2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Muaj ntau ntau hom kev ua hlau tsis zoo uas pab tsis tau tsuas yog txhim kho nws cov yam ntxwv zoo, tab sis kuj tseem txhim kho nws cov tsos. Tsis tas li ntawd, kev ua haujlwm ntawm cov hlau zoo li no tso cai rau koj coj cov ntsuas kev ua tau zoo rau cov ntsuas qhov xav tau.

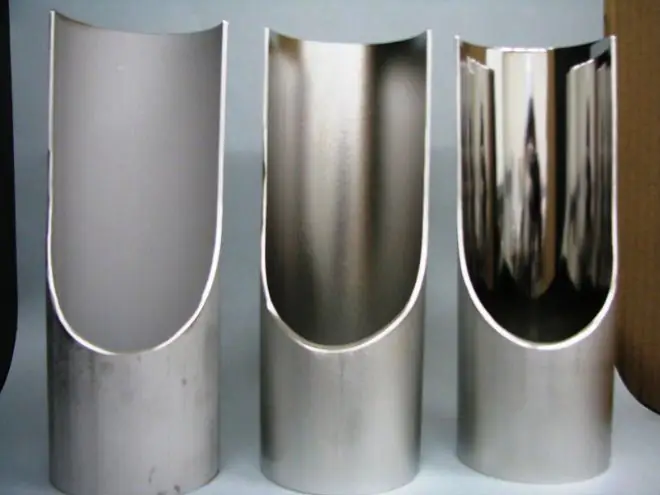

khoom sib tsoo

Vim txoj kev sib txawv ntawm kev ua cov hlau tsis huv, nws feem ntau siv tsis yog rau kev tsim cov khoom lossis cov khoom siv, tab sis kuj rau kev kho kom zoo nkauj. Txhawm rau txhim kho cov tsos, nrog rau kom ua tiav qhov yuav tsum tau ua ntawm roughness ntawm txheej, ib txoj kev xws li kev sib tsoo thiab polishing yog siv. Feem ntau, ob txoj kev no tau muab tso ua ke rau hauv ib qho, thiab nws hu ua sativation. Txoj kev ua haujlwm no tau txais nws lub npe vim qhov tseeb tias qhov chaw ntawm cov hlau zoo li no, tom qab ua tiav kev ua haujlwm, pib zoo li satin lossis satin ntaub.

Kev ua cov hlau tsis xeb hlau, piv txwv li, pib nrog qhov tseeb tias nws yog ib qho tsim nyog los nqa cov npoo mus rau qhov khawb me me. Rau qhov no, siv lub tshuab sib tsoo nrog lub voj voog ntawm cov paj ntoo.

Vim li cas xuab zeb

Ntxiv nrog rau kev pab txhim kho cov tsos ntawm cov hlau, xuab zeb tuaj yeem pab tshem tawm qhov tsis zoo. Yog tias koj tsis tuaj yeem tshem tawm tag nrho lawv, ces siv txoj kev no koj tuaj yeem ua rau lawv yuav luag tsis pom. Raws li rau txoj kev ua tiav, kev ua haujlwm tuaj yeem ua tau ob qho tib si manually thiab nrog kev pab los ntawm cov cuab yeej tshwj xeeb uas ua haujlwm los ntawm hluav taws xob lossis pneumatic tsav. Muaj qee yam khoom siv ntau tshaj plaws uas tau siv los ua cov txheej txheem ntawm kev ua cov hlau tsis muaj steel:

- pneumatic band file;

- drum siv sander;

- lwm yam khoom siv uas tuaj yeem siv xuab zeb siv.

Raws li kev ua haujlwm zoo li no hauv tsev, phau ntawv qhia feem ntau siv ntawm no. Ua li no, lawv feem ntau siv cov ntawv sib tsoo lossis cov khoom siv uas hu ua kev sib tsoo. Hauv cov nroj tsuag kev lag luam, tau kawg, kev txaus siab yog nqa tawm siv ntau yam khoom siv tshwj xeeb.

Nws yog ib qho tsim nyog ntxiv tias kev ua cov hlau tsis muaj steel seams, nplooj ntawv thiab lwm yam pib nrog qhov tseeb tias kev sib tsoo log nrog grit ntawm 180 yog siv. Tom qab ntawd yuav tsum siv ob lub voj voog ntxiv - 320 thiab 600. Txhawm rau ua kom tiav cov haujlwm, nws yog ib qho tsim nyog yuav tsum ua cov txheej txheem alloy nrog kev xav ib puag ncig.

Kev ua phau ntawv ua haujlwm

BNyob rau hauv cov kev tshwm sim uas cov txheej txheem ntawm stainless hlau tom qab vuam yog nqa tawm manually, ces nws yog tsim nyog los ua raws li cov nram qab no ib theem zuj zus ntawm kev ua hauj lwm:

- Vim qhov saum npoo tau welded ua ntej, qhov kub yuav tsum raug tshem tawm ua ntej.

- Qhov saum npoo ntawm cov hlau tsis muaj hlau, uas yuav yog thawj zaug rau kev kho mob, yuav tsum tau sib cais nrog txhuas daim kab xev. Nws haum hauv 2 lossis 3 txheej.

- Qhov uas tsis raug kaw nrog daim kab xev yuav tsum tau ua tiav siv cov lus tsa suab sib txuas. Txawm li cas los xij, koj yuav tsum nco ntsoov tias koj tsis tas yuav nias lub pob zeb hnyav dhau.

- Tom qab qhov xav tau qhov zoo ntawm qhov chaw tiav, cov ntaub nplaum txhuas rov qab ua rau thaj tsam uas tau ua tiav ua ntej, thiab cov txheej txheej dawb yog polished.

Sib tsoo ntawm cov tshuab

Nws yog tsim nyog sau cia tias stainless hlau tig yog ua tau. Ntawd yog, kev sib tsoo tuaj yeem ua tiav ntawm cov cuab yeej tig. Nyob rau hauv cov ntaub ntawv no, tshwj xeeb sib tsoo log yog ntsia rau xws li pab kiag li lawm. Nws tseem tsim nyog sau cia tias qhov kev ua haujlwm no tuaj yeem ua tiav ntawm lub tshuab ob qho tib si hauv kev tsim khoom thiab hauv tsev, yog tias muaj chav nyob. Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov ntawm no tias txawm tias cov cuab yeej tig tau yooj yim tshaj plaws yuav tso cai rau koj ua haujlwm tau zoo.

Raws li kev lag luam hauv phau ntawv qhia, nws tsis yog ib txwm xav kom siv lub tshuab sib tsoo, thiab yog li qee zaum siv cov ntawv sib tsoo. Hauv qhov no, heevNws yog ib qho tseem ceeb uas yuav tau xaiv cov qoob loo loj. Txhawm rau kom tsis txhob yuam kev, lawv feem ntau siv cov txheej txheem los xaiv.

Kev piav qhia

Lwm txoj hauv kev zoo los ua cov hlau tsis muaj steel tom qab vuam yog pickling. Kev ua haujlwm thev naus laus zis no yuav ua rau nws muaj peev xwm tiv taus qhov tsis xws luag uas tshwm sim los ntawm kev vuam, vim kev kho cua sov ntawm cov hlau, vim yog cov hlau ua los ntawm cov yas deformation. Lwm qhov zoo ntawm kev siv txoj kev etching raws li kev kho mob yog lub peev xwm tshem tawm cov xim ntawm cov khoom siv. Tsis tas li, cov txheej txheem no yuav rov ua dua tshiab cov txheej txheem tiv thaiv kev tiv thaiv ntawm cov txheej txheem, uas tiv thaiv cov hlau tsis zoo los ntawm qhov tsis zoo ntawm qhov kub siab.

Kev ua haujlwm

Txhawm rau ua tiav kev lag luam ntawm kev lag luam nplai, cov kua qaub yog siv los ua cov hlau tsis muaj steel lossis molten alkaline xov xwm. Nyob rau hauv cov kev tshwm sim uas ib tug acid nruab nrab yog siv rau etching, cov txheej txheem pib nyob rau hauv ob theem zuj zus. Nyob rau hauv thawj theem, cov alloy yog kho nrog sulfuric acid tov, nyob rau hauv lub thib ob, cov tshuaj raws li nitric acid yog siv.

Nyob rau hauv cov xwm txheej uas alkaline acid yog siv rau pickling, cov hlau yog muab tso rau hauv ib tug tov ntawm caustic soda. Cov tshuaj no muaj peev xwm tshem tawm cov oxide zaj duab xis los ntawm cov hlau tsis muaj kev puas tsuaj rau nws cov qauv.

Raws li kev ua haujlwm hauv tsev, siv cov kua qaublos yog alkaline cov neeg ua haujlwm tsis suav nrog. Rau qhov no, tshwj xeeb pickling pastes tau tsim. Lawv peculiarity nyob rau hauv lub fact tias lawv muaj ib tug zoo li jelly. Nws yog ib qho tsim nyog yuav tau siv cov tshuaj no nrog kev ceev faj heev, vim tias ntxiv rau nitric thiab hydrofluoric acid, hydrochloric acid thiab chloride kuj muaj nyob rau hauv cov khoom xyaw, thiab cov tshuaj no ua rau muaj kev hem thawj rau tib neeg kev noj qab haus huv.

Pab muab tshuaj txhuam

Etching muab tshuaj txhuam tsuas yog siv rau ntawm qhov chaw uas yav tas los tau zoo huv si thiab degreased. Txhawm rau ua tiav cov txiaj ntsig xav tau, koj tsuas yog yuav tsum tau yaug qhov chaw nrog dej sov, thiab tom qab ntawd yaug nrog cov tshuaj ntxuav tes. Tom qab siv cov tshuaj txhuam hniav, tso rau ntawm qhov chaw hlau. Lub sij hawm raug yog los ntawm 10 mus rau 60 feeb. Tom qab lub sijhawm xav tau, cov tshuaj txhuam yog ntxuav tawm nrog dej zoo tib yam. Txhawm rau siv cov khoom xyaw zoo li no, koj yuav tsum tau siv cov tshuaj tiv thaiv acid-resistant txhuam los yog cov yas tshwj xeeb spatula. Nws yog ib qho tsim nyog ntxiv tias yog tias thaj chaw hlau loj txaus, ces cov tshuaj etching tuaj yeem siv rau daim ntawv thov, uas yog txau siv cov khoom siv dav hlau txau. Txog niaj hnub no, muaj ntau lub tuam txhab tsim cov khoom noj khoom haus uas paub zoo tshaj plaws. Cov tuam txhab no suav nrog SAROX TS-K 2000, Avesta BlueOne thiab Stain Clean (ESAB).

Ntau txoj hauv kev ua haujlwm

Muaj ob peb lwm txoj hauv kev uas siv tsawg dua, tab sis tseem qee zaum siv. Ib ntawmCov txheej txheem no yog chromium plating. Kev siv hom kev ua haujlwm no tso cai rau koj kom ua tiav cov txiaj ntsig xws li:

- kev txhim kho;

- txhim kho kev tiv thaiv kev ntxhov siab;

- muaj zog nce hauv corrosion kuj.

Qhov tsis zoo ntawm txoj kev no yog nws tsuas yog ua tau raws li kev tsim khoom. Kev ua haujlwm yog qhov nyuaj heev, thiab yog li ntawd yuav tsum muaj tus kws tshaj lij los ua nws. Tsis tas li ntawd, cov khoom siv tshwj xeeb kuj xav tau. Vim li no, chrome plating hauv tsev yuav tsis ua haujlwm.

Txawm li cas los xij, hauv kev cob qhia hauv tsev, lwm txoj haujlwm tuaj yeem ua tiav, uas yog hu ua bluing. Nws yuav pab muab qhov chaw zoo nkauj. Cov txheej txheem no tuaj yeem ua tau peb txoj kev sib txawv. Thawj txoj kev yog kev siv cov kua qaub, txoj kev thib ob yog nrog kev siv cov alkali, qhov kawg kev xaiv yog kev siv cov thermal exposure.

Tig daim ntawv thov

Tig stainless hlau tam sim no kuj ua tau. Txawm li cas los xij, muaj ntau yam teeb meem. Parameters xws li tensile zog thiab hardness yuav luag tib yam rau stainless hlau thiab carbon hlau. Txawm li cas los xij, muaj qhov sib txawv loj hauv microstructure ntawm cov khoom, thiab yog li qee qhov teeb meem tshwm sim.

Piv txwv li, yog siv txoj kev txiav stainless hlau, ces nws yuav ua ntej yuav elastically deformed, tom qab uas nws tuaj yeem ua tau yooj yim, thiab tom qab ntawd pib hardening theem. Nyob rau theem notxiav hlau tsuas yog ua haujlwm yog tias siv zog ntau dua. Qhov sib txawv nyob rau hauv qhov tseeb hais tias high-alloy steel, zoo li stainless hlau, undergoes tag nrho cov theem no ntau noticeably tshaj li qub hlau. Muaj ob peb yam teeb meem loj uas sawv tawm nrog txoj kev ua no.

Qhov teeb meem thawj zaug yog kev ua haujlwm hnyav. Qhov teeb meem thib ob yog qhov yuav tsum tau tshem tawm cov chips. Qhov teeb meem thib peb yog qhov hnav ntawm cov cuab yeej ua haujlwm. Muaj lwm qhov teeb meem uas sawv tawm heev rau cov qib kub-resistant ntawm stainless alloys. Qhov teeb meem yog qhov siab viscosity coefficient. Vim li no, cov chips tsis crumble, tab sis tas li twist mus rau hauv ib tug ntev kauv.

Ciav cuab yeej

Vim qhov tseeb tias cov hlau muaj peev xwm ua rau nws tus kheej muaj zog, nws yog qhov tsim nyog los tsim tshwj xeeb ntawm cov npoo rau cov cuab yeej txiav. Tsis tas li ntawd, nws yog ib qho tsim nyog yuav tau siv cov alloys tshwj xeeb rau kev tsim cov cuab yeej tshwj xeeb. Hnub no muaj ob yam cuab yeej tshwj xeeb.

thawj hom yog kev txiav txuas uas muaj cov tshuaj tso rau txheej. Hom thib ob muaj txheej txheej ntawm lub cev tso rau ntawm qhov txiav ntawm cov cuab yeej txiav hlau.

Pom zoo:

Kev ntsuas kev nqis peev zoo ntawm kev lag luam: cov ntsiab lus yooj yim, txoj hauv kev, cov hauv paus ntsiab lus, txoj hauv kev txhim kho

Kev nqis peev tsim khoom yog lub hauv paus ntawm txhua lub lag luam. Kev nqis peev loj loj yuav tso cai rau kev tsim lossis hloov kho cov khoom siv thiab cov txheej txheem uas twb muaj lawm, hloov lub cev lossis kev coj ncaj ncees los ntawm cov cuab yeej cuab tam, nce ntim ntawm cov dej num, mastering cov khoom tshiab, nthuav kev muag khoom, thiab lwm yam

Dab tsi yog qhov zoo ntawm kev nrhiav neeg sab hauv? Cov txheej txheem xaiv, cov txheej txheem thiab cov lus pom zoo rau kev tswj cov neeg ua haujlwm

Kev nrhiav neeg sab hauv yog dab tsi? Dab tsi yog qhov txiaj ntsig tseem ceeb ntawm kev nrhiav neeg ua haujlwm sab hauv, lawv yog dab tsi thiab dab tsi yog cov cuab yeej xaiv sab hauv suav nrog - koj tuaj yeem paub los ntawm kev nyeem cov ntawv no

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

Yuav ua li cas los ua tus neeg muag khoom zoo dua: lub ntsiab lus ntawm lub tswv yim, kev piav qhia txoj haujlwm, cov xwm txheej thiab cov phiaj xwm, txoj hauv kev, kev cob qhia, zais cia, kev txhawb siab thiab cov lus qhia kws tshaj lij

Nyob tsis ntev los no, qhov chaw muag khoom tau tshwm sim. Txawm tias tom qab ntau tshaj li kaum xyoo, txoj haujlwm no ua rau ntau cov lus nug. Cov neeg thov uas tau txais txoj haujlwm no tsis tas yuav nkag siab meej txog lub luag haujlwm uas lawv yuav tsum tau ua thiab qhov txiaj ntsig ntawm kev tswj hwm xav tau

Vuam hauv qhov chaw tiv thaiv roj: ua haujlwm thev naus laus zis, txheej txheem piav qhia, cov txheej txheem ua tiav, cov khoom tsim nyog thiab cov cuab yeej, cov lus qhia ua haujlwm ib ntus thiab cov lus qhia kws tshaj lij

Vuam thev naus laus zis yog siv hauv ntau ceg ntawm tib neeg kev ua haujlwm. Versatility tau ua vuam nyob rau hauv ib puag ncig tiv thaiv roj ib qho tseem ceeb ntawm kev tsim khoom. Qhov ntau yam no ua rau nws yooj yim los txuas cov hlau nrog lub thickness ntawm 1 hli mus rau ob peb centimeters nyob rau hauv txhua txoj hauj lwm nyob rau hauv qhov chaw. Vuam nyob rau hauv ib puag ncig tiv thaiv yog maj mam hloov cov tsoos electrode vuam