2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

tooj liab thiab nws cov alloys yog siv nyob rau hauv ntau yam kev lag luam. Cov hlau no yog nyob rau hauv kev thov vim nws cov khoom physicochemical, uas kuj nyuaj rau kev ua ntawm nws cov qauv. Tshwj xeeb, kev vuam ntawm tooj liab yuav tsum muaj cov xwm txheej tshwj xeeb, txawm hais tias cov txheej txheem yog raws li kev siv thev naus laus zis zoo sib xws.

Tshwj xeeb vuam ntawm tooj liab blanks

Tsis zoo li ntau lwm yam hlau thiab alloys, cov khoom siv tooj liab yog cov yam ntxwv ntawm cov thermal conductivity, uas ua rau nws tsim nyog los ua kom lub zog thermal ntawm vuam arc. Nyob rau tib lub sijhawm, symmetrical cua sov tshem tawm ntawm qhov chaw ua haujlwm yog qhov yuav tsum tau ua, uas txo qhov kev pheej hmoo ntawm qhov tsis xws luag. Lwm qhov tsis zoo ntawm tooj liab yog fluidity. Cov cuab yeej no dhau los ua ib qho teeb meem hauv kev tsim cov qab nthab thiab ntsug seams. Nrog cov pas dej loj loj, cov haujlwm zoo li no tsis tuaj yeem ua tau. Txawm tias me me ntawm kev ua hauj lwm yuav tsum tau lub koom haum ntawm tshwj xeeb tej yam kev mob nrog rau kev siv ntawm txwv tsis pub liners raws li graphitethiab asbestos.

Txoj kev nyiam ntawm cov hlau rau oxidize kuj xav tau cov khoom tshwj xeeb xws li silicon, manganese thiab phosphorus gels siv rau hauv qee hom nrog kev tsim cov refractory oxides. Cov yam ntxwv ntawm tooj liab vuam muaj xws li nqus cov pa roj - piv txwv li, hydrogen thiab oxygen. Yog tias koj tsis xaiv qhov zoo tshaj plaws ntawm thermal raug, ces cov seam yuav tig mus rau qhov tsis zoo. Cov pores loj thiab cov kab nrib pleb yuav nyob hauv nws cov qauv vim muaj kev cuam tshuam nrog roj.

Kev sib cuam tshuam ntawm tooj liab nrog impurities

Nws yog ib qho tsim nyog yuav tsum tau coj mus rau hauv tus account qhov xwm txheej ntawm kev sib cuam tshuam ntawm tooj liab nrog ntau yam impurities thiab tshuaj lom neeg feem ntau, vim tias nyob rau hauv cov txheej txheem ntawm vuam cov hlau, electrodes thiab xov hlau los ntawm cov khoom sib txawv feem ntau siv. Piv txwv li, txhuas tuaj yeem yaj hauv tooj liab yaj, ua kom nws cov khoom tiv thaiv corrosion thiab txo oxidizability. Beryllium - ua kom cov neeg kho tshuab tsis kam, tab sis txo cov hluav taws xob conductivity. Txawm li cas los xij, cov teebmeem tshwj xeeb tseem yuav nyob ntawm qhov xwm txheej ntawm kev tiv thaiv ib puag ncig thiab kev tswj hwm kub. Yog li, vuam ntawm tooj liab ntawm 1050 ° C yuav pab txhawb kev nkag ntawm cov hlau tivthaiv rau hauv cov qauv ntawm cov khoom ua haujlwm nrog cov coefficient ntawm li 3.5%. Tab sis nyob rau hauv ib tug tsoom fwv ntawm txog 650 ° C, daim duab no yuav raug txo mus rau 0.15%. Nyob rau tib lub sijhawm, hlau xws li sharply txo cov corrosion kuj, hluav taws xob thiab thermal conductivity ntawm tooj liab, tab sis tsub kom nws lub zog. Ntawm cov hlau uas tsis cuam tshuam rau xws li workpieces, txhuas thiab nyiaj tuaj yeem paub qhov txawv.

Basic copper welding method

Txhua txoj kev siv vuam, suav nrog phau ntawv thiab tsis siv neeg, tau tso cai rau ntau yam kev teeb tsa. Kev xaiv ntawm ib lossis lwm txoj kev yog txiav txim siab los ntawm cov kev xav tau ntawm kev sib txuas thiab cov yam ntxwv ntawm lub workpiece. Ntawm cov txheej txheem tsim khoom tshaj plaws yog electroslag thiab submerged arc vuam. Yog tias nws tau npaj kom tau txais cov seam zoo hauv ib qho kev ua haujlwm, nws raug nquahu kom tig mus rau kev siv roj av. Qhov no txoj hauv kev rau vuam tooj liab thiab nws cov alloys ntawm qhov kub thiab txias gradients tsim cov kev mob zoo rau deoxidation thiab alloying ntawm lub workpiece. Yog li ntawd, lub seam tau zoo hloov kho thiab ruaj khov. Rau cov ntshiab tooj liab, arc vuam cov tswv yim nrog tungsten electrodes thiab shielding gases yuav siv tau. Tab sis, feem ntau lawv ua hauj lwm nrog tooj liab derivatives.

Cov cuab yeej siv dab tsi?

Cov khoom lag luam ua ntej tooj liab tuaj yeem ua tiav ntawm kev tig, sib tsoo thiab milling tshuab txhawm rau tsim qhov seem seem rau vuam. Kev lag luam kuj tseem siv cov txheej txheem plasma arc txiav, uas tso cai rau txiav nrog yuav luag zoo meej txiav npoo. Kev sib txuas ncaj qha ntawm tooj liab yog ua los ntawm argon-arc installation, semi-automatic li, nrog rau cov khoom siv inverter. Lub zog tam sim no ntawm cov cuab yeej tuaj yeem sib txawv ntawm 120 txog 240 A, nyob ntawm qhov loj ntawm lub workpiece. Lub thickness ntawm electrodes feem ntau yog 2.5-4 hli - dua, nws nyob ntawm qhov nyuaj thiab ntim ntawm kev ua haujlwm.

tooj liab argon welding

Ib txoj hauv kev nrov tshaj plaws. Hauv tshwj xeeb, cov txheej txheem hais txog argon-arc vuam, uas suav nrog kev siv tungsten electrodes, yog siv. Thaum lub sij hawm cua sov, tooj liab cuam tshuam nrog oxygen, tsim cov dioxide txheej ntawm qhov chaw ua haujlwm. Nyob rau theem no, lub workpiece yuav pliable thiab yuav tsum tau kev twb kev txuas ntawm ib tug uas tsis yog-consumable electrode. Piv txwv li, rods ntawm MMZ-2 hom muab qhov zoo tshaj plaws weld zoo thaum vuam tooj liab nrog argon nrog cov xov xwm tiv thaiv. Yog hais tias lub luag hauj lwm ntawm ib tug muaj zog nkag mus rau lub workpiece yog tsis teem, ces ib tug sib sib zog nqus version ntawm vuam nyob rau hauv ib tug nitrogen ib puag ncig yuav siv tau. Qhov no yog ib txoj hauv kev zoo ntawm kev ua haujlwm thermal ntawm qhov tsis tshua muaj hluav taws xob, tab sis muaj txiaj ntsig zoo dua nyob rau hauv cov nqe lus ntawm vuam zoo tuaj yeem ua tiav siv cov roj sib xyaw ua ke. Piv txwv li, cov kws muaj txuj ci, feem ntau siv cov khoom sib xyaw uas yog 75% argon.

Gas Vuam

Nyob rau hauv rooj plaub no, siv cov pa oxygen-acetylene nruab nrab, vim qhov kub ntawm cov nplaim taws nce siab. Nyob rau hauv cov txheej txheem ua hauj lwm, ib tug roj burner yog siv. Lub tshuab no yog qhov zoo hauv nws qhov kev ua tau zoo, tab sis nws qhov kev hloov pauv tsis txwv tsis tso cai rau koj los kho qhov tsis zoo ntawm lub pas dej vuam.

Feem ntau siv thiab cov txheej txheem ntawm kev faib thermal raug nrog kev sib txuas ntawm ob lub qhov cub. Ib qho ua haujlwm sov so rau thaj chaw ua haujlwm, thiab qhov thib ob - ncaj qha rau cov roj vuam ntawm lub hom phiaj workpiece. Txoj kev no yog pom zoo rau cov ntawv tuab 10mm. Yog tsis muaj qhov thib ob burner,tom qab ntawd koj tuaj yeem ua ob sab cua sov raws li txoj kab ntawm cov seam yav tom ntej. Cov nyhuv tsis yog qhov zoo, tab sis lub luag haujlwm tseem ceeb yog pom tau.

Tso cai rau cov txheej txheem roj vuam thiab kev txhaj tshuaj flux kom tau txais cov qauv sib koom ua ke. Hauv particular, gaseous fluxes yog siv, zoo li azeotropic daws ntawm boron methyl ether nrog methyl. Lub active vapors ntawm xws li sib tov yog xa mus rau lub burner, hloov cov yam ntxwv ntawm lub weld pas dej ua ke. Cov nplaim taws ntawm qhov taw tes no yuav siv lub ntsej muag ntsuab.

Txheej txheem ntawm carbon electrode vuam

Arc vuam txoj kev uas zoo rau cov hlau alloys. Nws lub ntsiab txawv feature tuaj yeem hu ua ergonomics thiab versatility - yam tsawg kawg hauv txhua yam cuam tshuam nrog kev ua haujlwm ntawm lub cev ua haujlwm los ntawm tus neeg teb xov tooj. Piv txwv li, ib tug welder muaj peev xwm nqa tawm manipulations ncaj qha nyob rau hauv cov huab cua, siv ib tug tsawg kawg nkaus txheej ntawm pab tiv thaiv cov khoom. Qhov no yog vim lub fact tias carbon electrodes thaum lub sij hawm cua sov txheej txheem muab tawm ib tug txaus tus nqi ntawm thermal zog, uas tsis muaj zog tooj liab yog welded. Cov txheej txheem hloov mus rau qhov tsis muaj txiaj ntsig, tab sis kev sib txuas tau txais tag nrho cov khoom tsim nyog.

Kev tuav arc vuam

Cov thev naus laus zis ntawm txoj kev vuam no suav nrog kev siv cov coated electrodes. Qhov no txhais tau hais tias kev sib txuas yuav tau txais cov yam ntxwv ntawm lub zog zoo, txawm li cas los xij, qhov sib xyaw ntawm cov khoom tsim yuav yog qhov sib txawv ntawm cov thawj workpiece. Cov kev hloov kho tshwj xeeb yog txiav txim siab los ntawm cov khoom ntawm alloying deoxidizers,uas muaj nyob rau hauv electrode txheej. Piv txwv li, cov khoom siv xws li cov pa roj carbon tsawg ferromanganese, fluorspar, aluminium hmoov, thiab lwm yam tuaj yeem siv rau hauv cov khoom siv hluav taws xob, qhov no tooj liab vuam tshuab thiab kev ywj pheej ntawm cov txheej txheem tso cai. Feem ntau, kev sib xyaw qhuav yog siv rau qhov no, uas yog kneaded hauv kua iav. Xws li txheej ua rau cov seam ntau ntom, tab sis cov hluav taws xob conductivity ntawm cov qauv yog txo qis. Cov txheej txheem vuam dav dav nrog coated electrodes yog tus cwj pwm los ntawm kev sib tw siab, uas yog qhov tsis zoo rau tooj liab.

Submerged Arc Vuam

Lub flux nws tus kheej rau vuam nrog tooj liab yog xav tau los ua ib qho arc stabilizer thiab, qhov tseem ceeb tshaj plaws, raws li kev tiv thaiv kev tiv thaiv kev tsis zoo ntawm huab cua. Cov txheej txheem yog tsim los siv cov khoom siv tsis siv graphite lossis carbon electrodes, nrog rau cov pas nrig siv tau raws li cov khoom siv hluav taws xob. Yog tias siv cov pa roj carbon consumables, ces cov electrodes rau tooj liab welding yog sharpened los ua ib tug ca lub taub hau nyob rau hauv cov duab ntawm ib tug spatula. Cov khoom muab tub lim ua los ntawm tombac lossis tooj dag kuj tau muab rau thaj chaw ua haujlwm los ntawm sab - qhov no yog qhov tsim nyog los deoxidize tus qauv ntawm seam.

Kev ua haujlwm yog ua los ntawm cov hluav taws xob ncaj qha nrog cua sov. Ntau qhov kev tiv thaiv kev tiv thaiv tswj cov qauv ntawm cov khoom ua haujlwm, txawm hais tias feem ntau cov neeg ua haujlwm welders nrhiav kev txhim kho cov khoom siv nrog cov hlau alloy. Ntxiv dua thiab, txhawm rau tiv thaiv qhov tsis xav tau yaj ntws, nws raug nquahu kom pib muab cov graphite substrate,uas tseem yuav ua raws li daim ntawv rau cov flux. Qhov zoo tshaj plaws kev khiav hauj lwm kub rau txoj kev no yog 300-400 ° C.

Guarded Arc Vuam

Vuam txheej xwm nrog kev sib txuas ntawm inverters thiab lwm yam khoom siv semi-automatic yog nqa tawm hauv cov xov xwm gaseous nrog hlau pub. Hauv qhov no, ntxiv rau argon thiab nitrogen, helium, nrog rau ntau yam kev sib xyaw ua ke ntawm cov roj sib xyaw, tuaj yeem siv tau. Qhov zoo ntawm cov txheej txheem no suav nrog qhov muaj peev xwm nkag mus tau zoo ntawm cov workpieces tuab nrog qib siab ntawm kev khaws cia ntawm cov khoom siv kho tshuab ntawm lub workpiece.

Cov nyhuv thermal muaj zog tau piav qhia los ntawm cov ntshav plasma uas muaj txiaj ntsig zoo hauv qhov nruab nrab ntawm cov pa roj carbon monoxide, tab sis cov kev txwv no tseem yuav txiav txim siab los ntawm cov yam ntxwv ntawm cov qauv inverter tshwj xeeb. Nyob rau tib lub sijhawm, cov txheej txheem ntawm argon-arc vuam ntawm tooj liab yog qhov zoo dua nyob rau hauv kev sib raug zoo rau workpieces nrog lub thickness ntawm 1-2 hli. Raws li kev tiv thaiv kev ua haujlwm ntawm qhov nruab nrab gaseous, nws tsis tuaj yeem tso siab rau tag nrho. Tseem muaj kev pheej hmoo ntawm oxides, porosity thiab qhov tsis zoo ntawm cov khoom siv ntxiv los ntawm cov hlau. Ntawm qhov tod tes, argon ib puag ncig zoo tiv thaiv cov khoom ua haujlwm los ntawm cov pa oxygen hauv huab cua.

Zaj lus

tooj liab muaj ntau yam uas txawv nws ntawm lwm yam hlau. Tab sis txawm nyob rau hauv cov pab pawg neeg ntawm nws alloys muaj ntau qhov sib txawv, uas nyob rau hauv txhua rooj plaub yuav tsum tau mus nrhiav ib tug neeg mus kom ze rau xaiv qhov zoo tshaj plaws technology rau tsim ib tug seam. Piv txwv li, cov roj welding yog tsim nyog nyob rau hauv rooj plaub uas koj yuav tsum tau txais ib tug muaj zog kev twb kev txuas nyob rau hauv ib tug loj workpiece. Txawm li cas los xij, cov neeg tuaj tshiabTxoj kev no tsis pom zoo vim tias muaj kev nyab xeeb siab rau kev ua haujlwm nrog cov hluav taws kub hnyiab thiab lub tog raj kheej roj. High-precision me me-hom vuam kev ua haujlwm tau tso siab rau cov tshuab ua haujlwm yooj yim thiab ua tau zoo. Tus neeg teb xov tooj tsis muaj kev paub kuj tuaj yeem ua cov cuab yeej zoo li no, tswj xyuas tag nrho cov kev txwv ntawm kev ua haujlwm. Tsis txhob hnov qab txog qhov tseem ceeb ntawm gaseous media. Lawv tuaj yeem siv tsis tau tsuas yog ua ib qho insulator ntawm lub workpiece thaum lub sij hawm vuam, tab sis kuj yog ib txoj hauv kev los txhim kho qee qhov kev ua haujlwm thiab lub cev ntawm cov khoom. Tib yam siv rau electrodes, uas tuaj yeem ua rau muaj txiaj ntsig zoo alloying.

Pom zoo:

Sturgeon yug me nyuam hauv RAS: cov khoom siv, kev noj haus, kev txhawb nqa thev naus laus zis, kev tsim khoom thiab cov lus qhia los ntawm cov kws kho tsiaj tshwj xeeb

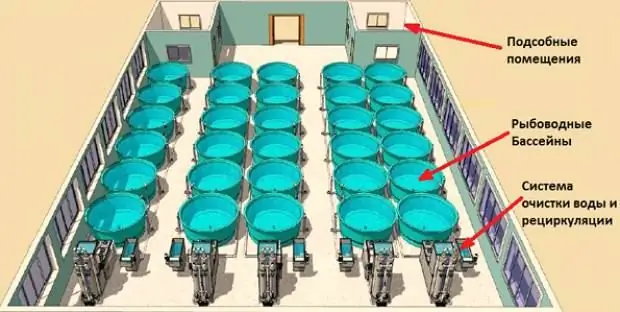

Sturgeon ua liaj ua teb yog ib lub lag luam uas cog lus tias yuav tau txais txiaj ntsig loj. Leej twg tuaj yeem ua tau, txawm lawv nyob qhov twg. Qhov no tuaj yeem ua tau vim yog kev siv cov tshuab xa dej rov qab (RAS). Thaum tsim lawv, nws tsuas yog tsim nyog los muab cov kev xav tau zoo, nrog rau thaj tsam xav tau. Nyob rau hauv cov ntaub ntawv no, cov ntses ua liaj ua teb yog tsim los ntawm hangar-hom vaj tse nyob rau hauv lub pas dej ua ke thiab ib tug purification system nyob rau hauv

Kev tsim cov khoom siv roj: cov txheej txheem thev naus laus zis, khoom siv thiab khoom siv

Hnub no, muaj ntau yam khoom siv hauv tsev uas nrov. Ib qho kev tsim kho tshiab yog kev tsim cov khoom siv roj av, uas yog cov pob zeb ntawm tes. Ntawm cov no, nws muaj txiaj ntsig tsis yog los tsim ib lub tsev ntiag tug xwb, tab sis kuj tsim khoom muag

Kev tsim cov plywood: thev naus laus zis, theem tseem ceeb ntawm cov txheej txheem thiab thaj chaw ntawm kev siv cov khoom siv

Plywood yog ib qho ntawm cov khoom siv pheej yig tshaj plaws thiab siv tau tshaj plaws. Txawm hais tias muaj ntau txheej txheej, nws yooj yim rau nruab thiab tuaj yeem ua tiav hauv tsev yam tsis muaj cov cuab yeej tshwj xeeb. Txuj kev tsim cov plywood suav nrog kev siv cov ntoo lamellas, nrog rau kev ua kom zoo uas koj tuaj yeem tau txais cov khoom tiav uas tiv taus ntau yam kev hem thawj

Vuam hauv qhov chaw tiv thaiv roj: ua haujlwm thev naus laus zis, txheej txheem piav qhia, cov txheej txheem ua tiav, cov khoom tsim nyog thiab cov cuab yeej, cov lus qhia ua haujlwm ib ntus thiab cov lus qhia kws tshaj lij

Vuam thev naus laus zis yog siv hauv ntau ceg ntawm tib neeg kev ua haujlwm. Versatility tau ua vuam nyob rau hauv ib puag ncig tiv thaiv roj ib qho tseem ceeb ntawm kev tsim khoom. Qhov ntau yam no ua rau nws yooj yim los txuas cov hlau nrog lub thickness ntawm 1 hli mus rau ob peb centimeters nyob rau hauv txhua txoj hauj lwm nyob rau hauv qhov chaw. Vuam nyob rau hauv ib puag ncig tiv thaiv yog maj mam hloov cov tsoos electrode vuam

Kev kho dua tshiab ntawm qhov chaw los ntawm vuam thiab ntog: cov txheej txheem thiab cov txheej txheem ntawm kev kho dua tshiab, nta, txheej txheem thev naus laus zis

Vuam thiab surfacing thev naus laus zis ua rau nws ua tau zoo los kho cov hlau seem, muab cov qib siab ntawm kev ntseeg siab thiab ua haujlwm ntev ntawm cov khoom. Qhov no tau lees paub los ntawm kev xyaum siv cov txheej txheem no thaum ua haujlwm kho hauv ntau qhov chaw - los ntawm kev kho tsheb mus rau kev tsim cov hlau dov. Hauv tag nrho cov nyiaj ua haujlwm ntawm kev kho cov qauv hlau, kev kho dua tshiab ntawm qhov chaw los ntawm kev vuam thiab surfacing yuav siv li 60-70%