2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Ntshiab hlau yog tus yam ntxwv los ntawm cov npe txwv ntawm cov khoom thiab raws li lub hauv paus hlau tsis txaus siab. Tab sis cov alloys raws li nws muaj peev xwm loj heev, koj tsuas yog yuav tsum tau txiav txim siab cov tshuaj muaj pes tsawg leeg thiab ua qhov kev kho cua sov zoo.

feem ntau cov qauv steels

Txhua cov hlau-raws li cov hlau muaj rau ferrous metallurgy thiab muaj ntau yam kev faib tawm. Nws yog tsim los ntawm ntau yam tsis muaj: los ntawm cov tshuaj muaj pes tsawg leeg, lub hom phiaj, cov ntsiab lus ntawm cov khoom tsis zoo, lub zog thiab kev cuam tshuam lub zog, hloov tau thiab ntau lwm yam. Kev tsim qauv - tau dhau los ua kev siv ntau tshaj plaws. Ib txhia ntawm lawv muaj universal zog thiab interchangeability.

Structural steel 20 belongs rau cov chav kawm carbon nruab nrab, muaj cov qauv ferrite-pearlite. Cov hlau yog cov khoom zoo, uas yog, nws muaj qhov txo qis ntawm cov ntsiab lus tsis zoo: sulfur thiab phosphorus. Tsis muaj kev txwv ntawm weldability. Kev pom zoo ua ke ntawm lub zog thiab plasticity ua rau nws tsuas yog ib qho khoom siv thoob ntiaj teb rau kev tsim cov yeeb nkab dov, cov khoom raug rau cov thermomechanical thiab thermochemical tom ntej.kev ua haujlwm (cementing, galvanizing thiab chrome plating).

G20 pom nws siv

Steel 20, cov khoom uas tuaj yeem sib txawv ntawm ntau yam nrog kev pab ntawm cov tshuaj-thermal, thermomechanical ua, feem ntau yog xav tau hauv cov yeeb nkab ntau lawm hauv kev tsim cov khoom nrog ib qho tawv tawv thiab qhov chaw mos. Cov no tuaj yeem yog shafts, sprockets, gears, bolts, crane hooks, fittings, stamping sheets (corrugated board), ceev thiab bolts rau tsis tseem ceeb fastening. Cov kav dej uas tsim los ntawm qib steel no yog siv los hloov cov pa roj carbon monoxide, chav dej, cov kua dej tsis zoo uas tau muab los ntawm lub siab. Cov no yog cov kav dej ntawm superheaters, cov kav dej, qhov kub siab boilers thiab cov khoom sau.

Hloov tus qauv los ntawm kev kho mob thermochemical

Tib hom tuaj yeem hloov nws cov yam ntxwv los ntawm kev kho cua sov. Hlau qib 20 muaj cov yam ntxwv zoo yas, yog li cov khoom siv los ntawm nws tau txais los ntawm ntau txoj hauv kev: casting, txias lossis kub dov lossis kos duab. Tom qab tau txais cov khoom los ntawm kev casting, chemical-thermal kho tuaj yeem siv rau lawv. Lub hom phiaj ntawm cov txheej txheem no yog kom tau txais cov txheej txheem hnav-tiv taus uas tsis ua rau corrosion thiab qhov chaw mos muag.

Rau qhov no, qhov ua tiav tau muab tso rau hauv qhov chaw tsim nyog (kab nrog cov khoom siv roj carbon qhuav, muab tso rau hauv cov pa roj lossis kua nruab nrab), tom qab ntawd nws tau khaws cia los ntawm ob peb teev mus rau 1.5 hnub ntawm qhov kub thiab txias.. Neeg kho tshuabKev ua haujlwm ntawm qhov chaw los ntawm lub sijhawm no yuav tsum ua kom tiav, txij li tom qab kev ua cov thermochemical cov khoom yuav twb muaj cov qauv kawg. Lub caij saturates lub sab sauv txheej ntawm cov khoom (los ntawm 0.3 mus rau 3.0 hli), yog li txhim kho nws cov qauv thiab cov khoom.

Nyob ntawm cov khoom siv, kev kho mob hu ua: cyanidation (zinc txheej), carburizing (carbon), chromium plating (chromium). Cov pa roj carbon muab lub zog, zinc - corrosion kuj, chromium, ntxiv rau tag nrho cov saum toj no, ua rau daim iav saum npoo.

Hloov cov qauv los ntawm machining

Tsis zoo li cov txheej txheem ua ntej dhau los, uas tsuas yog ua kom tawv tawv txheej sab saud ntawm cov hlau thiab yooj yim rau sab hauv, thermomechanical ua yog ib txoj hauv kev shaping. Hlau 20 tuaj yeem deformed ob qho tib si kub thiab txias. Txhua hom muaj nws qhov zoo thiab qhov tsis zoo. Tab sis lawv tau siv raws li cov khoom xav tau tshaj plaws.

Kub txoj kev yog siv rau cov khoom uas muaj phab ntsa thickness ntau tshaj 5 hli. Txij li thaum cov hlau yog rhuab, nplai thiab decarburized microlayer yog tsim, nws tsis pom zoo kom siv hom dov rau nyias-walled qhov chaw. Txawm li cas los xij, nws muaj ib qho txiaj ntsig zoo tshaj qhov txias txias.

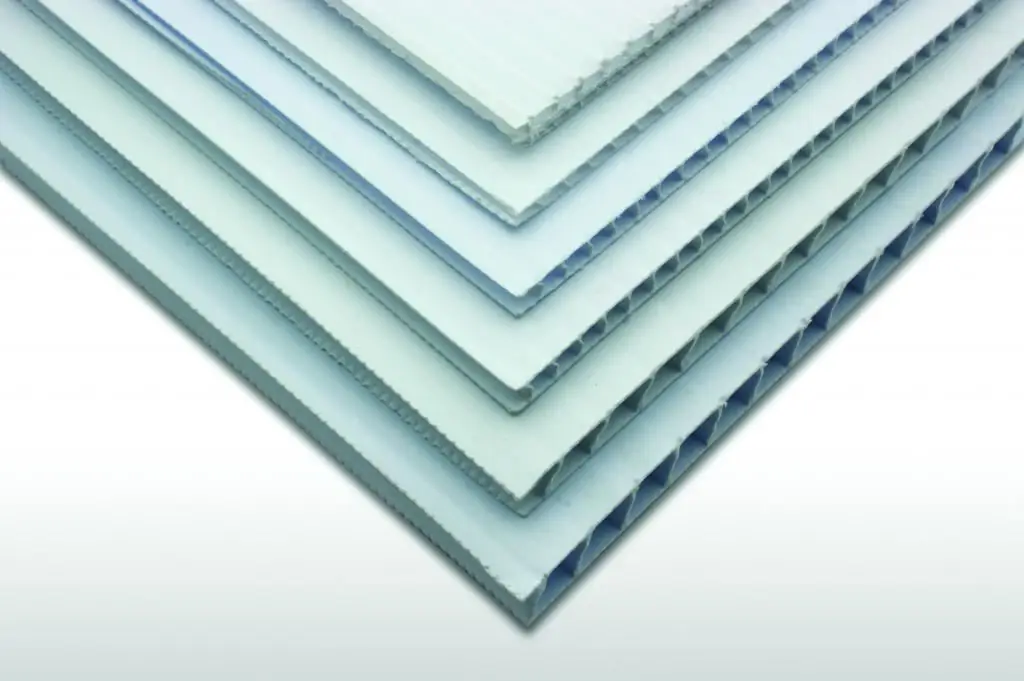

Cold forming yog siv rau qhov chaw uas tsawg dua 5 hli tuab. Tsuas yog "mos" hom hlau yog tsim rau kev kos duab txias. Thaum dov, cov kev paub ntawm cov hlautseem ceeb deformation, los yog hardening. Qhov no ua rau muaj kev nce hauv nws lub zog thiab muaj kev ntxhov siab ntau hauv cov qauv. Vim nws cov phab ntsa nyias, xws li cov hlau tsis tuaj yeem ua kom sov (kom siv sijhawm so, piv txwv li, kho cov qauv qub). Nws yooj yim dua rau kev puas tsuaj nyob rau hauv kev cuam tshuam thiab lwm yam dynamic loads. Cov yeeb nkab steel hlau (steel 20) sib txawv hauv kev tsim khoom thiab tau txais cov yam ntxwv ntawm kev ua haujlwm uas cuam tshuam rau daim ntawv thov. Rau kev tsim khoom ntawm txhua hom yeeb nkab, muaj cov qauv hauv xeev, qauv, khoom siv.

Cov kav dej txias txias nrog cov seam ncaj

Cov txheej txheem tsim khoom pib nrog kev npaj ntawm cov hlau nplaum. Ua li no, cov nplooj ntawv steel raug txiav rau hauv ib daim hlab thiab welded rau hauv ib lub strip ntev. Daim kab xev yog pub rau cov bending rolls, qhov twg nws yuav siv sij hawm daim ntawv ntawm ib tug yeeb nkab. Cov kauj ruam tom ntej yog vuam. Rau txhua qhov tsim, qhov no yog qhov tsis muaj zog tshaj plaws. Nws yog tsis yooj yim sua kom tshem tawm cov shortcomings uas tshwm sim thaum lub sij hawm welding (qhov tsos ntawm oxides thiab carbon burnout), tab sis siv ib co tswv yim, lawv yuav txo tau. Txhawm rau koom nrog steel 20, hluav taws xob arc vuam nyob rau hauv qhov chaw tiv thaiv ntawm cov roj inert (argon) lossis induction vuam (siab zaus tam sim no) yog siv. Cov yeeb nkab tau dhau los ua qhov yuav tsum tau soj ntsuam vuam seam, tom qab ntawd nws raug txiav mus rau hauv qhov ntev ntawm qhov xav tau thiab khaws cia.

Cold Drawn Kauv Seam Pipe

Kev npaj cov hlau rau kev tsim cov yeeb nkab hom no ua raws li cov txheej txheem tib yam li cov kav dej uas muaj cov seam ncaj nraim. Kuj zoo ib yam: vuam, tswj thiab txiav. Qhov txawv xwblub kaum sab xis ntawm daim kab xev folding uas cov seam tom ntej mus ncig ntawm cov yeeb nkab nyob rau hauv ib qho helical nkhaus. Vim nws cov qauv tsim, txoj kev no yog qhov ruaj khov tshaj plaws. Thiab tiv taus cov kua muag ntau dua li cov khoom ncaj nraim.

seamless kav

Cov kav dej tsis sib haum tshwj xeeb muaj zog, lawv muaj ntau qhov zoo: lawv tsis muaj welded (cov ntsiab lus tsis muaj zog), tsis muaj kev ntxhov siab hauv cov qauv hlau, lub thickness ntawm cov kav dej yog tsawg kawg yog 5 hli. Lawv ntau lawm yog ib tug complex txheej txheem, thiab yog li ntawd kim. Hlau 20 yog qhov tshwj xeeb hauv cov kav dej tuaj yeem tsim tau ob txoj hauv kev - txias thiab kub kos duab.

Kub dov seamless

Tom qab cua sov siab tshaj 1100ºС, lub workpiece raug tho nrog lub tes tsho thiab tsim ib txoj kab uas hla. Nrog rau kev kos duab ntxiv, cov yeeb nkab yuav siv sij hawm qhov ntev ntawm lub puab, sab nraud thiab phab ntsa thickness. Thaum lub sij hawm tag nrho cov txheej txheem thev naus laus zis, qhov kub ntawm cov dov billet tseem siab. Thiab tsuas yog tom qab cov duab kawg raug coj mus, lub raj yog txias. Thaum lub sij hawm ntev txias, tempering yuav siv qhov chaw, tag nrho cov kev tsis zoo ntawm dov, nce lub zog thiab brittleness raug tshem tawm. Thaum tag nrho txias, steel 20 tau txais cov yam ntxwv uas nws pib muaj. Cov txheej txheem thev naus laus zis no suav nrog kev tsim cov kav dej nkaus xwb nrog cov phab ntsa ntawm yam tsawg 5 hli, thiab qhov siab tshaj plaws thickness tuaj yeem ncav cuag 75 hli.

Coj kos seamless

Tsis zoo li txoj kev dhau los, qhov no muaj qhov ntsuas kub me ntsis. Lub workpiece heats li, tab sis tom qabQhov kub ntawm lub hauv paus firmware yog tsis tswj los ntawm lub tes tsho, thiab lub workpiece yog kos tawm nyob rau hauv ib tug txias lub xeev. Txoj kev no txawv ntawm qhov kub-kuav los tiag uas nws muaj peev xwm tsim cov kav dej muaj zog nrog cov phab ntsa nyias, thaum txoj kev kub-dov tsuas yog muab rau cov phab ntsa tuab. Rau cov qauv kawg, ob txoj hauv kev no zoo ib yam, txij li tom qab txias dov cov kav dej tau ua haujlwm zoo, uas cov qauv tau rov ua dua ib nrab thiab cov kev ntxhov siab ploj mus.

Qhov no tsis yog tag nrho cov npe ntawm cov khoom raws li cov hlau 20 GOST 1050-74. Cov kev xav tau ntawm cov pej xeem tau nce zuj zus, cov tswv yim tshiab thiab kev tsim tawm tau tshwm sim. Tab sis hom no tsuas yog hloov nws daim ntawv thiab lub hom phiaj, tseg txoj cai kom muaj nyob.

Pom zoo:

Kev siv zog ntawm kev ua haujlwm yog ib pawg kev lag luam kev lag luam uas ua rau muaj kev ntxhov siab ntawm kev ua haujlwm hauv kev ua haujlwm. Cov yam ntxwv, suav

Kev siv zog ntawm kev ua haujlwm yog ib pawg uas ib txhij hais txog kev lag luam kev lag luam, lub cev nqaij daim tawv, thiab lwm yam. Lub tswv yim no ntsuas tau. Nws yuav tsum tsis txhob totaub nrog kev ua haujlwm ntawm kev ua haujlwm - theej, cov no yog cov nqi rov qab

Hluav taws xob locomotive 2ES6: keeb kwm ntawm kev tsim, kev piav qhia nrog cov duab, cov yam ntxwv tseem ceeb, lub hauv paus ntsiab lus ntawm kev ua haujlwm, cov yam ntxwv ntawm kev ua haujlwm thiab kho

Hnub no, kev sib txuas lus ntawm cov nroog sib txawv, kev thauj neeg caij tsheb, kev xa khoom yog nqa tawm ntau txoj hauv kev. Ib txoj hauv kev no yog txoj kev tsheb ciav hlau. Hluav taws xob locomotive 2ES6 yog ib yam ntawm cov kev thauj mus los uas tam sim no nquag siv

Kev tsim cov khoom siv roj: cov txheej txheem thev naus laus zis, khoom siv thiab khoom siv

Hnub no, muaj ntau yam khoom siv hauv tsev uas nrov. Ib qho kev tsim kho tshiab yog kev tsim cov khoom siv roj av, uas yog cov pob zeb ntawm tes. Ntawm cov no, nws muaj txiaj ntsig tsis yog los tsim ib lub tsev ntiag tug xwb, tab sis kuj tsim khoom muag

Cov ntsiab lus pabcuam rau cov neeg siv khoom. Kev Pabcuam Cov Neeg Siv Khoom. Kev pabcuam neeg siv khoom yog

Cov txheej txheem tsis sib haum xeeb uas qee zaum tshwm sim ntawm cov neeg siv khoom thiab cov tuam txhab tsim kho tuaj yeem ua rau lub neej ntawm ob tog mus ntev. Qhov ntawd yog qhov kev pabcuam rau cov neeg siv khoom. Nws yog nws lub luag haujlwm ncaj qha los xyuas kom muaj kev sib raug zoo thiab muaj peev xwm koom tes

Polypropylene - yog dab tsi? Txhais, cov yam ntxwv ntawm cov khoom siv, kev siv hauv kev lag luam thiab lub neej txhua hnub

Koj tuaj yeem tsim lub tshuab cua sov nrog koj tus kheej tes los ntawm polypropylene. Cov khoom yog pheej yig thiab lub teeb yuag. Ua ntej pib ua haujlwm, nws yog ib qho tsim nyog los xaiv cov ntsiab lus txuas thiab nkag siab txog txoj kev teeb tsa. Rau cov kav dej soldering, cov khoom yuav tsum raug txiav kom loj. Cov pob qij txha yuav tsum sib npaug thiab muaj lub kaum sab xis. Cov seem yog degreased, chips raug tshem tawm ntawm qhov chaw tom qab txiav