2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

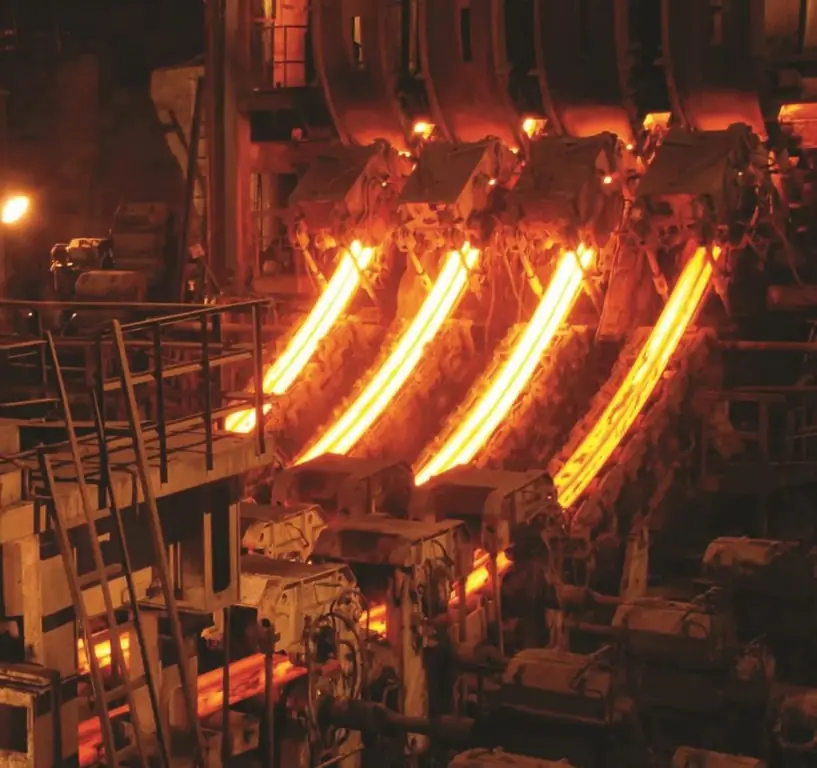

Hnub no, ntau ntau yam khoom, qhov chaw, thiab lwm yam yog ua los ntawm cov hlau, Yog lawm, qhov no yuav tsum muaj ntau yam khoom siv. Yog li ntawd, cov nroj tsuag tau ntev tau siv txoj kev nruam nruam ntawm cov hlau, uas yog qhov tseem ceeb tshaj plaws feature - high productivity.

khoom siv tseem ceeb rau kev ua haujlwm

Txog hnub tim, ntau qhov kev teeb tsa rau cov hlau nplaum hauv txoj kev no tau paub, thiab lawv raug hu ua UNRS. Thaum xub thawj, ib qho ntsug-hom kev teeb tsa tau tsim thiab muab tso rau hauv kev tsim khoom, nyob ntawm 20-30 meters hauv qab theem ntawm lub rooj cob qhia pem teb. Txawm li cas los xij, tom qab ntawd lub siab xav tso tseg qhov kev sib sib zog nqus hauv pem teb los ua lub cav tseem ceeb rau kev txhim kho cov kev teeb tsa no. Qhov no coj mus rau kev txhim kho thiab kev siv ntauwd-hom nruam casting nroj tsuag. Qhov siab ntawm cov kev teeb tsa no yog 40 m. Txawm li cas los xij, lub tshuab no tsis tau siv dav rau ob qho laj thawj. Ua ntej, tsimxws li ib chav nyob rau hauv lub rhiav yog heev teeb meem thiab laborious. Thib ob, txawm tias muaj teeb meem ntau dua nrog nws txoj haujlwm.

nkhaus thiab radial installation

Lub sijhawm dhau mus, kev nruam nruam ntawm cov hlau tau hloov mus ua haujlwm nrog cov tshuab ntsug ntsug. Lub ntsiab feature yog khoov ntawm lub ingot tawm tom qab lub shafts los ntawm 90 degrees. Tom qab ntawd, ib tug tshwj xeeb straightening mechanism tau siv nyob rau hauv lub installation kom ncaj lub ingot, thiab tsuas yog tom qab no theem ua lub txiav. Kev nruam nruam ntawm cov hlau ntawm cov cuab yeej zoo li no tsis tau nrov heev vim qee yam. Ua ntej, qhov khoov, tau kawg, ua kom txo tau qhov siab, tab sis tib lub sij hawm txwv tsis pub hla ntu ntawm ingot nws tus kheej. Qhov ntau nws yog qhov tsim nyog kom tau txais ib feem ntawm cov khoom siv, qhov khoov ntau dua yuav tsum yog, uas txhais tau hais tias qhov siab tau nce ntxiv. Qhov thib ob, cov tshuab dabtsi yog khoov tau muab tso rau hauv cov khw muag khoom hlau uas muaj teeb meem ntau dua li qhov ntsug.

Hnub no, kev teeb tsa rau kev nruam nruam ntawm cov hlau radial tau txais ntau thiab ntau qhov chaw. Nyob rau hauv xws li ib tug unit, lub ingot yog tsim nyob rau hauv lub pwm thiab tawm nws nyob rau tib lub arc raws li nws nkag mus rau nws. Tom qab ntawd, nws yuav ncaj nraim los ntawm kev rub-kho mechanism. Thiab tom qab ntawd koj tuaj yeem pib txiav cov ingot rau hauv qhov khoob. Nws yog qhov kev tsim no uas nyob rau hauv kev coj ua tau los ua qhov tseem ceeb tshaj plaws hauv kev npaj cov khoom ntws hauv lub khw steel.

pib qhov twg

Technology of nruamsteel casting yog txheej txheem nyuaj heev. Txawm li cas los xij, nws yog qhov ncaj ncees hais tias txoj cai tseem nyob ib yam txawm hais tias kev tsim khoom siv tau siv. Koj tuaj yeem xav txog cov thev naus laus zis siv qhov piv txwv ntawm qhov ntsug UNRS.

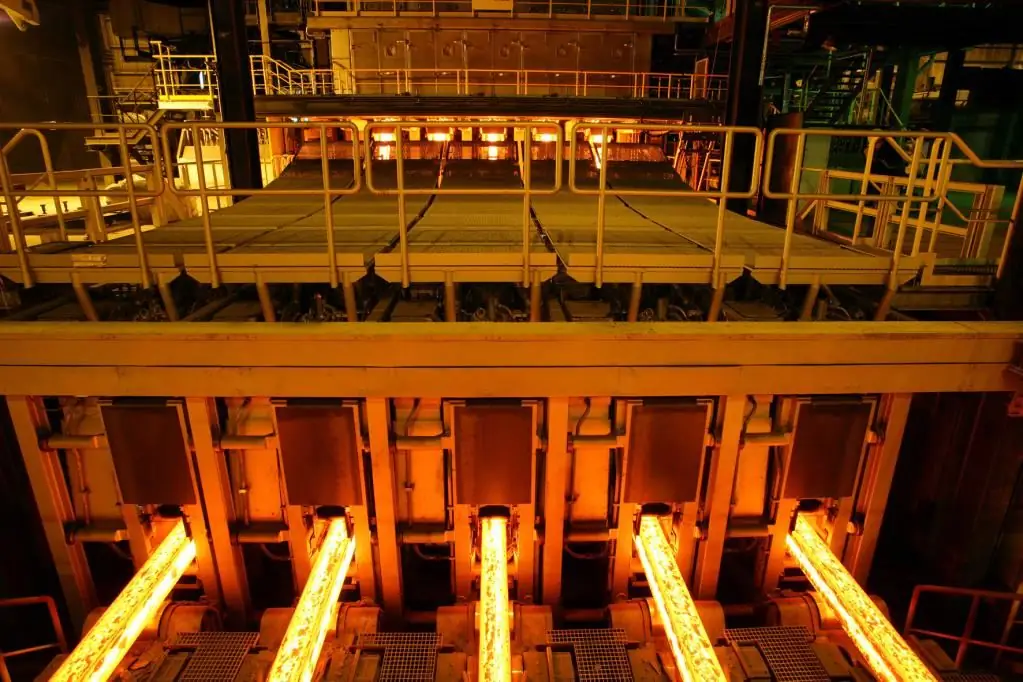

Lub tshuab tau muab nrog lub ladle rau cov hlau los ntawm lub crane tshwj xeeb. Tom qab ntawd, cov hlau ntws mus rau hauv lub tundish, uas muaj ib tug stopper. Rau ib lub tshuab strand yuav muaj ib qho chaw nres tsheb, rau ntau lub tshuab strand yuav muaj ib qho chaw nres tsheb. Tsis tas li ntawd, tundish muaj ib qho tshwj xeeb baffle los tuav lub slag. Los ntawm tundish, cov hlau yuav ntws mus rau hauv cov pwm, dhau los ntawm lub khob ntim tshuaj los yog ib lub stopper. Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov ntawm no tias ua ntej thawj casting, cov noob tau nkag mus rau hauv pwm los ntawm sab hauv qab. Nws sau ib qho hla ntu ntawm tag nrho cov pwm, lossis tsuas yog cov duab ntawm lub workpiece. Sab saum toj txheej ntawm cov noob yuav yog hauv qab ntawm pwm. Tsis tas li ntawd, nws kuj muaj qhov zoo li tus nqos tus Tsov tus tw rau yav tom ntej hitching nrog ib qho ingot.

Nkauj tawm tshiab

Tom ntej no, nyob rau hauv tus txheej txheem ntawm kev nruam nruam ntawm cov hlau, nws yog ib qho tsim nyog yuav tsum tau tos kom txog thaum theem ntawm cov ntaub ntawv raw nce siab saum cov noob mus rau qhov siab li ntawm 300-400 hli. Thaum qhov no tshwm sim, lub tshuab pib, uas coj cov cuab yeej rub mus rau hauv kev ua haujlwm. Nws muaj rub yob, nyob rau hauv tus ntawm cov noob yuav poob thiab rub lub tsim ingot nrog rau nws.

Lub tshuab nruam nruam muaj pwm feem ntau ua los ntawm tooj liab nrog cov phab ntsa hollow. Nws nyob hauv qab khauslos ntawm qhov kev txiav txim ntawm cov dej txias, thiab nws cov seem sab hauv sib raug rau cov duab ntawm lub ingot yuav tsum tau. Nws nyob ntawm no tias lub ingot-blank crust yog tsim. Nyob rau hauv high casting speeds, tearing ntawm no crust thiab to ntawm hlau yuav tshwm sim. Txhawm rau zam qhov no, cov pwm yog tus cwj pwm los ntawm kev sib txuas lus.

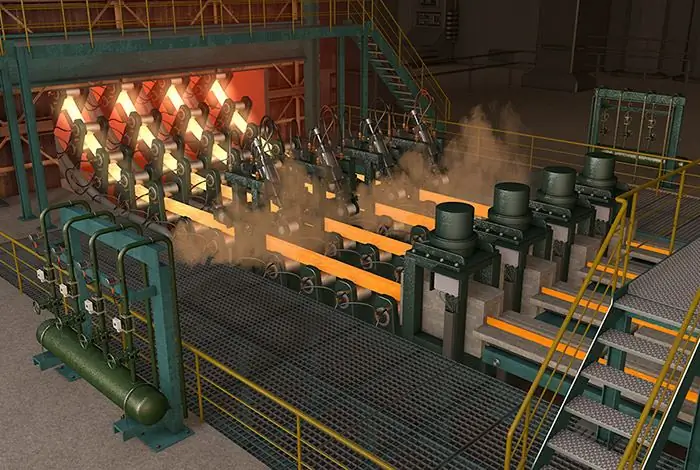

yam ntxwv ntawm kev ua haujlwm pwm

Lub tshuab nruam nruam muaj lub tshuab hluav taws xob lub luag haujlwm los tsim cov lus tsa suab sib txuas. Qhov no yog ua los ntawm lub zog ntawm lub gearbox nrog lub cam-hom viav vias mechanism. Ua ntej, cov pwm txav mus rau tib txoj kev raws li cov khoom ua haujlwm, uas yog, nqes, thiab tom qab ua tiav cov txheej txheem, nws rov qab los. Lub viav vias stroke yog los ntawm 10 mus rau 40 mm. Cov pwm yog qhov tseem ceeb hauv qhov nruam nruam ntawm cov hlau ntawm txhua yam khoom siv, thiab yog li ntawd nws cov phab ntsa yog lubricated nrog paraffin los yog lwm yam lubricant haum rau cov yam ntxwv.

Nws tsim nyog sau cia tias hauv cov cuab yeej siv niaj hnub no qib ntawm cov hlau yog tswj hwm radiometrically los ntawm kev siv lub teeb liab tswj rau lub ladle stopper. Hauv pwm nws tus kheej, txawm tias qhov nruab nrab lossis qhov txo qis tuaj yeem tsim los saum toj no cov qib hlau kom tsis txhob muaj cov khoom oxidation thaum tsim khoom.

Nws tsim nyog sau cia tias kev ua haujlwm hauv lub tshuab nqus tsev kuj tseem suav tias yog txoj kev cog lus casting. Ib chav tsev tuaj yeem ua taupouring los ntawm ob peb pwm ib zaug. Yog li, tus naj npawb ntawm cov kwj ntawm ib qho kev teeb tsa tuaj yeem ncav cuag yim.

Lub dab dej kub ntawm cov noob txias yog siv los ua hauv qab ntawm daim tawv nqaij. Lub ingot yuav tawm ntawm cov pwm nyob rau hauv lub zog ntawm cov noob, uas yog kos rau hauv qhov chaw txias txias (SCZ). Nyob rau hauv nruab nrab ntawm lub billet, cov hlau tseem yuav nyob rau hauv ib tug kua lub xeev. Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov ntawm no tias, raws li qhov yuav tsum tau ua ntawm cov cuab yeej siv hlau casting, cov tawv nqaij tuab yuav tsum yog tsawg kawg 25 hli thaum lub sij hawm tawm ntawm pwm. Yuav kom ua tau raws li cov kev cai no, nws yog ib qho tsim nyog los xaiv cov khoom txaus txaus.

yam ntxwv ntawm kev teeb tsa thiab txheej txheem casting

Technological yam ntxwv yog kwv yees li hauv qab no. Yog hais tias seem ntawm lub ingot yog 160x900 mm, ces nws ceev yuav tsum yog los ntawm 0.6 mus rau 0.9 m / min. Yog hais tias tus ntoo khaub lig yog 180x1000 mm, ces qhov ceev yog txo mus rau 0.55-0.85 m / min. Qhov taw qhia ceev tshaj plaws yog xav tau rau ntu ntu ntawm cov square-type ingot 200x200 mm - 0.8-1.2 m / min.

Raws li cov ntsuas saum toj no, peb tuaj yeem txiav txim siab tias qhov nruab nrab ntawm qhov nrawm nrawm ntawm ib txoj hlua siv tshuab nruam casting yog 44.2 t / h. Yog tias koj tshaj qhov kev pom zoo ntawm qhov ceev, ces lub hauv paus porosity yuav nce.

Ntxiv mus, nws tsim nyog sau cia tias qhov ruaj khov ntawm cov casting thiab qhov zoo ntawm cov khoom nws tus kheej raug cuam tshuam los ntawm qhov kub ntawm cov hlau. Empirically, nws tau pom tias ntawm qhov kub ntawm ntau tshaj 1560 degreesCelsius saum npoo ntawm qhov ingot feem ntau yog npog nrog cov kab nrib pleb. Yog tias qhov kub thiab txias qis dua qhov qhia, ces lub iav yuav nruj heev. Yog li, nws tau pom tias qhov zoo tshaj plaws kub rau txoj kev nruam casting hlau yuav yog 1540-1560 degrees Celsius. Txhawm rau tswj qhov ntsuas no, qhov kub ntawm qhov cub ua ntej tso tawm yuav tsum nyob rau hauv thaj tsam ntawm 1630-1650 degrees.

Secondary txias zone

Nyob rau hauv ntu no, qhov kub thiab txias tshaj plaws ntawm lub ingot yog nqa tawm nrog kev pab los ntawm cov dej los ntawm cov tshuaj tsuag. Nws muaj ib tug tshwj xeeb system ntawm idle, tsis muaj hwj chim rollers. Lawv cov kev sib hloov tiv thaiv lub ingot ntawm dabtsi yog khoov los yog warping. Vim qhov txias txias nyob rau hauv cheeb tsam no, cov phab ntsa ntawm lub ingot yuav sai sai ntxiv nyob rau hauv thickness, thiab crystallization yuav kis tau nyob rau hauv qhov tob. Kev nrawm ntawm kev kos lub ingot thiab qib ntawm nws cov cua txias yuav tsum tau xaiv nyob rau hauv xws li ib txoj kev uas los ntawm lub sij hawm lub ingot nkag mus rau hauv rub rolls nws twb kiag li ruaj khov.

Dab tsi yog cov txiaj ntsig ntawm kev nruam nruam

Vim txoj kev no ntawm cov hlau casting tau hloov txoj kev nchuav rau hauv pwm, nws tsim nyog muab piv nrog cov qauv no. Feem ntau, nws tsim nyog hais txog qhov zoo hauv qab no: kev tsim khoom ntau dua, txo cov nqi thiab txo kev siv zog ntawm cov txheej txheem. Vim yog qhov tsim tsis tu ncua ntawm lub ingot, lub shrinkage kab noj hniav yog pauv mus rau tus Tsov tus tw, nyob rau hauv sib piv rau ingot pwm, qhov twg txhua ingot muaj nws cov kab noj hniav. Vim li no, qhov feem pua ntawm cov txiaj ntsig ntawm cov hlau tsim nyog nce ntxiv. UNRS tso cai rau koj tau txaisib tug workpiece ntawm ntau yam duab, los ntawm ib tug me me square 40x40 mm mus rau ib tug duab plaub 250x1000 mm. Kev siv cov tshuab nruam nruam ua rau nws muaj peev xwm tso tseg tag nrho swaging mills. Qhov no txo qis tus nqi ntawm cov txheej txheem ntau lawm, thiab yog li tus nqi ntawm lub khw. Tsis tas li ntawd, cov txheej txheem ntawm metallurgical ua tau yooj yim.

Flaws

Txawm hais tias muaj peev xwm ntawm kev siv tshuab siab thiab automation ntawm cov txheej txheem, feem pua ntawm cov khoom zoo thiab lwm yam zoo tau piav qhia saum toj no, txoj kev no kuj muaj qee qhov tsis zoo. Qhov tsis zoo ntawm kev nruam casting steel yog raws li hauv qab no.

Ua ntej, tsis muaj qhov ua tau los tsim cov ingots ntawm kev teeb tsa nyuaj. Qhov thib ob, qhov ntau ntawm ingots thiab blanks yog heev txwv. Nws yog qhov nyuaj heev los hloov cov cav tov rau cov khoom siv raw ntawm cov khoom sib txawv, uas tuaj yeem nce tus nqi kawg ntawm cov khoom lag luam ntawm cov khoom sib txawv yog tias nws tau tsim ntawm tib tsob nroj. Qee qib steel, piv txwv li, boiling sawv daws yuav tsis tuaj yeem siv txoj kev no txhua.

Qhov kawg qhov tsis zoo ntawm txoj kev nruam ntawm cov hlau casting yog qhov tseem ceeb heev. Nws yog qhov ua tau cov cuab yeej ua tsis tiav. Kev ua tsis tiav ntawm UNRS yuav ua rau poob loj hauv kev ua haujlwm. Nws yuav siv sij hawm ntev mus kho, qhov poob ntau yuav loj tuaj.

Pom zoo:

Tus neeg tuav pov hwm kev ua haujlwm: kev ua haujlwm, kev kawm tsim nyog, lub luag haujlwm, qhov zoo thiab qhov tsis zoo ntawm kev ua haujlwm

Txhua lub tuam txhab uas lees txais cov nyiaj them los ntawm cov neeg siv khoom xav tau tus neeg nqa nyiaj. Nws yog nrog tus kws tshaj lij no uas cov neeg tuaj xyuas cov khw muag khoom noj thiab chaw noj mov, nrog rau cov neeg siv khoom ntawm cov tsev txhab nyiaj thiab lwm lub koom haum, yuav tsum tau nrog. Tsis yog qhov xav tsis thoob, txoj haujlwm ntawm tus neeg nqa nyiaj yog qhov xav tau ntawm cov tswv haujlwm muaj peev xwm. Nws nyiam cov neeg thov nrog cov kev xav tau qis uas siv rau txoj haujlwm

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

Cov neeg ua haujlwm hauv chav ua noj: cov dej num, kev ua haujlwm, kev tsim nyog, kev piav qhia txoj haujlwm, lub luag haujlwm rau kev ua haujlwm tsis zoo

Cov kev xav tau yooj yim rau "tus neeg ua haujlwm hauv chav ua noj". Lub luag haujlwm thiab cov yam ntxwv dab tsi yuav tsum tau ua raws li tus neeg ua haujlwm kom tau txais txoj haujlwm hauv kev lag luam? Tus neeg ua haujlwm tshwj xeeb yog dab tsi thiab nws ua haujlwm dab tsi hauv chav ua noj

Yuav ua li cas los ua tus neeg muag khoom zoo: lub tswv yim ntawm lub hauv paus ntawm kev ua haujlwm, thawj theem, tau txais kev paub dhau los, kev muag khoom, cov kev pabcuam zoo thiab muaj peev xwm piav qhia txhua qhov zoo ntawm kev yuav khoom

Yuav ua li cas thiaj ua tau tus neeg muag khoom zoo? Koj puas xav tau kev txawj ntse, lossis ib tus neeg tuaj yeem txhim kho qhov tsim nyog ntawm nws tus kheej? Leej twg tuaj yeem dhau los ua tus thawj coj zoo. Nws tsuas yog qhov ntawd rau qee tus neeg, tau txais cov txuj ci tsim nyog yuav yooj yim, thaum lwm tus yuav tau siv zog ntau. Tab sis thaum kawg, ob leeg yuav muag zoo sib xws

Yam koj yuav tsum tau ua haujlwm hauv tsheb tavxij: cov ntaub ntawv tsim nyog thiab cov cai, cov cai thiab kev cai lij choj. Cov lus teb thiab cov lus qhia los ntawm cov neeg tsav tsheb tavxij, cov neeg siv khoom thiab cov neeg xa khoom

Raws li ntau tus neeg caij tsheb, txoj haujlwm ntawm tus tsav tsheb tavxij yog qhov yooj yim tshaj plaws. Koj zaum, mloog suab paj nruag zoo nkauj thiab tsav tsheb rov qab los. Thiab lawv muab nyiaj rau koj. Tab sis qhov no tsuas yog sab nraud ntawm lub npib. Qhov rov qab yog ntau dua rosy. Peb yuav tham txog nws hauv kab lus no. Thiab peb tseem yuav qhia txog yam koj xav tau ua haujlwm hauv tsheb tavxij