2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2024-01-17 18:53

Carbon dub (GOST 7885-86) yog hom kev lag luam carbon cov khoom siv feem ntau hauv kev tsim cov roj hmab ua cov muab tub lim uas txhim kho nws cov txiaj ntsig zoo. Tsis zoo li coke thiab suab, nws muaj yuav luag ib qho carbon, nws zoo li soot.

Scope of application

Kwv yees li 70% ntawm cov khoom siv roj carbon dub yog siv rau kev tsim cov log tsheb, 20% - rau cov khoom siv roj hmab. Tsis tas li ntawd, cov pa roj carbon monoxide yog siv rau hauv cov xim thiab cov kua roj vanish thiab hauv kev tsim cov ntawv luam ntawv, qhov twg nws ua raws li cov xim dub.

Lwm thaj chaw ntawm daim ntawv thov yog kev tsim cov yas thiab cable sheaths. Ntawm no cov khoom yog ntxiv raws li ib tug muab tub lim thiab muab cov khoom tshwj xeeb cov khoom. Cov pa roj carbon dub kuj tseem siv rau hauv cov ntim me me hauv lwm qhov kev lag luam.

yam ntxwv

Cov pa roj carbon dub yog cov khoom lag luam ntawm cov txheej txheem uas suav nrog kev tsim kho tshiab thiab kev tswj hwm cov txheej txheem. Vim nws purity thiab nruj me ntsis teevLub cev thiab tshuaj lom neeg lub zog, nws tsis muaj dab tsi ua nrog cov kua qaub uas ua rau cov khoom qias neeg los ntawm kev kub hnyiab ntawm cov thee thiab cov roj roj, lossis los ntawm kev ua haujlwm ntawm cov tshuab tsis muaj kev sib txuas nrog lub tshuab hluav taws xob. Raws li kev faib thoob ntiaj teb feem ntau lees paub, carbon dub yog tsim Carbon Black (cov pa roj carbon dub txhais los ntawm Askiv), soot hauv lus Askiv yog soot. Ntawd yog, cov ntsiab lus tam sim no tsis sib xyaw ua ke.

Cov txiaj ntsig ntawm kev txhawb nqa vim yog txhaws ntawm cov roj hmab nrog cov pa roj carbon dub tsis yog qhov tseem ceeb rau kev txhim kho cov roj hmab kev lag luam tshaj qhov kev tshawb pom ntawm qhov tshwm sim ntawm vulcanization ntawm roj hmab nrog leej faj. Nyob rau hauv cov roj hmab tebchaw, carbon los ntawm ib tug loj tus naj npawb ntawm cov khoom xyaw siv los luj yuav siv sij hawm qhov chaw thib ob tom qab roj hmab. Kev cuam tshuam ntawm qhov ntsuas zoo ntawm cov pa roj carbon dub ntawm cov khoom ntawm cov khoom siv roj hmab yog ntau dua li qhov ntsuas qhov zoo ntawm cov khoom tseem ceeb - roj hmab.

Txoj kev muaj zog

Txhim kho lub cev lub cev ntawm cov khoom siv los ntawm kev qhia cov khoom siv yog hu ua kev txhawb zog (reinforcement), thiab cov khoom siv no hu ua amplifiers (carbon dub, precipitated silicon oxide). Ntawm tag nrho cov amplifiers, technical carbon muaj cov yam ntxwv tshwj xeeb. Txawm tias ua ntej vulcanization, nws khi rau roj hmab, thiab qhov sib tov no tsis tuaj yeem sib cais tag nrho rau hauv cov pa roj carbon dub thiab roj hmab nrog cov kuab tshuaj.

Lub zog ntawm cov roj hmab raws li qhov tseem ceeb tshaj plaws elastomers:

| Elastomer | Tensile zog, MPa | |

| Unfilled vulcanizate | Vulcanizate puv nrog carbon dub | |

| Styrene Butadiene Rubber | 3,5 | 24, 6 |

| NBR | 4,9 | 28, 1 |

| EPDM | 3,5 | 21, 1 |

| YPolyacrylate roj hmab | 2, 1 | 17, 6 |

| YPolybutadiene roj hmab | 5,6 | 21, 1 |

Lub rooj qhia cov khoom ntawm vulcanizates tau los ntawm ntau hom roj hmab uas tsis tau sau thiab ntim nrog cov pa roj carbon dub. Los ntawm cov ntaub ntawv saum toj no, nws tuaj yeem pom tias carbon filling cuam tshuam li cas rau lub zog tensile ntawm roj hmab. Los ntawm txoj kev, lwm cov hmoov dispersed siv nyob rau hauv cov roj hmab tebchaw muab cov xim uas xav tau los yog txo tus nqi ntawm cov sib tov - chalk, kaolin, talc, hlau oxide thiab lwm yam tsis muaj zog ntxiv zog.

qauv

Ntshiab carbons yog pob zeb diamond thiab graphite. Lawv muaj cov qauv crystalline uas txawv ntawm ib leeg. Qhov zoo sib xws hauv cov qauv ntawm ntuj graphite thiab cov khoom siv dag zog carbon dub tau tsim los ntawm X-ray diffraction. Cov pa roj carbon atoms hauv graphite tsim cov txheej txheem loj ntawm condensed aromatic nplhaib systems, nrog kev sib cuam tshuam ntawm 0.142 nm. Cov txheej graphite nocondensed aromatic systems yog hu ua basal dav hlau. Qhov kev ncua deb ntawm cov dav hlau yog nruj me ntsis txwv thiab yog 0.335 nm. Txhua txheej yog parallel rau ib leeg. Qhov ceev ntawm graphite yog 2.26g / cm 3.

Tsis zoo li graphite, uas muaj qhov kev txiav txim peb-dimensional, cov pa roj carbon monoxide yog tus cwj pwm los ntawm kev txiav txim ob sab xwb. Nws muaj cov dav hlau graphite tsim tau zoo, nyob ze ntawm qhov sib npaug rau ib leeg, tab sis offset nrog kev hwm rau cov khaubncaws sab nraud povtseg - uas yog, cov dav hlau yog arbitrarily oriented nrog kev hwm rau qhov qub.

Cov qauv graphite yog piv rau piv rau lub lawj folded zoo nkauj ntawm daim npav, thiab cov qauv carbon dub piv rau lub lawj ntawm daim npav uas cov ntawv hloov pauv. Nyob rau hauv nws, qhov kev ncua deb ntawm interplanar yog ntau dua li ntawm graphite thiab yog 0.350-0.365 nm. Yog li ntawd, qhov ceev ntawm carbon dub yog qis dua qhov ceev ntawm graphite thiab nyob rau hauv thaj tsam ntawm 1.76-1.9 g / cm3, nyob ntawm hom (feem ntau 1.8 g / cm 3).

Xim

Pigmented (xim) qib ntawm carbon dub yog siv rau hauv kev tsim cov ntawv luam ntawv, txheej, yas, fibers, ntawv thiab khoom siv hauv tsev. Lawv muab faib ua:

- siab xim carbon dub (HC);

- medium (MS);

- xim xim (RC);

- xim qis (LC).

Tsab ntawv thib peb qhia txog txoj kev tau txais - rauv (F) lossis channel (C). Piv txwv li: HCF - High Colour Furnace Black (Hiqh Color Furnace).

Lub zog xim ntawm cov khoom muaj feem cuam tshuam rau nws qhov loj me. Nyob ntawm lawv qhov loj me, cov khoom siv hluav taws xob tau muab faib ua pawg:

| Average particle loj, nm | Kub dub qib |

| 10-15 | HCF |

| 16-24 | MCF |

| 25-35 | RCF |

| >36 | LCF |

Kev faib tawm

Cov pa roj carbon monoxide rau roj hmab raws li qib ntawm kev txhawb zog ntxiv yog muab faib ua:

- Kev txhawb zog siab (tread, nyuaj). Nws yog faib nrog qhov nce durability thiab resilience rau attrition. Qhov loj me me (18-30 nm). Siv nyob rau hauv conveyor siv, log tsheb treads.

- Semi-reinforced (lub hauv paus, mos). Qhov loj me me yog qhov nruab nrab (40-60 nm). Lawv siv rau hauv cov khoom siv roj hmab sib txawv, lub log tsheb carcasses.

- nce qis. Qhov loj me me yog loj (tshaj 60 nm). Kev txwv tsis pub siv hauv kev lag luam log tsheb. Muab lub zog tsim nyog thaum tuav cov elasticity siab hauv cov khoom siv roj hmab.

Ua tiav kev faib tawm ntawm cov pa roj carbon dub tau muab rau hauv ASTM D1765-03, lees txais los ntawm tag nrho cov tuam ntxhab thiab cov neeg siv khoom thoob ntiaj teb. Hauv nws, kev faib tawm, tshwj xeeb, yog ua raws li thaj tsam ntawm thaj chaw tshwj xeeb ntawm cov khoom:

| Group | Average ib cheeb tsamnto los ntawm nitrogen adsorption, m2/g |

| 0 | >150 |

| 1 | 121-150 |

| 2 | 100-120 |

| 3 | 70-99 |

| 4 | 50-69 |

| 5 | 40-49 |

| 6 | 33-39 |

| 7 | 21-32 |

| 8 | 11-20 |

| 9 | 0-10 |

Kev tsim cov pa roj carbon dub

Muaj peb lub thev naus laus zis los tsim cov pa roj carbon dub uas siv lub voj voog tawg tsis tiav ntawm hydrocarbons:

- furnace;

- tube;

- plasma.

Tseem kuj tseem muaj cov txheej txheem thermal uas decomposes acetylene lossis natural gas ntawm qhov kub thiab txias.

Ntau qib ua los ntawm cov thev naus laus zis sib txawv muaj cov yam ntxwv sib txawv.

Tsev tsim khoom

Txoj kev xav, nws tuaj yeem tau txais cov pa roj carbon dub los ntawm tag nrho cov txheej txheem saum toj no, txawm li cas los xij, ntau dua 96% ntawm cov khoom tsim tawm yog tau los ntawm cov txheej txheem rauv los ntawm cov khoom siv kua. Txoj kev ua rau nws muaj peev xwm tau txais ntau qib ntawm cov pa roj carbon dub nrog rau qee yam khoom siv. Piv txwv li, Omsk Carbon Black Plant tsim ntau tshaj 20 qib ntawm carbon dub siv lub tshuab no.

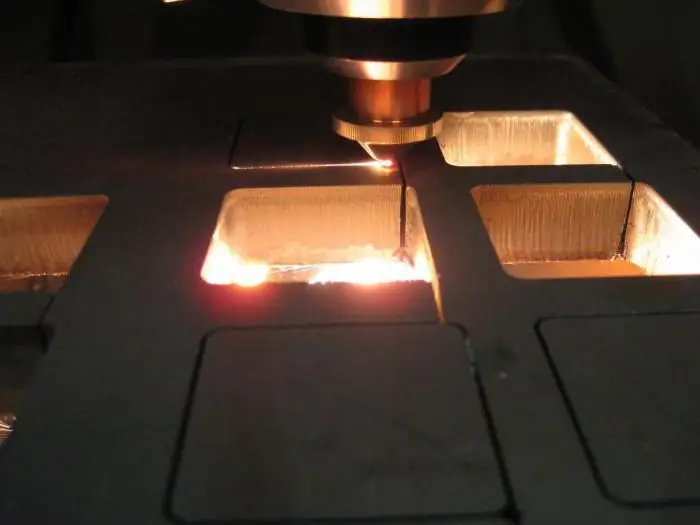

Kev siv tshuab dav dav yog qhov no. Lub reactor, lined nrog cov ntaub ntawv refractory heev, yog pub nrog cov pa roj thiab cua sov rau 800 ° C. Vim yog combustion ntawm natural gas, cov khoom ntawm tag nrho combustion yog tsim nrog ib tug kub ntawm 1820-1900 ° C, muaj ib tug tej yam nqi ntawm cov pa dawb. Cov ntaub ntawv ua kua hydrocarbon yog txhaj rau hauv cov khoom kub kub ntawm kev ua kom tiav, sib xyaw ua ntej thiab ua kom sov rau 200-300 ° C. Lub pyrolysis ntawm raw cov ntaub ntawv yuav siv sij hawm qhov chaw nyob rau hauv ib tug nruj tswj kub, uas, nyob ntawm seb lub hom ntawm cov carbon dub tsim, muaj qhov sib txawv ntawm 1400 txog 1750 ° C.

Ntawm qhov deb ntawm qhov chaw ntawm cov khoom siv raw, cov tshuaj tiv thaiv thermo-oxidative nres los ntawm kev txhaj tshuaj dej. Cov pa roj carbon dub thiab cov tshuaj tiv thaiv gases tsim los ntawm pyrolysis nkag mus rau hauv lub tshuab cua sov, qhov uas lawv muab ib feem ntawm lawv cov cua sov rau cov cua siv hauv cov txheej txheem, thaum qhov kub ntawm cov pa roj carbon sib tov txo los ntawm 950-1000 ° C rau. 500-600 ° C.

Tom qab txias rau 260-280 ° C vim kev txhaj tshuaj ntxiv, cov pa roj carbon dub thiab cov roj sib xyaw xa mus rau lub hnab lim, qhov twg cov pa roj carbon dub tau cais tawm ntawm cov pa roj thiab nkag mus rau lub lim dej. Cov pa roj carbon dub sib cais los ntawm lub lim lim yog pub los ntawm cov kav dej los ntawm lub kiv cua (turbo blower) mus rau seem granulation.

Carbon dub producers

Ntiaj teb kev tsim cov pa roj carbon dub tshaj 10 lab tons. Xws li qhov kev thov zoo rau cov khoom tau piav qhia, ua ntej ntawm tag nrho, los ntawm nws cov khoom tshwj xeeb txhawb zog. Cov locomotives ntawm kev lag luam yog:

- Aditya Birla Group (India) - kwv yees li 15% ntawm kev ua lag luam.

- Cabot Corporation (USA) - 14% ntawm kev ua lag luam.

- Orion Engineered Carbons (Luxembourg) - 9%.

Cov neeg tsim khoom loj tshaj plaws hauv tebchaws Russia:

- Omsktehuglerod LLC - 40% ntawm Lavxias teb sab kev ua lag luam. Factories hauv Omsk, Volgograd, Mogilev.

- JSC Yaroslavl Technical Carbon - 32%.

- JSC Nizhnekamsktekhuglerod - 17%.

Pom zoo:

Technical passport rau ib chav tsev: yuav ua li cas kom tau nws, leej twg muab nws thiab lub sij hawm siv tau

Ib ntawm cov ntaub ntawv tseem ceeb tshaj plaws uas tau tshaj tawm thaum tau txais lub tsev tshiab yog daim ntawv hla tebchaws kev tshaj lij rau chav tsev. Tej zaum nws yuav zoo li nws tsis tseem ceeb npaum li cov ntaub ntawv ntawm kev tsim cov tswv cuab ntawm vaj tse lossis cov ntaub ntawv pov thawj ntawm lub npe

Cov ntaub ntawv carbon yog dab tsi? Kev siv cov pa roj carbon fiber ntau hauv kev ua haujlwm

Cov ntaub ntawv carbon yog dab tsi? Qhov no yog ib yam khoom uas muaj lub teeb heev thiab muaj zog fibers ntawm ib tug reinforced polymer. Ntawm nws cov tub ntxhais, cov polymer no yog cov saw ntev ntawm cov molecules tuav ua ke los ntawm carbon atoms. Feem ntau, cov polymer siv los ua cov ntaub ntawv carbon yog cuaj caum feem pua carbon tov nrog kaum feem pua ntawm lwm yam additives

Roj ntau lawm hauv ntiaj teb. Roj ntau lawm nyob rau hauv lub ntiaj teb no ( rooj)

Lub ntiaj teb li peb paub nws yuav txawv heev yog tias tsis muaj roj. Nws yog ib qho nyuaj rau xav txog tias muaj pes tsawg yam khoom txhua hnub yog tsim los ntawm cov roj. Synthetic fibers uas ua rau cov khaub ncaws, tag nrho cov yas siv nyob rau hauv lub neej txhua hnub thiab kev lag luam, tshuaj, tshuaj pleev ib ce - tag nrho cov no yog tsim los ntawm cov roj. Yuav luag ib nrab ntawm lub zog siv los ntawm noob neej yog tsim los ntawm roj. Nws yog siv los ntawm aircraft xyaw, nrog rau yuav luag tag nrho cov tsheb nyob rau hauv lub ntiaj teb no

Pob kws yield: qhov nruab nrab, ntau lawm technology thiab ntau yam

Pob kws yog cov qoob loo muaj txiaj ntsig uas tau cog rau ntau thaj tsam ntawm peb lub tebchaws. Hauv 2018, piv txwv li, kwv yees li 2.5 lab hectares ntawm thaj av tau nyob rau hauv Russia. Cov qoob loo ntawm pob kws nyob ntawm ntau yam. Txawm li cas los xij, kev cog qoob loo ntawm cov qoob loo no tuaj yeem tsim nyog tsuas yog yog tias cov txheej txheem kev saib xyuas yuav tsum tau ua nruj me ntsis thiab xaiv ntau yam kom raug

Ytterbium fiber ntau laser: ntaus ntawv, kev khiav hauj lwm hauv paus ntsiab lus, lub zog, ntau lawm, daim ntawv thov

Fiber lasers yog compact thiab rugged, taw tes precisely thiab dissipate thermal zog yooj yim. Lawv tuaj hauv ntau hom thiab, muaj ntau yam sib xws nrog lwm hom optical quantum generators, muaj lawv tus kheej zoo