2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2024-01-17 18:53

Kev sib txhuam cov pob qij txha muaj peev xwm ua haujlwm siab thiab tsis tshua muaj zog ntau dua li cov pob qij txha. Vim li no, lawv tau siv dav hauv kev tsim cov vaj tsev hlau. Tau txais cov kev sib txhuam tsim nyog hauv kev sib koom ua ke yog ua tiav nyob rau hauv ntau txoj hauv kev - abrasive blasting thiab nplaim taws kho, nrog rau kev siv cov nplaum nplaum.

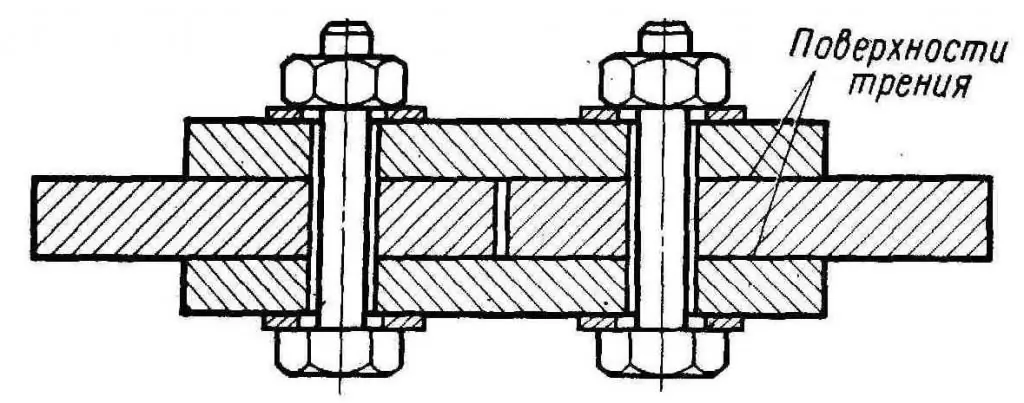

Kev piav qhia thiab daim ntawv thov

Hauv kev tsim kho tshuab, muaj 2 hom kev sib txuas bolted raws li qhov xwm txheej ntawm lub zog hloov hauv lawv:

- Shear resistant. Feem ntau lawv yog tsim los ntawm bolts ntawm ntxhib, ib txwm thiab nce qhov tseeb (tsis tshua muaj siab zog). Lub zog nruj yog tsis tswj. Kev suav suav suav suav rau hauv cov tensile, compressive thiab shear stresses, tab sis tsis txhob suav rau hauv tus account frictional rog.

- Kev sib txhuam (shear resistant). Lub zog sab nraud yog counteracted los ntawm kev sib txhuam rog tshwm sim nyob rau hauv kev sib cuag dav hlau ntawm qhov chaw yuav tsum tau koom. Qhov kev sib txhuam yog vim qhov preload ntawm qhov kho bolts, uas yuav tsum tau siab tshaj plaws. Yog li ntawd, nyob rau hauv xws li pob qij txha, high-strength hardware nrog thermalprocessing.

hom kawg tau muab faib ua 2 pawg: kev sib txhuam thiab kev sib txhuam-shear cov pob qij txha, uas ib feem ntawm lub zog kis tau los ntawm kev sib txhuam, thiab lwm yam los ntawm kev sib tsoo.

Qhov tsis zoo ntawm cov kev sib txuas no yog tus nqi siab ntawm fasteners. Ntawm qhov tod tes, kev siv cov kev sib txhuam cov pob qij txha ntawm lub zog muaj zog bolts txhim kho kev ntseeg tau thiab txo cov naj npawb ntawm cov welds. Raws li, qhov nyuaj ntawm kev sib dhos yog txo los ntawm yuav luag 3 zaug. Hom kev sib txuas no yog siv rau hauv kev tsim kho vaj tse, hauv kev tsim cov choj, cranes, thiab lwm cov qauv lattice uas muaj kev vibration lossis dynamic loads.

Kev cog lus cov lus qhia hauv kev txhim kho cov kev daws teeb meem no yog kev siv cov txheej txheem tshem tawm kev txuag thiab kev siv "thaiv" tshuab tsim, thaum sib dhos thiab pleev xim ntawm cov khoom loj yog nqa tawm ntawm cov nroj tsuag, thiab tsuas yog qhov kawg. kev teeb tsa tau ua tiav ntawm qhov chaw tsim kho.

Roughness factor

Qhov yuav tsum tau muaj qhov roughness, uas muab cov kev sib txhuam quab yuam, yog ua tiav los ntawm abrasive, nplaim kho ntawm mating nto los yog siv cov txheej tshwj xeeb. Cov coefficient ntawm kev sib txhuam rau kev suav yog muab los ntawm cov lus hauv qab no.

| hom kev ua haujlwm | Coefficient ntawm kev sib txhuam |

| Tsis khaws cia | |

| 0, 35 | |

| 0, 38 | |

| Txiav nplaim | 0, 42 |

| Tua- lossis sandblasting | 0, 58 |

| Tua blasting, ntxuav ntawm ob qhov chaw, nplaim hluav taws kub txog 300 ° C nyob ib ncig ntawm lub qhov ntsia hlau. Qhov chaw kho cua sov - tsis tsawg dua qhov loj me me | 0, 61 |

| Nrog kev khaws cia tom ntej | |

| Thawj nthuav dav - xuab zeb lossis tua blasting, khaws cia nrog kua nplaum. Qhov thib ob mating part - txhuam, tsis muaj kev khaws cia ntxiv | 0, 5 |

Hom kev ua haujlwm yuav tsum tau qhia ntawm cov duab kos. Cov mating nto yog kiag li tsis muaj dej khov, daus, roj, nplai, xeb thiab lwm yam kab mob ua ntej bolt los ua ke.

Sandblasting

Cov kev cai hauv qab no siv rau kev tu cov qauv hlau nrog kev sib txhuam cov pob qij txha siv cov tshuab sandblasting:

- roughness ntawm qhov chaw npaj - tsis ntau tshaj Ra 6, 3;

- ua tiav tshem tawm cov oxides thiab xeb (2nd degree ntawm kev huv raws li GOST 9.402-2004);

- degree ntawm degreasing degreasing - thawj (dej zaj duab xis so lub sij hawm - ntau tshaj 1 feeb, tsis muaj roj stains ntawm daim ntawv lim);

- ua ntej ntxuav ntawm compressed cua nkag rau hauv sandblaster los ntawm cov roj thiab noo noo (qhov no yog tswj tsawg kawg yog 1 zaug ib zaug);ziab quartz xuab zeb kom cov dej noo tsis ntau tshaj 2%.

Tom qab sandblasting, plua plav yuav tsum tau muab tshem tawm ntawm qhov chaw los ntawm kev tshuab cua lossis so nrog ib daim ntaub huv.

Nplaim kho mob

Cov nplaim hluav taws oxy-acetylene yog siv thaum ntxuav qhov chaw nrog lub teeb roj. Cov khoom combustion (oxides) tom qab raug tshem tawm nrog cov txhuam hlau. Hauv qhov no, koj tsis tuaj yeem nqa cov hlau mus rau qhov ci. Nplaim tu tsuas yog siv tau rau qhov chaw nrog lub thickness tsawg kawg yog 5 hli, txhawm rau kom tsis txhob muaj lawv cov thermal warping. Kev ua haujlwm yog nqa tawm hauv cov qauv hauv qab no:

- oxygen siab - 0.6 MPa, acetylene hauv lub tog raj kheej - 0.05 MPa;

- oxygen mov - qhov siab tshaj plaws (qhov tseem ceeb ntawm cov nplaim taws yuav tsum tawm ntawm lub tshuab cua sov, tab sis tsis tawm mus);

- taws mus los nrawm - 1 m / min (rau nyias-walled hlau qauv 5-10 mm - 1.5-2 m / min);

- kis tom ntej yuav tsum sib tshooj dhau los ntawm 15-20mm;

- taws lub kaum sab xis txog 45 °.

Thaum lub sijhawm ua haujlwm thev naus laus zis no, cov hluav taws kub tshwj xeeb uas muaj nplaim taws dav siv.

Ua ntej ua cov txhuam hlau (txhaj tshuaj txhuam), cov xim raug tshem tawm ntawm qhov chaw nrog cov kuab tshuaj los yog hauv txoj kev siv roj. Nws yog tsis yooj yim sua kom ntxuav qhov chaw mus rau ib tug metallic sheen, vim qhov no tiv thaiv kev tsim ntawm zoo coefficient ntawm kev sib txhuam. Kev ua haujlwm yog ua los ntawm kev siv tshuab pneumatic lossis hluav taws xobcuab tam. Cov plua plav uas tseem tshuav raug tshem tawm los ntawm tshuab cua lossis txhuam plaub hau.

Kev txhaj tshuaj blasting, steel lossis cam khwb cia hlau chipped (tws) txhaj nrog ib feem ntawm 0.8-1.2 hli yog siv. Txhaj tshuaj tua kab mob siv cov cam khwb cia hlau.

Txhawm rau kom muaj kev sib txhuam quab yuam hauv flange thiab kev sib txhuam cov pob qij txha, cov tshuaj nplaum kuj tseem siv - cov nplaum. Raws li kev sib txhuam txheej, kev sib xyaw yog siv, cov khoom tseem ceeb uas yog epoxy resin, thiab cov khoom ntxiv yog cov tawv tawv, hnyav, accelerator lossis isopropanol.

Kev ua haujlwm ua ke yog ua raws li hauv qab no:

- Cov qauv loj loj yog ntxuav los ntawm ib txoj hauv kev tau piav qhia saum toj no, tshwj tsis yog cov nplaim taws, thiab kuj degreased. Lub sijhawm nruab nrab ntawm kev ntxuav thiab gluing yuav tsum tsis pub tshaj 0.5 hnub. Kev khaws cia rau tib lub sijhawm yog nqa tawm hauv cov av noo tsis tshaj 80%.

- Cov kua nplaum yog npaj tam sim ua ntej siv.

- Adhesive muaj pes tsawg leeg yog siv rau saum npoo ntawm cov khoom me me thiab ntim nrog silicon carbide hmoov 2 hli tuab, dov nrog cov menyuam hlau. Nws raug tso cai rau cov nplaum ob qho tib si sib cuag nrog cov kua nplaum. Tsis pub dhau 1-2 teev, cov kua nplaum tshiab yuav tsum tau siv tag nrho.

- Tshem tawm cov hmoov ntau dhau los ntawm kev tig ib sab thiab ua ob peb kais.

- Cia sijhawm kom txog thaum cov epoxy kho tau zoo.

- Txoj kev sib txhuam yog sib sau ua ke ntawm lub zog muaj zog bolts.

Hardware quality

Fasteners rau kev sib txhuam cov pob qij txha yuav tsum tau nrog rau daim ntawv pov thawj zoo. Bolts, ntxhua khaub ncaws thiab txiv ntoo tau npaj raws li hauv qab no:

- ntxuav cov roj khaws cia hauv cov tshuaj alkaline (raug rau hauv lub thawv rau 15-20 feeb);

- ziab, tshuab nrog cua compressed;

- xov nrog wrenches lossis ntawm lub tshuab dhos;

- mineral roj lubrication;

- ua tiav cov bolts nrog cov txiv ntseej uas tau siv thaum khiav;

- khaws cia kom txog thaum sib dhos ua haujlwm (tsis pub dhau 10 hnub).

Xaiv ntawm kev sib txhuam kev sib txuas

Qhov kev sib txuas tseem ceeb tshaj plaws ntawm hom no yog:

- kev sib txhuam coefficient Μ ntawm qhov chaw tiv tauj, txiav txim siab los ntawm cov lus saum toj no, nyob ntawm seb hom kev ua haujlwm;

- bolt torque ratio;

- bolt zawm quab yuam;

- torque xav tau kom tau txais tus nqi xav tau ntawm qhov ntsuas dhau los.

Tus nqi torque xam pom los ntawm tus qauv:

M=K∙N∙dnom, qhov twg K yog qhov ntsuas torque tau txiav txim siab raws li GOST 22356-77;

N – bolt nro quab yuam, kN;

dnom – its nominal diameter, mm.

Tus nqi ntawm N yog txiav txim los ntawm tus qauv:

N=σr∙Sn∙ k,

qhov twg σr yog lub zog tensile ntawm cov khoom siv ntsia liaj qhov rooj, N / mm2;

Sn – bolt cross-sectional area,net, mm2;

k – ua hauj lwm tej yam kev mob coefficient (rau steel qauv thiab txoj kev choj nws yog sib npaug rau 1).

Lub zog tsim tawm hauv ib qho kev sib cuag yog pom los ntawm tus qauv:

N1=N∙Μ/ɣ, qhov twg ɣ yog qhov coefficient ntawm kev ntseeg tau, xaiv nyob ntawm seb muaj pes tsawg tus bolts hauv kev sib txuas.

Qhov tsawg kawg nkaus yuav tsum muaj tus lej ntawm lub zog siab bolts yog txiav txim siab raws li hauv qab no:

n=P/(k∙N1∙s), qhov twg P yog qhov ua haujlwm ntev, kN;

s – tus naj npawb ntawm kev sib cuag.

Sib Tham

Txoj cai ua kom muaj kev sib txhuam yog ua raws li cov cai hauv qab no:

- Ua ntej sib dhos, nws yog qhov tsim nyog los npaj qhov chaw siv ib qho ntawm cov txheej txheem saum toj no (raws li cov ntaub ntawv ua haujlwm), tshem tawm cov pob thiab burrs uas tiv thaiv cov khoom los ntawm kev sib haum xeeb snugly.

- Thaum lub sijhawm kev thauj mus los thiab kev cia nruab nrab ntawm qhov chaw, roj lossis kis kab mob ntawm cov chaw npaj yuav tsum raug cais tawm. Yog tias tsis tuaj yeem zam qhov no, ces yuav tsum muaj txheej txheem ntxuav thib ob.

- Thaum thawj theem ntawm kev sib dhos, cov khoom tau ua raws li qhov siv cov ntsaws ntsaws.

- Nruab bolts nrog lub tshuab ntxhua khaub ncaws (tsis pub ntau tshaj ib qho hauv qab lub taub hau ntsia liaj qhov rooj thiab cov txiv ntoo), nruj nreem nrog cov txiv ntseej los ntawm 50-90% ntawm kev suav quab yuam thiab xyuas qhov nruj ntawm kev sib txuas.

- Kho qhov ntsuas nruj torque nrog torque wrenches.

- Thov cov tshuaj pleev los yog cov tshuaj pleev xim nrogcement, av nplaum dawb, chalk. Qhov no yog ua kom kaw qhov kev sib txuas los ntawm ya raws.

Quality check

Kev tswj kom zoo yog ua tiav ntawm txhua theem ntawm kev npaj thiab sib dhos. Cov txiaj ntsig ntawm kev txheeb xyuas kev ua haujlwm tau sau tseg hauv thaj chaw kev sib txuas ntawm kev tsim khoom.

Cov haujlwm ntawm cov haujlwm no suav nrog cov haujlwm hauv qab no:

- nkag los tswj cov khoom siv raw, cov khoom, cov khoom yuav khoom;

- tshuaj xyuas cov cuab yeej, tare torque wrenches;

- tswj kev ntxuav saum npoo thiab npaj kho vajtse;

- Tshuaj xyuas qhov ntom ntawm cov pob qij txha nruj (siv kev sojntsuam);

- xaiv nruj torque tswj;

- tswj lub siab;

- kuaj cov qauv (raws li cov neeg siv khoom ntawm kev ua haujlwm pej xeem xav tau).

Pom zoo:

Kev sib koom tes zoo yog kev pom zoo ntawm ob lossis ntau lub tuam txhab ywj pheej los koom tes kom ua tiav qee lub hom phiaj kev lag luam. Cov qauv thiab cov piv txwv ntawm kev sib koom tes thoob ntiaj teb kev sib tw

Cov kev sib koom tes zoo yog qhov kev pom zoo ntawm ob lossis ntau lub tog kom ua tiav cov hom phiaj pom zoo thaum tswj hwm kev ywj pheej ntawm cov koom haum. Lawv zoo li poob qis ntawm kev cai lij choj thiab kev koom tes nrog kev koom tes. Cov tuam txhab tsim kev sib koom tes thaum lawv txhua tus muaj ib lossis ntau dua cov cuab yeej ua lag luam thiab tuaj yeem sib koom ua lag luam kev paub rau ib leeg

Txiv tus nqi sib txawv. Kev suav nyiaj rau qhov sib txawv ntawm qhov sib txawv. Kev sib pauv sib txawv: kev tshaj tawm

Txoj cai lij choj uas muaj nyob rau niaj hnub no hauv Lavxias Federation, nyob rau hauv lub moj khaum ntawm Tsoom Fwv Teb Chaws Txoj Cai No. 402 "Rau Nyiaj Txiag" hnub tim 06 Lub Kaum Ob Hlis 2011, muab rau kev suav nyiaj ntawm kev lag luam kev lag luam, kev lav phib xaub thiab cov cuab yeej nruj me ntsis hauv rubles. Tax accounting, los yog theej nws cov txij nkawm, kuj tau ua nyob rau hauv cov txiaj ntsig tau teev tseg. Tab sis qee cov ntawv txais nyiaj tsis tau ua hauv rubles. Cov nyiaj txawv teb chaws, raws li txoj cai, yuav tsum tau hloov dua siab tshiab

Ultrasonic kuaj ntawm cov pob qij txha welded, txoj kev thiab thev naus laus zis ntawm kev sim

Ultrasonic kuaj - cov cuab yeej siv siab tshaj plaws rau kev kawm ntawm vuam pob qij txha thiab cov seams. Nws yuav tau tham hauv kab lus no

Kev txiav txim siab ntawm kev ua vaj tse: txoj hauv kev, khoom siv, GOST. Kev tswj thiab kev ntsuam xyuas ntawm cov pob zeb ua kom muaj zog

Thaum kuaj xyuas cov qauv hauv tsev, kev txiav txim siab ntawm lub zog ntawm cov pob zeb ua tiav los txiav txim siab lawv lub xeev nyob rau lub sijhawm tam sim no. Kev ua tau zoo tiag tiag tom qab pib ua haujlwm feem ntau tsis phim cov qauv tsim

Tsis muaj kev puas tsuaj ntawm cov pob qij txha welded: khoom siv, GOST

Cov kab lus no tau mob siab rau txoj hauv kev tsis muaj kev puas tsuaj ntawm cov pob qij txha welded. Cov txheej txheem tswj tau tso cai los ntawm GOST thiab cov cuab yeej siv tau piav qhia