2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Cov yas muaj zog siab tau siv ntau dua hauv kev tsim kho thiab tsim khoom. Lawv zoo tshaj rau cov khoom siv tawv tawv vim lawv qhov hnyav, malleability thiab practicality. Txawm li cas los xij, hlau tseem nyob hauv ntau qhov kev lag luam uas yog cov khoom siv zoo tshaj plaws ntawm kev sib xyaw ua ke ntawm lub zog, rigidity thiab durability. Nyob rau tib lub sijhawm, kev siv cov qauv tsim tsis yog ib txwm ua rau nws tus kheej. Ntau zuj zus, cov kws tshaj lij siv hlau txau, uas tso cai rau koj tso cai rau cov khoom ua haujlwm nrog qee yam ntawm cov khoom siv uas haum tshaj plaws hauv kev ua haujlwm.

Cov ntaub ntawv dav dav txog metallization technologies

Ntawm cov txheej txheem niaj hnub ntawm kev ua kom zoo nkauj, galvanic deposition, nrog rau immersion hauv melts, feem ntau siv. Kev siv thev naus laus zis tseem suav nrog lub tshuab nqus tsev sputtering, uas muaj nws cov kev faib tawm nyob ntawm cov khoom siv siv. Ib txoj hauv kev los yog lwm qhov, kev tso tawm ntawm cov hlau yuav ua rau lub hauv paus ntawm cov khoom siv kom tau txais qee yam kev tiv thaiv zoo. Qhov no tuaj yeem yog tsim los ntawm cov txheej txheem tiv thaiv corrosion, kho dua tshiab ntawm cov qauv ploj, lossis kho cov khoom siv coj los siv.

Tib lub sijhawm, qhov chaw ua haujlwm nws tus kheej yogfeem ntau nws yog kho cua sov. Ua ntej siv cov khoom siv hlau, nws yog melted los ntawm burners, inductors los yog raug rau cov ntshav plasma tsawg. Yog li, lub hauv paus nrog kev pom zoo ntawm lub cev thiab tshuaj zoo yog npaj, uas cov hlau tau tom qab txau rau hauv daim ntawv ntawm cov hmoov. Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias tib cov hlau, iav, yas lossis qee hom ntoo thiab pob zeb tuaj yeem ua cov khoom tseem ceeb.

Tshuaj chromium plating method

Tshuaj reagents yog siv los ua ib feem tseem ceeb rau kev ua raws li qhov tso tawm. Cov muaj pes tsawg leeg muaj xws li chromium chloride, sodium, acetic acid, thiab dej nrog rau kev daws ntawm caustic soda. Cov txheej txheem txau yog nqa tawm ntawm qhov kub txog li 80 ° C. Kev ua haujlwm pib nrog kev npaj cov khoom siv. Feem ntau, chromium plating yog siv los kho cov hlau nto, tshwj xeeb yog hlau. Ua ntej qhov kev ua haujlwm nws tus kheej, cov khoom siv tau raug rau lub txheej txheej txheej nrog tooj liab. Tom ntej no, tshuaj chromium plating yog ua los ntawm kev siv sandblaster txuas nrog lub tshuab compressor. Tom qab cov txheej txheem tiav lawm, cov khoom raug ntxuav hauv dej huv thiab qhuav.

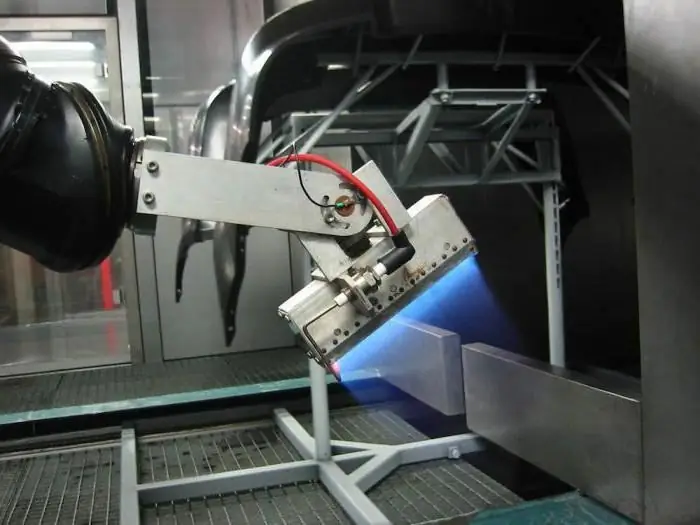

Txoj kev kho nplaim taws

Yog tias yav dhau los thev naus laus zis muab kev npaj txhij txog ntawm lub hauv paus kom coated, qhov no, tshwj xeeb yog them nyiaj rau cov khoom metallization. Cov nplaim hluav taws niaj hnub no tuaj yeem nqa tau siv cov hmoov polymer, xaim lossiscov khoom siv hlua. Qhov loj no raug xa mus rau cov nplaim hluav taws ntawm cov pa oxygen-propane lossis acetylene-oxygen burner, uas nws yog yaj thiab xa mus rau lub hauv paus txau los ntawm huab cua compressed. Tsis tas li ntawd, qhov sib xyaw ua ke txias, tsim cov txheej txheem npaj siv.

Nrog kev pab ntawm cov txheej txheem no, nws muaj peev xwm muab cov khoom siv nrog kev tiv thaiv corrosion thiab lub zog txhua yam. Cov khoom siv nquag tuaj yeem ua cov txhuas, npib tsib xee, zinc, hlau thiab tooj liab alloys. Tshwj xeeb, cov nplaim hluav taws yog siv los txhim kho cov kev ua tau zoo ntawm cov bearings, insulating coatings, cov khoom siv hluav taws xob, thiab lwm yam. Tsis tas li ntawd, cov cuab yeej siv rau sab hauv thiab vaj tse tsim los muab cov qauv nrog cov khoom zoo nkauj.

Nqus deposition method

Nyob rau hauv cov ntaub ntawv no, peb tab tom tham txog ib pab pawg ntawm cov txheej txheem uas koom nrog kev tsim cov yeeb yaj kiab nyias hauv lub tshuab nqus tsev nyob rau hauv qhov cuam tshuam ntawm cov vapor condensation ncaj qha. Kev siv tshuab yog siv ntau txoj hauv kev, suav nrog kev ua haujlwm thermal, evaporation los ntawm electron thiab laser beams. Lub tshuab nqus tsev vacuum yog siv los txhim kho cov khoom zoo ntawm cov khoom, cov cuab yeej thiab cov cuab yeej. Piv txwv li, kev ua haujlwm zoo li no tso cai rau tsim tshwj xeeb "ua haujlwm" txheej uas tuaj yeem txhim kho hluav taws xob conductivity, insulating zog, hnav tsis kam thiab tiv thaiv corrosion.

Cov cuab yeej siv kuj tseem siv los tsim cov txheej txheem zoo nkauj. Nyob rau hauv cov ntaub ntawv no, cov txheej txheem yuav siv tau nyob rau hauv kev khiav hauj lwm uas yuav tsum tau high precision. Piv txwv li, nqus tsev vacuumsputtering yog siv nyob rau hauv kev tsim cov kub-plated watches, muab ib tug zoo nkauj tsos rau cov tsom iav, thiab lwm yam.

Khoom siv siv

Feem ntau yog siv rau cov cuab yeej tshuaj tsuag uas muaj lub ntsej muag supersonic. Ib lub tshuab hluav taws xob me me uas siv los ntawm cov cua compressed kuj tseem siv tau. Ib qho tshwj xeeb ntawm cov qauv tshiab tshaj plaws yog qhov muaj peev xwm nqa tau qhov kub txog li 600 ° C. Txog thaum tsis ntev los no, kev siv cov khoom siv txheem, nco txog lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm pneumatic pistols, yog qhov nyuaj los ntawm qhov tseeb tias cov khoom hnav tawm lub nozzles ntawm lub cuab yeej. Cov cuab yeej siv niaj hnub no, ua tsaug rau cov hlau txau yog nqa tawm, siv lub hauv paus ntsiab lus ntawm rab phom txau. Qhov no txhais tau hais tias thaum lub sijhawm ua haujlwm gaseous nruab nrab dhau los ntawm lub dav hlau xa khoom, qhov ntws nrawm nce ntxiv thaum cov yeeb nkab nqaim. Nyob rau tib lub sijhawm, lub siab zoo li qub kuj txo qis. Lub hauv paus ntsiab lus ntawm kev ua haujlwm no txo qhov hnav thiab ua kom lub neej ua haujlwm ntawm cov khoom siv.

Zaj lus

txhawm rau txo tus nqi ntawm kev ua haujlwm thev naus laus zis los tiv thaiv cov hlau los ntawm kev cuam tshuam sab nraud, tshwj xeeb heev, tab sis tsis tshua muaj txiaj ntsig txhais tau siv ntau zaus. Nyob rau tib lub sijhawm, cov tshuaj tsuag hlau kuj tseem pab txuag nyiaj, tus nqi ntawm qhov nruab nrab yog 8-10 txhiab rubles. rau qhov nthuav dav. Kev muaj peev xwm nyiaj txiag yog vim qhov tseeb tias cov txheej txheem zoo li no tuaj yeem muab ntau yam kev ua haujlwm zoo ib zaug. Piv txwv li, los ntawm machining ib tug hlau tivthaiv ntawm lub ru tsev qauv, koj yuav tau txaiscov khoom xws li kev tiv thaiv corrosion, tiv thaiv los nag, kev tiv thaiv txhua yam. Kuj tseem muaj cov txheej tshwj xeeb metallized uas tuaj yeem tiv thaiv qhov cuam tshuam ntawm cov tshuaj lom neeg thiab thermal influences.

Pom zoo:

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

Nruam nruam ntawm cov hlau: txoj hauv kev ntawm kev ua haujlwm, cov khoom tsim nyog, qhov zoo thiab qhov tsis zoo ntawm txoj kev

Hnub no, ntau ntau yam khoom, qhov chaw, thiab lwm yam yog ua los ntawm cov hlau, Yog lawm, qhov no yuav tsum muaj ntau yam khoom siv. Yog li ntawd, cov nroj tsuag tau ntev tau siv txoj kev nruam nruam ntawm cov hlau, uas yog qhov tseem ceeb tshaj plaws feature - high productivity

Txoj cai ntawm cov khoom lag luam ntawm cov khoom siv emission. Kev txiav txim ntawm cov khoom muag thiab qhov muaj pes tsawg leeg ntawm cov khoom muag commission

Cov khoom pov tseg pov tseg rau hauv cov huab cua yog txheej txheej ntawm cov dej num uas ua los ntawm cov neeg siv xwm txheej, suav nrog kev tsim cov ntaub ntawv ntawm cov pa phem, kev txheeb xyuas lawv qhov chaw, kev txiav txim siab ntawm cov paib ntsuas. Nyeem ntxiv txog yuav ua li cas cov txheej txheem no mus thiab yuav ua li cas cov khoom lag luam ntawm emissions tau sau rau hauv, nyeem rau

Yuav ua li cas los ua tus neeg muag khoom zoo: lub tswv yim ntawm lub hauv paus ntawm kev ua haujlwm, thawj theem, tau txais kev paub dhau los, kev muag khoom, cov kev pabcuam zoo thiab muaj peev xwm piav qhia txhua qhov zoo ntawm kev yuav khoom

Yuav ua li cas thiaj ua tau tus neeg muag khoom zoo? Koj puas xav tau kev txawj ntse, lossis ib tus neeg tuaj yeem txhim kho qhov tsim nyog ntawm nws tus kheej? Leej twg tuaj yeem dhau los ua tus thawj coj zoo. Nws tsuas yog qhov ntawd rau qee tus neeg, tau txais cov txuj ci tsim nyog yuav yooj yim, thaum lwm tus yuav tau siv zog ntau. Tab sis thaum kawg, ob leeg yuav muag zoo sib xws

Kev txiav txim siab ntawm kev ua vaj tse: txoj hauv kev, khoom siv, GOST. Kev tswj thiab kev ntsuam xyuas ntawm cov pob zeb ua kom muaj zog

Thaum kuaj xyuas cov qauv hauv tsev, kev txiav txim siab ntawm lub zog ntawm cov pob zeb ua tiav los txiav txim siab lawv lub xeev nyob rau lub sijhawm tam sim no. Kev ua tau zoo tiag tiag tom qab pib ua haujlwm feem ntau tsis phim cov qauv tsim