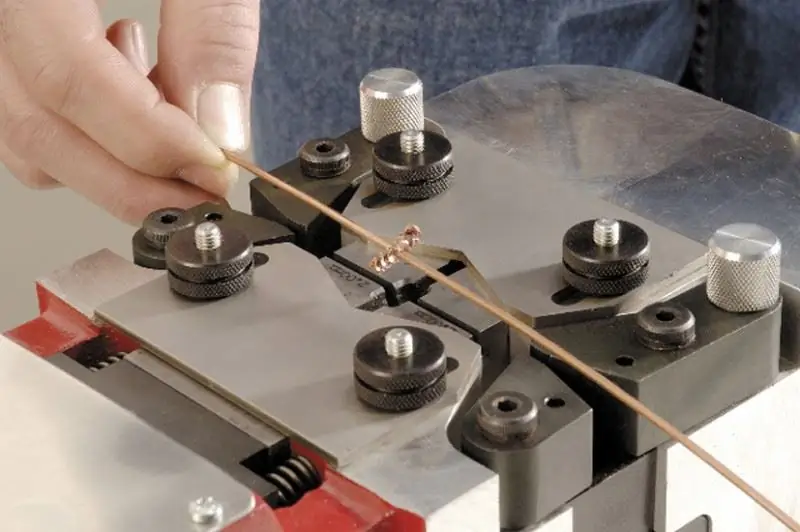

Thaum vuam, lub zog hluav taws xob, cov khoom siv los tuav qhov thiab ncaj qha cov arc yuav tsum tau siv. Ntau zaus, lub vuam converter yog siv, uas suav nrog lub cev muaj zog nrog lub tshuab hluav taws xob DC los ntawm 70 txog 800 A. Rectifiers nrog transformers kuj siv tau.tam sim no thiab tswj iav. Yog hais tias peb tham txog consumables thiab auxiliary pab kiag li lawm, lub restoration ntawm qhov chaw los ntawm welding thiab surfacing yog ua los ntawm kev sib txuas ntawm tuav lub qhov ncauj, electrodes thiab txias tshuab. Thaum surfacing, deforming lub taub hau nrog calipers thiab lifters kuj siv, uas tso cai rau mounting ntawm lub tshuab cuab yeej (lathes los yog ntsia hlau-txiav). Cov cutters tshwj xeeb yog siv los tshem tawm cov npoo hlau thiab cov khaubncaws sab nraud povtseg.

Part npaj yuav tsum

Ob leeg nyob rau hauv vuam thiab nyob rau hauv cov txheej txheem ntawm surfacing, qhov zoo ntawm kev ua hauj lwm yuav txiav txim siab mus rau ib tug loj npaum li cas los ntawm thawj lub xeev ntawm lub workpiece. Qhov chaw ntawm qhov yuav tsum tau ntxuav ntawm xeb, nplai, av thiab roj. Txwv tsis pub, qhov kev pheej hmoo ntawm kev khaws cia tsis muaj kev nkag mus, tawg thiab slag suav nrog nce. Kev saib xyuas tshwj xeeb yuav tsum tau them rau degreasing los ntawm lub Hoobkas thiab kev txuag roj. Cov txheej txheem no yog ua nyob rau hauv ib tug kub tov, tom qab uas cov khoom yog ntxuav thiab qhuav. Ua ntej kho qhov chaw los ntawm vuam, nws raug nquahu kom ua sandblasting, uas txhim kho qhov zoo ntawm kev kho. Rau cov haujlwm zoo li no, cov txheej txheem ua haujlwm abrasive yog siv nrog kev sib txuas ntawm cov khoom siv compressor, sib tsoo discs thiab cutters. Cov kab me me ntawm kev puas tsuaj corrosion kuj tuaj yeem raug tshem tawm nrog phau ntawv txhuam hlau.

Cov electrodes twg yog siv rau kev rov qab?

Tom qab npaj cov cuab yeej ua haujlwm tseem ceeb thiab cov khoom ua haujlwm, koj tuaj yeem mus rau kev xaiv cov electrodes. Kev xaiv nyob ntawm hom hlau, qhov xwm txheej ntawm qhov tsis xws luag thiabcov kev xav tau rau cov txheej txheem overlay. Raws li txoj cai, feem ntau ntawm kev tawg thiab tawg, cov pa vuam electrodes nrog lub zog tensile txog 4 MPa yog siv. Txhawm rau ua haujlwm nrog cov pa roj carbon steel, nws raug nquahu kom siv cov khoom siv, cov rods uas yog ua los ntawm cov hlau qib Sv-08 nrog lub thickness ntawm 1.5-12 hli. Tsis txhob las mees cov yam ntxwv ntawm lub txheej. Cov nyhuv ruaj khov siab hauv kev kho dua tshiab ntawm qhov chaw los ntawm vuam thiab ntog yuav muab los ntawm chalk txheej ntawm E-34 hom electrode. Nws yuav ua rau muaj kev ruaj khov arc hlawv, uas yuav tso cai rau koj los tsim ib qho ntom ntom thiab txawm seam.

Tsis yog tus qauv electrode consumables xws li daim kab xev thiab tubular hmoov ntsiab kuj siv niaj hnub no. Feem ntau lawv yog dov hlau strips txog li 0.8 hli tuab, qhov saum npoo uas muaj ntau cov hmoov sib tov sib xyaw ua ke raws li ferromanganese, stalinite, thiab lwm yam. Cov electrodes yuav tsum tau hais txog yog tias nws tau npaj los muab thaj chaw kho nrog cov khoom siv ntxiv.

Kev tuav arc vuam thiab txheej txheem txheej

Thaum kho cov welds puas, sib khi cov kab nrib pleb thiab sealing hermetic rooj plaub, koj tuaj yeem siv txoj kev qhia nrog graphite, carbon lossis tungsten electrodes. Nyob rau hauv chav kawm ntawm kev ua hauj lwm, ib pob ntawm rods nrog txheej yog coj thiab fastened nrog hlau. Qhov kawg yuav tsum tau pre-welded thiab muab tso rau hauv lub thawv npaj. Thaum lub sij hawm ua hauj lwm, cov electrodes yuav tsim ib tug thiaj li hu ua wandering arc nrog ib tug dav teb ntawm kev txiav txim. Yuav ua li casqhov loj dua qhov chaw puas tsuaj, qhov loj ntawm lub nqaj yuav tsum yog. Lub ntsiab nyuaj ntawm txoj kev vuam nyob rau hauv txoj kev no yog nyob rau hauv qhov yuav tsum tau mus cuag ib tug peb-theem network, txij li thaum tib lub surfacing nrog ib tug beam ntawm 5-6 electrodes yuav tsum tau nqa tawm ntawm ib tug nce tam sim no. Txoj kev no yog siv los kho qhov chaw ua los ntawm alloyed thiab low-alloyed steels ntawm nruab nrab thiab loj thickness.

Tsis siv neeg submerged arc vuam txoj kev

Tsis siv neeg surfacing txheej txheem sib txawv nyob rau hauv uas cov khoom siv electrode nrog lub zog ntawm arc nws tus kheej raws li qhov chaw ua haujlwm yog tag nrho cov tshuab. Lub flux, nyob rau hauv lem, muab cais ntawm lub hom phiaj cheeb tsam los ntawm cov teeb meem ntawm oxygen. Cov txheej txheem yog siv los kho qhov chaw tiaj tus thiab cylindrical qhov chaw nrog qhov tob txog li 15 hli. Raws li qhov loj ntawm qhov tsis xws luag nce, ob peb txheej ntawm hardfacing tuaj yeem siv tau, tab sis qhov no yuav tsum tau tos rau lub polymerization ntawm txhua txheej dhau los. Cov cuab yeej no ntawm kev kho qhov chaw los ntawm vuam thiab surfacing yuav tsum muaj kev sib txuas ntawm cov khoom siv tam sim no nyob rau hauv daim ntawv ntawm lub converter lossis rectifier nrog lub tshuab dhos ntsia hlau. Lub flux txheej 1-4 hli tuab yog tsim nyob rau hauv qhov chaw ua hauj lwm, tom qab uas ib tug electrode hlau nrog ib tug arc yog cia li coj. Lub ntsiab zoo ntawm txoj kev no txheeb ze rau phau ntawv welding muaj xws li qhov tsawg kawg nkaus ntawm cov hlau los ntawm spatter. Txoj kev phau ntawv muab ob peb zaug ntxiv cinders thiab pov tseg.

Vibro-arc surfacing method

Nyob rau hauv rooj plaub no, fusible electrodes yog siv, uas nyob rau hauv tus txheej txheemhlawv arcs vibrate nrog luv circuits. Kev ua haujlwm ntawm kev muab khoom thiab txav khoom siv kuj tseem siv tau. Txawm hais tias muaj kev nyuaj sab nraud ntawm cov txheej txheem, cov txheej txheem yog qhov yooj yim heev thiab tsis tas yuav siv cov cuab yeej tshwj xeeb. Ntxiv mus, nyob rau hauv lub sij hawm ntev, ib tug muaj peev xwm cia siab tias yuav tshem tawm ntawm deformation ntawm ib feem nrog preservation ntawm hardness yam tsis muaj kev kho cua sov. Txawm li cas los xij, kuj muaj kev txwv. Yog li, kev vibration txoj kev los kho qhov chaw los ntawm vuam thiab nto yog tsim rau workpieces nrog ib txoj kab uas hla ntawm yam tsawg 8 hli los yog ib tug tuab ntawm 0.5 mus rau 3.5 hli. Txoj kev xav, vibro-arc surfacing tuaj yeem ua tau nyob rau hauv ntau qhov chaw tiv thaiv nrog roj lossis flux, tab sis hauv kev xyaum ua kua rwb thaiv tsev feem ntau siv - piv txwv li, soda tshauv tov.

Vuam thiab ntog hauv qhov chaw tiv thaiv roj

Txoj kev no suav nrog kev npaj ntawm lub tog raj kheej tshwj xeeb nrog cov roj sib xyaw ua ke. Argon thiab carbon dioxide gases tuaj yeem siv tau, coj mus rau qhov chaw vuam nyob rau hauv siab. Lub luag haujlwm ntawm kev sib tov kuj tseem txo qis rau kev tiv thaiv kev ua haujlwm ntawm kev cais cov khoom ua haujlwm los ntawm qhov tsis zoo ntawm nitrogen thiab oxygen hauv huab cua. Cov pob qij txha zoo tshaj plaws los ntawm kev vuam hauv cov khoom siv hluav taws xob tau txais los ntawm kev siv tungsten electrodes nrog cov khoom sib cais ntawm cov khoom muab tub lim rau hauv qhov chaw ua haujlwm. Surfacing yog nqa tawm nyob rau hauv ncaj qha tam sim no nrog rov qab polarity. Cov txheej txheem tuaj yeem hloov kho yog siv cov hlau electrode, tab sis cov roj hluav taws xob feem ntau yog ua manually.

Semi-automatic welding thiab surfacing txoj kev

Txoj kev zoo rau kev ua haujlwm nrog txhuas thiab ntau yam tsis-ferrous alloys. Ua tsaug rau qhov hloov tau yooj yim ntawm cov khoom siv tsis tau thiab muaj peev xwm siv cov kev tiv thaiv sib txawv, tus neeg teb xov tooj tuaj yeem tau txais cov seam zoo ntawm lub workpiece txog li 12 hli tuab ntawm lub zog qis tam sim no. Cov txheej txheem semi-automatic ntawm kev kho qhov chaw los ntawm vuam yog ua los ntawm tungsten electrodes nrog lub thickness ntawm 0.8-6 hli. Qhov voltage hauv qhov no tuaj yeem sib txawv ntawm 20 txog 25 V, thiab lub zog tam sim no nyob rau hauv 120 A.

Txoj Kev Siv Hluav Taws Xob Rov Qab Technology

Ntxiv rau cov txheej txheem thermal ntawm vuam thiab ntog, ib pab pawg neeg sib cuag lossis cov txheej txheem txias ntawm kev hloov cov qauv ntawm cov hlau blanks kuj tseem siv. Hauv particular, kev kho dua tshiab ntawm qhov chaw los ntawm kev vuam nyob rau hauv lub siab yog nqa tawm siv cov cuab yeej cuab tam nrog xuas nrig ntaus. Nyob rau hauv tus txheej txheem ntawm yas deformation, ib tug welded sib koom ua ke nrog tej yam tsis yog tsim nyob rau hauv cov ntsiab lus sib cuag. Kev teeb tsa ntawm cov nyhuv deforming yuav nyob ntawm seb cov yam ntxwv ntawm cov punch thiab cov txheej txheem compression.

Zaj lus

Hnub no, tsis muaj txoj hauv kev zoo los kho qhov tsis xws luag hauv cov qauv hlau dua li vuam thiab ntog. Lwm qhov yog tias nyob rau hauv cov ntu no muaj kev txhim kho ntau yam kev siv thev naus laus zis hauv kev xyaum. Qhov kev cog lus zoo tshaj plaws tuaj yeem raug hu ua kev kho dua tshiab ntawm qhov chaw los ntawm kev vuam thiab surfacing ntawm cov cuab yeej siv tshuab. Mechanization ntawm kev kho cov hauj lwm tsub kom cov productivity ntawm cov txheej txheem, nwsergonomics thiab qib kev nyab xeeb rau tus welder. Nyob rau tib lub sijhawm, cov txheej txheem ntawm high-precision argon-arc welding nrog kev sib txuas ntawm cov roj thaiv kev tawm xov xwm raug tsim. Nws yog ntxov dhau los tham txog tag nrho automation nyob rau hauv cov kev taw qhia no, tab sis hais txog qhov zoo ntawm qhov tshwm sim, cheeb tsam no yog advanced.

Pom zoo:

"Renault": chaw tsim khoom, keeb kwm thiab hnub tsim, kev tswj hwm, lub teb chaws, kev tsom xam, theem ntawm kev txhim kho, kev taw qhia txog cov thev naus laus zis niaj hnub thiab lub tsheb zoo

Cov chaw tsim khoom Renault tsim cov tsheb zoo uas xav tau hauv ntau lub tebchaws hauv ntiaj teb. Cov khoom tau mus saj ntawm Lavxias teb sab tsav tsheb. Hauv 2015, kev txhawj xeeb Fabkis tau tsim lub tsheb thib peb los ntawm cov kab ntawm cov nroj tsuag Lavxias

Kev tsim cov plywood: thev naus laus zis, theem tseem ceeb ntawm cov txheej txheem thiab thaj chaw ntawm kev siv cov khoom siv

Plywood yog ib qho ntawm cov khoom siv pheej yig tshaj plaws thiab siv tau tshaj plaws. Txawm hais tias muaj ntau txheej txheej, nws yooj yim rau nruab thiab tuaj yeem ua tiav hauv tsev yam tsis muaj cov cuab yeej tshwj xeeb. Txuj kev tsim cov plywood suav nrog kev siv cov ntoo lamellas, nrog rau kev ua kom zoo uas koj tuaj yeem tau txais cov khoom tiav uas tiv taus ntau yam kev hem thawj

Dab tsi yog qhov nyiaj thiab kev pov hwm ib feem ntawm cov nyiaj laus? Lub sij hawm rau kev hloov ntawm cov nyiaj tau los ntawm cov nyiaj laus. Qhov twg ntawm cov nyiaj laus yog kev tuav pov hwm thiab qhov twg yog nyiaj

Hauv tebchaws Russia, kev hloov pauv nyiaj laus tau siv sijhawm ntev, me ntsis dhau kaum xyoo. Txawm li cas los xij, ntau tus pej xeem ua haujlwm tseem tsis tuaj yeem nkag siab tias qhov nyiaj tau los thiab kev pov hwm ntawm cov nyiaj laus yog dab tsi, thiab yog li ntawd, qhov kev nyab xeeb npaum li cas tos lawv thaum laus. Txhawm rau kom nkag siab txog qhov teeb meem no, koj yuav tsum tau nyeem cov lus qhia hauv kab lus

Vuam hauv qhov chaw tiv thaiv roj: ua haujlwm thev naus laus zis, txheej txheem piav qhia, cov txheej txheem ua tiav, cov khoom tsim nyog thiab cov cuab yeej, cov lus qhia ua haujlwm ib ntus thiab cov lus qhia kws tshaj lij

Vuam thev naus laus zis yog siv hauv ntau ceg ntawm tib neeg kev ua haujlwm. Versatility tau ua vuam nyob rau hauv ib puag ncig tiv thaiv roj ib qho tseem ceeb ntawm kev tsim khoom. Qhov ntau yam no ua rau nws yooj yim los txuas cov hlau nrog lub thickness ntawm 1 hli mus rau ob peb centimeters nyob rau hauv txhua txoj hauj lwm nyob rau hauv qhov chaw. Vuam nyob rau hauv ib puag ncig tiv thaiv yog maj mam hloov cov tsoos electrode vuam

Vitamin cog hauv Ufa: keeb kwm thiab hnub tsim, kev tswj hwm, chaw nyob, kev tsom xam, theem ntawm kev txhim kho, kev taw qhia txog cov thev naus laus zis niaj hnub thiab cov khoom lag luam zoo

Lub neej ntawm ib tug neeg niaj hnub no tshwm sim nyob rau hauv ib qho chaw tsis zoo nyob hauv ib puag ncig, nrog rau kev txawj ntse thiab kev xav ntau dhau. Koj ua tsis tau yam tsis noj cov vitamins thiab minerals txawm nyob rau lub caij ntuj sov. Cov khoom no yuav tsom mus rau ib qho ntawm cov tuam txhab qub tshaj plaws hauv Ufa, uas koom nrog kev tsim cov khoom siv tau zoo