2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Technologies rau kev siv cov vuam ua haujlwm nyob rau hauv kev sib raug zoo rau cov hlau workpieces hnub no ua rau nws muaj peev xwm mus cuag ib theem siab ntawm lub koom haum ntawm cov txheej txheem nyob rau hauv cov nqe lus ntawm kev ruaj ntseg, ergonomics thiab functionality. Qhov no yog pov thawj los ntawm kev sib kis ntawm cov khoom siv semi-automatic thiab robotic rau kev ua haujlwm ntawm cov txheej txheem thev naus laus zis hauv kev sib koom ua ke thermal ntawm qhov chaw. Nyob rau hauv parallel nrog qhov no, qhov yuav tsum tau rau qhov zoo ntawm seams kuj loj hlob. Hauv qhov kev taw qhia no, qhov kev vam meej tshaj plaws tuaj yeem ua tiav los ntawm kev sib txuas hauv cov roj thaiv kev tiv thaiv, uas muaj peev xwm cais thaj chaw ua haujlwm los ntawm qhov tsis zoo ntawm huab cua.

Lub ntsiab ntawm technology

Cov txheej txheem vuam nyob rau hauv ib puag ncig tiv thaiv roj yog ib qho derivative ntawm kev sib xyaw ua ke ntawm ntau txoj hauv kev thermal ua rau cov hlau nrog qhov ua tau ntawm cov qauv kev sib txuas ntawm cov khoom ua haujlwm. Ua ntej ntawm tag nrho cov, txoj kev no yog raws li arc vuam txoj kev, uas nyob rau hauv nws tus kheej muab kev pom zoo tswj ntawm electrodes thiab nto ntawm lub hom phiaj qhov chaw nrog cov qauv. Hauv hom ntawv no, tus neeg siv tuaj yeem nyob txhua qhov chawtxoj haujlwm siv cov khoom siv mobile thiab compact. Tag nrho cov no cuam tshuam txog lub koom haum ergonomics ntawm qhov kev tshwm sim ua haujlwm, thiab cov ntsiab lus ntawm cov txheej txheem electrochemical ntawm vuam hauv shielding gas yog qhia los ntawm qhov tshwj xeeb ntawm ib puag ncig hauv kev ua haujlwm. Yuav pib nrog, nws yog ib qho tsim nyog yuav tsum tau hais txog qhov tseem ceeb ntawm kev tiv thaiv lub pas dej weld los ntawm qhov tsis zoo ntawm huab cua hauv huab cua. Kev sib cuag ncaj qha ntawm billet yaj nrog oxygen ua rau tsim cov slag rau ntawm qhov chaw, oxidation ntawm txheej, thiab tsis muaj kev tswj hwm ntawm cov hlau qauv. Raws li, txhawm rau tshem tawm cov teebmeem no, cov insulators tshwj xeeb yog siv - txheej, cov ntaub ntawv loj xws li flux thiab roj, uas tau nkag mus rau hauv thaj chaw ua haujlwm nrog cov cuab yeej tshwj xeeb. Cov txheej txheem kawg ntawm kev tiv thaiv txiav txim siab cov yam ntxwv ntawm txoj kev txiav txim siab ntawm vuam ntau lawm.

Cov cai dav dav rau vuam raws li GOST 14771-76

Raws li GOST tau teev tseg, txoj kev vuam no tuaj yeem siv los ua ib sab thiab ob sab seams siv lub pob tw, kaum, tee thiab sib tshooj sib txuas. Raws li qhov tseem ceeb ntawm cov txheej txheem, lawv suav nrog cov hauv qab no:

- Thickness ntawm qhov chaw - thaj tsam ntawm 0.5 txog 120 mm.

- Kev tso cai yuam kev thaum vuam qhov nrog lub thickness ntawm 12 hli - los ntawm 2 mus rau 5 hli.

- Txoj kab nqes ntawm seam nto tsuas yog tso cai yog tias kev hloov pauv ntawm ib qho chaw ua haujlwm mus rau lwm qhov tau lees paub.

- Thaum vuam qhov sib txawv nrog qhov sib txawv ntawm qhov tuab, lub bevel tau ua tiav ua ntej ntawm kev taw qhia los ntawm cov khoom loj dua mus rau ib qho me me.

- Concavity thiab convexity ntawm fillet welds raws liKev ua siab ntev ntawm GOST 14771-76 yuav tsum tsis pub ntau tshaj 30% ntawm ceg ntawm lub kaum sab xis tsim, tab sis tib lub sijhawm haum hauv 3 hli.

- Tus nqi tso cai offset ntawm cov npoo ua ntej welding hauv kev sib raug zoo yog nyob ntawm qhov tuab ntawm cov khoom. Piv txwv li, nyob rau hauv cov ntaub ntawv ntawm cov khoom txog li 4 hli tuab, daim duab no yog hais txog 0.8-1 hli, thiab yog hais tias peb tham txog 100 hli blanks, ces qhov offset nrug yuav tsum tau haum rau 6 hli.

Siv vuam gases

Los ntawm qhov pom ntawm vuam, tag nrho cov xov xwm gaseous tau muab faib ua inert thiab nquag. Txij li thaum lub luag haujlwm tseem ceeb ntawm cov roj sib tov yog cov haujlwm insulating, qhov tseem ceeb tshaj plaws yog cov xov xwm uas tsis cuam tshuam rau cov hlau ua tiav. Xws li cov khoom sib xyaw muaj xws li inert monatomic tshuaj xws li helium thiab argon. Txawm hais tias, raws li GOST, welding nyob rau hauv shielding gases yuav tsum tau nqa tawm nyob rau hauv ib tug carbon dioxide ib puag ncig, thiab ua ke nrog cov pa sib tov kuj tso cai. Raws li rau cov roj ntsha nquag, lawv tuaj yeem cuam tshuam cov hlau ob qho tib si hauv cov molten thiab hauv cov khoom hauv lub xeev. Lub xub ntiag ntawm cov pa roj hauv cov qauv molecular ntawm cov hlau feem ntau suav tias yog qhov tsis xav tau, tab sis muaj qhov tshwj xeeb vim yog qhov tshwj xeeb ntawm cov kev sib xyaw ua ke hauv cov xwm txheej sib txawv.

Qhov cuam tshuam ntawm cov pa ib puag ncig ntawm cov hlau

Tam sim ntawd nws tsim nyog hais txog qhov tsis zoo ntawm cov pa roj thaum lub sij hawm arc vuam ntawm workpieces. Thaum lub sij hawm txias thiab muaj zog cua sov, cov khoom siv roj yaj hauv cov qauv molecular tuaj yeem ua rau tsim cov pores, uas yog qhov tsim nyog.lub zog ntawm cov khoom. Ntawm qhov tod tes, hydrogen thiab oxygen atoms tuaj yeem pab tau hauv kev ua haujlwm doping yav tom ntej. Thiab qhov no tsis yog hais txog qhov muaj txiaj ntsig ntawm cov khoom siv tiv thaiv hluav taws xob hauv vuam austenitic alloys thiab steels, uas nyuaj rau yaj yog tias siv cov khoom siv inert insulating. Raws li qhov tshwm sim, qhov teeb meem rau cov kws tshaj lij tsis yog nyob rau hauv kev xaiv cov roj sib xyaw kom raug, tab sis hauv kev tsim cov xwm txheej uas tuaj yeem txo qhov teeb meem ntawm cov roj nquag ntawm lub pas dej sib txuas thiab tib lub sijhawm khaws cov txiaj ntsig zoo ntawm solubility.

Vuam txheej txheem txheej txheem

Ib qhov hluav taws xob tam sim no tau muab rau cov khoom ua haujlwm thiab cov khoom siv hluav taws xob, tom qab ntawd yuav siv los tsim thiab tswj cov vuam arc. Los ntawm lub sijhawm ntawm qhov hluav taws kub ntawm lub arc, tus neeg teb xov tooj yuav tsum tswj xyuas qhov kev pom zoo ntawm qhov nruab nrab ntawm lub tshuab hluav taws xob thiab lub pas dej ua ke, suav nrog qhov ntsuas kub thiab qhov chaw uas muaj cov teebmeem thermal. Nyob rau tib lub sijhawm, cov pa roj nkag mus rau thaj chaw ua haujlwm siv lub tshuab hluav taws xob los ntawm lub tog raj kheej txuas. Gas rwb thaiv tsev yog tsim nyob ib ncig ntawm lub arc. Qhov kev siv ntawm kev tsim cov seam yuav nyob ntawm seb qhov chaw ntawm cov npoo thiab cov thickness ntawm cov khoom. Raws li txoj cai, qhov kev faib ua feem ntawm lub hauv paus hlau nyob rau hauv weld qauv, uas yog tsim thaum lub sij hawm vuam nyob rau hauv ib tug shielding roj, yog 15-35%. Qhov tob ntawm qhov chaw ua haujlwm hauv qhov no tuaj yeem ncav cuag 7 hli, thiab qhov ntsuas ntawm nws qhov ntev thiab dav - los ntawm 10 txog 30 hli.

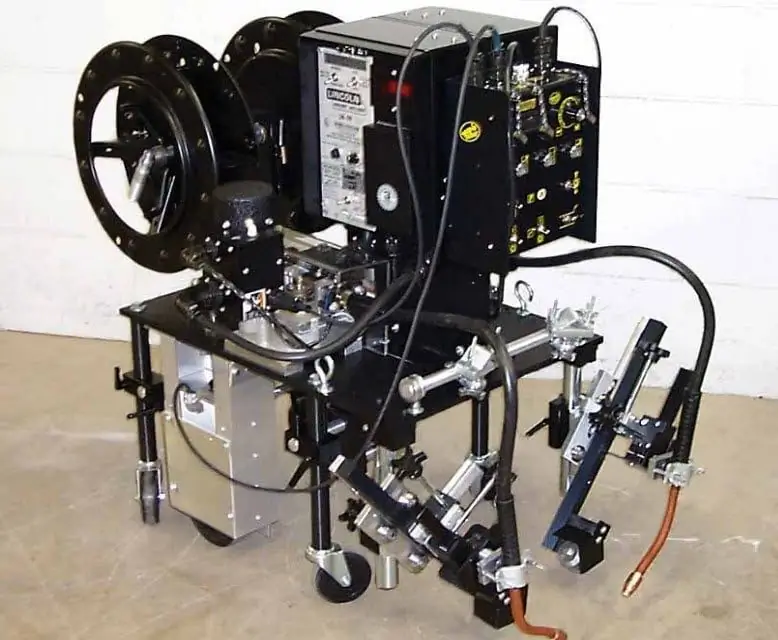

Khoom siv rau roj vuam

Ib txheej ntawm cov khoom siv rau xws lihom kev khiav hauj lwm nyob ntawm hom thiab hom ntawm vuam ntau lawm. Lub hauv paus txheej txheem yog ncaj qha tsim los ntawm semi-automatic li, tshem tawm vuam taub hau, lub hwj chim qhov chaw, rectifiers thiab complex tsis siv neeg modules nrog electrode tuav, uas maximally cawm tus neeg teb xov tooj los ntawm kev raug manipulations. Qhov tseem ceeb niaj hnub no yog nyob rau hauv kev siv tshuab vuam hauv shielding roj, cov infrastructure ntawm uas kuj yog tsim los ntawm ib tug roj kab, burners, pab kiag li lawm rau kev yooj yim kev tso kawm ntawm cov khoom nyob rau hauv txawv txoj hauj lwm, thiab lwm yam. Tshwj xeeb posts yog teem nyob rau hauv loj industries nrog cov tsim nyog txheej txheem. khoom siv rau vuam. Conversely, ib tug optimized hom ntawv rau ua xws li cov hauj lwm nyob rau hauv tsev yuav tsum tau siv tsuas yog ib tug compact inverter nrog converters thiab ib lub tog raj kheej roj nrog ntws tswj cov khoom.

Accessories

Txoj kev txhais tau tias thiab cov cuab yeej siv feem ntau ua kev sib txuas lus ntawm cov cuab yeej tseem ceeb, thiab tseem tso cai rau kev daws cov haujlwm thib ob uas tsis cuam tshuam ncaj qha rau vuam. Cov khoom siv no suav nrog:

- Gas cylinder infrastructure, uas suav nrog coils, reducers, heaters, casing, thiab lwm yam.

- Cov cuab yeej ntxuav thiab cov khoom sib cais tsim los tshem tawm cov khoom siv hluav taws xob hauv thaj chaw ua haujlwm. Qhov no yog qhov tseeb tshwj xeeb tshaj yog rau kev ua haujlwm vuam hauv shielding gases nrog cov khoom siv tsis siv hluav taws xob, cov yaj uas tsis ncaj qha suav nrog hauv cov qauv ntawm cov khoom. Ob qho tib si thaum thiab tom qab ua haujlwmSeam sanding tej zaum yuav tsum tau.

- tshuab ziab khaub ncaws. Tshem tawm thiab tswj cov dej noo uas muaj nyob hauv carbon dioxide. Ib hom desiccant uas ua haujlwm ntawm qhov siab lossis qis qis.

- Cov khoom siv lim. Ntxuav cov roj ntws ntawm cov khoom tsis xav tau, thiab ua kom muaj qhov huv huv.

- ntsuas khoom. Feem ntau, cov ntsuas ntsuas siab yog siv los taug qab cov ntsuas ntawm tib lub siab thiab roj ntws ntsuas.

Vuam hom thiab lawv qhov tsis muaj

Txoj hauv kev rau lub koom haum ntawm cov txheej txheem vuam nyob rau hauv cov ntaub ntawv no txawv raws li ntau yam kev cai, uas thaum kawg tso cai rau peb tham txog kev faib ntawm ntau hom kev ua haujlwm. Piv txwv li, txoj kev sib txawv raws li lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm kev ua haujlwm - phau ntawv, semi-automatic thiab tsis siv neeg. Hauv kev suav kom ntxaws ntxiv ntawm cov qauv vuam hauv cov khoom siv tiv thaiv, cov kev txwv hauv qab no raug coj mus rau hauv tus account:

- Tam sim no - thaj tsam ntawm 30 txog 550 A. Raws li txoj cai, feem ntau kev ua haujlwm yuav tsum muaj kev sib txuas ntawm qhov chaw ntawm 80-120 A.

- Electrode thickness - los ntawm 4 mus rau 12 hli.

- Voltage - 20 txog 100 W ntawm qhov nruab nrab.

- vuam ceev - ntawm 30 txog 60 m / h.

- Kev siv roj sib xyaw - ntawm 7 txog 12 l / min.

Kev xaiv ntawm cov ntsuas tshwj xeeb feem ntau nyob ntawm hom hlau, thickness ntawm lub workpiece, cov xwm txheej ntawm kev ua haujlwm thiab qhov yuav tsum tau ua rau kev sib koom ua ke.

Kev siv vuam

Lub luag haujlwm tseem ceeb hauv cov txheej txheem yog ua los ntawm kev txawj ntawm tus neeg teb xov tooj thiab cov yam ntxwv ntawm cov electrode. Yuav luag tag nrho cov welderkhaws cov txheej txheem nyob rau hauv nws cov kev tswj hwm, orienting lub arc txheeb ze rau qhov chaw ua hauj lwm thiab saib xyuas cov tsis muaj roj sib tov muab los ntawm lub tog raj kheej. Hais txog kev ua tau zoo, qhov ceev thiab lub zog tam sim no, nrog rau qhov ntev ntawm txoj kev vuam, yuav los ua ntej. Nyob rau hauv phau ntawv welding nyob rau hauv shielding roj, ob peb kis feem ntau yog ua, tshwj xeeb tshaj yog yog hais tias ib tug tuab workpiece yog machined. Hauv lwm qhov xwm txheej, qhov nce ntawm cov ntawv hla yog cuam tshuam nrog qhov yuav tsum tau kho qhov vuam, hloov nws qhov ntev thiab cov yam ntxwv ntawm qhov nto.

Semi-automatic vuam

Hnub no, qhov no yog hom kev siv vuam ntau tshaj plaws hauv kev tiv thaiv ib puag ncig. Qhov sib txawv tseem ceeb ntawm txoj kev no thiab phau ntawv qhia ib qho yog qhov muaj cov khoom siv tshuab nrog cov rectifiers thiab muaj peev xwm tsis siv neeg xaim pub los ntawm cov kauj tshwj xeeb. Nrog semi-automatic vuam nyob rau hauv shielding roj, tus neeg teb xov tooj tsis tas yuav cuam tshuam los hloov cov khoom siv, tab sis cov txheej txheem ntawm kev sib cuam tshuam ntawm arc nrog rau saum npoo ntawm lub workpiece tseem yog nyob ntawm tus neeg siv. Tus neeg teb xov tooj saib xyuas cov txheej txheem ntawm kev tsim cov vuam sib koom ua ke, kho qhov ntsuas tam sim no, hloov lub kaum sab xis ntawm inclination, thiab lwm yam.

tsis siv neeg vuam

Cov txheej txheem vuam tshuab tag nrho, uas tus neeg siv tsuas tuaj yeem cuam tshuam ncaj qha rau cov khoom siv khoom siv, roj sib tov thiab hmoov flux. Technically, lub lag luam yog muab los ntawm multifunctional chaw nres tsheb thiab platforms nrog robotic khoom. Ntawm cov chaw tsim khoom tshwj xeeb niaj hnub no rau kev siv vuam tsis siv neeg hauv kev tiv thaiv rojlub tsheb laij teb hu ua lub tsheb laij teb yog siv, tus tsim ntawm uas muab rau tag nrho cov tsim nyog functional units. Qhov no yog lub tshuab txawb uas txav tau thaum lub sij hawm vuam txheej txheem raws li seam tsim kab thiab tib lub sij hawm coj cov kev tiv thaiv sib tov rau hauv vuam cheeb tsam. Ib qho yuav tsum tau ua ntawm cov qauv no yog cov tswj hwm, uas pib muaj cov txheej txheem algorithms nrog kev ua rau txhua tus thawj coj.

Zaj lus

Kev siv txoj hauv kev los tiv thaiv lub pas dej welding los ntawm oxygen tso cai, yog tias tsis tshem tawm tag nrho, ces txo qis tus yam ntxwv tsis xws luag hauv kev tsim cov seam. Qhov no siv rau qhov tsis muaj kev nkag mus, tawg, kub hnyiab, sagging thiab lwm yam tsis zoo uas yuav tshwm sim vim yog kev sib cuag ntawm lub molten nto ntawm lub workpiece nrog qhib cua. Qhov zoo ntawm kev siv vuam hauv kev tiv thaiv cov roj cua tshaj cov txheej txheem ntawm kev siv flux muaj xws li qhov tsis muaj qhov xav tau tshem tawm cov sludge hauv thaj chaw ua haujlwm. Nyob rau tib lub sijhawm, lwm yam zoo ntawm cov txheej txheem yog khaws cia, xws li qhov ua tau ntawm kev pom kev pom ntawm qhov zoo ntawm cov txheej txheem tsim. Yog hais tias peb tham txog cov shortcomings ntawm txoj kev, ces nws tsis zoo yam tseem ceeb yog lub thermal thiab lub teeb hluav taws xob ntawm lub arc, uas yuav tsum tau muab cov kev ntsuas tshwj xeeb rau tus neeg tiv thaiv ntawm lub welder.

Pom zoo:

Beech ntom. Nta, daim ntawv thov thiab thev naus laus zis ntawm cov ntoo

Beech yog ib hom ntoo ntau tshaj plaws uas pom muaj nyob hauv cov hav zoov sib xyaw thiab deciduous thoob plaws ntau lub tebchaws Europe. Nws yog dav siv nyob rau hauv kev tsim cov rooj tog. Nws cov ntoo muaj lub zog zoo, toughness thiab inelasticity. Qhov ceev ntawm beech, uas yuav tau tham nyob rau hauv tsab xov xwm, nyob ntawm seb lub cellular qauv thiab av noo

Kev tswj hwm thev naus laus zis: hom, yam ntxwv, daim ntawv thov

Kev tswj hwm thev naus laus zis muaj ntau yam khoom siv kho vajtse thiab software daws teeb meem tsim los txhim kho kev ua haujlwm ntawm cov thawj coj tseem ceeb. Txij li cov thev naus laus zis tau hloov kho los ua haujlwm rau kev tswj hwm, thev naus laus zis tuaj yeem piav qhia hauv cov ntsiab lus xws li kev sib txuas lus, kev npaj, kev saib xyuas thiab kev tswj hwm. Nkag siab txog yuav ua li cas thev naus laus zis tuaj yeem txhim kho txhua qhov tseem ceeb yog qhov tseem ceeb rau kev siv nws kom zoo rau kev sib tw kom zoo dua

Kev tiv thaiv corrosion ntawm cov qauv hlau: cov khoom siv thiab thev naus laus zis

Kev tiv thaiv corrosion ntawm cov qauv hlau yog tsom rau kev tiv thaiv qhov chaw los ntawm qhov tsis zoo ntawm ib puag ncig

Vuam hauv qhov chaw tiv thaiv roj: ua haujlwm thev naus laus zis, txheej txheem piav qhia, cov txheej txheem ua tiav, cov khoom tsim nyog thiab cov cuab yeej, cov lus qhia ua haujlwm ib ntus thiab cov lus qhia kws tshaj lij

Vuam thev naus laus zis yog siv hauv ntau ceg ntawm tib neeg kev ua haujlwm. Versatility tau ua vuam nyob rau hauv ib puag ncig tiv thaiv roj ib qho tseem ceeb ntawm kev tsim khoom. Qhov ntau yam no ua rau nws yooj yim los txuas cov hlau nrog lub thickness ntawm 1 hli mus rau ob peb centimeters nyob rau hauv txhua txoj hauj lwm nyob rau hauv qhov chaw. Vuam nyob rau hauv ib puag ncig tiv thaiv yog maj mam hloov cov tsoos electrode vuam

Flux rau vuam: lub hom phiaj, hom vuam, flux muaj pes tsawg leeg, cov cai ntawm kev siv, GOST cov cai, qhov zoo thiab qhov tsis zoo ntawm daim ntawv thov

Qhov zoo ntawm cov vuam yog txiav txim siab tsis yog los ntawm lub peev xwm ntawm tus tswv los npaj lub arc kom raug, tab sis kuj los ntawm kev tiv thaiv tshwj xeeb ntawm thaj chaw ua haujlwm los ntawm kev cuam tshuam sab nraud. Tus yeeb ncuab tseem ceeb ntawm txoj hauv kev los tsim kom muaj kev sib txuas ntawm cov hlau uas muaj zog thiab ruaj khov yog cov huab cua puag ncig ntuj. Lub vuam yog cais tawm los ntawm cov pa oxygen los ntawm cov flux rau vuam, tab sis qhov no tsis yog nws txoj haujlwm xwb