2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Cov alloy ntawm ib lub caij ntawm yim pawg ntawm lub sij hawm ntawm Mendeleev nrog atomic tooj 26 (hlau) nrog carbon thiab lwm yam ntsiab lus feem ntau hu ua hlau. Nws muaj zog thiab hardness, tsis muaj plasticity thiab viscosity vim carbon. Alloying ntsiab nce qhov zoo ntawm cov alloy. Txawm li cas los xij, hlau yog suav tias yog cov khoom siv hlau uas muaj tsawg kawg yog 45% hlau.

Cia peb xav txog ib qho hlau xws li R6M5 steel thiab nrhiav seb nws muaj dab tsi thiab hauv thaj chaw twg nws siv.

Manganese ua cov khoom sib xyaw

Txog xyoo pua 19th, cov hlau zoo tib yam tau siv los ua cov hlau tsis-ferrous thiab ntoo. Nws cov yam ntxwv txiav tau txaus txaus rau qhov no. Txawm li cas los xij, thaum sim ua cov txheej txheem steel, lub cuab yeej heats sai heev, hnav tawm thiab txawm deforms.

Tus Askiv metallurgist R. Muschette, dhau los ntawm kev sim, pom qhov ntawd rauTxhawm rau ua kom cov alloy muaj zog, nws yog ib qho tsim nyog yuav tsum tau ntxiv cov oxidizing tus neeg sawv cev rau nws, uas yuav tso tawm cov pa ntau dhau los ntawm nws. Lawv pib ntxiv daim iav cam khwb cia hlau, uas muaj manganese, los cam khwb cia hlau. Txij li nws yog cov khoom siv alloying, nws cov feem pua yuav tsum tsis pub tshaj 0.8%. Yog li, R6M5 steel muaj los ntawm 0.2% mus rau 0.5% manganese.

Tungsten Hlau

Tam sim no xyoo 1858, ntau tus kws tshawb fawb thiab cov kws tshawb fawb metallurgists tau ua haujlwm ntawm kev tau txais cov alloys nrog tungsten. Lawv paub tseeb tias nws yog ib qho ntawm cov hlau refractory tshaj plaws. Ntxiv rau cov hlau ua cov hlau alloying ua rau nws tuaj yeem tau txais cov hlau uas tuaj yeem tiv taus qhov kub thiab txias thiab tseem tsis hnav.

Steel R6M5 muaj 5.5-6.5% tungsten. Alloys nrog nws cov ntsiab lus feem ntau pib nrog tsab ntawv "P" thiab hu ua high-speed. Xyoo 1858 Muschette tau txais thawj cov hlau uas muaj 9% tungsten, 2.5% manganese thiab 1.85 carbon. Tom qab ntawd, ntxiv 0.3% C, 0.4% Cr rau nws thiab tshem tawm 1.62% Mn, 3.56% W, metallurgist tau txais ib qho alloy hu ua samokal (P6M5). Raws li nws cov yam ntxwv, nws kuj zoo ib yam li P18 steel.

Tungsten tsis txaus

Tau kawg, nyob rau xyoo 1860, thaum muaj ntau lub ntsiab lus muaj ntau, hlau nrog ntxiv ntawm tungsten tau suav tias yog qhov muaj zog tshaj plaws. Thaum lub sij hawm, lub caij no nyob rau hauv cov xwm yuav tsawg thiab tsawg, thiab tus nqi rau nws loj hlob.

Los ntawm qhov kev xav ntawm kev lag luam, ntxiv ntau W rau hlau tau dhau los ua qhov tsis zoo. Vim li no, R6M5 steel yog nrov dua R18. Saib ntawm lawv cov tshuaj muaj pes tsawg leeg, koj tuaj yeem pom tias cov ntsiab lus tungsten hauv P18 yog 17-18.5%, thaum nyob rau hauv tungsten-molybdenum alloy nws yog siab tshaj 6.5%. Tsis tas li ntawd, txog li 0.25% tooj liab thiab mus txog 5.3% molybdenum muaj nyob rau hauv tus kheej hu.

Lwm cov ntsiab lus alloying

Ntxiv rau cov pa roj carbon monoxide saum toj no, manganese, tungsten thiab molybdenum, R6M5 steel kuj muaj cob alt (txog 0.5%), chromium (4.4%), tooj liab (0.25%), vanadium (2.1%), phosphorus (0.03%), sulfur (0.025%), nickel (0.6%) silicon (0.5%). Lawv yog dab tsi?

Txhua lub ntsiab lus alloying muaj nws txoj haujlwm. Yog li, piv txwv li, chromium yog tsim nyog rau thermal hardening, thaum nickel nce toughness. Molybdenum thiab vanadium zoo li tshem tawm temper brittleness. Qee lub ntsiab lus alloying txhim kho cov khoom steel xws li liab hardness thiab kub hardness.

Steel R6M5, cov yam ntxwv uas peb tab tom kawm, nyob rau hauv lub xeev hardened muaj ib tug hardness ntawm 66 HRC ntawm qhov ntsuas kub txog li 600 ° C. Qhov no txhais tau tias txawm tias muaj cua sov muaj zog, nws tsis poob nws cov yam ntxwv ntawm lub zog, uas txhais tau tias nws tsis hnav lossis deform.

Designation Р6M5

Deciphering steel nyob ntawm seb nws ua li cas, cov ntsiab lus alloying nws suav nrog thiab pes tsawg carbon nws muaj. Muaj cov npe rau ntau hom. Yog tias, piv txwv li, cov hlau tsis muaj cov ntsiab lus alloying, ces nws raug xaiv "St" thiab ib sab ntawm nws yog tus lej uas qhia cov ntsiab lus nruab nrab ntawm cov hlau (St20,Art45)..

Hauv cov alloys qis, thawj zaug los ntawm feem pua ntawm cov pa roj carbon monoxide, thiab tom qab ntawd cov ntawv qhia txog tshuaj lom neeg (10KhSND, 20KhN4FA). Yog tias tsis muaj tus lej nyob ib sab ntawm lawv, zoo li hauv qhov piv txwv, cov ntsiab lus ntawm txhua tus ntawm lawv tsis pub tshaj 1%. Tsab ntawv "P" nyob rau qib ntawm cov hlau qhia tias nws yog kev txiav ceev ceev (ceev ceev).

Ua raws nws yog tus lej - qhov no yog feem pua ntawm tungsten (P9, P18), thiab tom qab ntawd cov ntawv thiab cov lej yog cov ntsiab lus alloying thiab lawv feem pua. Los ntawm qhov no nws ua raws li R6M5 kev kub ceev hlau muaj txog li 6% tungsten thiab mus txog 5% molybdenum.

Raws li txoj cai, kev tsim cov hlau zoo li no yog classical thiab yuav siv rau txhua qhov kev kub ceev steels. Txawm li cas los xij, nws yuav tsum tau nco ntsoov tias txhawm rau txhawm rau tungsten-molybdenum alloy kom muaj zog tiag tiag, tawv thiab hnav-tiv taus, nws yuav tsum tau muab tshem tawm.

Yog lwm qib, piv txwv li, St45, poob lawv lub zog ntawm lub zog thaum lub sij hawm annealing, ces cov siab ceev, ntawm qhov tsis sib xws, txhim kho thiab ua kom muaj zog thiab nyuaj. Tias yog vim li cas R6M5 yog annealed ua ntej hardening. Nws tshwm sim li cas?

Rolled khoom (piv txwv li, R6M5 steel ntawv) nrog ib tug tuab ntawm txog 22 hli yog rhuab nyob rau hauv ib tug tshwj xeeb rauv rau qhov kub ntawm 870 ° C, ces txias rau 800 ° C, thiab ces rhuab dua. Yuav muaj txog 10 lub voj voog zoo li no.

Ntxiv rau, tom qab thib tsib, nws yog qhov yuav tsum tau maj mam txo qhov kub thiab txias. Piv txwv li, cua sov dua tab sis mus txog 850 ° C, txias mus rau 780 ° C. Thiab mus txog rau thaum nws nce mus txog 600 ° C.

Cov txheej txheem annealing nyuaj no yog vim muaj cov nplejaustenite nyob rau hauv alloyed alloys, uas yog heev undesirable. Cua sov thiab cua txias tso cai rau cov alloying ntsiab kom yaj ntau li ntau tau, tab sis lub austenite yuav tsis loj hlob.

Yog tias koj tsis tuaj yeem tiv thaiv qhov kub thiab txias ntawm qhov kub ntawm ntau tshaj 900 ° C, tom qab ntawd qhov nce ntawm austenite yog tsim nyob rau hauv alloy thiab hardness txo. Kev ua kom txias yog pom zoo kom siv cov roj da dej, qhov no yuav tiv thaiv cov tungsten-molybdenum alloy los ntawm cov kab nrib pleb thiab punctures.

P6M5 kev tsim khoom

Tau kawg, zoo li lwm yam hlau, R6M5 yog tsim nyob rau hauv ntau yam khoom. Yog li, nyob rau hauv qee qhov kev cob qhia, high-speed kub steel yog poured rau hauv ingots. Hauv lwm qhov ntau lawm, nws yog dov nrog kub dov. Ua li no, cov cua sov ingots yog compressed nruab nrab ntawm cov yob ntawm dov zeb. Nws cov duab tshwm sim yuav nyob ntawm seb cov duab ntawm cov ncej lawv tus kheej.

R6M5 steel qib yog dav siv rau qhov chaw ua haujlwm ntawm qhov kub thiab txias. Vim li no, hmoov-coated steel tau ib txoj kev nrov heev ntawm kev ua hlau lately.

Thaum nchuav cov hlau kub rau hauv ingots, muaj kev tso tawm sai heev ntawm carbides los ntawm yaj. Hauv qee thaj chaw, lawv tsim cov cheeb tsam tsis sib xws, uas tom qab ntawd dhau los ua qhov chaw pib tawg.

Hauv kev tsim cov hmoov, cov hmoov tshwj xeeb yog siv, uas muaj tag nrho cov khoom tsim nyog. Nws yog sintered nyob rau hauv ib tug tshwj xeeb lub tshuab nqus tsev ntim ntawm kub thiab siab. Qhov no ua rau muaj qhov tseeb tias cov khoom tau txaishomogeneous.

Daim ntawv thov

R6M5 steel yog dav siv hauv ntau yam lag luam. Feem ntau nws yog siv rau kev tsim cov cuab yeej txiav rau txoj siav, milling thiab drilling tshuab hauv metallurgy. Qhov no yog vim nws cov yam ntxwv ntawm lub zog, kub tsis kam, hardness.

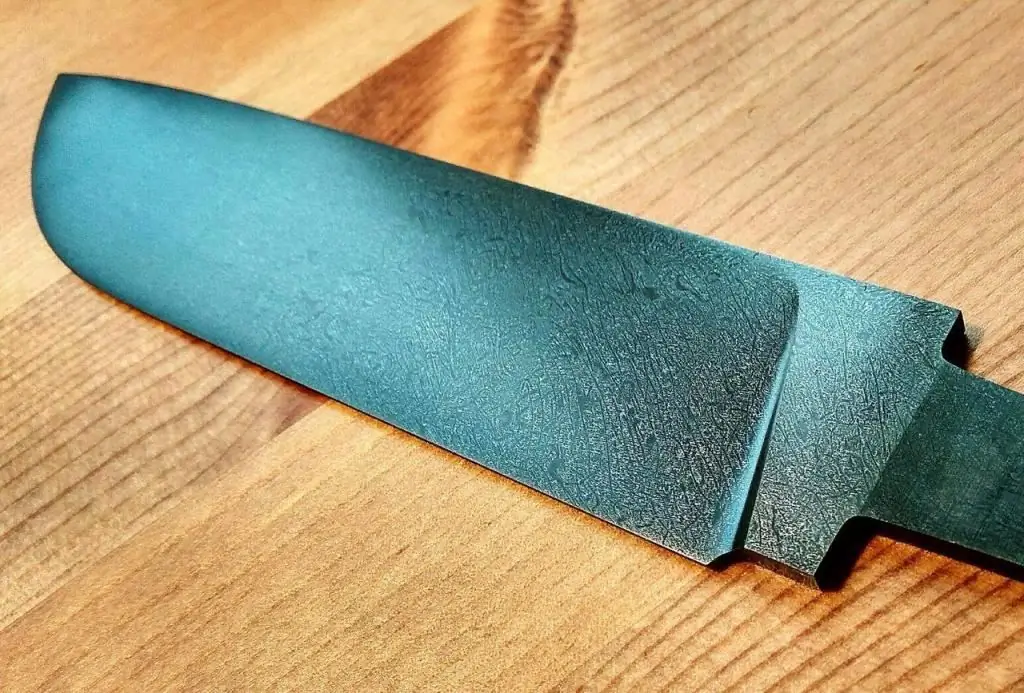

Raws li txoj cai, xyaum, kais, tuag, cutters yog tsim los ntawm nws. Cov cuab yeej txiav hlau ua los ntawm R6M5 steel yog zoo heev rau kev txiav ntawm kev kub ceev, tsis tas li ntawd, nws tsis tas yuav ua kom txias txias. Ib rab riam ua los ntawm R6M5 steel kuj tsis tshua muaj.

Vim tias tungsten-molybdenum alloy muaj siab hardness thiab siab toughness, nws yog feem ntau siv los ua riam nrog muaj zog tuav thiab cov qauv zoo nkauj.

Alloying ntsiab nyob rau hauv qhov yuav tsum tau muaj tso cai los tsim ib tug tshwj xeeb hlau uas xyaum tsis xeb thiab muaj zoo grindability. Qhov no tso cai rau kev ua haujlwm ntawm locksmith kom nce kev txiav ceev los ntawm 4 zaug.

Nws kuj tseem siv los tsim cov pob bearings uas muaj cua sov ua haujlwm ntawm kev kub ceev ntawm 500-600 ° C. Cov analogues ntawm R6M5 alloy yog R12, R10K5F5, R14F4, R9K10, R6M3, R9F5, R9K5, R18F2, 6M5K5. Yog tias tungsten-molybdenum alloys, raws li txoj cai, siv rau kev tsim cov cuab yeej rau roughing (drills, cutters), ces vanadium (R14F4) rau xov (reamers, broaches). Txhua lub cuab yeej txiav yuav tsum muaj lub cim uas tso cai rau koj kom paub tias nws yog dab tsi.

Pom zoo:

Daim ntawv thov rov qab los ntawm kev tuav pov hwm qiv nyiaj: piv txwv, cov cai ntawm daim ntawv thov, lub sijhawm xa tawm

Nyob rau hauv tus txheej txheem ntawm tau txais cov nyiaj qiv, cov tsev txhab nyiaj muaj peev xwm qiv nyiaj los xaus daim ntawv cog lus pov hwm. Yog tias tus neeg siv tsis tuaj yeem them cov nuj nqis, lub luag haujlwm kaw nws mus rau lub txhab nyiaj yog nrog lub tuam txhab pov hwm. Tab sis hauv kev xyaum, qhov xwm txheej tsis sib xws feem ntau tshwm sim, thiab cov neeg them nyiaj siab xav tau xav txog qhov muaj peev xwm rov qab tau txais kev pov hwm qiv nyiaj thaum them rov qab ntxov. Tab sis yuav tau txais ntau npaum li cas? Thiab leej twg yuav tsum muab cov nyiaj - tus tuav pov hwm lossis lub txhab nyiaj?

CVG steel: muaj pes tsawg leeg, daim ntawv thov thiab cov yam ntxwv

Kawm metallurgy thiab tag nrho nws cov subtleties, koj tsis yeem pib muaj kev xav tsis thoob kom tau txais cov ntaub ntawv muaj txiaj ntsig ntau npaum li qhov ua tau thiab siv sijhawm me ntsis thiab siv zog li sai tau. Nyob rau hauv cov ntaub ntawv no, kab lus no tshwm sim. Nws muaj tag nrho cov ntaub ntawv tseem ceeb tshaj plaws ntsig txog CVG steel: txiav txim siab lub cim, kawm txog kev muaj pes tsawg leeg, kev siv cov hlau no, nrog rau kev mus ncig luv luv rau hauv cov hlau hloov pauv thiab txawv teb chaws analogues. Txhua yam koj xav tau nyob rau hauv ib qho chaw rau txhua tus neeg yooj yim

Tooj liab phaj, ntawv ci, daim kab xev: ntau lawm, yam ntxwv, daim ntawv thov

Tooj liab yog ib qho ntawm cov hlau nrov tshaj plaws nyob rau hauv lub ntiaj teb niaj hnub no, nws yog siv nyob rau hauv ntau qhov chaw ntawm ntau lawm

Steel qib R6M5: yam ntxwv thiab daim ntawv thov

Ua ntej pib tsim riam, tus tswv yuav tsum paub meej txog txhua yam ntawm cov hlau uas cov khoom kawg yuav ua rau yav tom ntej. Txhua tus neeg hlau, tshwj tsis yog cov analogues, uas yuav tau tham hauv qab no, yog qhov tshwj xeeb hauv nws cov khoom, uas txhais tau hais tias nws cov txheej txheem yuav tsum tau ua kom zoo. Yog li, qhov tseem ceeb ntawm peb cov xim yog R6M5 steel, cov yam ntxwv thiab daim ntawv thov uas peb yuav piav qhia hauv qab no

Daim ntawv teev cov hlau tsis-ferrous: yam ntxwv, daim ntawv thov

Kev loj hlob ntawm kev vam meej tsis tuaj yeem tshwm sim sai heev yog tias tus txiv neej tsis pom txoj hauv kev rau kuv thiab ua ntau yam hlau. Thiab yog tias thaum xub thawj qhov no tau ua kom yooj yim los ntawm kev pom zoo ntawm ntuj nuggets dag ncaj qha rau saum npoo av, tom qab ntawd tsis ntev cov npe ntawm cov hlau tsis muaj hlau uas tib neeg tau tswj kom "tame" pib nthuav dav. Thawj qhov kev sim thiab kev tshawb fawb ntxaws ntxiv ntawm cov khoom ntawm cov khoom tshiab tau pom tias txhua yam khoom muaj cov khoom sib txawv thiab lawv cov kev siv