2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Lub ntxaiv ntawm cov cuab yeej siv tshuab feem ntau yog nthuav tawm raws li ib qho ntawm cov ntsiab lus ntawm lub tshuab tsav lub luag haujlwm rau kev kho thiab kho cov khoom ua haujlwm. Nyob rau tib lub sijhawm, nws qhov kev sib txuas nrog lub tshuab fais fab, cov kabmob thiab cov cuab yeej ua haujlwm ntawm lub tsev yog nruj heev uas peb tuaj yeem tham txog tag nrho cov txheej txheem ntawm qhov no. Ib txoj hauv kev los yog lwm qhov, lub spindle sib dhos (SHU) yuav tsum raug suav hais tias yog lub luag haujlwm tseem ceeb ntawm lub tshuab, muab kev ua haujlwm ntawm kev xa tawm torque thiab coj cov kev ua haujlwm quab yuam.

Cov khoom lag luam nthuav dav

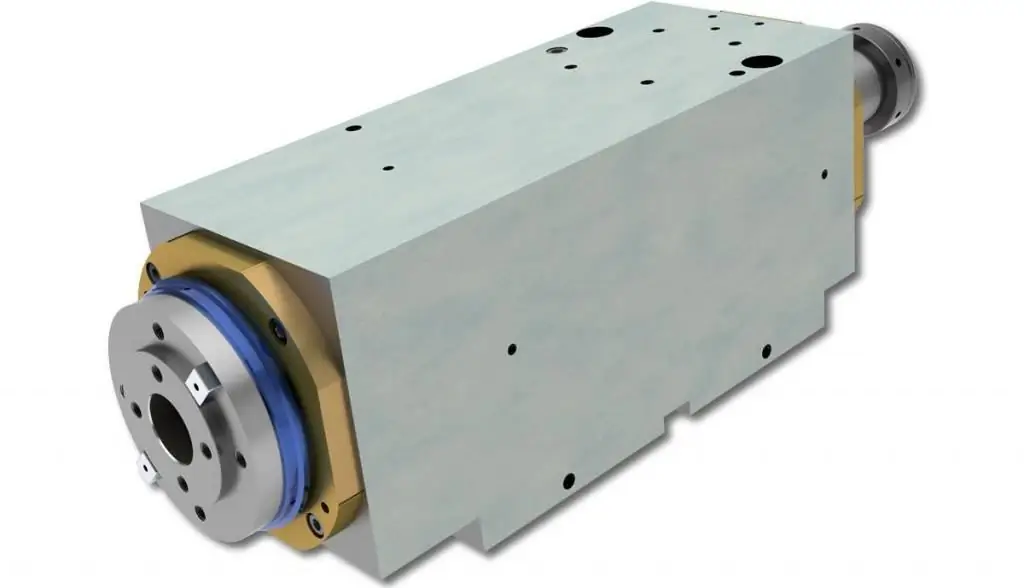

Lub tshuab no tseem hu ua lub cev muaj zog spindle thiab tsim ib qho ntawm cov khoom sib dhos tseem ceeb ntawm cov ntoo niaj hnub thiab cov tshuab ua hlau. Kev ua tau zoo thiab, rau qhov ntau dua, qhov tseeb ntawm qhov cuam tshuam ntawm cov khoom siv ua haujlwm nyob ntawm nws cov yam ntxwv. Raws li twb tau hais lawm, peb tab tom tham txog tag nrho cov ntsiab lus,tsim lub hauv paus ntawm spindle units. Txhawb nqa, lubrication system, ntsaws ruaj ruaj, torque kis tau tus mob thiab bearing qhov chaw tsim lub hauv paus ntawm no mechanism. Feem ntau cov no yog cov khoom uas ua haujlwm txhawb nqa thiab pab txhawb kev ua haujlwm ntawm lub nozzle hauv daim ntawv ntawm cov cuab yeej txiav.

Nws feem ntau lees txais tias lub zog muaj peev xwm ntawm cov cuab yeej siv tshuab feem ntau nyob ntawm lub cav. Qhov no muaj tseeb, tab sis tsuas yog ib feem. Piv txwv li, cov spindle units ntawm hlau-txiav tshuab muaj lawv tus kheej zaus ntawm kev sib hloov, ua rau muaj kev txwv rau kev txiav ceev. Tab sis nws yog ib qho tseem ceeb kom nkag siab tias qhov ntau yam no yog ntau dua ntawm kev ua haujlwm ntawm kev kho qhov kev ua haujlwm zoo tshaj plaws nrog kev txhawb nqa ntawm qhov tseeb txaus txaus.

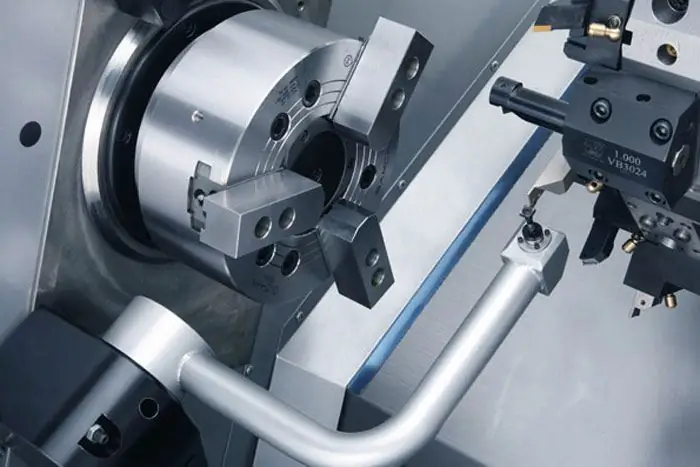

Lwm yam ntawm cov haujlwm tseem ceeb ntawm cov ntxaiv yog kev tuav ncaj qha ntawm cov cuab yeej machining, thiab qee zaum lub workpiece nws tus kheej. Rau hom fastening no, tshwj xeeb clamps thiab clamps yog siv, zoo li lub cuab yeej tuav thiab cartridges. Yog li ntawd, nws yog ib qho tseem ceeb uas yuav tsum tau coj mus rau hauv tus account tus yam ntxwv ntawm lub spindle thaum xaiv ib tug tooling raws li qhov ntev ntawm lub shank thiab txiav txim siab tsis pub dhau lub machining txheej txheem.

ShU design

Thaum lub sijhawm txhim kho ntawm kev tsim cov kev daws teeb meem rau lub cev muaj zog spindle, cov neeg ua haujlwm ua haujlwm yuav tsum tsom mus rau qhov siab tshaj plaws ntawm kev txo qis ntawm cov khoom siv hluav taws xob thiab kev co ntawm lub tshuab. Kev ua tiav qhov zoo ntawm pawg neeg ua haujlwm ncaj qha cuam tshuam rau lub zog ntawm lub tshuab thiab kev ua haujlwm zoo. Vim li no, lub spindle sib dhos yog ncetsim los ua ib qho khoom siv ywj pheej nyob rau hauv ib lub tsev nyob sib cais, uas yog hu ua headstock.

Cov hauv qab no raug coj los ua cov ntaub ntawv thawj zaug rau kev tsim qauv:

- Power.

- Kev sib hloov raug.

- Speediness.

- cua sov siab tshaj plaws rau kev txhawb nqa.

- Vibration resistance.

- Rigidity.

Raws li thawj qhov tsis sib xws, cov qauv txheej txheem, cov ntsiab lus layout thiab cov khoom tsim tau raug xaiv. Hom ntawm lub tshuab yav tom ntej kuj muaj kev cuam tshuam rau kev xaiv ntawm qee qhov kev tsim qauv daws teeb meem. Piv txwv li, kev tsim cov spindle sib dhos rau cov cuab yeej siv high-precision machining yog ua raws li cov txheej txheem ntawm hydrodynamic bearings uas tuaj yeem ua kom ntseeg tau qhov tseeb ntawm cov khoom siv hluav taws xob hauv thaj tsam ntawm 0.5 txog 2 microns. Rau tshwj xeeb tshaj yog high-ceev units nrog kev sib tsoo taub hau, tshwj xeeb zawv zawg bearings yog siv, uas yuav tsum tau cua lubrication. Feem ntau, cov hauv paus ntsiab lus ntawm kev tsim lub hauv paus spindle nrog rau kev txhawb nqa kev ua haujlwm siab ntawm 600 rpm yog siv rau pob zeb diamond tho txawv thiab universal hlau-txiav tshuab. Cov yam ntxwv ntawm cov khoom siv los txhawb kev ceev qis yog ib txwm suav rau milling, turret thiab drilling tshuab. Ntawm no txoj cai siv, qhov ntau ilv qhov tseeb ntawm cov neeg kho tshuab kev txiav txim, siab dua lub torque yuav tsum nyob rau ntawm spindle. Rau qhov nyuaj roughing thiab txiav, qis RPM configurations yog siv.

Xaiv ntawm qhov sib dhos spindle

Bstiffness yog xam raws li lub ntsiab tsim yam ntxwv. Nws yog qhia raws li ib qho kev qhia ntawm elastic displacements nyob rau hauv qhov chaw ua hauj lwm nyob rau hauv tag nrho cov acting quab yuam los ntawm tus kheej elastic deformation ntawm spindle nrog nws cov ntsiab lus txhawb. Lub zog kuj tseem siv los ua tus yam ntxwv ntawm cov khoom sib dhos hnyav, thiab rau siab RPM headstocks, qhov tsawg kawg nkaus tus nqi resonance, piv txwv li kev vibration siab, yuav yog qhov tseem ceeb hauv kev ua tiav.

Xyaum txhua qhov sib dhos spindle rau cov tshuab txiav hlau yog cais los ntawm kev txiav qhov tseeb. Qhov kev suav no yog ua rau cov kabmob raws li radial run-out coefficient ntawm spindle kawg. Tus nqi tso cai khiav tawm yog nyob ntawm cov chav kawm raug tsim, hauv cov ntsiab lus uas cov neeg tsim khoom tau ua los ntawm cov kev xav tau rau cov txheej txheem machining.

Qhov Performance index ntawm radial runout nyob rau sab hauv ntawm lub nplhaib bearing nyob ntawm nws eccentricity thiab qhov tsis raug ntawm cov lem nrog dov ntsiab. Qhov no qhov tseeb parameter yog qhia los ntawm cov nyhuv ntawm lub thiaj li hu ua wandering yeej. Nyob rau hauv tus txheej txheem ntawm kev tswj cov kabmob, lawv ua raws li cov qauv tsim tau txiav txim siab, tom qab ntawd, yog tias muaj kev sib txawv, cov khoom tuaj yeem raug xa mus rau kev kho dua tshiab. Ntawm cov kev ntsuas txhawm rau txhim kho qhov tseeb ntawm cov bearings rau kev sib dhos spindle thaum sib dhos, cov hauv qab no tuaj yeem paub qhov txawv:

- Cov eccentricities ntawm lub nplhaib puab thiab cov kabmob cov ntaub ntawv nyob rau hauv opposite lus qhia.

- Eccentricities ntawm cov kabmob sab nraud thiabLub cev qhov tseem raug muab tso rau ntawm qhov sib txawv.

- Thaum txhim kho qhov eccentricities ntawm lub nplhaib puab ntawm cov kabmob ntawm lub nraub qaum thiab pem hauv ntej, lawv yuav tsum tau khaws cia rau tib lub dav hlau.

ShU Performance

Rigidity thiab raug teeb tsa ntawm cov cim tseem ceeb thiab lub cev ntawm lub spindle tsis txwv. Ntawm lwm cov khoom tseem ceeb ntawm cov txheej txheem no, nws tsim nyog hais txog:

- Vibration kuj. Lub peev xwm ntawm SHU muab kev sib hloov ruaj khov yam tsis muaj oscillation. Nws yog tsis yooj yim sua kom tshem tawm tag nrho cov vibration nyhuv, txawm li cas los xij, ua tsaug rau kev ua tib zoo tsim kev suav, nws tuaj yeem txo qis los ntawm kev txo cov txiaj ntsig ntawm kev sib hloov thiab torsional vibrations, xws li pulsating rog hauv cheeb tsam ua haujlwm thiab lub zog ntawm lub tshuab tsav.

- Speediness. Cov yam ntxwv ntawm qhov ceev ntawm spindle sib dhos, xav txog tus naj npawb ntawm revolutions ib feeb tso cai rau kev pom kev ua haujlwm zoo. Hauv lwm lo lus, qhov siab tshaj plaws tso cai hloov pauv ceev, uas yog txiav txim siab los ntawm cov txheej txheem thiab thev naus laus zis zoo ntawm cov khoom.

- cua sov bearings. Intensive tshav kub tiam yog ib tug natural derivative yam thaum lub sij hawm machining ntawm high speeds. Txij li thaum cua sov tuaj yeem ua rau deformation ntawm lub hauv paus, qhov ntsuas no yuav tsum raug xam thaum lub sijhawm tsim. Qhov tseem ceeb tshaj plaws ntawm lub rooj sib txoos yog cov kabmob, uas nws qhov kev hloov pauv tuaj yeem cuam tshuam qhov kev ua haujlwm ntawm spindle. Yuav kom txo tau cov txheej txheem thermal deforming, manufacturers yuav tsumUa raws li cov cai ntawm kev tso cai cua sov ntawm cov kabmob sab nraud.

- Bearing peev. Txiav txim siab los ntawm qhov ua tau zoo ntawm spindle bearings nyob rau hauv tej yam kev mob ntawm qhov siab tshaj plaws permissible static loads.

- Durability. Lub sij hawm taw qhia qhia tus naj npawb ntawm cov sij hawm ua haujlwm ntawm cov khoom ua ntej overhaul. Muab hais tias axial thiab radial rigidity ntawm spindle sib dhos yog sib npaug, lub durability tuaj yeem ncav cuag 20 txhiab teev. Lub sij hawm tsawg kawg nkaus rau kev ua tsis tiav yog ob thiab tsib txhiab teev, uas yog qhov zoo rau kev sib tsoo thiab cov tshuab sib tsoo sab hauv, feem.

Khoom siv ua SHU

Kev xaiv cov khoom siv rau lub hauv paus ntawm lub ntxaiv kuj yog qhov tseem ceeb hauv kev ua kom ntseeg tau qee yam kev ua haujlwm thiab kev ua haujlwm ntawm cov khoom siv. Nyob rau hauv lapping, threading thiab drilling units, qhov tseem ceeb yog muab tso rau kev tiv thaiv los ntawm torque, thiab spindle sib dhos ntawm lub tshuab milling, piv txwv li, yog sib sau ua ke raws li cov teebmeem ntawm dabtsi yog khoov lub sijhawm. Nyob rau hauv txhua rooj plaub, cov khoom yuav tsum muaj txaus hnav tsis kam ntawm lub actuating nto raws li zoo raws li nyob rau hauv lub bearing phau ntawv journal. Kev ruaj ntseg ntawm cov duab thiab qhov ntev yog qhov tseem ceeb rau kev ua haujlwm zoo ntawm cov khoom, feem ntau nyob ntawm tus yam ntxwv ntawm qib ntawm cov khoom siv.

Hauv cov tshuab nrog cov chav kawm raug H thiab P, cov spindles ua los ntawm cov hlau alloys ntawm qib 40X, 45, 50 yog siv. Qee zaum, kev txiav txim siab tsim yuavyuav tsum tau thiab tshwj xeeb refinement ntawm cov hlau los ntawm hardening nrog induction thermal ua. Feem ntau hardening ntawm cov khoom los ntawm hardening yog siv rau qhov kev kawm nto thiab bearing cov ntaub ntawv raws li qhov tseem ceeb tshaj plaws qhov chaw ntawm ib feem.

Rau cov ntsiab lus ntawm cov duab nyuaj nrog lub conical qhov, grooves, flanges thiab stepped hloov, ntim-hardened steel yog siv. Qhov kev siv tshuab no tsuas yog tso cai rau cov khoom ua haujlwm los ntawm qhov nws tau npaj los tsim cov khoom hauv ntej ntawm lub tshuab spindle sib dhos nrog cov carburizing tom ntej. Hauv qhov no, steels 40XGR thiab 50X tau siv.

Khoom siv nrog cov chav kawm raug raug A thiab B yog muab nrog cov spindles ua los ntawm cov qib steel 18KhGT thiab 40KhFA, nitrided. Cov txheej txheem kev kho nitrogen yog yuav tsum tau ua kom lub hardness ntawm ib feem, nrog rau kev tswj qhov qub duab thiab qhov ntev. Kev ua kom muaj zog thiab kev ruaj ntseg yog qhov yuav tsum tau ua ua ntej rau cov spindles siv hauv cov tshuab nrog cov dej sib txhuam.

Nyob rau hauv qhov yooj yim layout ntawm chav tswj, cov kev xav tau ntawm cov ntaub ntawv tsis yog siab heev. Cov ntsiab lus nrog cov duab yooj yim tuaj yeem ua los ntawm cov qib steel 20Kh, 12KhNZA thiab 18KhGT, tab sis txawm nyob rau hauv cov ntaub ntawv no, cov blanks ua ntej yuav quenching, carburizing thiab tempering.

ShU qauv qauv

Qhov tseem ceeb ntawm spindle mechanisms siv nyob rau hauv cov cuab yeej siv tshuab niaj hnub muaj ob-cov kabmob. Qhov kev teeb tsa no yog qhov zoo tshaj plaws nyob rau hauv cov nqe lus ntawm cov cuab yeej optimization thiab yooj yim ntawm lub koom haum technical.txheej txheem ntau lawm. Txawm li cas los xij, cov tuam txhab loj kuj siv cov qauv nrog kev txhawb nqa ntxiv los ntawm tus ncej thib peb.

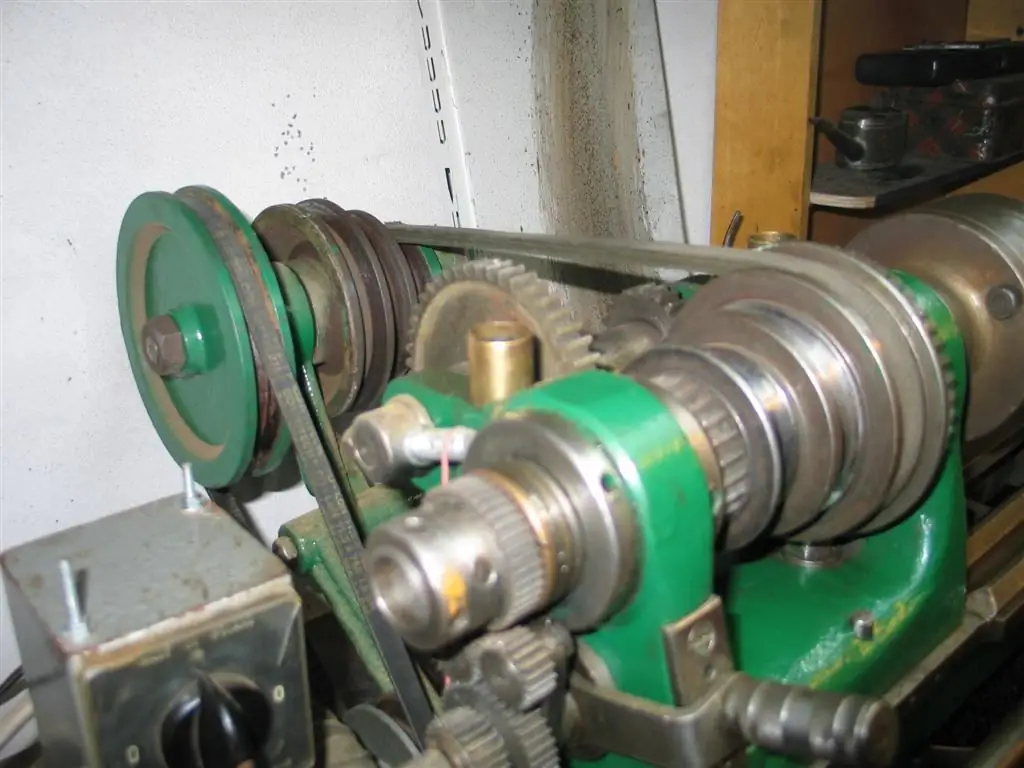

Cov kev tso kawm ntawm cov kabmob kuj tseem tsis meej meej ntawm cov txheej txheem siv. Niaj hnub no, muaj kev hloov pauv ntawm kev tswj hwm kev tswj hwm tseem ceeb rau thaj chaw headstock, uas txo cov kev cuam tshuam ntawm thermal los. Hauv cov qauv yooj yim ntawm kev sib dhos spindle, cov menyuam bearings yog siv, uas kuj txo qhov kev pheej hmoo ntawm deformation los ntawm kev tsim hluav taws xob thiab ua kom cov kev hloov kho kom zoo. Nyob rau tib lub sijhawm, nrog rau kev nce hauv rigidity thiab nce qhov tseeb ntawm kev sib hloov, cov txheej txheem no muaj qhov tsis zoo nyob rau hauv daim ntawv ntawm kev txo qis. Yog li ntawd, qhov kev teeb tsa no yog qhov zoo tshaj plaws rau cov tshuab dhos nrog qis ceev.

Slow-speed sib tsoo units kuj tau nruab nrog cov menyuam bearings nyob rau hauv pem hauv ntej kev them nyiaj yug, thiab sab nraub qaum yog muab nrog ib tug duplex ntawm angular contact ntsiab. Tshwj xeeb, qhov no yog li cas spindle units tau siv nyob rau hauv kev tsim ntawm lub voj voog thiab sab hauv kev sib tsoo tshuab. Txhawm rau kom yooj yim rau kev ua haujlwm ntawm chav tsev, tapered roller bearings kuj tso cai. Xws li kev daws teeb meem hauv kev sib raug zoo rau milling units tshem tawm qhov xav tau los suav nrog pawg axial bearing. Raws li qhov tshwm sim, qhov kev pom zoo ntawm qhov rigidity tau khaws cia, tab sis nrog nws cov teeb meem ntawm kev tsim hluav taws xob nrog lub zog tsawg tsis mus qhov twg.

Cov khoom lag luam zoo

Tom qab sib dhos lub taub hau, qhov kev tshem tawm-preload ntawm pawg kabmob raug kuaj xyuas. Qhov kev ua haujlwm notsim nyog los ntsuam xyuas qhov kev npaj ntawm lub mechanism rau tag nrho-fledged workloads. Kev kuaj xyuas yog nqa tawm los ntawm kev thauj khoom nrog lub jack thiab lub dynamometer. Kev ntsuas yog coj ncaj qha nrog cov ntsuas ntsuas, suav nrog ntsuas lub taub hau, sensors, microcators, thiab lwm yam. Cov cuab yeej ntsuas tau nruab rau ntawm lub taub hau kom ze li sai tau rau cov kabmob pem hauv ntej. Thaum kho cov kauj ruam hloov pauv, daim duab ntawm kev hloov pauv ntawm qhov kawg spindle yog tsim.

Lub rigidity ntawm tig spindle sib dhos nrog cov khoom txhawb nqa yog tswj los ntawm ob txoj kev ntsuas. Ua ntej, ob lub ntsiab lus tswj tau teem rau ntawm cov kab tawm ntawm qhov nkhaus load. Tsis tas li ntawd, cov ntaub ntawv deformation raug kaw rau txhua kab, tom qab ntawd qhov kev sib piv tau ua tiav. Raws li tus qauv ntsuas, ob qho tib si tsim qhov tseem ceeb thiab cov duab los ntawm cov kev cai dav dav rau lub tshuab tuaj yeem siv. Tsis tas li ntawd, cov ntaub ntawv nyuaj rau kev sib piv, tau txais los ntawm kev sim, yuav tsum tau nthuav tawm nyob rau hauv daim ntawv ntawm tus lej lej txhais tau tias muaj nuj nqis. Nyob rau hauv tib txoj kev, kev ntsuas ntawm axial thiab radial loads yog ua nrog fixation ntawm qhov sib txawv ntawm cov bearings.

Yog tias qhov sib txawv ntawm tus qauv tus nqi raug kuaj pom, qhov kev tshem tawm-preload raug kho. Thaum muab kev pabcuam spindle sib dhos ntawm lub tshuab dhos rau cov haujlwm zoo li no, cov txheej txheem ntawm kev txhawb nqa cua sov yog siv. Nyob rau hauv cov xwm txheej ntawm thermal raug tus pas ntsuas kub thiab cov thermocouples nyob rau hauv ib tug tej yam ntau yam, cov txiv ntseej yog nruj thiab kho.

Seals rau SHU mechanism

Cov ntsiab lus ntawm lub taub hau suav nrog thiabtshwj xeeb cov ntsaws ruaj ruaj uas ua rau kom cov insulating thiab sealing zog ntawm lub mechanism. Nws yog rau dab tsi? Txij li thaum lub tshuab ua haujlwm ntawm lub tshuab dhos yog txuam nrog kev tso tawm ntau ntawm cov khib nyiab zoo nyob rau hauv cov txheej txheem lubricating, clogging ntawm qhov chaw ua haujlwm yog ib txwm muaj. Raws li, thaum sib sau ua ke spindle sib dhos, cov khoom siv yuav tsum tau muab los tiv thaiv cov khoom ua haujlwm los ntawm plua plav, av thiab ya raws. Qhov no yog qhov sealant rau. Raws li txoj cai, qhov no yog ib qho khoom siv nyob rau hauv daim ntawv ntawm lub nplhaib, uas yog mounted rau ntawm spindle siv ib tug centering siv. Thaum lub sijhawm ua haujlwm ntawm lub tshuab, nws yuav tsum tau hloov lub sijhawm lossis hloov ntawm txoj haujlwm. Nyob rau hauv cov xwm txheej ntawm kev sib kis ntau ntxiv, lub nplhaib tiv thaiv tuaj yeem siv ntxiv. Yog tias lub tshuab ua haujlwm ntawm qhov nruab nrab lossis qis qis, ces daim di ncauj yuav tsum tau kho.

SHU Maintenance

Lub luag haujlwm tseem ceeb ntawm cov neeg ua haujlwm thaum lub sijhawm ua haujlwm ntawm lub taub hau yog saib xyuas cov roj ntawm nws cov khoom. Qhov no feem ntau yog ua los ntawm kev txau rau ntawm qhov chaw ntawm lub zog tig, impellers thiab cov khoom siv disk. Qhov zoo tshaj plaws muaj pes tsawg leeg rau hom lubricant no yuav tsum muaj viscosity Performance index ntawm 20 thaum rhuab mus rau 50 ° C. Cov qauv tsim ntawm milling spindle los ua ke muab kev muaj peev xwm ntawm kev coj cov roj mus rau hauv cov kabmob los ntawm tus neeg sau lossis ncaj qha rau pawg neeg ua haujlwm. Ntxiv mus, ib feem ntawm cov roj yuav tsum nyob twj ywm txawm tias tom qab ua tiav ntawm kev sib ntsib ua haujlwm. Cov kua dej qub qub raug hloov nrog ib qho tshiab. Txhawm rau ua kom yooj yim cov txheej txheem sau hauv cov tshuab niaj hnub no, cov roj circulating yog npaj ib txhij rau lub gearbox thiab spindle nyob rau hauv tsis siv neeg hom raws li cov khib nyiab loj yog drained.

Ntxiv nrog rau kev hloov kho cov roj, nws yog ib qho tsim nyog los tswj cov txheej txheem kev siv tshuab. Cov teeb meem technical thiab cov qauv tuaj yeem tshwm sim vim overheating, ntau deformation, siab vibrations los yog inter-tig luv Circuit Court. Ib qho kev kho ntawm spindle sib dhos ua ib feem ntawm cov txheej txheem tsim khoom yuav yog los hloov cov khoom puas, khoom siv, lossis rov tsim cov rooj zaum. Piv txwv li, thaum deforming los yog txhim kho cov ntsiab lus tshiab, kev kho ntxiv ntawm lub qhov (socket) lossis cov khoom ntawm lawv tus kheej yog qee zaum yuav tsum tau ua kom zoo, sib tsoo, lapping lossis txhim kho.

Kev tsim khoom ntawm SHU hauv Russia

Qee yam ntawm cov khoom siv spindle yuav tsum tau ua kom tiav cov cuab yeej siv tshuab yog tsim los ntawm cov tuam txhab tsim khoom hauv tsev ntawm lawv tus kheej cov cuab yeej siv tshuab, tso siab rau kev txhim kho thiab kev paub ntawm Soviet kev lag luam. Muaj kev xyaum tsis muaj teeb meem nrog kev tsim cov khoom siv sib xyaw ua ke rau cov tshuab milling lossis tig units uas tsis tsom rau kev ua haujlwm siab. Txawm li cas los xij, niaj hnub high-tech electrospindles yog tsim nyob rau hauv Russia tsuas yog nyob rau hauv qhov chaw thiab nyob rau hauv lub hauv paus ntawm txawv teb chaws Cheebtsam. Cov kev txwv no tau txuas nrog tsis yog tsuas yog qhov tsis muaj cov thev naus laus zis siab tshaj hauv cheeb tsam no, tab sis kuj tseem muaj cov neeg ua haujlwm tsis txaus uas yuav tsum daws teeb meem engineering thiab kev tsim khoom.

Zaj lus

Lub ntxaiv yog ib qho ntawm cov khoom siv hauv nruab nrab ntawm ntau hom tshuab cuab yeej. Qhov tseeb ntawm kev ua haujlwm ntawm kev ua haujlwm ntawm kev ua haujlwm, ergonomics ntawm cov cuab yeej tswj thiab kev ua haujlwm ntawm kev tswj hwm lub zog ntawm lub tshuab tsav yog nyob ntawm qhov zoo ntawm nws cov haujlwm tseem ceeb. Yog li ntawd, nws yog ib qho tseem ceeb heev uas yuav tau xyuam xim rau cov yam ntxwv ntawm spindle sib dhos nyob rau hauv lub tshuab dhos thaum xaiv nws. Thiab qhov no siv tsis tau tsuas yog rau ntu kev lag luam, qhov twg hauv-kab machining kev ua haujlwm tau ua. Tus tswv tsev zoo tib yam uas ua haujlwm yooj yim hauv chav nres tsheb lossis lub tsev hauv lub tebchaws yuav tsum muaj kev paub yooj yim ntawm headstock. Kev txawj ntse hauv kev tuav lub tshuab spindle yuav ua rau kev lag luam txhim khu kev qha thiab kev saib xyuas lub tshuab kom txuag tau ntau dua.

Pom zoo:

Kev sib koom tes zoo yog kev pom zoo ntawm ob lossis ntau lub tuam txhab ywj pheej los koom tes kom ua tiav qee lub hom phiaj kev lag luam. Cov qauv thiab cov piv txwv ntawm kev sib koom tes thoob ntiaj teb kev sib tw

Cov kev sib koom tes zoo yog qhov kev pom zoo ntawm ob lossis ntau lub tog kom ua tiav cov hom phiaj pom zoo thaum tswj hwm kev ywj pheej ntawm cov koom haum. Lawv zoo li poob qis ntawm kev cai lij choj thiab kev koom tes nrog kev koom tes. Cov tuam txhab tsim kev sib koom tes thaum lawv txhua tus muaj ib lossis ntau dua cov cuab yeej ua lag luam thiab tuaj yeem sib koom ua lag luam kev paub rau ib leeg

Dab tsi yog kev ua tau zoo: lub tswv yim, cov qauv thiab cov ntsuas kev ua tau zoo

Txhawm rau tsim kom muaj kev txhawb nqa cov neeg ua haujlwm thiab txhim kho kev tswj hwm, nws yuav tsum nkag siab tias cov neeg ua haujlwm thiab cov thawj coj ua haujlwm tau zoo npaum li cas. Qhov no ua rau lub tswv yim ntawm kev ua tau zoo heev cuam tshuam hauv kev tswj hwm. Yog li ntawd, koj yuav tsum paub tias qhov kev ua tau zoo yog dab tsi, nws cov txheej txheem thiab cov kev ntsuam xyuas yog dab tsi

Tsis siv neeg tshuab dhos thiab nws cov yam ntxwv. Tsis siv neeg tshuab dhos ntau spindle longitudinal tig nrog CNC. Manufacturing thiab processing ntawm qhov chaw ntawm tsis siv neeg lathes

Tsis siv neeg tshuab dhos yog cov cuab yeej siv niaj hnub siv feem ntau hauv kev tsim khoom ntau. Muaj ntau ntau yam ntawm cov tshuab xws li. Ib hom nrov tshaj plaws yog longitudinal tig lathes

Yuav ua li cas kom tau nyiaj ntawm kev sib tw: cov ntsiab lus ntawm cov nyiaj tau los, qhov zoo thiab qhov tsis zoo, kev sib tw sib tw thiab kev suav nyiaj tau los

Kev sib tw ntawm kev sib tw thiab kev yuav khoom pej xeem tuaj yeem yog txoj hauv kev zoo kom tau nyiaj thiab nthuav koj txoj kev lag luam. Txoj hauv kev zoo rau kev sib tw yuav pab koj yeej thiab tau txais cov neeg siv khoom ruaj khov, thiab qhov tseem ceeb tshaj - cov nyiaj tau los. Yuav ua li cas thiab yuav ua li cas kom tau nyiaj ntawm kev sib tw?

Yuav ua li cas los ua tus neeg muag khoom zoo: lub tswv yim ntawm lub hauv paus ntawm kev ua haujlwm, thawj theem, tau txais kev paub dhau los, kev muag khoom, cov kev pabcuam zoo thiab muaj peev xwm piav qhia txhua qhov zoo ntawm kev yuav khoom

Yuav ua li cas thiaj ua tau tus neeg muag khoom zoo? Koj puas xav tau kev txawj ntse, lossis ib tus neeg tuaj yeem txhim kho qhov tsim nyog ntawm nws tus kheej? Leej twg tuaj yeem dhau los ua tus thawj coj zoo. Nws tsuas yog qhov ntawd rau qee tus neeg, tau txais cov txuj ci tsim nyog yuav yooj yim, thaum lwm tus yuav tau siv zog ntau. Tab sis thaum kawg, ob leeg yuav muag zoo sib xws