2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Txhua xyoo, ntau cov hlau poob vim kev xeb. Txawm li cas los xij, qhov kev puas tsuaj ntau dua yog tshwm sim los ntawm kev tsis ua haujlwm ntawm cov khoom hlau vim yog corrosion. Cov nqi tsim nyog rau kev hloov cov khoom lossis kev kho tam sim no ntawm cov khoom siv, tsheb, hiav txwv thiab dej hiav txwv, cov khoom siv hauv kev tsim tshuaj muaj ntau zaus ntau dua li cov nqi ntawm cov khoom siv los tsim lawv.

Tseem tseem muaj kev poob qis tsis ncaj. Cov no suav nrog, piv txwv li, roj av los yog roj los ntawm cov kav dej puas los ntawm kev xeb, khoom noj khoom haus, kev puas tsuaj ntawm lub tsev, thiab ntau ntxiv. Yog li ntawd, kev sib ntaus tawm tsam hlau corrosion yog qhov tseem ceeb heev.

Vim li cas cov khoom hlau puas tawg?

Ua ntej peb mus rau lo lus nug ntawm dab tsi yog corrosion-resistant steel, cia peb nkag siab lub tswvyim ntawm corrosion thiab lub ntsiab ntawm cov txheej txheem no.

Txhais los ntawm Latin corroder - corrosive. Kev qeeb qeeb ntawm kev puas tsuaj ntawm cov hlau thiab alloys raws li lawv, tshwm sim nyob rau hauv cov tshuaj cuam tshuam ntawm ib puag ncigib puag ncig hu ua corrosion. Yog vim li cas rau qhov kev puas tsuaj no yog cov tshuaj lom neeg sib cuam tshuam (redox cov tshuaj tiv thaiv) ntawm cov khoom siv hlau nrog cov roj av lossis kua nruab nrab uas lawv nyob.

Stainless hlau thiab alloys yog dab tsi?

Cov khoom lag luam ua los ntawm cov hlau tsis muaj zog thiab kub-resistant los yog lawv cov alloys yog tsim los ua haujlwm nyob rau hauv ib puag ncig hnyav ntawm qhov kub thiab txias. Yog li ntawd, qhov tseem ceeb ntawm cov ntaub ntawv ntawm cov pab pawg no yog kub tsis kam (tsis kam mus rau ib puag ncig gaseous lossis chav kub ntawm qhov kub siab) los yog corrosion kuj (lub peev xwm los tiv thaiv cov teebmeem ntawm kev txhoj puab heev ntawm qhov kub thiab txias).

Corrosion resistance yog yam ntxwv ntawm cov khoom hlau, ntawm qhov chaw uas muaj zog passivating zaj duab xis yog tsim nyob rau hauv ib qho kev txhoj puab heev, uas tiv thaiv kev nkag mus rau hauv tob txheej ntawm cov hlau thiab kev sib cuam tshuam ntawm cov khoom hnyav nrog lawv.

Ib lo lus, stainless hlau yog hlau uas tiv taus intergranular, tshuaj, electrochemical thiab lwm yam corrosion.

tshuaj muaj pes tsawg leeg

Cov khoom ntawm cov hlau yog txiav txim siab los ntawm nws cov tshuaj muaj pes tsawg leeg. Nrog cov ntsiab lus chromium ntawm 12-13%, cov hlau ua stainless, uas yog, ruaj khov nyob rau hauv cov huab cua thiab tshuaj lom neeg ib puag ncig. Nce cov ntsiab lus chromium rau 28-30% ua rau nws ruaj khov nyob rau hauv ib puag ncig nruj.

Ntawm lwm cov khoom siv rau alloying,muaj xws li manganese, aluminium, titanium, nickel. Feem ntau siv yog alloys, nyob rau hauv uas qhov nruab nrab nickel ntsiab lus yog 10%, chromium - 18%, carbon - los ntawm 0.08 los yog 0.12%, titanium - 1% (12X18H10T - corrosion-resistant steel, GOST 5632).

Kev faib tawm los ntawm microstructure hom: austenitic stainless hlau qib

Qhov kev tiv thaiv ntawm chav kawm no rau corrosive nres yog nce los ntawm nickel (los ntawm 5 mus rau 15%) thiab chromium (los ntawm 15 mus rau 20%) alloying ntsiab. Austenitic alloys yog insensitive rau intergranular corrosion, yog hais tias cov pa roj carbon ntsiab lus nyob rau hauv lawv yog tsawg tshaj li qhov txwv ntawm nws solubility nyob rau hauv austenite (0.02-0.03% los yog tsawg dua). Tsis-sib nqus, zoo raug vuam, txias thiab kub deformation. Lawv muaj technology zoo heev. Nws yog cov hlau zoo tshaj plaws rau fasteners, weldments thiab daim ntaub ntawv nyob rau hauv ntau yam lag luam.

Martensitic chav kawm

Stainless steels suav nrog hauv chav martensitic tuaj yeem sib nqus thiab muaj siab dua - piv nrog austenitic - ntsuas qhov siab tshaj plaws hardness. Hardening yog tiav los ntawm quenching thiab tempering. Zoo rau cov khoom uas npaj rau siv nyob rau hauv nruab nrab mus rau lub teeb ib puag ncig (xws li tej yam khoom noj khoom haus los yog rab chais hniav).

Ferrite Qib

Nrog rau kev tiv thaiv corrosion siab, cov khoom ntawm cov qib no zoo ib yam li cov hlau me me. Cov ntsiab lus nruab nrab ntawm chromium yog11-17%. Siv rau hauv kev tsim cov khoom siv hauv tsev, cov khoom siv hauv tsev kho kom zoo nkauj sab hauv, chav ua noj.

Austenitic ferritic qib

Corrosion-resistant stainless hlau ntawm chav kawm no yog qhov txawv ntawm cov ntsiab lus nickel txo thiab cov ntsiab lus chromium siab (los ntawm 21 txog 28%). Niobium, titanium, tooj liab ua raws li cov ntsiab lus alloying ntxiv. Tom qab kev kho cua sov, qhov piv ntawm ferrite thiab austenite yog kwv yees li ib mus rau ib qho.

Austenitic-ferritic steels yog ob npaug zog li austenitic steels. Nyob rau tib lub sij hawm, lawv yog ductile, tiv thaiv poob siab loads zoo, muaj ib tug tsawg theem ntawm corrosion cracking thiab siab tsis kam mus rau intergranular corrosion. Pom zoo siv rau hauv kev tsim kho kev lag luam, kev lag luam tsim khoom, rau kev tsim cov khoom lag luam uas yuav tuaj rau hauv dej hiav txwv.

Austenitic-martensitic qib

Chromium cov ntsiab lus los ntawm 12 txog 18%, npib tsib xee - los ntawm 3.7 txog 7.5%. Cov ntsiab lus ntxiv - chrome thiab aluminium. Lawv yog hardening los ntawm hardening (t > 975 ° C) thiab tom qab tempering (t=450-500 ° C). Austenitic-martensitic stainless hlau tau zoo welded thiab muaj cov khoom siv tshuab siab.

Stainless steel: nqe (factors influencing formation)

Cov khoom siv ntawm cov hlau tsis muaj zog muaj xws li cov khoom siv kim kim xws li chromium, npib tsib xee, titanium, molybdenum. Lawv tus nqi yog txiav txim siab ntawm tus nqi. Vim lwm qib (carbon, structural,pob bearing, cuab yeej, thiab lwm yam) muaj cov npe teev nyob rau hauv ntau me me, ces nyob rau hauv kev sib piv nrog lawv, tus nqi ntawm corrosion-resistant steels yog ib txwm siab dua. Txawm li cas los xij, tus nqi yuav txawv nyob ntawm kev ua lag luam thiab cov nqi tsim nyog los tsim cov hlau tsis muaj steel.

Mechanical Properties

Cov qib stainless hlau yuav tsum muaj cov khoom siv kho tshuab uas ua tau raws li cov qauv tsim. Cov no suav nrog:

- siab tshaj Brinell hardness (HB);

- elongation (%);

- yield zog (H/mm2);

- tensile lub zog (H / mm 2).

Tom qab ntau lawm, txhua pawg (melting) ntawm cov khoom lag luam raug kuaj xyuas kom ua raws li cov khoom siv kho tshuab thiab microstructure ntawm qib steel rau GOST. Cov txiaj ntsig ntawm kev kuaj xyuas cov qauv yog qhia hauv daim ntawv pov thawj ntawm kev tsim khoom.

Steel grade designation system

Ntau yam alloys thiab steels yog tsim nyob rau hauv ntau lub teb chaws ntawm lub ntiaj teb no. Tib lub sijhawm, tsis muaj ib qho kev thoob ntiaj teb rau lawv cov ntawv sau npe tsis tau.

Nyob hauv Tebchaws Meskas, muaj ntau qhov kev xaiv tsa ib zaug. Qhov xwm txheej no, vim muaj ntau lub koom haum tsim qauv (AJS, ANSI, ACJ, SAE, AWS, ASTM, ASME), ua rau muaj qee yam teeb meem rau cov neeg koom tes, cov neeg cog lus thiab cov neeg siv khoom ntawm cov khoom hlau los ntawm Asmeskas cov tuam txhab los ntawm lwm lub tebchaws.

In Japan steelyog cim nrog cov tsiaj ntawv thiab cov lej qhia lawv pab pawg (tsawg-alloyed, high-alloyed, tshwj xeeb-hom alloys, nruab nrab-alloyed, high-zoo, high-zoo, thiab lwm yam), serial tooj nyob rau hauv nws thiab cov khoom ntawm cov hlau..

Nyob rau hauv lub tebchaws ntawm European Union, cov kev xaiv tau tswj hwm los ntawm EN 100 27 tus qauv, uas txiav txim siab qhov kev txiav txim uas lub npe thiab tus lej raug muab.

Nyob rau hauv Lavxias teb sab Federation muaj ib tug alphanumeric system tsim thaum lub sij hawm lub Soviet Union, raws li cov qib steel raug xaiv. GOST tau tshaj tawm los qhia txog txhua yam khoom siv tshuaj lom neeg uas yog ib feem ntawm cov hlau nrog ib tsab ntawv Lavxias.

Rau manganese, qhov no yog G, silicon - C, chromium - X, nickel - H, molybdenum - M, tungsten - B, vanadium - F, titanium - T, aluminium - Yu, niobium - B, cob alt - K, zirconium - C, boron - R.

Tus lej tom qab tsab ntawv qhia txog feem pua ntawm cov ntsiab lus alloying. Yog hais tias cov hlau muaj pes tsawg leeg muaj tsawg dua 1% ntawm cov khoom alloying, ces tus naj npawb tsis tau affixed, nrog rau cov ntsiab lus ntawm 1 mus rau 2% tom qab tsab ntawv muab tso rau 1. Qhov thib ob tus lej qhia thaum pib ntawm qib yog tsim nyog. qhia qhov nruab nrab cov ntsiab lus carbon nyob rau hauv pua pua ntawm ib feem pua hauv qib qeb.

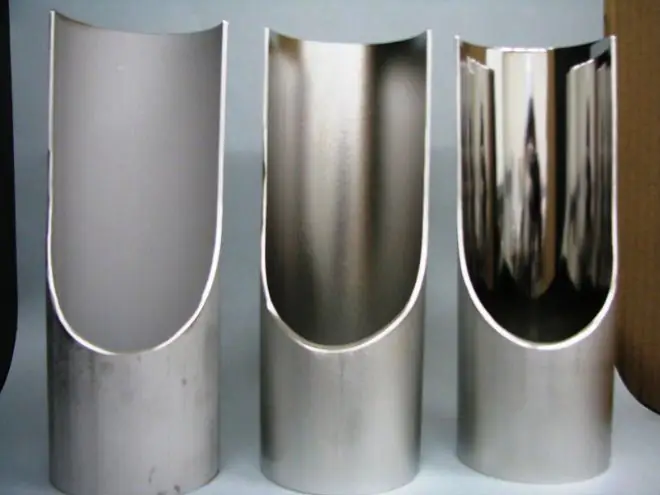

Stainless khoom ntau yam

Corrosion resistant steel yog siv rau cov khoom hauv qab no:

- tshav kub-kho etched thiab polished nplooj;

- tshav kub-kho cov ntawv tsis-etched;

- thermallycov nplooj ntawv nyoos thiab tsis tau khawb;

- heat-, txias- thiab kub ua haujlwm seamless kav;

- kub-kuav los tiag steel sawb rau dav dav;

- calibrated hexagons;

- stainless lub voj voog;

- stainless hlau (kub kho thiab kos txias);

- castings nrog cov khoom tshwj xeeb;

- lwm yam uas GOSTs thiab cov lus qhia (TU) tau tsim.

Scope of application

Raws li ib qho piv txwv zoo tshaj plaws ntawm lub zog, kev zoo nkauj, ua haujlwm rau kev puas tsuaj ntawm corrosion thiab kub kub, recyclability thiab durability, nrog zoo heev deg tiav uas ua tau raws li tag nrho cov kev tu cev thiab tu cev, stainless hlau yog dav siv nyob rau hauv yuav luag. tag nrho cov spheres ntawm kev ua lag luam.

Stainless hlau yog nyob rau hauv kev thov siab hauv petrochemical, tshuaj, pulp thiab ntawv, khoom noj, kev tsim kho, hluav taws xob, nkoj tsim thiab thauj engineering, ntsuas thiab ib puag ncig kev lag luam.

Kev ua tau zoo thiab ua haujlwm ntev ntawm cov khoom ua los ntawm cov hlau tsis muaj steel yog txiav txim siab los ntawm txoj cai xaiv ntawm nws cov chav kawm thiab hom, kev nkag siab ntawm lub cev thiab tshuaj lom neeg thiab cov qauv microstructure. Los ntawm kev siv cov hlau uas tiv taus cov kev puas tsuaj ntawm corrosion, raws li lawv cov khoom, peb muaj peev xwm coj kom zoo dua ntawm tag nrho cov undeniable.cov txiaj ntsig ntawm cov cuab yeej siv niaj hnub no.

Pom zoo:

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

Pitting corrosion: ua rau. Txoj kev tiv thaiv cov hlau los ntawm corrosion

Thaum lub sijhawm ua haujlwm ntawm cov khoom siv hlau, lawv raug rau ntau hom kev puas tsuaj, ntawm cov pitting corrosion sawv tawm raws li qhov txaus ntshai tshaj plaws thiab tsis muaj kev cia siab

Stainless hlau ua: cov txheej txheem nrov, txoj hauv kev thiab cov lus pom zoo

Hnub no, tib neeg siv ntau yam khoom. Ib qho ntawm feem ntau yog stainless hlau. Cov khoom siv yog cov yam ntxwv ntawm kev ua haujlwm siab, thiab yog li ntawd tau dhau los ua neeg nyiam. Tsis tas li ntawd, kev ua haujlwm ntawm cov hlau tsis muaj steel kuj pab ua kom cov hlau zoo li qub

Solder rau soldering tooj liab, txhuas, tooj dag, hlau, stainless hlau. Solder muaj pes tsawg leeg rau soldering. Hom solders rau soldering

Thaum nws yuav tsum tau ua kom ruaj khov ntau yam khoom sib txuas ua ke, soldering feem ntau xaiv rau qhov no. Cov txheej txheem no tau nthuav dav hauv ntau lub lag luam. Peb yuav tsum tau solder thiab tsev craftsmen

440 steel - stainless hlau. Steel 440: yam ntxwv

Ntau tus neeg paub 440 steel. Nws tau tsim nws tus kheej raws li kev txhim khu kev qha, tiv thaiv corrosion, lub sij hawm-kuaj cov khoom siv nyuaj, uas feem ntau yog siv rau kev tsim cov riam rau ntau lub hom phiaj. Dab tsi yog qhov zais ntawm no alloy? Dab tsi yog nws cov tshuaj, cov yam ntxwv ntawm lub cev thiab kev siv?