2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Lub khw electroplating tam sim no xav tau txhawm rau txhawm rau siv cov txheej tshwj xeeb rau cov khoom siv hlau. Los ntawm nws tus kheej, cov khoom no raug corrosion, thiab nws cov kev pab cuam lub neej tsis ntev heev. Tias yog vim li cas ib txoj kev siv nyob rau hauv uas ib txheej nyias ntawm lwm cov hlau yog tso rau saum npoo ntawm cov khoom siv raw hauv cov tshuaj electrolyte thiab siv hluav taws xob tam sim no. Qhov no yog lub hom phiaj tseem ceeb ntawm lub khw electroplating.

Khoom siv rau kev ua haujlwm. Bath

Hauv cov kev cob qhia no muaj ntau yam khoom siv, tab sis lub ntsiab yog da dej galvanic. Cov cuab yeej no tau muab faib ua ob hom. Thawj yog hu ua nquag, qhov thib ob - pab. Lawv txawv nyob rau hauv hais tias nyob rau hauv thawj hom ntawm da dej, qhov xav tau txheej yog siv ncaj qha rau cov khoom. Hauv cov cuab yeej pabcuam ntawm lub khw electroplating, theem ntawm kev npaj cov txheej txheem ntxiv yuav tshwm sim. Ntawm no nws yog ib qho tseem ceeb kom nkag siab tias cov cuab yeej pab cuam yog ib qho tseem ceeb raws li lub ntsiab. Ntawm lawv yog ntxuav, ziab, sib tov da dej.

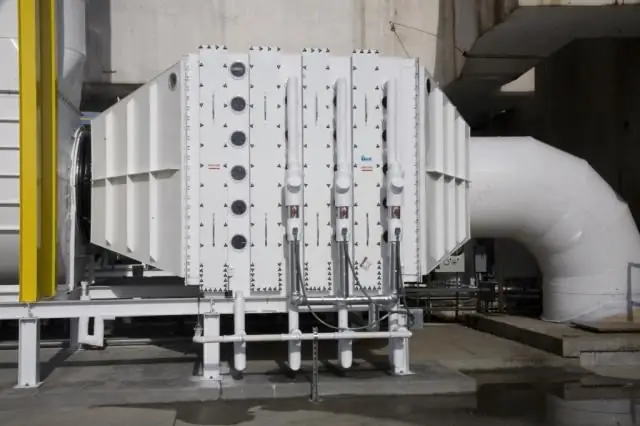

dawb tsim

Los ntawm lawv tus qauv tsim, lub khw electroplating da dej yog qhov yooj yim heev thiab yog ib lub voos xwmfab uas muaj cov ribs ntxiv, nrog rau qee yam ntxiv. Ntawm cov khoom siv ntxiv no, piv txwv li, muaj cov khoom siv cua sov, lub hau npog, pom, lub tshuab ua kom txias, dej thiab tso tawm, ntxuav tshuab, ncua kev kawm ntawv, anodes, thiab lwm yam.

Stainless steel, PVC, polypropylene, thiab lwm yam khoom siv raw nrog cov yam ntxwv zoo sib xws tuaj yeem siv rau kev tsim khoom. Txawm li cas los xij, PVC thiab polypropylene yog tam sim no siv dav tshaj plaws, thaum cov khoom siv hlau thiab hlau tau ploj mus rau hauv keeb kwm yav dhau. Qhov no yog vim qhov tseeb tias cov ntaub ntawv polymer muaj zog tiv taus cov tshuaj lom neeg thiab kub kub.

Special Purpose Devices

Kev lag luam electroplating xav tau cov chav da dej tshwj xeeb uas tsim los ua haujlwm nrog cov khoom me me.

thawj cov cuab yeej ntawm hom no yog lub tswb da dej. Qhov sib txawv tseem ceeb ntawm cov cuab yeej no thiab lub ntsiab yog tias nws muaj lub tswb tshwj xeeb, thiab lub hom phiaj tseem ceeb yog siv galvanic txheej rau cov khoom me me hauv ntau. Lub tswb nws tus kheej yog truncated thiab muaj ib tug multifaceted tsim. Xws li cov cuab yeej siv ob qho tib si ua lub tshuab ywj pheej thiab hauv kab.

Electroplating ntau lawm ib ntus xav tau cov cuab yeej xws li lub nruas galvanic. Nws yog prism uasua los ntawm PVC los yog polypropylene, uas muaj ntau yam facets, thiab tag nrho cov ntawm lawv yog perforated. Yuav kom tig lub prism, lub cev muaj zog nrog lub gearbox yog siv, thiab lub torque yog kis los ntawm ib tug system ntawm gear-type log. Koj tuaj yeem siv lub nruas hauv phau ntawv, automated thiab mechanized hom kab.

Dab tsi yog kab

Galvanic kab yog txheej ntawm ntau yam khoom siv uas ua haujlwm hauv ib cheeb tsam. Lub ntsiab tsis zoo rau kev tsim cov tshuab zoo li no yog lawv cov kev ua tau zoo, nrog rau qhov ntev ntawm cov khoom uas cov kab no yuav tsum tau tsim. Hom kab yuav ncaj qha nyob ntawm seb qhov loj npaum li cas ntawm cov khoom yuav yog thiab hom serialization nws yuav muaj li cas. Galvanic kab tuaj yeem yog hom ntsia hlau, lawv tuaj yeem yog phau ntawv lossis phau ntawv nrog lub hoist. Niaj hnub no, tus neeg teb xov tooj tsis siv neeg kab hom nrog cov kev tswj hwm tau nrov heev.

Cov khoom siv pabcuam kuj tseem tuaj yeem suav nrog hauv kab. Nws yog ib qho tsim nyog txhawm rau tiv thaiv cov txheej txheem thev naus laus zis, nrog rau kom ua tiav kev nyab xeeb ntawm kev ua haujlwm ntawm cov neeg ntawm lub xaib.

Ntau yam kev pabcuam kev teeb tsa

Electroplating cov cuab yeej siv hauv thaj chaw yuav tsum npaj cov khoom siv raw thiab cov khoom siv rau kev ua haujlwm ntxiv. Rau qhov no, piv txwv li, muaj ob lub lim dej. Ib ntawm lawv nyob ruaj ruaj, lwm qhov yog txawb.

Yog tias peb tham txog thawj hom kev teeb tsa, ces UFE-1C qauv feem ntau yog siv. Nws yog npaj raupom cov dej los yog electrolyte los ntawm tej impurities ntawm ib tug neeg kho tshuab hom. Ib qho ntxiv ntawm qhov chaw nres tsheb yog tias nws tuaj yeem txuas nrog lub tshuab cua tsis sib xyaw, qhov twg muaj cov tshuaj pom kev ua haujlwm.

Lub tshuab lim dej feem ntau yog sawv cev los ntawm tus qauv UV 2400. Lawv qhov txawv yog qhov tseeb tias lub twj tso kua mis no tuaj yeem tso cov dej no lossis lwm yam tshuaj lom neeg.

Cov khoom siv ua kua demineralization kuj tseem siv. Chav tsev tau nthuav tawm nyob rau hauv daim ntawv ntawm UVD-500 chav tsev, uas muaj peev xwm tshem tawm cov ntsev ntawm cov kua kom nws ua tau raws li lub xeev tus qauv raws li 6709-97. Cov dej no yog siv rau kev npaj cov electrolyte tshiab, nrog rau kev ua haujlwm ntxhua khaub ncaws hauv khw.

Tseem kuj tseem muaj cov khoom siv me me, xws li cov twj tso kua mis, tab sis muaj zog tiv thaiv cov tshuaj txhawm rau txhawm rau ua tiav cov tshuab electrolyte. Cov khoom siv ziab yog siv.

Qhov cua

Qhov cua ntawm lub khw electroplating yog ib qho tseem ceeb tshaj plaws ntawm kev nyab xeeb. Qhov no yog ib qho tseem ceeb heev, vim hais tias thaum lub sij hawm txheej txheem galvanic, uas yog, cov khoom txheej, cov pa phem raug tso tawm rau saum huab cua, uas yog qhov txaus ntshai tsis yog rau tib neeg nkaus xwb, tab sis kuj rau chav tsev uas lawv tso tawm. Vim li no, thaum tsim ib lub rooj cob qhia, tshwj xeeb yog them rau cov khoom siv cua thiabqhov cua feem ntau.

Polypropylene qhov cua cov kav dej tau tso cai rau hom kev cob qhia no. Qhov no yog vim lub fact tias cov khoom no belongs rau cov pab pawg neeg ntawm tsis-combustible, yog noo-pov thawj, resistant rau tshuaj tua kab mob, thiab nws kuj yog heev yooj yim rau mount lawv ob leeg rau ntawm lub qab nthab thiab nyob rau hauv pem teb los yog phab ntsa.

Kev nyab xeeb hauv khw

Qhov phom sij ntawm lub khw electroplating rau tib neeg noj qab haus huv yog qhov siab heev. Qhov tseeb yog tias muaj ntau yam txaus ntshai heev. Ua ntej, muaj peev xwm tau txais hluav taws xob muaj zog, qhov thib ob, muaj kev pheej hmoo ntawm cov tshuaj lom neeg, alkaline lossis kua qaub ntawm qhov kub hnyiab, thiab qhov thib peb, muaj kev pheej hmoo ntawm tawg thiab tawg.

Txawm li cas los xij, kev puas tsuaj rau tib neeg kev noj qab haus huv tsis xaus rau ntawd. Piv txwv li, thaum npaj ib yam khoom, nws raug rau txhua yam ntawm kev ua. Qhov no tuaj yeem yog kev sib tsoo, moj tej tawg tu siv cov khoom siv plua plav, thiab lwm yam. Tag nrho cov ntawm lawv koom siab los ntawm qhov tseeb hais tias thaum lub sij hawm lawv coj ib tug loj npaum li cas ntawm plua plav tawm mus rau saum huab cua. Tsis tas li ntawd, lub suab nrov thiab kev co siab tshaj qhov tso cai. Txij li thaum muaj hluav taws xob tam sim no tau siv thaum lub sij hawm txheej, qhov tshwm sim ntawm kev raug ntaus los ntawm qhov tam sim no tau nce ntau heev. Vim li no, 12 V ncaj qha tam sim no feem ntau yog siv. Txawm li cas los xij, muaj qee qhov kev ua haujlwm uas yuav tsum muaj qhov hluav taws xob nce mus rau 120 V. Piv txwv li, qhov no tshwm sim thaum txhuas yog oxidized.

Kev nyab xeeb hluav taws raucov khw electroplating kuj yog siab heev. Txhawm rau tiv thaiv hluav taws hauv thaj chaw zoo li no, nws yog ib qho tsim nyog yuav tsum siv cov kev tiv thaiv hluav taws thiab tiv thaiv hluav taws uas yuav ua raws li GOST 12.1.004-76. Kev nyab xeeb tawg nyob rau hauv cov cheeb tsam no yuav tsum tau ua kom ntseeg tau siv kev tiv thaiv kev tawg thiab kev tiv thaiv kev tawg raws li GOST 12.1.010-76.

Kev ntxuav dej

Nws tsim nyog hais tias cov khw muag khoom electroplating yuav tsum muaj cov khoom siv los ntxuav cov kua uas siv hauv kev ua haujlwm. Qhov no yog ib qho tseem ceeb heev, vim hais tias thaum lub sij hawm siv technology, dej yog tov nrog acids, alkalis thiab hnyav hlau. Cov nroj tsuag kho dej tsis muaj peev xwm tiv taus cov pa phem li no, thiab yog li ntawd, thaum tsim lub tsev, koj yuav tsum pib faib qhov chaw rau kev teeb tsa tshwj xeeb.

Chromic anhydride

Los ntawm qhov kev xav ntawm kev pom, qhov no yog kev sib xyaw ntawm ob yam khoom xws li chromium thiab oxygen. Nws yog feem ntau siv hauv kev lag luam tshuaj, thiab yog li ntawd feem ntau hu ua chemical acid. Cov tshuaj no yog heev soluble nyob rau hauv dej, uas yog zoo heev rau siv nyob rau hauv lub khw uas feem ntau cov hauj lwm yog nqa tawm nrog cov ntsiab lus ntawm cov kua rau ib tug degree los yog lwm yam. Chromic anhydride yog tam sim no siv dav hauv peb thaj chaw: mechanical engineering, metallurgy, chemical thiab petrochemical industries. Nyob ntawm nws lub hom phiaj, cov tshuaj no yog tsim nyob rau hauv peb pawg: A, B thiab C.

- Qib A yog siv thaum nyob rau hauv cov xwm txheej tsim khoomKoj yuav tsum tau txais cov xim hlau chromium los yog lwm yam ntaub ntawv, tab sis nrog txaus hardness.

- Qib B yog siv rau kev tsim cov electrolytic chromium thiab hauv kev tsim cov catalysts. Nws yog cov anhydride no uas yog siv hauv khw muag khoom electroplating.

- Raws rau Qib B, nws yog qhov tsim nyog tshaj plaws rau kev ua haujlwm ntawm cov khoom siv raw.

Feem ntau hais lus, hom kev cob qhia no yog qhov tsim nyog heev, tab sis tib lub sijhawm muaj kev phom sij thiab txaus ntshai. Vim li no, txhua yam kev nyab xeeb yuav tsum tau ua tiav hauv nws, nrog rau qhov cua zoo tshaj plaws.

Pom zoo:

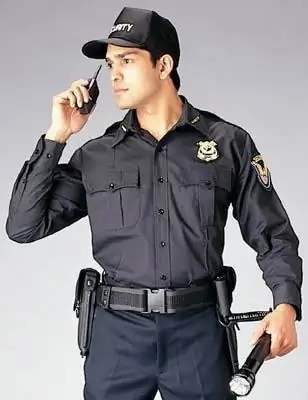

Cov nyiaj hli ntawm tus neeg saib xyuas kev ruaj ntseg hauv Moscow. Kev ua haujlwm raws li tus neeg saib xyuas kev ruaj ntseg hauv Moscow

Ntau tus xav tau txoj haujlwm ua tus saib xyuas kev nyab xeeb hauv lub nroog Russia. Xav txog qib ntawm cov nyiaj hli ntawm cov kws tshaj lij no. Dab tsi txiav txim siab txog qib nyiaj hli? Puas muaj tseeb tias tsuas yog cov neeg ua haujlwm nrog daim ntawv tso cai thiab daim ntawv tso cai nqa riam phom raug ntiav?

Kev faib tawm ntawm kev tsim khoom thiab kev siv pov tseg. Kev faib cov khoom pov tseg los ntawm chav kawm phom sij

Tsis muaj kev faib tawm dav dav ntawm kev noj thiab cov khoom pov tseg. Yog li ntawd, kom yooj yim, cov hauv paus ntsiab lus ntawm kev sib cais yog feem ntau siv, uas yuav tau tham hauv tsab xov xwm no

Tus saib xyuas kev ruaj ntseg yog dab tsi? Lub luag haujlwm thiab lub luag haujlwm ntawm tus neeg saib xyuas kev ruaj ntseg

Txoj haujlwm ntawm tus neeg saib xyuas kev nyab xeeb yog nrov heev hnub no. Thiab tag nrho vim tias ntau thiab ntau lub khw thiab khw muag khoom tau qhib hnub no, uas yuav tsum tau ua kom muaj kev nyab xeeb ntawm ob tus neeg ua haujlwm thiab cov neeg siv khoom, nrog rau cov khoom thiab cov nyiaj, nyob rau theem tsim nyog. Tsis tas li ntawd, cov chaw tsim khoom, ntau lub tsev hauv nroog thiab cov tswv tsev ntawm lwm yam khoom siv tas li xav tau cov kev pabcuam ntawm cov neeg saib xyuas kev ruaj ntseg. Peb muab niaj hnub no kom paub meej tias dab tsi suav nrog hauv lub luag haujlwm ntawm tus neeg saib xyuas kev ruaj ntseg

Electroplating. Kev siv tshuab electroplating. Electroplating

Electroplating yog ib txoj hauv kev ntawm txheej ib lub hlau nrog lwm tus los ntawm kev siv electrolysis. Cov txheej txheem no yog ua los ntawm kev siv cov txheej txheem immersion ib txwm

Tus neeg saib xyuas kev ruaj ntseg ntawm qeb 6: kev xeem, daim ntawv tso cai, daim ntawv pov thawj, khoom tshwj xeeb thiab riam phom

Txoj haujlwm ntawm tus neeg saib xyuas kev nyab xeeb ntawm 4-6 pawg suav nrog kev cob qhia, kev xeem dhau los kom tau txais daim ntawv pov thawj ntawm kev cob qhia thiab kev tsim nyog ntawm Ministry of Internal Affairs nyob rau hauv daim ntawv ntawm kev xeem thiab kev siv riam phom, nrog rau lub sijhawm. kev pom zoo ntawm kev ua raws li txoj haujlwm tuav