2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

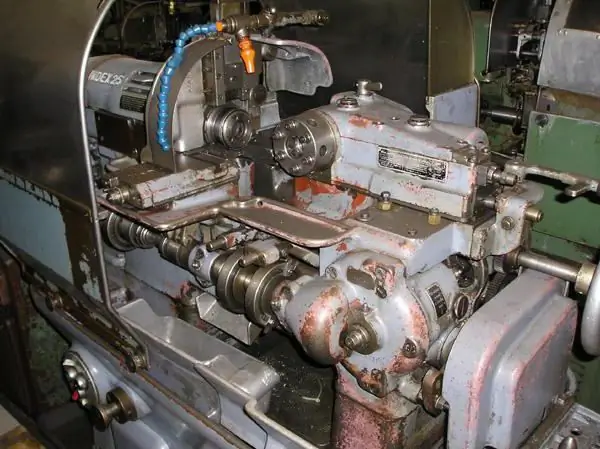

Lub tshuab dhos yog lub tshuab tshwj xeeb, kev ua haujlwm ntawm cov khoom uas tau ua yam tsis muaj kev koom tes ntawm tus neeg ua haujlwm. Hom khoom siv no kim dua li niaj zaus. Txawm li cas los xij, nws kuj pom tau tias yooj yim dua rau siv. Tag nrho cov haujlwm ntawm cov tshuab no tau ua tiav. Tus neeg ua haujlwm tsuas yog saib xyuas kev thauj khoom ntawm qhov khoob thiab tswj qhov zoo ntawm cov khoom tsim.

Ntau yam ntawm cov cuab yeej siv tshuab

Muaj ntau hom khoom siv. Cov khoom tuaj yeem tsim los ntawm ib leeg-spindle lossis multi-spindle tsis siv neeg tshuab. Structurely, lawv txawv me ntsis. Qhov sib txawv tsuas yog ntawm cov khoom siv xws li ib leeg-spindle lathes, tig yog siv tsuas yog ib qho cuab yeej ua haujlwm. Muaj ob peb ntawm lawv nyob rau hauv kev tsim ntawm multi-spindle tshuab. Raws li hom workpieces, tag nrho cov tshuab dhos tau muab faib ua:

- screw-txiav;

- carousel;

- ntsej muag tig;

- tig-milling;

- turret tig;

- ntev tig.

Screw-txiav cov cav tov yog siv los ua txhua hom kev ua haujlwm tig, carousel - ua cov khoom ua haujlwm ntawm cov khoom loj. Lub ntsej muag tig tshuab yog siv los tig cylindrical, frontal thiab conical khoom. Cov cuab yeej milling yog siv rau kev ua haujlwm nyem. Turret lathes yog siv rau kev tsim cov khoom ntawm cov duab complex. Hais txog dab tsi longitudinal seem tshuab yog npaj rau thiab dab tsi yog cov yam ntxwv ntawm lawv tsim, peb yuav tham nyob rau hauv kom meej hauv qab no.

Kev ua haujlwm ntawm lub tshuab dhos tsis siv neeg

Raws li nrog cov tshuab pa, cov khoom siv no ua haujlwm xws li:

- longitudinal tig ntawm cylindrical thiab stepped nto;

- txheej txheem bevel;

- tho qhov;

- drilling;

- xov txiav;

- grooving;

- profile tig.

qauv tsim dav dav

Txhua qhov tsis siv neeg thiab semi-automatic lathes, nrog rau cov tshuab pa, yog li tsim los tshem tawm qee qhov ntawm cov khoom ua haujlwm thaum tig tom kawg. Los ntawm kev tsim, ntau hom khoom siv no tuaj yeem sib txawv heev. Txawm li cas los xij, cov yam ntxwv tseem ceeb rau ntau hom muaj ntau. Kev tsim ntawm txhua lub tshuab dhos muaj xws li: lub txaj,pem hauv ntej thiab nram qab headstock, carriage. Cov tom kawg yog tsim los tuav lub cuab yeej thiab txav mus rau qhov raug. Lub tshuab pub tshwj xeeb yog lub luag haujlwm rau cov txheej txheem no.

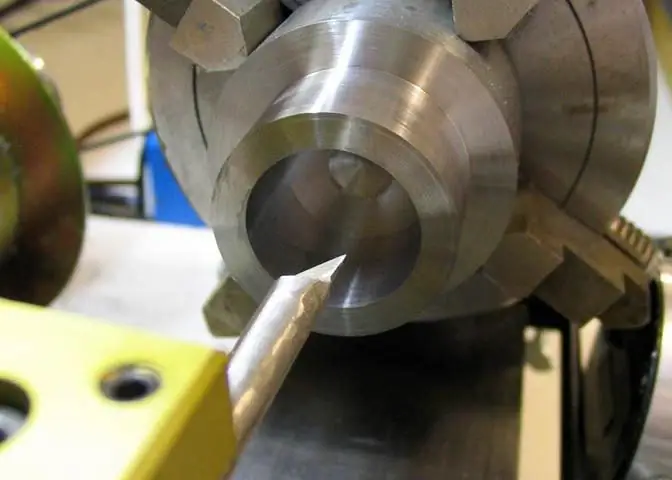

Rau lub taub hau ntawm cov khoom siv xws li tshuab dhos tsis siv neeg, lub ntxaiv thiab lub tshuab hloov ceev tau txuas nrog. Nws tau ruaj khov heev, vim tias nws tuaj yeem ua rau muaj kev vibrations uas kis tau mus rau lub workpiece thiab txo qhov zoo ntawm qhov tiav. Lub spindle nyob rau hauv headstock yog tsau rau bearings thiab nruab nrog tshwj xeeb clamping pab kiag li lawm (loops los yog chucks). Nws yog tsav los ntawm lub tshuab hluav taws xob cais los ntawm lub gearbox.

Lub txaj hauv tshuab dhos tuaj yeem siv sib txawv (inverted, V-shaped, ca). Cov txheej txheem no yuav tsum tau nyob kom raug raws li qhov ua tau. Txhua qhov sib txawv ua rau txo qis hauv qhov zoo ntawm cov khoom tsim.

Cov tailstock yog siv los txhawb cov workpieces ntev thaum tig. Nws feem ntau yog nyob ntawm lub rooj thiab tsau rau hauv txoj haujlwm yooj yim tshaj plaws rau kev tsim khoom.

Lathes tuaj yeem ua haujlwm tau siv tus maub los lossis cov cuab yeej siv tshuab. Cov cuab yeej ntawm hom no txawv ntawm cov tshuab CNC yooj yim nyob rau hauv uas cov workpieces nyob rau hauv cov ntaub ntawv no kuj cia li pub rau kev ua. CNC tej tshuab tuaj yeem nruab ntxiv.

Qhov txawv ntawm cov tshuab tsis siv neeg thiab cov tshuab pa

Ua haujlwm ntawm cov tshuab ntawm hom no tuaj yeem ua tau zoo ib yam li ntawm cov cuab yeej tig yooj yim. Qhov sib txawv nyob rau hauv qhov tseeb hais tias txoj kev tig ntawm qhov chawntawm cov tshuab tsis siv neeg nws yog ua raws li lub voj voog rigidly. Ntawm lub tshuab pa, tus neeg ua haujlwm, ua tiav qhov tsim khoom ntawm ib feem, tuaj yeem pib tig lwm qhov tam sim ntawd. Ntawm lub tshuab, lub cam changeover yuav siv sij hawm ob peb teev, thiab kev npaj rau nws yuav siv sij hawm ob peb hnub.

siv thaj chaw

Tsis siv neeg tshuab dhos ua haujlwm ntau dua li cov tshuab ua haujlwm. Txij li thaum lawv qhov kev hloov pauv tsis tu ncua ua rau poob lub sijhawm ntau lawm, cov cuab yeej no feem ntau yog siv rau hauv cov khoom loj. Tsis tas li ntawd, txij li cov cuab yeej zoo li no kim heev, nws raug nquahu kom siv nws tsuas yog xav tau los tsim cov khoom ntawm cov duab nyuaj nrog ntau qhov kev hloov pauv. Feem ntau, cov tuam txhab siv cov tshuab tshwj xeeb ntawm hom no, tsim los tsim ib feem lossis ib pawg me me ntawm cov khoom.

Multi-spindle machine

Cov khoom siv tig tsis siv neeg no yog siv hauv cov chaw tsim khoom los tsim cov khoom ntawm ntau yam duab thiab ntau thiab tsawg. Nyob rau hauv txoj kev no, xws li cov cav tov txawv ntawm ib leeg-spindle machinery, uas yog siv tsuas yog rau zus tau tej cov serial zoo tib yam khoom. Muaj ob hom tshuab xws li:

-

Kab rov tav. Lub ntsiab kom zoo dua ntawm cov tshuab no yog qhov yooj yim ntawm kev thauj cov khoom siv. Yog li ntawd, lawv tau siv qhov chaw noj khoom noj tsis tu ncua.

- Vertical. Qhov zoo ntawm ntau lub tshuab spindle ntawm no ntau yam yog qhov me me. Muab cov khoom siv sab hauv tsevhom no tsis noj ntau dhau.

Multi-spindle tsis siv neeg tshuab dhos qee zaum siv tau rau hauv cov khoom me me. Tab sis tsuas yog nruab nrog CNC.

Longitudinal tig machine

Cov khoom siv ntawm hom no tau dhau los ua neeg nyiam. Longitudinal tig tshuab yog siv rau kev tsim khoom ntawm feem ntau me me ntawm cov duab nyuaj heev. Ib qho tshwj xeeb ntawm lawv cov qauv tsim yog lub xub ntiag ntawm lub taub hau txav txav tau. Hom clamp nyob rau hauv xws li cov cav tov yog siv collet. Lub txee ntxaiv hauv zawv zawg lub taub hau tshuab yog mounted ntawm high-precision linear guides.

Ib yam ntawm cov tshuab ntawm ntau yam no, nrog rau lwm yam, yog qhov me me. Lawv thaj chaw ua haujlwm kuj tsis dav heev. Cov tshuab ntawm hom no feem ntau ua haujlwm ntawm qhov ceev heev.

Lub tshuab dhos tsis siv neeg longitudinal tig tuaj yeem siv rau hauv ob qho tib si loj thiab ntau lawm ntawm qhov chaw. Feem ntau, cov cuab yeej ntawm hom no yog siv hauv cov khoom siv kho qhov muag, hluav taws xob thiab cov cuab yeej ua lag luam. Cov cutters nyob rau hauv xws li cov cav tov yog mounted nyob rau hauv calipers thiab txav tsuas yog nyob rau hauv txoj kab rov tav. Nyob rau hauv ntau lawm, longitudinal tig tshuab yog siv, ob leeg-spindle thiab multi-spindle.

Sliding tig tsis siv neeg tshuab dhos yog tsim los ua haujlwm xws li:

- tig kauj ruam;

- -grooving thiab conving;

- dhuavqhov ntiav;

- kho qhov chaw zoo li qub;

- xov sab hauv thiab sab nraud;

- ream qhov;

- knurling ntawm sab nrauv;

- milling slots rau screws;

- drilling.

Ntog ntawm cov tshuab tsis siv neeg ntawm hom no tuaj yeem ua tiav ntau yam: conical, cylindrical, stepped, thiab lwm yam. Txhawm rau nthuav dav lub peev xwm ntawm longitudinal tig tshuab, txhua yam khoom siv ntxiv yog siv. Piv txwv li, kev siv cov iav levers txo qhov hnav ntawm cov cams thiab khau khiab.

Tsim nta ntawm longitudinal tig tshuab

Lub taub hau ntawm cov tshuab xws li yog tsau rau saum lub dav hlau ntawm lub txaj. Ua ntej ntawm nws muaj ib lub phaj tshwj xeeb tsim los rau nruab cov khoom siv ntxiv. Lub caliper ntsug yog ntsia rau ntawm nws lub dav hlau sab saud, thiab lub viav vias nres yog ntsia rau tom qab. Cov khoom siv xws li lub tshuab dhos longitudinal yog tswj los ntawm lub kaw lus ntawm cams thiab camshafts tsau rau hauv tus ncej.

Key Benefits

Qhov zoo ntawm longitudinal tig tshuab feem ntau suav nrog:

- muaj peev xwm tau txais qhov zoo li tus thiab conical nto thaum siv prismatic cutters;

- khoom zoo ua tiav;

- muaj peev xwm milling ob qho tib si raws axis ntawm ib feem thiab hlanws;

- muaj peev xwm yob cov lej me, cov cim thiab cov ntawv.

Machining qhov chaw ntawm lub tshuab dhos tsis siv neeg ntawm hom no tuaj yeem ua tiav nrog qhov siab tshaj plaws.

Txoj Cai Ua Haujlwm

Nyob rau hauv cov txheej txheem ntawm kev ua, cov khoom siv ntawm cov tshuab no tsis yog tsuas yog kev sib hloov, xws li cov pa, tab sis kuj txhais lus - raws axis. Cov cutters lawv tus kheej hauv cov cuab yeej xws li zawv zawg bar lathes txav tsuas yog perpendicular rau lub bar. Lub zog radial tshwm sim thaum lub sij hawm machining txheej txheem yog coj los ntawm qhov tsis tu ncua. Qhov no tshem tawm txhua yam kev vibrations thiab deflections thiab, raws li, kom ntseeg tau siab machining raug.

Lub voj voog ntawm kev txav ntawm lub taub hau thiab cov cuab yeej hauv cov tshuab ua haujlwm ntev ntev yog teem los ntawm cams tuned tshwj xeeb rau qhov tshwj xeeb no. Cov tom kawg yog mounted rau ib tug tshwj xeeb ncej, tus naj npawb ntawm revolutions uas yuav txawv txawm nyob rau hauv ib tug tas li ntxaiv ceev.

Kev tu cov tshuab Swiss

Kev ua haujlwm, hom tshuab no yooj yim. Txawm li cas los xij, tau kawg, lawv xav tau qee qhov kev saib xyuas. Piv txwv li, txhawm rau kom lub tshuab ua kom txias ua haujlwm zoo, nws yuav tsum tau hloov cov roj ib ntus. Nws tseem pom zoo kom yaug cov dej da dej txhua hli. Kev tsim ntawm lub tshuab ua kom txias kuj suav nrog cov lim dej, uas yuav tsum tau ntxuav ntawm tib zaus. Cov lus pom zoo no yuav tsum ua raws. Kho lub tshuab dhos yog kim.

CNC tshuab

Raws li twb tau hais lawm, cov tshuab tsim los tsim cov khoom siv hlau tuaj yeem ntxiv nrog CNC. Cov kev tswj hwm zoo li no feem ntau yog siv yog tias lub tshuab dhos tsis siv neeg yog npaj rau kev tsim cov khoom hauv cov khoom loj lossis cov khoom me me. Cov software siv hauv CNC tso cai:

- automate cov txheej txheem ua;

- txhim kho qhov zoo ntawm cov khoom siv;

- txo qis lub sijhawm lub tshuab teeb tsa.

Ntau hom tsav thiab hloov pauv hauv CNC yog siv cov digital. Lawv yog cov tshuab hluav taws xob uas khiav ntawm AC lossis DC. Thaum siv lub CNC, tshwj xeeb sensors yog tsim rau hauv lub kinematic scheme ntawm lub tshuab. Cov cuab yeej ua haujlwm hauv cov tshuab nruab nrog CNC yog siv kom ntev li ntev tau, vim tias lawv ua haujlwm ntawm kev kub ceev thiab kev tsim khoom. Lub hauv paus qauv ntawm cov tshuab no yuav tsum nruj heev.

CNC multi-spindle longitudinal tig tshuab

Qhov tseeb, cov lej software nws tus kheej tsis muaj dab tsi ntau dua li lub khoos phis tawj nrog cov software tshwj xeeb nruab rau nws uas tswj cov tsav ntawm lub tshuab. Feem ntau cov cuab yeej txheem ntawm CNC tshuab yog raws li nram no:

- spindle;

- txias system;

- tus ntxaiv;

- teeb rau thaj chaw ua haujlwm;

- machine ejection sensor;

- tes tsho hloov pauv;

- khoom tshwj xeeb kom tau txais cov khoom tiav;

- cuab yeej rau sab nraud thiab sab hauv tig;

- pem hauv ntej thiab hla cov cuab yeej tsav tsheb;

- the CNC system nws tus kheej.

Yooj yim lathes multi-spindle longitudinal tig yam tsis muaj CNC feem ntau yog siv rau kev tsim khoom ntau ntawm ntau yam me me, feem ntau ntev thiab me me, cov duab nyuaj. Cov tom kawg feem ntau yog cov khoom siv ntawm cov khoom siv kho mob niaj hnub thiab cov chaw sim, hluav taws xob, watches, thiab lwm yam.

Txhim kho CNC ntawm cov tshuab zoo li no kuj tso cai rau koj los tsim cov khoom lag luam ntau, tab sis tsis zoo ib yam, tab sis cov duab sib txawv (uas yog, hauv cov khoom me me). Ordinary automata feem ntau yog tsim los tsim ib feem, thiab tsuas yog ib zaug xwb. Qhov tseeb yog tias txhua yam "reprogramming" ntawm cov cuab yeej no, raws li twb tau hais lawm, yog cov txheej txheem nyuaj thiab ntev. Lub downtime ntawm ntau lawm thaum lub sij hawm hloov pauv zoo heev cuam tshuam nws profitability. Yog li ntawd, kev siv cov tshuab pa rau kev tsim cov khoom me me ntawm qhov chaw ntawm ntau cov duab yog suav tias yog qhov tsis tsim nyog.

CNC installation pab daws qhov teeb meem no thiab muab cov txiaj ntsig zoo ntawm lub tshuab nrog rau kev nthuav dav ntau yam ntawm cov khoom tsim. Yog hais tias lub tshuab muaj ib tug lej tswj qhov system, koj muaj peev xwm reconfigure nwsceev heev. Piv txwv li, qhov kev hloov ntawm cov ntawv txiav yog nqa tawm ncaj qha rau ntawm lub tshuab nws tus kheej yam tsis tau tshem tawm tus tuav. Txhawm rau hloov qhov nrawm ntawm kev sib hloov ntawm cov cuab yeej thiab qhov kev txiav txim ntawm lawv txoj haujlwm, koj tsuas yog yuav tsum tau nkag mus rau qee qhov txiaj ntsig hauv qhov program qhov rais ntawm lub computer CNC.

Kev tsim khoom ntawm CNC tshuab dhos: nta

Kev koom tes ntawm cov neeg ua haujlwm thaum siv cov tshuab ntawm hom no raug txo kom tsawg. Txhua yam uas yuav tsum tau los ntawm tus kws tshaj lij yog los saib xyuas kev ua haujlwm zoo ntawm cov khoom siv. Ntawm chav kawm, qhov zoo ntawm cov khoom nyob rau hauv rooj plaub no ncaj qha nyob ntawm qhov tseeb ntawm kev teeb tsa lub tshuab. Yog li ntawd, NC cov kev pab cuam yuav tsum tau xav raws li qhov ua tau.

Lub luag haujlwm tseem ceeb ntawm cov kev lag luam uas siv cov khoom siv xws li CNC tshuab dhos tsis siv neeg ntawm txoj kab ntev yog los tsim cov khoom nrog cov kev txwv tshwj xeeb thiab tib lub sijhawm tus nqi qis. Cov tuav siv los ua cov khoom pib ntawm cov tshuab no feem ntau tsis muaj cov duab geometric heev (txawm tias ntsuas tau). Hauv qhov no, txhua qhov yuam kev thiab qhov tsis raug tuaj yeem yooj yim pauv mus rau qhov ua tiav. Tom qab tag nrho, cov cuab yeej ua haujlwm, tau kawg, tsis tuaj yeem hloov pauv lawv txoj haujlwm lossis kev sib hloov ceev yam tsis muaj kev cuam tshuam tib neeg. Qhov tshwj xeeb ntawm kev txiav ntawm cov tshuab tsis siv neeg no hu ua "heredity" thiab yog qhov teeb meem tseem ceeb rau cov kws tshaj lij kev lag luam. Nws yog feem ntau daws los ntawm kev txo qhov ceev ntawm kev ua hom raws li tag nrho cov txiav ntev. Qhov twg, tau kawg, ua rau nce tus nqi ntawm cov khoom vim qhov nce ntawm cov nqi sijhawm.

Meanwhile, nws muaj peev xwm tshem tau ntawm "heredity" nrog tsawg tsawg los siv tshwj xeeb niaj hnub CNC daim ntawv thov kev pab cuam tsim los rau hauv tus account lub dynamic yam ntxwv ntawm cov txheej txheem uas txiav txim nws. Lawv txoj kev siv tso cai rau koj los teeb tsa cov kev txiav kom raug tshaj plaws nrog kev txo lub sijhawm poob ntau dua ob zaug.

Top brands

Yog li, qhov raug kho ntawm Swiss-hom tshuab dhos siv CNC cov kev pab cuam tso cai rau koj los tsim cov khoom me me raws li tus nqi tsim nyog. Tab sis tau kawg, tsuas yog tias cov cuab yeej nws tus kheej yog qhov zoo. Kev kho ntawm qhov tsis siv neeg longitudinal tig tshuab nrog CNC yog qhov nyuaj, kim thiab siv sijhawm ntev. Yog li ntawd, kev xaiv ntawm cov tshuab no yog ib qho teeb meem loj thiab lub luag haujlwm.

Thaum yuav khoom xws li tshuab dhos tsis siv neeg, ua ntej ntawm tag nrho cov, koj yuav tsum xyuam xim rau nws cov chaw tsim khoom. Piv txwv li, CNC multi-spindle longitudinal tig tshuab ntawm cov npe hauv qab no tsim nyog cov kev tshuaj xyuas zoo:

- Tornos ntawm MultiSwiss series.

- LA155F30.

- HJM SQC38.

Tornos machines

Qhov zoo ntawm MultiSwiss series ntawm cov cav tov suav nrog, ua ntej ntawm tag nrho cov, tsim khoom siab thiab tsim qauv yooj yim. Lub Tornos multi-spindle CNC tshuab dhos yog yooj yim heev thiab ceev los teeb tsa thiab kho dua tshiab. Txhawm rau ua haujlwm ntawm lub tshuab zoo li no, koj tsis tas yuav yog tus kws tshaj lij hauv ntau lub tshuab spindle. Tswjua tiav los ntawm CNC. Cov yam ntxwv ntawm cov tshuab ntawm kab no tau nthuav tawm hauv lub rooj.

| Parameter | Meaning |

| Ntau tus neeg nqa khoom | 7 pcs |

| Max bar diameter | 14mm |

| siab tshaj workpiece ntev | 40mm |

| ntau tus spindles | 6 pcs |

| siab kawg spindle | 8000rpm |

| Power | 5.6 kW |

| siab tshaj plaws torque | 7.5 Nm |

| Tus lej ntawm tus lej spindles | 1 pcs |

| Ntau tshaj qhov ntsuas spindle nrawm | 8000rpm |

| Lub zog ntawm txee ntxaiv | 5kW |

| CNC system | Fanuc |

| Nyhav ntawm lub tshuab | 7000kg |

| Dimensions | 1440x5920x2120mm |

LA155F30 qauv

Peb-spindle tsis siv neeg tshuab dhos ntawm hom no yog nyob rau hauv chav kawm raug "B". Lub ntsiab zoo ntawm LA155F30 tshuab yog kev ntseeg siab thiab kev pab lub neej ntev. Txawm tias tom qab ntevsiv cov tshuab no tso cai rau koj los ua cov khoom siv nrog qhov siab tshaj plaws. Tsis tas li ntawd, LA155F30 cov cav tov tsis kim heev thiab kev ruaj ntseg.

Cov yam ntxwv ntawm cov chaw tsim khoom siv tshuab dhos tsis siv neeg no yog raws li hauv qab no:

- txoj kab uas hla ntawm cov txheej txheem min / max - 6/16 mm;

- qhov khoom ntev tshaj plaws - 160mm;

- main spindle ceev - 80-8000rpm;

- fais fab lub cev muaj zog - 5.5 kW;

- machine hnyav - 2270 kg;

- dimensions nrog attachments - 5600x900x1720 mm.

HJM SQC38 machines

Hom no ntau lub tshuab dhos tsis siv neeg spindle kuj ua kom qhov siab tshaj plaws hauv kev ua haujlwm. Cov cuab yeej no yog npaj rau kev ua haujlwm siab ntawm qhov chaw (longitudinal tig thiab milling). Hauv qab no yog cov specifications ntawm HJM SQC38.

| Parameter | Meaning |

| Tus lej ntawm cov cuab yeej tsav | 6 pcs |

| Max bar diameter | 38mm |

| Ntau yam khoom ntev | 210mm |

| Drive tool speed | 4000 rpm |

| Spindle speed | 8000rpm |

| tshuab hnyav | 4500kg |

| Dimensions | 2100x1450x1700 mm |

Zoo kawg

Yog li, niaj hnub CNC longitudinal tig tshuab yog yooj yim heev, tsim tau thiab, feem ntau, cov cuab yeej txhim khu kev qha. Qhov tseem ceeb tshaj plaws hauv nws txoj haujlwm yog siv cov kev xav zoo tshaj plaws. Qhov no yuav ua rau kom muaj txiaj ntsig ntawm kev tsim khoom thiab tsim cov khoom zoo nrog qhov tseeb.

Pom zoo:

Yog qhov yuav tsum tau foob rau tus neeg ua lag luam: cov yam ntxwv ntawm kev cai lij choj ntawm Lavxias Federation, cov xwm txheej uas tus neeg ua lag luam yuav tsum muaj lub foob, tsab ntawv lees paub txog qhov tsis muaj foob, cov qauv sau, qhov zoo thiab cons ntawm kev ua haujlwm nrog lub foob

Qhov xav tau siv luam ntawv yog txiav txim siab los ntawm hom kev ua haujlwm uas tus neeg ua lag luam ua. Feem ntau, thaum ua haujlwm nrog cov neeg siv khoom loj, lub xub ntiag ntawm lub thwj yuav yog qhov tsim nyog rau kev koom tes, txawm tias tsis tas yuav tsum tau ua los ntawm txoj cai. Tab sis thaum ua hauj lwm nrog tsoom fwv txiav txim, luam ntawv yog tsim nyog

Cov khoom tsis nyob hauv tsev: kev cai lij choj txhais, hom thaj chaw, lawv lub hom phiaj, cov ntaub ntawv tswj hwm thaum lub sijhawm sau npe thiab cov yam ntxwv ntawm kev hloov chaw nyob rau hauv cov chaw tsis nyob

Cov kab lus txiav txim siab lub ntsiab lus ntawm qhov chaw tsis nyob hauv tsev, nws cov yam ntxwv tseem ceeb. Yog vim li cas rau qhov muaj koob meej loj hlob ntawm kev tau txais cov chav tsev nrog kev pom rau lawv qhov kev hloov pauv tom ntej mus rau qhov chaw tsis nyob hauv tsev tau nthuav tawm. Cov lus piav qhia ntawm cov yam ntxwv ntawm kev txhais lus thiab cov nuances uas yuav tshwm sim hauv qhov no tau nthuav tawm

Txoj kev tsheb ciav hlau yog Txhais, tswvyim, yam ntxwv thiab qhov ntev. Tsheb ciav hlau qhov ntev thiab cov yam ntxwv ntawm cov chaw khiav haujlwm

Kev mus los ntawm tsheb ciav hlau hla lub nroog thiab cov nroog, koj tuaj yeem kawm ntau yam nthuav thiab lom zem txog lub ntiaj teb ntawm txoj kev tsheb ciav hlau. Ntau tshaj ib zaug, cov neeg taug kev tau nug lawv tus kheej cov lus nug txog qhov twg qhov no lossis txoj kev tsheb ciav hlau coj mus? Thiab tus engineer uas tswj lub tsheb ciav hlau xav li cas thaum lub tsheb ciav hlau pib tawm lossis tuaj txog ntawm qhov chaw nres tsheb? Yuav ua li cas thiab los ntawm qhov twg cov tsheb hlau txav thiab txoj hauv kev ntawm cov khoom dov yog dab tsi?

Yam koj yuav tsum tau ua haujlwm hauv tsheb tavxij: cov ntaub ntawv tsim nyog thiab cov cai, cov cai thiab kev cai lij choj. Cov lus teb thiab cov lus qhia los ntawm cov neeg tsav tsheb tavxij, cov neeg siv khoom thiab cov neeg xa khoom

Raws li ntau tus neeg caij tsheb, txoj haujlwm ntawm tus tsav tsheb tavxij yog qhov yooj yim tshaj plaws. Koj zaum, mloog suab paj nruag zoo nkauj thiab tsav tsheb rov qab los. Thiab lawv muab nyiaj rau koj. Tab sis qhov no tsuas yog sab nraud ntawm lub npib. Qhov rov qab yog ntau dua rosy. Peb yuav tham txog nws hauv kab lus no. Thiab peb tseem yuav qhia txog yam koj xav tau ua haujlwm hauv tsheb tavxij

Txiv lws suav Kievlyanka: cov yam ntxwv ntawm ntau yam, nws qhov zoo thiab qhov tsis zoo

Nyob rau hauv tsev cog khoom ntawm Lavxias teb sab zaub cog, cov txiv lws suav Kievlyanka tau ntev nyob ib qho chaw tsim nyog. Qhov no ntau yam yog ib qho ntawm cov nyiam ntawm amateur gardeners thiab loj ua liaj ua teb. Giant txiv hmab txiv ntoo thiab unpretentiousness ua rau cov nroj tsuag nrhiav-tom qab hom ntawm nightshade tsev neeg