2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Kev taw qhia ntawm kev ua cov ntshav rau hauv kev lag luam tau cim kev ua haujlwm thev naus laus zis thiab hloov mus rau qib tshiab ntawm cov khoom tsim tau zoo. Lub Scope ntawm cov khoom muaj txiaj ntsig ntawm plasma yog qhov dav heev. Ua ntej tshaj plaws, qhov no yog kev tsim cov khoom siv hluav taws xob thiab cov khoom siv semiconductor. Yog tsis muaj plasma-chemical etching, niaj hnub ua haujlwm siab ntawm tus kheej lub computer yuav tsis pom lub teeb. Tab sis qhov ntawd tsis yog tag nrho.

Ion-plasma ua kuj tseem siv rau hauv optics thiab mechanical engineering rau polishing khoom, siv cov txheej txheem tiv thaiv, diffusion saturation ntawm cov hlau thiab alloys, nrog rau kev vuam thiab txiav cov ntawv hlau. Hauv daim ntawv no, kev tsom mus rau vuam thiab txiav cov thev naus laus zis uas siv plasma.

khoom siv dav dav

Los ntawm tsev kawm ntawv cov lus qhia physics txhua tus paub tias qhov teeb meem tuaj yeem muaj nyob hauv plaub lub xeev: khoom, kua, roj, thiab ntshav. Cov lus nug feem ntau tshwm sim thaum sim sawv cev rau lub xeev kawg. Tab sis qhov tseeb, txhua yam tsis nyuaj li ntawd. Plasma kuj yog roj, tsuas yog nws cov molecules yog, raws li lawv hais, ionized (uas yog, cais los ntawm electrons). Lub xeev no tuaj yeem ua tiavnyob rau hauv ntau txoj kev: raws li qhov tshwm sim ntawm raug kub kub, thiab raws li ib tug tshwm sim ntawm electron bombardment ntawm gas atoms nyob rau hauv lub nqus tsev vacuum.

Cov ntshav no hu ua low-temperature. Lub physics ntawm cov txheej txheem no yog siv rau hauv kev siv cov plasma deposition (etching, saturation) nyob rau hauv lub nqus tsev vacuum. Los ntawm muab cov plasma hais nyob rau hauv ib qho chaw sib nqus, lawv tuaj yeem muab cov lus taw qhia. Raws li kev xyaum tau pom, kev ua haujlwm zoo li no tau zoo dua nyob rau hauv ntau qhov kev ua haujlwm ntawm kev ua haujlwm hauv kev siv tshuab engineering (saturation hauv hmoov xov xwm, nplaim taws txiav, nchuav nrog cov tshuaj txhuam raws li chromium oxide, thiab lwm yam).

Kev kho ntshav plasma

Tam sim no, plasma tau nquag siv hauv yuav luag txhua qhov kev lag luam thiab kev lag luam hauv tebchaws: tshuaj, engineering, instrumentation, kev tsim kho, science, thiab lwm yam.

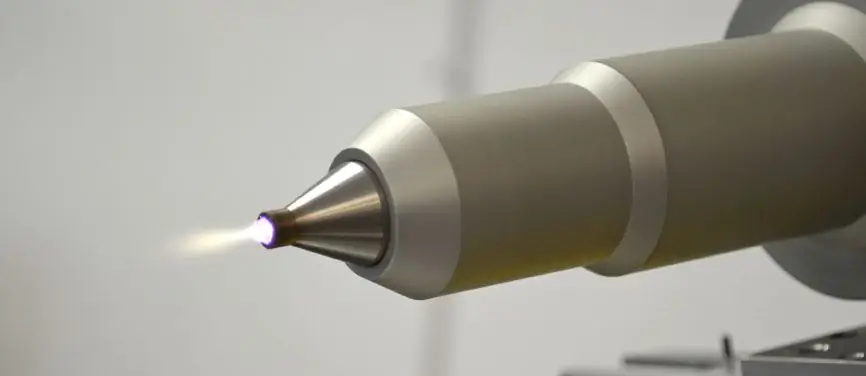

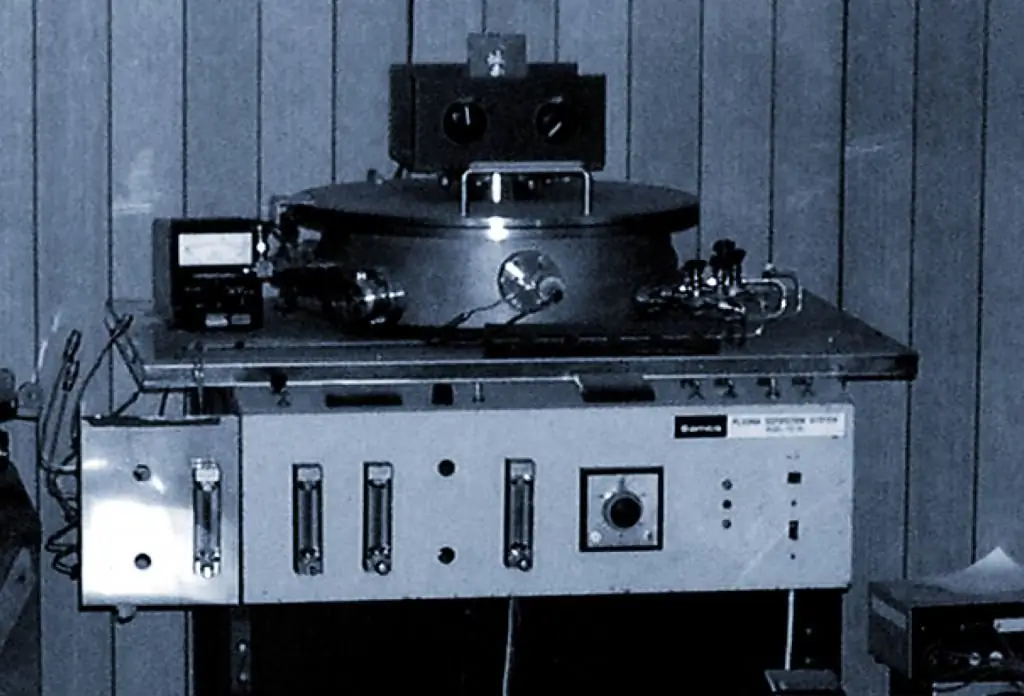

Pioneer hauv kev siv cov tshuab ntshav ntshav yog ntsuas. Kev lag luam kev lag luam ntawm kev ua cov plasma pib nrog kev siv cov khoom ntawm cov roj ionized los tsuag txhua yam ntaub ntawv thiab siv rau hauv ob sab phlu, nrog rau cov etch channel kom tau txais microcircuits. Nyob ntawm qee yam ntawm cov cuab yeej ntawm kev teeb tsa thev naus laus zis, plasma-chemical etching, ion-chemical, thiab ion-beam etching yog qhov txawv.

Txoj kev loj hlob ntawm plasma yog ib qho txiaj ntsig zoo kawg nkaus rau kev txhim kho thev naus laus zis thiab kev txhim kho, yam tsis muaj kev nthuav dav, kev ua neej zoo ntawm tib neeg. Nrog txoj kevlub sijhawm, thaj chaw ntawm kev siv cov roj ions tau nthuav dav. Thiab niaj hnub no, plasma ua (hauv ib daim ntawv lossis lwm qhov) yog siv los tsim cov khoom siv tshwj xeeb (kub tsis kam, tawv tawv, corrosion resistance, thiab lwm yam), rau kev txiav hlau zoo, vuam, polishing nto thiab tshem tawm microroughness.

Daim ntawv teev npe no tsis txwv rau kev siv thev naus laus zis raws li cov txiaj ntsig ntawm cov ntshav plasma ntawm qhov chaw kho. Tam sim no, txhais tau tias thiab cov txheej txheem ntawm kev txau cov ntshav plasma yog tsim los siv ntau yam ntaub ntawv thiab kev ua haujlwm kom ua tiav qhov siab tshaj plaws txhua yam thiab lub cev.

Qhov Tseem Ceeb ntawm Plasma Vuam

Tsis zoo li kev teeb tsa ntawm ion-plasma saturation thiab sputtering, qhov no, kev kho ntshav ntshav yog ua los ntawm kev siv cov ntshav plasma kub. Qhov ua tau zoo ntawm txoj kev no yog siab dua thaum siv cov txheej txheem vuam tsoos (nplaim, hluav taws xob arc, submerged arc vuam, thiab lwm yam). Raws li kev sib xyaw ua haujlwm roj, raws li txoj cai, huab cua zoo tib yam hauv huab cua hauv siab yog siv. Yog li, cov txheej txheem no yog tus yam ntxwv los ntawm qhov tsis muaj nqi rau cov khoom siv roj.

Qhov zoo ntawm plasma vuam

Piv rau cov khoom siv vuam ib txwm siv, siv lub tshuab plasma vuam zoo dua. Yog vim li cas yog qhov tseeb heev - kev siv cov pa pa hauv huab cua hauv siab ua cov pa ua haujlwm. Tam sim no, kev nyab xeeb hauv kev tsim khoom tau txais kev saib xyuas zoo heev los ntawm cov tswvcov lag luam, cov thawj coj thiab cov tswj hwm.

Lwm qhov txiaj ntsig tseem ceeb yog qhov zoo ntawm qhov vuam (tsawg kawg sagging, tsis muaj kev nkag mus thiab lwm yam tsis xws luag). Txawm hais tias, txhawm rau kawm paub siv lub tshuab plasma welding zoo li cas, xav tau ntau lub hlis ntawm kev xyaum. Tsuas yog nyob rau hauv rooj plaub no, qhov vuam thiab cov pob qij txha tag nrho yuav ua tau raws li cov qauv siab.

Qhov tshuab no muaj ntau yam zoo. Ntawm lawv: kev kub ceev ntawm cov txheej txheem vuam (kev tsim khoom nce), kev siv hluav taws xob tsawg (hluav taws xob), kev sib txuas siab raug, tsis muaj deformation thiab warping.

Plasma tej khoom

Cov txheej txheem nws tus kheej yog qhov nkag siab zoo rau cov khoom siv tam sim no. Yog li ntawd, nws raug tso cai siv tsuas yog high-zoo thiab txhim khu kev qha transformers uas ua kom pom qhov tsis tu ncua ntawm cov zis voltage. Kauj ruam-down transformers yog siv los hloov siab input voltage mus rau qhov tso zis voltage tsawg. Tus nqi ntawm cov khoom siv no yog ob peb zaug tsawg dua tus nqi ntawm cov khoom siv ib txwm siv rau hluav taws xob arc vuam. Lawv kuj pheej yig dua.

Plasma cov cuab yeej siv tau yooj yim. Yog li ntawd, yog tias koj muaj tsawg kawg nkaus kev paub thiab kev txawj ntse, koj tuaj yeem ua txhua yam haujlwm vuam koj tus kheej.

Plasma Vuam Technology

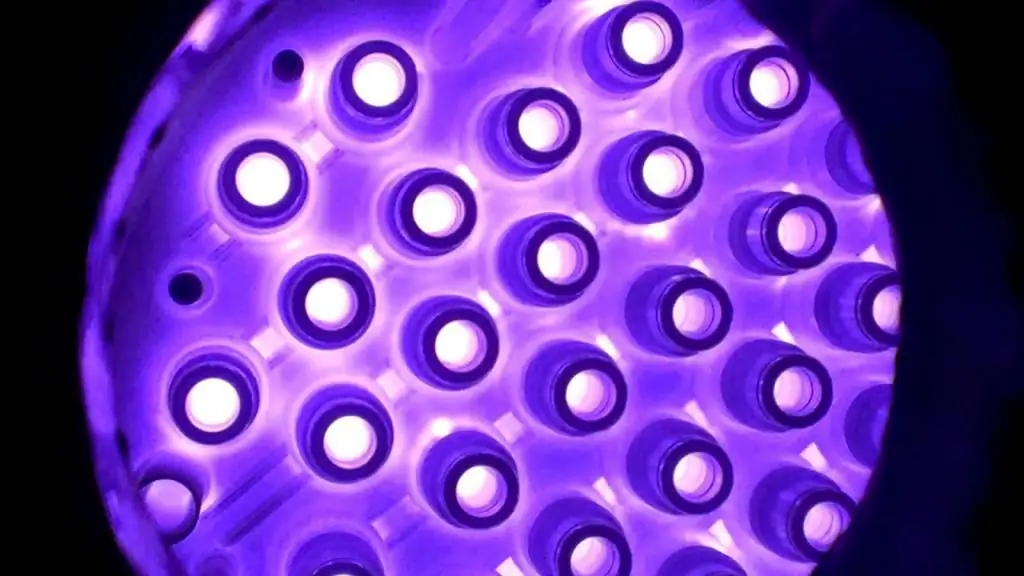

Nyob ntawm cov khoom siv hluav taws xob, plasma vuam tau muab faib ua micro vuam, vuam rau hauvnruab nrab thiab siab tam sim no. Cov txheej txheem nws tus kheej yog ua raws li qhov kev txiav txim ntawm kev taw qhia ntws ntawm high-temperature plasma ntawm ib qho hluav taws xob thiab ntawm qhov chaw yuav tsum tau welded. Cov electrode melts, ua rau muaj kev sib txuas mus tas li.

plasma txiav

Plasma txiav yog txheej txheem uas cov hlau raug txiav rau hauv nws cov khoom siv los ntawm cov kwj ntawm cov plasma kub. Qhov no technology muab ib tug zoo kawg nkaus txawm txiav kab. Tom qab lub plasma cutter, yuav tsum tau ua ntxiv ntawm cov contour ntawm cov khoom (txawm yog cov ntaub ntawv los yog cov yeeb nkab khoom) raug tshem tawm.

Cov txheej txheem tuaj yeem ua tiav ob qho tib si nrog lub tshuab txiav thiab nrog lub tshuab txiav ntshav rau txiav cov ntawv hlau. Plasma yog tsim thaum muaj hluav taws xob arc siv rau cov roj ua haujlwm. Raws li qhov tshwm sim ntawm cov cua kub tseem ceeb hauv zos, ionization tshwm sim (kev sib cais ntawm cov hluav taws xob tsis zoo los ntawm cov khoom siv hluav taws xob zoo).

Plasma txiav daim ntawv thov

Lub dav hlau kub kub plasma muaj lub zog siab heev. Nws qhov kub yog siab heev uas nws cia evaporates ntau cov hlau thiab alloys yooj yim. Cov tshuab no tsuas yog siv los txiav cov ntawv hlau, cov ntawv txhuas, tooj liab, tooj dag thiab txawm tias titanium. Ntxiv mus, lub thickness ntawm daim ntawv yuav txawv heev. Qhov no yuav tsis cuam tshuam rau qhov zoo ntawm txoj kab txiav - nws yuav zoo kawg nkaus du thiab txawm, tsis muaj streaks.

Txawm li cas los xij, nws yuav tsum tau sau tseg tias txhawm rau kom tau txais txiaj ntsig zoo thiab txawm tiastxiav thaum ua hauj lwm nrog cov khoom tuab-walled, koj yuav tsum siv lub tshuab plasma. Lub hwj chim ntawm lub teeb txawb yuav tsis txaus los txiav hlau nrog lub thickness ntawm 5 mus rau 30 millimeters.

Gas txiav lossis plasma txiav?

Yuav ua li cas txiav thiab txiav hlau yuav tsum nyiam? Qhov twg yog qhov zoo dua: oxy-fuel txiav lossis plasma txiav tshuab? Qhov kev xaiv thib ob yog kab tias muaj ntau yam, vim tias nws yog qhov tsim nyog rau yuav luag txhua yam khoom siv (txawm tias cov neeg nyiam oxidation ntawm qhov kub siab). Tsis tas li ntawd, kev txiav ntshav plasma yog ua los ntawm kev siv cov huab cua zoo tib yam, uas txhais tau hais tias nws tsis xav tau kev yuav khoom kim heev. Thiab txoj kab txiav yog zoo kawg nkaus txawm thiab tsis xav tau kev kho kom zoo. Tag nrho cov no hauv kev sib xyaw ua ke txo tus nqi ntawm cov khoom thiab ua rau cov khoom sib tw ntau dua.

Plasma tej ntaub ntawv

Nws yuav tsum raug coj mus rau hauv tus account qhov tseeb tias qhov siab tshaj plaws ntawm cov khoom siv hlau ua tiav yog nyob ntawm cov khoom nws tus kheej lossis nws qib. Raws li kev paub ntau xyoo ntawm kev tsim khoom thiab kev tshawb fawb hauv chaw soj nstuam, cov kws tshaj lij muab cov lus pom zoo hauv qab no rau cov tuab ntawm cov ntaub ntawv ua tiav: cam khwb cia hlau - tsis muaj ntau tshaj li cuaj centimeters, hlau (tsis hais txog cov tshuaj muaj pes tsawg leeg thiab muaj cov ntsiab lus alloying) - tsis muaj ntau tshaj tsib centimeters, tooj liab thiab alloys raws li nws - tsis ntau tshaj yim centimeters, txhuas thiab nws alloys - tsis ntau tshaj 12 centimeters.

Txhua tus nqi teev tseg yog qhov raug rau phau ntawvua. Ib qho piv txwv ntawm xws li lub tsev tsim khoom hauv tsev yog Gorynych plasma apparatus. Nws yog ntau pheej yig dua li txawv teb chaws analogues, thaum nws yog nyob rau hauv tsis muaj txoj kev inferior, thiab tej zaum txawm superior rau lawv nyob rau hauv zoo. Ntau yam khoom siv los ntawm cov chaw tsim khoom no tau nthuav tawm nyob rau hauv kev ua lag luam, uas yog tsim los ua ntau yam haujlwm (tsim vuam, txiav thiab vuam hlau ntawm ntau yam thicknesses, suav nrog). Cov ntawv tuab tsuas tuaj yeem ua tiav ntawm cov tshuab fais fab loj.

Txoj kev txiav ntshav plasma uas twb muaj lawm

Txhua txoj kev uas twb muaj lawm ntawm kev txiav ntshav tuaj yeem muab faib ua dav hlau thiab arc. Tsis tas li ntawd, nws tsis muaj teeb meem txawm tias siv lub tshuab txiav tes lossis CNC ntshav txiav thiab txiav tshuab. Nyob rau hauv thawj rooj plaub, tag nrho cov tsim nyog tej yam kev mob rau cov roj ionization yog siv nyob rau hauv lub cutter nws tus kheej. Cov cuab yeej zoo li no tuaj yeem ua tiav yuav luag txhua yam khoom (hlau thiab tsis yog hlau). Hauv qhov thib ob, cov khoom ua tiav yuav tsum muaj hluav taws xob conductivity (lwm yam, tsis muaj hluav taws xob arc yuav tshwm sim thiab roj ionization yuav tshwm sim).

Ntxiv rau qhov sib txawv ntawm txoj kev plasma tsim, kev ua cov plasma kuj tuaj yeem raug cais raws li cov txheej txheem thev naus laus zis ntawm kev txiav rau hauv qhov yooj yim (tsis tas siv cov khoom pabcuam), ua haujlwm nrog dej thiab ua haujlwm hauv qhov chaw tiv thaiv roj.. Ob txoj hauv kev dhau los tso cai rau koj kom nce qhov nrawm nrawm thiab tib lub sijhawm tsis txhob ntshai ntawm cov hlau oxidation.

Pom zoo:

Cov ntaub ntawv xa tuaj: tus kheej xaj, daim ntawv them nqi, daim ntawv xaj, cov ntaub ntawv xa khoom thiab cov chaw xa khoom xa tuaj

Kev ua haujlwm hauv kev xa khoom yog nrov heev niaj hnub no, tshwj xeeb tshaj yog cov tub ntxhais hluas muaj siab nyiam. Tus neeg xa xov tsis yog ib tus neeg xa khoom xwb, tab sis yog tus kws tshaj lij uas muaj kev txawj ntse thiab tuaj yeem nqa parcel los yog xa mus rau qhov chaw nyob uas tau teev tseg nrog cov khoom zoo thiab sai

Cov ntaub ntawv sau nyiaj yog Lub tswv yim, cov cai rau kev sau npe thiab khaws cov ntaub ntawv sau nyiaj. 402-FZ "Rau Accounting". Tshooj 9. Cov ntaub ntawv sau nyiaj txiag tseem ceeb

Kev ua tiav ntawm cov ntaub ntawv sau nyiaj tau zoo yog qhov tseem ceeb heev rau cov txheej txheem ntawm kev tsim cov ntaub ntawv nyiaj txiag thiab txiav txim siab txog se. Yog li ntawd, yuav tsum tau kho cov ntaub ntawv nrog kev saib xyuas tshwj xeeb. Cov kws tshaj lij ntawm cov kev pabcuam nyiaj txiag, cov neeg sawv cev ntawm cov lag luam me uas khaws cov ntaub ntawv ywj pheej yuav tsum paub txog cov ntsiab lus tseem ceeb rau kev tsim, tsim, txav, khaws cov ntaub ntawv

Kev sib cog lus ntawm cov koom haum: kos daim ntawv cog lus, cov ntaub ntawv tsim nyog, cov ntaub ntawv thiab cov cai rau kev sau cov piv txwv

Kev sib pauv kev lag luam (offsets thiab kev sib cog lus) ntawm cov chaw lag luam yog qhov muaj ntau hauv kev ua lag luam. Qhov tshwm sim ntawm cov haujlwm no yog kev txiav tawm ntawm kev sib nrig sib cai thiab kev lav phib xaub ntawm cov neeg koom nrog kev sib raug zoo hauv pej xeem

Cov ntaub ntawv rau kev txiav tawm cov cuab yeej: cov ntaub ntawv dav dav, cov ntaub ntawv xav tau thiab cov ntawv

Kev sau npe ntawm kev txiav tawm cov cuab yeej yog txheej txheem uas ntau tus pej xeem hauv Lavxias xav tau. Kab lus no yuav qhia koj yuav ua li cas kom tau nws. Yuav tsum npaj dabtsi? Raws li cov xwm txheej twg thiab qhov twg ib tus tuaj yeem thov qhov kev txiav tawm ntawm cov cuab yeej?

Yam koj yuav tsum tau ua haujlwm hauv tsheb tavxij: cov ntaub ntawv tsim nyog thiab cov cai, cov cai thiab kev cai lij choj. Cov lus teb thiab cov lus qhia los ntawm cov neeg tsav tsheb tavxij, cov neeg siv khoom thiab cov neeg xa khoom

Raws li ntau tus neeg caij tsheb, txoj haujlwm ntawm tus tsav tsheb tavxij yog qhov yooj yim tshaj plaws. Koj zaum, mloog suab paj nruag zoo nkauj thiab tsav tsheb rov qab los. Thiab lawv muab nyiaj rau koj. Tab sis qhov no tsuas yog sab nraud ntawm lub npib. Qhov rov qab yog ntau dua rosy. Peb yuav tham txog nws hauv kab lus no. Thiab peb tseem yuav qhia txog yam koj xav tau ua haujlwm hauv tsheb tavxij