2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Ua ntej pib tsim riam, tus tswv yuav tsum paub meej txog txhua yam ntawm cov hlau uas cov khoom kawg yuav ua rau yav tom ntej. Txhua tus neeg hlau, tshwj tsis yog cov analogues, uas yuav tau tham hauv qab no, yog qhov tshwj xeeb hauv nws cov khoom, uas txhais tau hais tias nws cov txheej txheem yuav tsum tau ua kom zoo. Yog li, lub hom phiaj ntawm peb cov xim yog R6M5 steel, cov yam ntxwv thiab daim ntawv thov uas peb yuav piav qhia hauv qab no.

Tshuaj muaj pes tsawg leeg ntawm R6M5 steel

Leej twg paub txog Soviet system ntawm cov hlau kos npe, tam sim ntawd lees paub lub hom phiaj tseem ceeb ntawm hom no. Txawm li cas los xij, rau cov neeg uas nyuam qhuav pib kawm cov ncauj lus no, nws yuav tsum tau hais:

R6M5 steel yog cov cuab yeej kub ceev

Raws li lub npe qhia, R6M5 steel muaj ntau tshaj li qhov ua tau zoo rau kev tsim cov khoom txiav. Nws yog ib qho yooj yim los twv tias tag nrho cov hlau ntawm hom noLub Soviet system tau tsim los ntawm thawj tsab ntawv "R", los ntawm Lus Askiv Rapid, uas yog, "ceev". Tus so ntawm lub cim yog lub npe ntawm lub ntsiab alloying additives. Hauv qhov no, tus lej "6" qhia txog tus nqi ntawm tungsten (W) hauv cov khoom xyaw, thiab cov ntawv luv "M5" qhia peb txog qhov muaj molybdenum (Mo) nyob rau hauv qhov muaj pes tsawg leeg ntawm tsib feem pua ntawm tag nrho qhov hnyav.. Txawm li cas los xij, lub ntsiab ligature muaj pes tsawg leeg zoo li no:

- 0.9% carbon (C);

- 6% tungsten (W);

- 5% molybdenum (Mo);

- 4% chromium (Cr);

- 2% vanadium (V).

Ntxiv rau cov txheej txheem no, muaj ntau cov khoom siv me me, tab sis lawv tuaj yeem tsis quav ntsej txog kev nyab xeeb, vim tias hauv R6M5 steel cov yam ntxwv raug teeb tsa los ntawm cov ntsiab lus alloying saum toj no.

Thiab cov lus cog tseg:

- Nyob hauv Tebchaws Meskas, qhov ze tshaj analogue hu ua T11302 lossis M2.

- Nyob hauv Thaj Av Ntawm Lub Hnub Tuaj, qhov analogue hu ua SKH51.

- Hauv Tebchaws Europe koj tuaj yeem pom cov analogues hu ua Hs6-5-2 lossis 1.3339.

Nyob rau hauv kev kawm

Tom ntej no, cov yam ntxwv ntawm R6M5 hauv kev ua haujlwm yuav raug txiav txim siab, peb yuav teev cov txheej txheem ua cov hlau tseem ceeb thiab qhov ntsuas kub kom meej. So:

- Ntxhais. Qhov limiting annealing kub yog 880 ° C nrog qhov txo qis ntawm 50 ° C ib teev twg. Peb ncav cuag qhov ntsuas kub qis ntawm 650 ° C, tom qab ntawd peb txias lub workpiece hauv huab cua.

- Txhob Cia Siab. Qhov kub ntawm txoj kev hauv tsev no pib ntawm 1160 ° C thiab xaus ntawm 860 ° C.

- Ntxhais. Nyob rau theem no, koj yuav tsum tau tawm hws, vim qhov pib kub ntawm no yog 1200 ° C. Tom ntej no, lub workpiece yog txo mus rau hauvroj mus txog 200 ° C, ces rov qab mus rau huab cua. Raws li qhov tshwm sim, peb tau txais cov hniav nrog lub hardness ntawm 62 units ntawm Rockwell nplai. Muaj kev xav tias cov hlau no tuaj yeem ua kom tawv nqaij hauv dej, tab sis qhov no yog cov lus dag ntawm cov neeg ua haujlwm tub nkeeg.

- Vajtswv. Koj yuav tsum tso cov hniav peb zaug: rau ib teev twg thiab ntawm qhov kub ntawm 500 ° C. Tom qab ntawd, nws hardness yuav nce li ntawm peb units thiab yuav yog 65 units. los ntawm Rockwell.

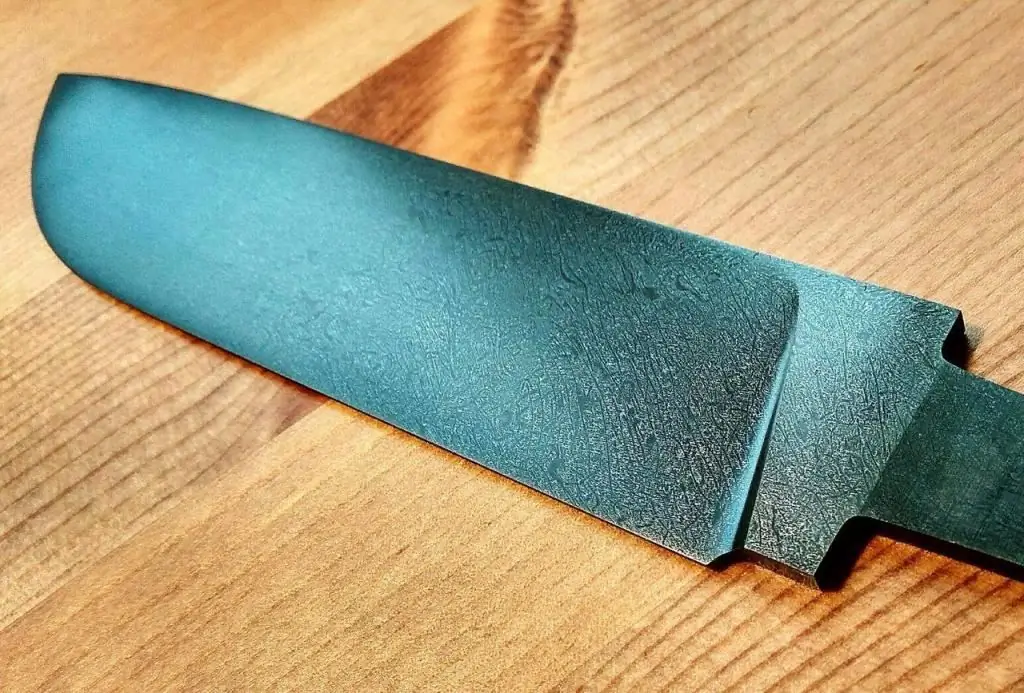

R6M5 steel: yam ntxwv thiab daim ntawv thov rau riam

Qhov tshwm sim ntawm tag nrho koj cov kev siv zog yog cov hniav uas muaj zog txiav, tab sis viscous txaus kom maj mam npub yam tsis muaj qhov me me thiab tsis chips heev. Txawm li cas los xij, cov hniav, txawm tias tag nrho cov kev siv zog, yuav dhau los ua tsis yooj yim, yog li peb tsis qhia koj kom ua rau nws ntau dhau.

Yog tsis muaj kev saib xyuas zoo, nws maj mam tab sis xeb. Thaum etched, nws tau txais ib qho xim dub. Kev sib tsoo thiab polishing yog qhov zoo, tab sis nyuaj - vim qhov nyuaj siab.

Result

Hauv kev tsim khoom ntawm koj yuav xav tau kev saib xyuas tshwj xeeb, vim tias cov hlau tsis tshua muaj siab heev nyob rau theem ntawm kev kho cua sov thiab ua rau decarburization thaum overheated. Nws tseem tsim nyog ua siab ntev rau lub sijhawm ua haujlwm hlau, vim tias R6M5 steel muaj cov yam ntxwv muaj zog heev. Tab sis yog tias koj ua raws li tag nrho cov subtleties, cov khoom kawg yuav ua tau zoo heev thiab ruaj khov.

Pom zoo:

Tus kws qhia ntawv qib siab hauv tsev kawm qib siab: hauj lwm piav qhia, lub luag haujlwm thiab cov yam ntxwv ntawm kev ua haujlwm

Rector, Dean, Professor, Associate Professor… Yog koj yog ib tug tub kawm, cov lus no yuav ua rau muaj kev xav thiab xav tsis thoob. Thiab nws nyuaj heev los piav cov ntsiab lus no rau "tus neeg tsis yog menyuam kawm ntawv". Txawm li cas los xij, ntau tus neeg tsis nco qab txog ib txoj haujlwm ntxiv uas nyob hauv txhua lub tsev kawm ntawv - tus kws qhia ntawv laus

Steel R6M5: yam ntxwv, daim ntawv thov

Cov alloy ntawm ib lub caij ntawm yim pawg ntawm lub sij hawm ntawm Mendeleev nrog atomic tooj 26 (hlau) nrog carbon thiab lwm yam ntsiab lus feem ntau hu ua hlau. Nws muaj zog thiab hardness, tsis muaj plasticity thiab viscosity vim carbon. Alloying ntsiab nce qhov zoo ntawm cov alloy. Txawm li cas los xij, hlau yog suav tias yog cov khoom siv hlau uas muaj tsawg kawg yog 45% hlau

Coal: kev faib tawm, hom, qib, yam ntxwv, combustion nta, qhov chaw rho tawm, daim ntawv thov thiab qhov tseem ceeb rau kev lag luam

Coal yog ib qho chaw sib txawv thiab ntau yam. Vim nws peculiarity ntawm tsim nyob rau hauv lub plab hnyuv ntawm lub ntiaj teb, nws muaj peev xwm muaj ntau yam txawv. Yog li ntawd, nws yog txoj cai los faib cov thee. Yuav ua li cas qhov no tshwm sim yog piav nyob rau hauv tsab xov xwm no

Sodium hypochlorite qib A: yam ntxwv, daim ntawv thov

Sodium hypochlorite yog cov khoom siv tshuaj siv hauv ntau yam ua tshuaj tua kab mob. Cov tshuaj no tuaj yeem siv los tua txhua yam ntawm qhov chaw, khoom siv, kua, thiab lwm yam. Muaj ntau ntau yam ntawm cov khoom no. Feem ntau, piv txwv li, qib A sodium hypochlorite yog siv los ua tshuaj tua kab mob

Pob zeb sib xyaw: cov khoom, muaj pes tsawg leeg, hom, qib ntawm pob zeb, yam ntxwv, ua raws li GOST cov qauv thiab daim ntawv thov

Ntawm cov khoom tseem ceeb ntawm cov pob zeb sib tov, uas tseem hu ua hydrotechnical pob zeb, nws yog ib qho tsim nyog los qhia txog qhov ua kom muaj dej ntau ntxiv. Cov vaj tse raug tsim los ntawm cov khoom siv no los siv rau hauv thaj chaw swampy lossis hauv cheeb tsam uas muaj dej nyab