2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Polymers synthesized los ntawm cov khoom siv roj, roj thiab thee ua, thiab lwm yam, rau kev tsim cov khoom tshwj xeeb - hluavtaws fiber. Cov khoom zoo li no yog siv rau hauv kev tsim cov xov paj siv los tsim cov ntaub rau ntau lub hom phiaj. Nylon thiab polyester yog cov piv txwv ntawm ntau hom ntawm cov khoom no.

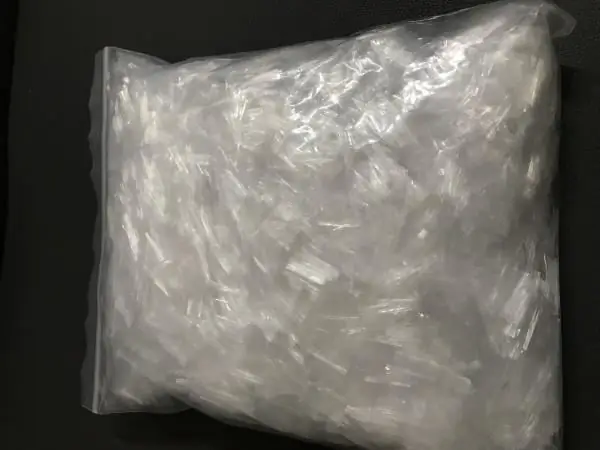

Tsis ntev los no, cov kws tshawb fawb tau tsim ntau yam tshiab ntawm cov hluavtaws fibers. Tag nrho cov ntau yam no muaj cov yam ntxwv ua tau zoo heev thiab tuaj yeem siv dav heev. Piv txwv li, ib qho ntawm cov khoom siv nrov tshaj plaws tam sim no yog pheej yig polypropylene fiber ntau.

yog dab tsi

Cov khoom siv niaj hnub no yog cov pab pawg ntawm polyolefins - high-molecular hydrocarbons ntawm aliphatic series. Hom fiber ntau no tiv taus ntau dua rau ob leeg khoov thiab elastic dua li polyamide. Lub melting point ntawm cov khoom no yog 165 ° C, ignition - 325-385 ° C. Qhov ntomPolypropylene fiber ntau yog 900-910kg / m 3.

Dab tsi yog qhov zoo thiab qhov tsis zoo

Qhov zoo ntawm cov khoom siv no, ntxiv rau cov qib siab txaus ntawm elasticity, suav nrog:

-

ua rau cov kua qaub, cov kuab tshuaj organic, alkalis;

- zog;

- zoo thermal rwb thaiv tsev zoo.

Qhov tsis zoo ntawm polypropylene fiber ntau yog lub teeb nrawm nrawm. Raws li kev cuam tshuam ntawm UV rays, cov khoom no pib tawg sai heev. Tsis tas li ntawd, qhov tsis zoo ntawm hom hluavtaws fiber ntau no tsis yog qhov siab heev ntawm kev hnav tsis kam. Tsis tas li ntawd, cov khoom zoo li no, hmoov tsis, tsis qiv nws tus kheej zoo rau qhov chaw staining.

Yuav ua li cas yog qhov muaj pes tsawg leeg

Cov khoom siv niaj hnub no yog tsim, raws li nws lub npe qhia, los ntawm polypropylene. Tsis tas li ntawd, cov tshuaj stabilizing tshwj xeeb tuaj yeem muab ntxiv rau hauv cov khoom sib txuas ntawm cov xov hluavtaws, tsim los ua kom lawv muaj zog:

- hnav tsis kam;

- kev nrawm nrawm.

Yuav ua li cas

Propylene yog cov khoom pheej yig, tab sis muaj ntau yam hais txog lub cev thiab tshuaj lom neeg. Nws yog tsim los ntawm kev siv cov cuab yeej siv niaj hnub zoo sib xws. Nyob rau tib lub sijhawm, muaj ob txoj hauv kev los rub cov polypropylene fiber ntau nws tus kheej:

- los ntawm kev daws;

- ntawmyaj.

Ua los ntawm mortar

Txoj kev tsim khoom no muaj ntau qhov tsis zoo. Nyob rau hauv industrial tej yam kev mob, nws yog siv, tab sis heev tsis tshua muaj. Siv cov txheej txheem no, cov fibers yog spun los ntawm cov ntsiab lus daws teeb meem ntawm propylene, uas paub tias yaj ntawm qhov kub thiab txias hauv ntau cov organic kua formulations. Nws tuaj yeem yog, piv txwv li, cov roj ntxhia lossis roj av. Thaum siv cov thev naus laus zis no, cov tshuaj rhuab tuaj yeem raug yuam los ntawm lub lim thiab nqaim qhov tuag los ntawm lub twj tso kua mis tshwj xeeb:

- rau hauv lub tshuab nqus tsev rau ntawm qhov cub superheated;

- rau hauv cov tshuaj ntawm butylene lossis propyl cawv ntawm cov kua.

Nyob rau hauv rooj plaub tom kawg, nyias cov kwj deg polypropylene yog cua tshuab ua ntej nkag mus rau cov kua hauv thaj tsam li ntawm 10 cm. Hauv kev sib xyaw cawv, lawv tau tso tawm los ntawm cov kuab tshuaj residues.

Thaum siv thawj txoj kev tsim khoom, hu ua qhuav, tiav xov yog thawj qhov txhab rau hauv bobbins. Tom qab ntawd cov khoom yog muab tso rau hauv da dej da dej nrog boiling dej. Qhov kev ua haujlwm no tseem tsim nyog los tshem tawm cov kuab tshuaj seem.

Ntxhais yaj production

Siv cov txheej txheem tsim khoom no, polypropylene fiber ntau yog tsim los ntawm cov tshuab tshwj xeeb spinning extrusion. Cov txheej txheem tseem ceeb ntawm cov khoom siv no yog:

- ntsia hlau extruder;

- spinning iav twj tso kua mis.

High viscosity polypropylene yaj hauv xws lilub tshuab yog pub rau lub twj tso kua mis nrog kev pab los ntawm ib tug cab, uas tso cai rau kom txo nws cov kub. Tom ntej no, cov khoom yog dhau los ntawm ib tug spinneret. Cov xov uas tawm ntawm cov xov kawg yog sib npaug los ntawm qhov ntws ntawm tus neeg ua haujlwm txias (feem ntau yog huab cua nrog cov av noo tas li thiab qhov kub thiab txias).

Txoj kev no ntawm kev tsim cov khoom siv polypropylene, piv nrog cov uas tau piav qhia saum toj no, feem ntau yog tus cwj pwm los ntawm kev tsim khoom ntau dua. Yog li ntawd, nws yog tus uas feem ntau siv thaum tso cov khoom no.

Khoom ntawm polypropylene fiber

Ntawm lwm yam, cov khoom ntawm ntau yam no muaj cov hauv qab no specifications:

- strength - 35-80 gs/tex;

- degree ntawm elongation nyob rau hauv ntub thiab qhuav xeev (tib yam taw qhia) - 30-40%;

- density - 0.91 g/cm3;

- degree ntawm Frost tsis kam - mus txog -70 ° C;

- hygroscopicity - 0.01-0.02%.

Cov khoom tsim los ntawm cov khoom siv, tig, muaj:

- lub teeb;

- puas tsuaj;

- me me ntawm capillary nce ntawm noo noo;

- kev kub ceev kom qhuav.

Qhov hnyav ntawm cov ntaub npuag ntawm polypropylene fiber ntau yog lub teeb uas nws tsis poob hauv dej. Nyob rau hauv cov nqe lus ntawm hnav tsis kam, ib daim ntaub ua los ntawm xws li threads, piv txwv li, yog me ntsis inferior rau tib polyamide. Tab sis tib lub sijhawm, nws tseem tuaj yeem ua haujlwm tau ntev.

Ntawm lwm yam, cov ntaub ntawv ua los ntawmpolypropylene fiber, tiv taus kab mob los ntawm fungus thiab microbes. Raws li, lawv kuj muaj cov khoom tu cev zoo. Polypropylene kuj tseem tiv taus cov kua qaub, alkalis thiab txawm tias aqua regia. Lwm qhov txiaj ntsig tsis txaus ntseeg ntawm cov ntaub ua los ntawm cov khoom siv no yog tias lawv tsis muaj hluav taws xob thiab muaj plua plav thiab av-tiv taus.

Kev thov ntawm polypropylene fiber

30% ntawm tag nrho cov polypropylene tsim los ntawm kev lag luam niaj hnub no yog siv rau kev tsim cov fiber ntau. Cov khoom no yeej nrov heev. Nws tuaj yeem siv rau kev tsim khoom:

- cov ntaub ruaj khov;

- txhuam (tsheb) tsim rau kev tu;

- khau thiab hnab;

- cement mortar;

- nuv ntses;

- ropes, hlua, ribes;

- ntaub pua plag thiab hnab.

Khaub ncaws los ntawm cov khoom no, vim nws nyuaj rau zas thiab tsis nqus dej noo zoo, tsis tshua muaj ua. Yeej, xws li threads yog siv rau zus tau tej cov ntaub fabrics. Ntxiv rau cov substrates, polypropylene fiber ntau tuaj yeem siv los ua:

- decorative npuag rau rooj tog upholstery;

- cov ntaub tiav;

- phais sutures thiab ntaub so ntswg;

- filter fabrics.

Polypropylene fiber ntau tsheb txhuam tus nqikim tshaj cov uas ua los ntawm bristles. Tab sis tib lub sij hawm lawv yog 10-20 lub sij hawm ntev dua. Nyob rau hauv cov nqe lus ntawm lub zog, polypropylene bristles yog 5 lub sij hawm siab dua li cov polystyrene haum. Nws yog qhov tsawg heev los hloov cov txhuam hniav ua nrog nws.

Nws siv tau qhov twg

Hauv kev tsim kho, polypropylene fiber ntau yog siv ntau hauv kev npaj cov cement. Nws siv nyob rau hauv cov ntaub ntawv no ua rau nws muaj peev xwm mus cuag ib tug uniform tis ntawm kev ntxhov siab nyob rau hauv tag nrho cov loj ntawm cov khoom.

Cov khoom siv no kuj tuaj yeem siv rau kev tsim cov fillers. Synthetic paj rwb yog spun los ntawm polypropylene fiber. Nyob rau hauv lub neej yav tom ntej, nws yog siv rau stuffing upholstered rooj tog. Tsis tas li ntawd, ib qho muab tub lim ua los ntawm cov tuab tuab polypropylene fibers feem ntau yog siv rau kev tsim cov riam. Nyob rau hauv cov ntaub ntawv no, tuab "bristles" tsuas yog muab tso rau hauv lub siab, nqaim lub thawv yas. Polypropylene fibers nyob rau hauv cov khoom no yooj yim tuav riam upright.

Pom zoo:

Pyrotechnic muaj pes tsawg leeg: kev faib tawm, cov khoom siv, daim ntawv thov

Ib pyrotechnic muaj pes tsawg leeg yog ib yam khoom los yog sib tov ntawm cov khoom tsim los tsim cov nyhuv ntawm cov cua sov, lub teeb, suab, roj, pa luam yeeb, los yog ib qho kev sib xyaw ua ke, raws li nws tus kheej txhawb nqa exothermic tshuaj tiv thaiv uas. coj qhov chaw tsis muaj detonation. Cov txheej txheem zoo sib xws tsis yog nyob ntawm cov pa oxygen los ntawm lwm qhov chaw

Khoom noj khoom haus silicone: muaj pes tsawg leeg, daim ntawv thov

Khoom noj khoom haus qib silicone feem ntau yog siv rau ci pwm. Tsis tas li ntawd, cov tais diav thiab ntau yam khoom siv hauv chav ua noj yog tsim los ntawm nws. Qhov zoo ntawm cov khoom no suav nrog, ua ntej ntawm tag nrho cov, zoo heev uas tsis yog-stick zog thiab hypoallergenicity

Hlau sulphate: muaj pes tsawg leeg, mis, khoom, lub hom phiaj thiab daim ntawv thov

Vim hlau sulphate yog ib qho yooj yim-rau-ua thiab yooj yim muaj tshuaj, nws yog dav siv nyob rau hauv ntau yam kev siv. Nyob rau hauv lub neej txhua hnub, nws yog ib tug zoo-paub hlau sulphate, feem ntau nyob rau hauv vaj. Yog hais tias peb tham txog kev siv ntawm ib tug loj scale, ces nws yog siv tsis tau tsuas yog nyob rau hauv kev ua liaj ua teb sector, tab sis kuj nyob rau hauv kev lag luam

Zirconium alloys: muaj pes tsawg leeg, khoom, daim ntawv thov

Tam sim no, cov khoom siv xws li zirconium alloy tau dhau los siv dav hauv qee qhov chaw. Cov kws tshawb fawb txheeb xyuas ntau qhov zoo ntawm cov khoom siv no

Cement slurry: cov khoom, kev npaj cov cai, muaj pes tsawg leeg, ua raws li GOST cov cai, lub hom phiaj thiab daim ntawv thov

Thaum lub sijhawm drilling, cov kev daws teeb meem tshwj xeeb yog siv los tshem tawm cov txiav thiab cov khoom los ntawm kev txhim kho pob zeb hauv zos. Qhov kev ua haujlwm no yog qhov tsim nyog los ua kom muaj kev ua tau zoo ntawm cov neeg kho tshuab kev cuam tshuam ntawm qhov drilling rig thiab tshem tawm qhov hauv qab. Kev ntxuav tawm yog nqa tawm siv cov cement slurries, uas tau npaj siv cov thev naus laus zis tshwj xeeb