2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2024-01-02 13:55

Hlau ore tau txais raws li ib txwm muaj: qhib qhov av lossis hauv av mining thiab thauj tom ntej rau kev npaj thawj zaug, qhov twg cov khoom raug crushed, ntxuav thiab ua tiav.

Cov ore yog nchuav rau hauv lub qhov cub tawg thiab tawg nrog cua kub thiab cua sov, uas hloov mus ua hlau molten. Tom qab ntawd nws raug tshem tawm hauv qab ntawm lub qhov cub rau hauv cov pwm hu ua npua, qhov twg nws yog txias los tsim npua hlau. Nws tau hloov mus ua hlau los yog ua tiav rau hauv steel ntau txoj kev.

steel yog dab tsi?

Thaum pib muaj hlau. Nws yog ib qho ntawm cov hlau ntau tshaj plaws nyob rau hauv lub ntiaj teb crust. Nws tuaj yeem pom yuav luag txhua qhov chaw, ua ke nrog ntau lwm cov ntsiab lus, hauv daim ntawv ore. Hauv Tebchaws Europe, kev ua haujlwm hlau hnub rov qab mus rau 1700 BC

Hauv xyoo 1786, Fabkis cov kws tshawb fawb Berthollet, Monge thiab Vandermonde tau txiav txim siab tseeb tias qhov sib txawv ntawm cov hlau, cam khwb cia hlau thiab hlau yog vim muaj cov ntsiab lus carbon sib txawv. Txawm li cas los xij, steel, ua los ntawm hlau, sai sai tau los ua cov hlau tseem ceeb tshaj plaws ntawm Kev Lag Luam Kev Lag Luam. Thaum pib ntawm lub xyoo pua 20th, lub ntiaj teb steel ntau lawm yog 28lab tons - qhov no yog rau lub sijhawm ntau tshaj li xyoo 1880. Thaum pib ntawm Kev Tsov Rog Thoob Ntiaj Teb thib 1, nws cov khoom tsim tau yog 85 lab tons. Tau ntau xyoo lawm, nws tau xyaum hloov hlau.

Cov ntsiab lus carbon cuam tshuam rau cov yam ntxwv ntawm cov hlau. Muaj ob hom hlau tseem ceeb: alloyed thiab unalloyed. Hlau alloy hais txog cov khoom siv tshuaj uas tsis yog carbon ntxiv rau hlau. Yog li, ib qho alloy ntawm 17% chromium thiab 8% npib tsib xee yog siv los tsim stainless hlau.

Tam sim no, muaj ntau dua 3000 hom npe (cov tshuaj muaj pes tsawg leeg), tsis suav cov tsim los ua kom tau raws li tus neeg xav tau. Tag nrho cov no pab ua kom cov hlau yog cov khoom tsim nyog tshaj plaws rau cov kev cov nyom yav tom ntej.

Steelmaking raw khoom: thawj thiab theem nrab

Smelting no hlau siv ntau yam yog ib txoj kev mining feem ntau. Cov ntaub ntawv them nqi tuaj yeem yog thawj thiab theem nrab. Lub ntsiab muaj pes tsawg leeg ntawm tus nqi, raws li txoj cai, yog 55% npua hlau thiab 45% ntawm cov seem hlau seem. Ferroalloys, hloov dua siab tshiab cam khwb cia hlau thiab ua lag luam ntshiab hlau yog siv los ua lub ntsiab ntawm cov alloy, raws li txoj cai, txhua hom ferrous hlau raug cais raws li theem nrab.

Hlau ore yog qhov tseem ceeb tshaj plaws thiab cov khoom siv tseem ceeb hauv kev lag luam hlau thiab hlau. Nws yuav siv li 1.5 tons ntawm cov khoom no los tsim ib tuj ntawm npua hlau. Kwv yees li 450 tons ntawm coke yog siv los tsim ib tuj npua hlau. Ntau cov hlau ua haujlwmtxawm siv charcoal.

Dej yog cov khoom siv tseem ceeb rau kev lag luam hlau thiab hlau. Nws yog tsuas yog siv rau coke quenching, moj tej tawg rauv cua txias, thee rauv qhov rooj chav tsev ntau lawm, hydraulic khoom lag luam thiab pov tseg dej pov tseg. Nws yuav siv li 4 tons ntawm huab cua los tsim ib tuj hlau. Flux yog siv rau hauv qhov cub tawg kom tshem tawm cov kab mob los ntawm cov smelter ore. Limestone thiab dolomite ua ke nrog cov impurities rho tawm los ua slag.

Ob lub tshuab tawg thiab steel rauv kab nrog cov refractories. Lawv yog siv los tig rau lub cub tawg npaj rau hlau ore smelting. Silicon dioxide los yog xuab zeb yog siv rau molding. Cov hlau tsis muaj hlau yog siv los tsim cov hlau ntawm ntau qib: txhuas, chromium, cob alt, tooj liab, txhuas, manganese, molybdenum, npib tsib xee, tin, tungsten, zinc, vanadium, thiab lwm yam. Ntawm tag nrho cov ferroalloys, manganese yog dav siv hauv steelmaking.

Hlau khib nyiab los ntawm kev rhuav tshem lub Hoobkas cov qauv, tshuab, tsheb qub, thiab lwm yam. yog rov siv dua thiab siv dav hauv kev lag luam.

Hlau rau steel

Steel smelting nrog cam khwb cia hlau yog ntau ntau dua li nrog rau lwm yam ntaub ntawv. Cam khwb cia hlau yog ib lo lus uas feem ntau yog hais txog grey hlau, tab sis nws kuj tau txheeb xyuas nrog ib pawg loj ntawm ferroalloys. Cov pa roj carbon ua kom txog li 2.1 txog 4 wt% thaum silicon feem ntau yog 1 txog 3 wt% hauv cov hlau.

Hlau thiab hlau smelting tshwm sim ntawm qhov kub thiab txiasmelting point ntawm 1150 thiab 1200 degrees, uas yog hais txog 300 degrees qis dua lub melting point ntawm ntshiab hlau. Cam khwb cia hlau kuj pom zoo fluidity, zoo heev machinability, tsis kam mus deformation, oxidation thiab casting.

Hlau kuj yog ib qho hlau hlau nrog cov ntsiab lus sib txawv ntawm cov pa roj carbon. Cov ntsiab lus carbon ntawm cov hlau yog 0.2 txog 2.1 pawg%, thiab nws yog cov khoom siv nyiaj txiag tshaj plaws rau cov hlau. Smelting steel los ntawm cam khwb cia hlau yog pab tau rau ntau yam engineering thiab structural hom phiaj.

hlau ore rau steel

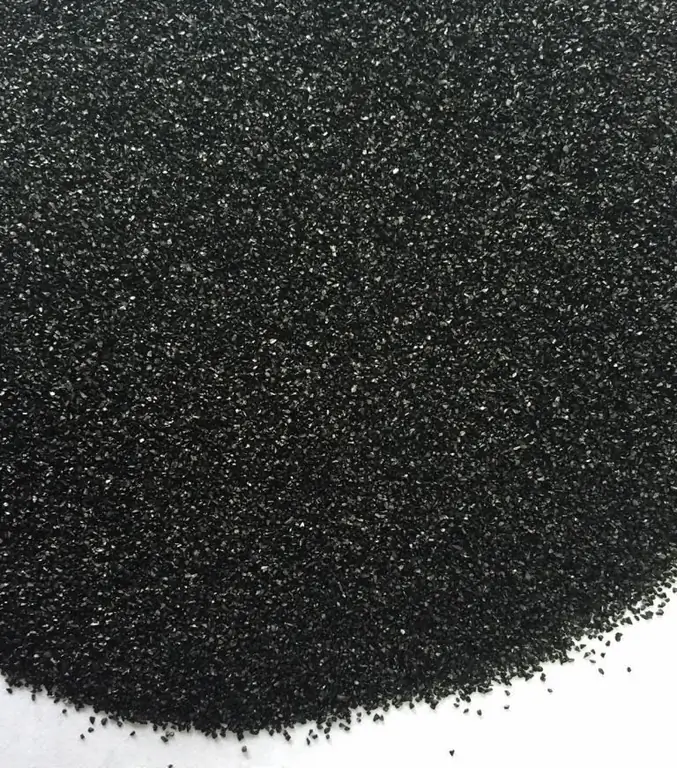

txheej txheem ntawm kev ua hlau pib nrog kev ua cov hlau ore. Lub pob zeb uas muaj hlau ore yog crushed. Ore yog mined siv magnetic rollers. Fine-grained hlau ore yog ua tiav rau hauv coarse-grained lumps rau siv nyob rau hauv lub moj tej tawg rauv. Coal yog refined nyob rau hauv lub qhov cub coke los tsim ib tug yuav luag ntshiab daim ntawv ntawm carbon. Kev sib xyaw ntawm cov hlau ore thiab thee yog tom qab ntawd rhaub kom tsim cov hlau molten, lossis npua hlau, los ntawm cov hlau ua.

Nyob rau hauv lub ntsiab pa taws cub, molten hlau ore yog lub ntsiab raw khoom thiab yog tov nrog ntau npaum li cas ntawm cov seem hlau thiab alloys los tsim ntau qib ntawm hlau. Nyob rau hauv ib qho hluav taws xob arc rauv, rov siv cov hlau seem yog yaj ncaj qha rau hauv cov hlau tshiab. Kwv yees li 12% ntawm cov hlau yog tsim los ntawm cov khoom siv rov ua dua.

Smelting technology

Smelting yog txheej txheem uas cov hlau tau txais los ntawm cov khoom,xws li ib qho yooj yim compound los ntawm nws cov ore los ntawm cua sov saum toj no nws melting point, feem ntau nyob rau hauv lub xub ntiag ntawm oxidizing agents xws li cua los yog txo cov neeg ua hauj lwm xws li coke.

In steelmaking technology, cov hlau uas ua ke nrog oxygen, xws li hlau oxide, yog rhuab mus rau qhov kub thiab txias, thiab cov oxide yog tsim ua ke nrog carbon nyob rau hauv cov roj, uas yog tso tawm raws li carbon monoxide los yog carbon. dioxide. Lwm cov impurities, sib sau ua ke hu ua leeg, raug tshem tawm los ntawm kev ntxiv cov kwj deg uas lawv sib xyaw ua cov slag.

Niaj hnub nimno steelmaking siv lub reverberatory rauv. Cov concentrated ore thiab kwj dej (feem ntau yog limestone) yog loaded rau saum, thaum lub molten matte (chaw ntawm tooj liab, hlau, sulfur, thiab slag) yog kos los ntawm hauv qab. Kev kho cua sov thib ob hauv lub tshuab hluav taws xob hloov hluav taws xob yog qhov tsim nyog kom tshem tawm cov hlau los ntawm cov matte tiav.

Oxygen-convector method

Cov txheej txheem BOF yog lub ntiaj teb ua cov txheej txheem steelmaking. Lub ntiaj teb kev tsim cov hlau hloov pauv hauv xyoo 2003 yog 964.8 lab tons lossis 63.3% ntawm tag nrho cov khoom. Hloov ntau lawm yog ib qhov chaw ntawm ib puag ncig muaj kuab paug. Cov teeb meem tseem ceeb ntawm qhov no yog kev txo qis emissions, tso tawm thiab txo cov pov tseg. Lawv cov ntsiab lus yog nyob rau hauv kev siv lub zog thib ob thiab cov khoom siv.

Exothermic tshav kub yog tsim los ntawm oxidation cov tshuaj tiv thaiv thaum lub tshuab nqus tsev.

Cov txheej txheem tseem ceeb ntawm steelmaking siv peb tus kheejstocks:

- Molten hlau (qee zaum hu ua hlau kub) los ntawm lub qhov cub tawg yog nchuav rau hauv lub thawv loj refractory lined hu ua ladle.

- Cov hlau hauv lub ladle yog xa ncaj qha mus rau lub ntsiab steel ntau lawm los yog ua ntej kev kho mob theem.

- High purity oxygen ntawm qhov siab ntawm 700-1000 kilopascals yog txhaj ntawm supersonic ceev mus rau saum npoo ntawm cov hlau da dej los ntawm cov dej txias uas tau muab tshem tawm hauv lub nkoj thiab tuav ob peb taw saum da dej.

Kev txiav txim siab ua ntej kho yog nyob ntawm qhov zoo ntawm cov hlau kub thiab qhov xav tau kawg steel zoo. Tus thawj heev tshem tau hauv qab converters uas yuav tsum tau detached thiab kho yog tseem siv. Cov hmuv siv los tshuab tau hloov lawm. Txhawm rau tiv thaiv kev sib tsoo ntawm lub lance thaum tshuab, siv cov dab tshos nrog ib lub taub ntev ntawm cov tooj liab. Cov lus qhia ntawm lub ntsis, tom qab combustion, hlawv tawm cov CO tsim thaum tshuab rau CO2 thiab muab cua sov ntxiv. Darts, pob refractory thiab slag detectors yog siv los tshem tawm slag.

Oxygen-convector method: qhov zoo thiab qhov tsis zoo

Tsis xav tau tus nqi ntawm cov khoom siv roj purification, txij li kev tsim cov hmoov av, piv txwv li hlau evaporation, txo los ntawm 3 zaug. Vim qhov txo qis ntawm cov khoom siv hlau, qhov nce ntawm cov kua hlau tawm los ntawm 1.5 - 2.5%. Qhov zoo dua yog tias lub tshuab siv zog hauv txoj kev no nce, uas muabmuaj peev xwm nce qhov kev ua tau zoo ntawm lub converter los ntawm 18%. Qhov zoo ntawm cov hlau yog siab dua vim tias qhov kub thiab txias hauv thaj chaw huv si qis dua, uas ua rau muaj nitrogen tsawg dua.

Qhov tsis txaus ntawm txoj kev no ntawm cov hlau smelting ua rau txo qis hauv kev thov rau kev siv, vim tias qib ntawm cov pa oxygen nce 7% vim yog kev siv roj ntau. Muaj cov ntsiab lus hydrogen ntau ntxiv hauv cov hlau siv dua tshiab, uas yog vim li cas nws yuav siv sijhawm qee lub sijhawm tom qab qhov kawg ntawm cov txheej txheem los ua kom tshem tawm cov pa oxygen. Ntawm tag nrho cov txheej txheem, oxygen-converter muaj lub siab tshaj plaws slag tsim, yog vim li cas yog tsis muaj peev xwm saib xyuas cov txheej txheem oxidation hauv cov khoom.

Open-hearth method

Cov txheej txheem qhib-hearth rau feem ntau ntawm xyoo pua 20th yog qhov tseem ceeb ntawm kev ua cov hlau ua hauv ntiaj teb. William Siemens, nyob rau xyoo 1860, nrhiav ib txoj hauv kev los txhim kho qhov kub thiab txias hauv lub tshuab hluav taws xob metallurgical, resurrecting ib tug qub tswv yim siv cov khib nyiab hluav taws xob tsim los ntawm lub cub tawg. Nws ua kom sov lub cib kom sov, ces siv tib txoj kev los qhia huab cua rau hauv qhov cub. Cov cua preheated nce qhov kub ntawm cov nplaim taws ntau.

Natural gas los yog atomized hnyav roj siv los ua roj; cua thiab roj yog rhuab ua ntej combustion. Lub cub tawg yog loaded nrog kua npua hlau thiab steel seem nrog rau hlau ore, limestone, dolomite thiab fluxes.

Lub qhov cub nws tus kheej yog ua los ntawmcov ntaub ntawv refractory heev xws li magnesite hearth cib. Qhib hearth furnaces hnyav txog li 600 tons thiab feem ntau yog nruab rau hauv pab pawg, kom cov khoom siv pabcuam loj uas xav tau los them cov khoom siv hluav taws xob thiab cov txheej txheem ua kua hlau tuaj yeem siv tau zoo.

Txawm hais tias cov txheej txheem qhib hearth tau yuav luag hloov tag nrho hauv ntau lub tebchaws industrialized los ntawm cov txheej txheem oxygen yooj yim thiab hluav taws xob arc rauv, nws ua rau kwv yees li 1/6 ntawm tag nrho cov hlau tsim thoob ntiaj teb.

Qhov zoo thiab qhov tsis zoo ntawm txoj kev no

Qhov zoo suav nrog kev siv yooj yim thiab yooj yim ntawm kev tsim cov hlau alloy nrog ntau yam khoom ntxiv uas muab cov khoom siv ntau yam tshwj xeeb. Qhov tsim nyog additives thiab alloys yog ntxiv tam sim ua ntej qhov kawg ntawm smelting.

Qhov tsis zoo suav nrog txo kev ua haujlwm piv rau cov pa oxygen converter. Tsis tas li ntawd, qhov zoo ntawm cov hlau yog qis dua piv rau lwm cov hlau smelting txoj kev.

Electric steelmaking method

Txoj kev niaj hnub ntawm smelting steel siv peb tus kheej reserves yog lub cub tawg uas ua kom sov cov khoom siv nrog hluav taws xob arc. Industrial arc furnaces muaj qhov loj me los ntawm cov chav me me nrog lub peev xwm ntawm ib tuj (siv hauv cov chaw tsim khoom rau kev tsim cov khoom hlau) mus txog 400 tons ntawm cov khoom siv hauv cov khoom siv hlau thib ob.

Arc furnaces,siv nyob rau hauv kev tshawb fawb soj ntsuam tej zaum yuav muaj peev xwm tsuas yog ob peb kaum grams. Muaj hluav taws xob arc rauv kub tuaj yeem ncav cuag 1800 ° C (3, 272 ° F), thaum lub chaw kuaj xyuas tuaj yeem tshaj 3000 ° C (5432 ° F).

Arc furnaces txawv ntawm qhov cub induction nyob rau hauv uas cov khoom siv them ncaj qha raug rau hluav taws xob arc, thiab tam sim no hauv cov terminals dhau los ntawm cov khoom siv. Lub tshuab hluav taws xob arc rauv yog siv rau kev tsim cov hlau, muaj cov txheej txheem refractory, feem ntau yog dej txias, loj loj, npog nrog lub ru tsev retractable.

Lub qhov cub feem ntau muab faib ua peb ntu:

- Plhaub muaj cov phab ntsa sab thiab qis steel tais.

- Lub hearth muaj lub refractory uas rub tawm lub tais qis.

- Lub ru tsev refractory los yog dej txias lub ru tsev tuaj yeem ua tau raws li lub pob los yog lub khob hliav qab (conical seem).

Qhov zoo thiab qhov tsis zoo ntawm txoj kev

Txoj kev no tuav txoj haujlwm tseem ceeb hauv kev tsim cov hlau. Cov txheej txheem hlau smelting yog siv los tsim cov hlau zoo uas yog tsis muaj tag nrho, lossis muaj me me ntawm cov khoom tsis zoo xws li sulfur, phosphorus thiab oxygen.

Qhov txiaj ntsig tseem ceeb ntawm txoj kev yog kev siv hluav taws xob rau cua sov, yog li koj tuaj yeem tswj tau qhov kub thiab txias thiab ua tiav qhov zoo kawg ntawm cov cua sov ntawm cov hlau. Automated ua haujlwm yuav dhau losib qho qab ntxiag ntxiv rau lub sijhawm zoo rau kev ua haujlwm zoo ntawm ntau yam khoom seem hlau.

Qhov tsis zoo suav nrog kev siv hluav taws xob siab.

Pom zoo:

Kev tsom xam cov khoom lag luam: cov txheej txheem ntawm kev coj ua, xaiv txoj hauv kev ntawm kev tshuaj xyuas, cov lus qhia thiab kev ua kom yuam kev

Dab tsi yog cov khoom lag luam. Yuav ua li cas txheeb xyuas cov khoom lag luam, cov ntaub ntawv twg yog siv rau qhov no. Dab tsi yog qhov txaus ntshai cuam tshuam nrog kev yuav shares? Hom kev tsom xam cov khoom lag luam, cov qauv siv dab tsi. Dab tsi yog cov yam ntxwv ntawm kev tsom xam ntawm kev sib koom ntawm cov tuam txhab Lavxias, cov lus qhia thiab kev ua kom yuam kev rau kev sau cov ntaub ntawv thiab tshuaj xyuas kev sib koom

Kev kho dej khib nyiab los ntawm cov khoom siv roj: txoj hauv kev, txoj hauv kev thiab kev ua haujlwm

Tam sim no, thev naus laus zis thiab txhais tau tias, txoj hauv kev thiab chav ua haujlwm, ua tsaug rau kev kho dej khib nyiab los ntawm cov khoom siv roj, yog ib qho tseem ceeb tshaj plaws ntawm kev tiv thaiv ib puag ncig. Hauv peb lub tebchaws, txog li tsib xyoos, tau tsim cov qauv kev cai rau kev ua kom huv ntawm cov kua dej tawm los ntawm kev lag luam. Cov ntaub ntawv ntawm qhov teeb meem no tsim kom muaj qhov zoo thiab qhov ntim ntawm cov dej uas tuaj yeem tsim los ntawm cov chaw tsim khoom

Kev lag luam khaub ncaws ua ib ceg ntawm kev lag luam teeb. Tshuab, khoom siv thiab raw khoom rau kev lag luam khaub ncaws

Cov lus no mob siab rau kev lag luam khaub ncaws. Cov thev naus laus zis siv hauv kev lag luam no, cov cuab yeej siv, cov khoom siv raw, thiab lwm yam raug txiav txim siab

Yuav ua li cas los ua tus neeg muag khoom zoo dua: lub ntsiab lus ntawm lub tswv yim, kev piav qhia txoj haujlwm, cov xwm txheej thiab cov phiaj xwm, txoj hauv kev, kev cob qhia, zais cia, kev txhawb siab thiab cov lus qhia kws tshaj lij

Nyob tsis ntev los no, qhov chaw muag khoom tau tshwm sim. Txawm tias tom qab ntau tshaj li kaum xyoo, txoj haujlwm no ua rau ntau cov lus nug. Cov neeg thov uas tau txais txoj haujlwm no tsis tas yuav nkag siab meej txog lub luag haujlwm uas lawv yuav tsum tau ua thiab qhov txiaj ntsig ntawm kev tswj hwm xav tau

Yuav ua li cas los ua tus neeg muag khoom zoo: lub tswv yim ntawm lub hauv paus ntawm kev ua haujlwm, thawj theem, tau txais kev paub dhau los, kev muag khoom, cov kev pabcuam zoo thiab muaj peev xwm piav qhia txhua qhov zoo ntawm kev yuav khoom

Yuav ua li cas thiaj ua tau tus neeg muag khoom zoo? Koj puas xav tau kev txawj ntse, lossis ib tus neeg tuaj yeem txhim kho qhov tsim nyog ntawm nws tus kheej? Leej twg tuaj yeem dhau los ua tus thawj coj zoo. Nws tsuas yog qhov ntawd rau qee tus neeg, tau txais cov txuj ci tsim nyog yuav yooj yim, thaum lwm tus yuav tau siv zog ntau. Tab sis thaum kawg, ob leeg yuav muag zoo sib xws