2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Kev tsim cov qauv hlau ib txwm hais txog kev sib txuas ruaj khov thiab ruaj khov ntawm tus kheej cov khoom thiab cov khoom rau hauv ib chav tsev kho tshuab. Tau kawg, cov khoom siv hlau tuaj yeem tsim ua monolithic, ib feem, piv txwv li los ntawm casting. Txawm li cas los xij, feem ntau nws yog ib qho tsim nyog los tsim ib qho kev sib txuas los ntawm cov txheej txheem ntawm interatomic hlau bonds, nrog rau cov cua kub siab ntawm qhov chaw uas cov khoom sib txuas. Yooj yim muab, nyem taub qab vuam.

Cov cuab yeej siv, cov txheej txheem thiab txheej txheem thev naus laus zis yog qhov txaus siab rau ntau tus pib vuam. Hom kev sib txuas no yog siv dav hauv aerospace thiab automotive industries, raws li nws tso cai rau koj los tsim kom muaj zog thiab txhim khu kev qha vuam seam.

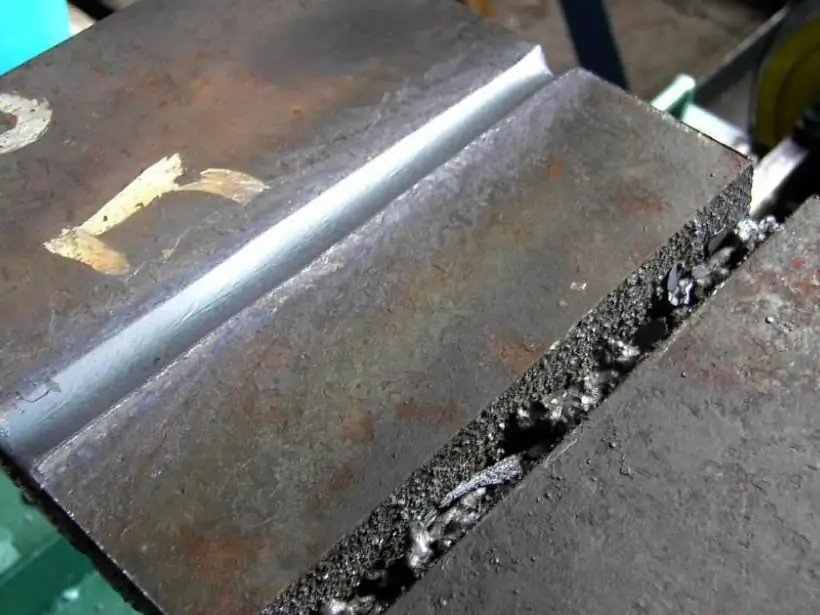

Txhim kho pob tw welding

Butt vuam ntawm ntau yam ntaub ntawv yog ib qho ntawm ntau hom kev sib txuas muaj zog nyob rau hauv lub zog ntawm compressive quab yuam thiab hluav taws xob tam sim no. Ntawd yog, cov khoom txuas nrog lub sijhawm flash taub qab vuam yog ib txhij nias tawm tsam ib leeg thiab ua kom sov los ntawm hluav taws xob arc.

Yog qhov chaw sib koomqhov chaw mus rau lub xeev yas (tsis muaj melting), ces hom kev sib txuas no yog hu ua tsis kam vuam. Thaum lub workpieces tau rhuab mus rau melting, lub taub qab ntawm cov pob qij txha yog hais tias siv txoj kev flashing. Txhua txoj hauv kev no yog siv nyob rau hauv qee qhov xwm txheej, uas tau soj ntsuam los ntawm tus welder, nyob ntawm qhov yuav tsum tau muaj rau qhov zoo thiab kev ntseeg siab ntawm cov hlua txuas, nrog rau cov cuab yeej siv.

Qhov muaj qhov tsis xws luag hauv welds ua rau tsis zoo ntawm kev ua haujlwm. Yog li ntawd, txhawm rau txhawm rau tshem tawm qhov teeb meem no, nws yog qhov yuav tsum tau ua ntej ntxuav qhov chaw tiv tauj los ntawm oxides, irregularities thiab av.

Nws tseem yuav tsum nco ntsoov tias raws li qhov loj ntawm qhov sib koom ua ke nce, lub zog thiab qhov zoo ntawm cov vuam deteriorate ntau. Qhov no yog vim lub fact tias ib tug loj cheeb tsam tsis sov li zoo thiab pab mus rau lub ceev tsim ntawm oxides, uas tsis zoo rau qhov zoo ntawm cov welded sib koom.

Butt Joint Benefits

Txhua yam kev vuam muaj nws qhov zoo thiab qhov tsis zoo. Butt welding, raws li ntau tus welders, muaj ntau yam zoo uas nws txawv ntawm lwm yam technologies.

Cov txiaj ntsig ntawm lub pob taws vuam muaj xws li:

- thaum siv cov qauv no ntawm kev rov ua dua, tsis tas yuav tsum tau ua kom sov ua ntej sib koom ua ke thiab npaj cov npoo ntawm qhov sib koom;

- nrog kev ua raws li kev siv tshuab vuam, nws yooj yim kom tau txais qhov muaj zog thiab txhim khu kev qhakev sib txuas uas tuaj yeem kav ntev ntau xyoo tsis muaj xwm txheej;

- khaws cov tshuaj lom neeg zoo ntawm cov khoom tom qab vuam, uas ua rau kom muaj zog ntawm kev sib koom ua ke;

- yooj yim thiab yooj yim ntawm kev ua haujlwm tsis tas yuav muaj kev paub tshwj xeeb txawm tias los ntawm ib tus neeg tshiab welder;

- muaj peev xwm ua cov txheej txheem ntawm lub pob nyem vuam hauv hom tsis siv neeg siab;

- kev kub ceev ntawm kev ua haujlwm thev naus laus zis;

- versatility hauv kev siv yuav luag txhua yam khoom.

Tag nrho cov txiaj ntsig zoo tshaj qhov tsis zoo me me ntawm cov txheej txheem vuam pob tw.

Qhov tsis zoo ntawm vuam

Qee qhov tsis zoo ntawm hom vuam no suav nrog:

- kev siv hluav taws xob ntau;

- tus nqi siab ntawm lub tshuab vuam siv lub tshuab siv hauv tsev, yog li nws yog qhov zoo tshaj los ua lub pob tw ua ke ntawm koj tus kheej;

- qhov xav tau kom nruj ua raws li qhov yuav tsum tau ua rau qhov loj ntawm qhov chaw ntawm qhov sib koom;

- nyuaj hauv vuam hauv cov av noo siab.

Types ntawm taub qab vuam

Cov txheej txheem vuam ntawm lub pob tw yog ua raws li txoj cai Joule-Lenz. Cov txheej txheem ntawm interatomic bonds ua tiav raws li qhov kev txiav txim ntawm cov hluav taws xob tam sim no los ntawm kev siv zog compression siv rau qhov chaw sib cuag ntawm cov khoom.

Muaj ob hom pob tw vuam:

- vuamtsis kam;

- flash vuam.

Hauv qhov tseem ceeb, ob txoj hauv kev no siv tib txoj kev siv tshuab electro-deformation, tab sis kuj muaj qhov sib txawv tshwj xeeb.

Resistance vuam

Qhov tshwj xeeb ntawm txoj kev no yog cov txheej txheem ntawm kev sib koom ua ke ua haujlwm yam tsis tau yaj lub hauv paus. Nyob rau hauv rooj plaub no, cov hlau nto yog raug rau cov yas deformation hnyav. Raws li txoj cai, cov welding rods yog txuas nrog ib qho hluav taws xob tam sim no, thiab thaum lawv nkag mus rau hauv kev sib cuag nrog cov hlau nto, lub kaw lus kaw tau tsim. Nyob rau ntawm qhov chaw ntawm kev sib cuag, ib qho kev tiv thaiv siab tshwm sim, uas muab cov cua sov me me. Cov pas nrig, rhuab mus rau ib qho nqi, yog nruj nreem nias rau ib leeg, thiab qhov tam sim no raug tua.

Tom qab cov pas nrig rhuab pib tawv, qhov no yog vim li cas qhov kev siv tshuab no hu ua kev vuam vuam. Txhawm rau kom tsis txhob muaj qhov tsis xws luag hauv qhov vuam, qhov chaw ntawm cov khoom yuav tsum tau welded yuav tsum tau ua tib zoo kho ua ntej kom thaum cov hlau sib txuas, tsis muaj cov khoom me me ntawm txawv teb chaws.

Kev tiv thaiv vuam yog siv los txuas cov hlau lossis cov kav dej, thiab cov ntaub ntawv tuaj yeem sib txawv (steel thiab tooj liab, cam khwb cia hlau thiab txhuas).

Reflow txuas

Ib qho tshwj xeeb ntawm lub pob tw vuam yog qhov khoom ntawm qhov hluav taws xob rau lub tshuab hloov mus txog thaum sib cuag ntawm qhov chaw welded. Nyob rau hauv cov ntaub ntawv no, lub protruding microroughnesses ntawm nto yog rhuab thiab crushed. Yog li ntawd, cov hluav taws xob tam sim no tsis ntws raws qhov loj dua protrusion, tab sis tam sim ntawd nrogtag nrho lub dav hlau ntawm kev sib cuag.

Muaj ob hom flash taub qab vuam:

- Nruam vuam yog tus cwj pwm los ntawm kev txav mus los ntawm ob feem ntawm cov khoom, clamped nyob rau hauv tshwj xeeb clamps ntawm vuam chav tsev, ntawm ib leeg. Tom qab ntawd ib qho tam sim no yog siv, thiab cov khoom sib cuam tshuam, hu rau tag nrho lub dav hlau. Cov khoom yog welded, tom qab uas qhov kev daws teeb meem tshwm sim ntawm ib qho nqi thiab cov hluav taws xob tam sim no raug tua.

- Kev sib cuam tshuam ntawm melting tshwm sim vim qhov hloov pauv ntawm lub sijhawm sib khi thiab tsis muaj zog ntawm cov pob qij txha, thaum cov hluav taws xob tseem nyob. Qhov kev txav mus los no kaw lub voj voog mus txog qhov melting point ntawm cov khoom.

Ntawm qhov yuav tsum tau ua thiab ntxuav tshuab

Qhov chaw ntawm cov ntaub ntawv yuav tsum tau koom ua ke kom tau txais cov vuam zoo yuav tsum ua tau raws li qee qhov kev xav tau:

- Tus nqi tiv thaiv thoob plaws lub dav hlau tiv tauj yuav tsum kwv yees li sib npaug.

- Kev tiv thaiv hluav taws xob yuav tsum tsawg li sai tau.

- Cov dav hlau ntawm ob qhov chaw yuav tsum tau welded yuav tsum sib npaug hauv qib.

- Txawm tias qhov pom ntawm qhov chaw yog tus yuam sij rau kev vuam zoo.

Txhawm rau ua kom tiav cov xwm txheej no, nws yog ib qho tsim nyog yuav tsum tau npaj ua ntej. Rau qhov no koj xav tau:

- Ua kom degreasing ntawm kev sib koom ua ke.

- Tshem tawm cov oxide zaj duab xis hla tag nrho lub dav hlau tiv tauj.

- Ua kev sib koom ua ke nruab nrab.

- Nyob qhov chaw zoo.

Tom qab tu, koj yuav tsum pom qhov pom kev npaj ntawm qhov chaw rau vuam.

Butt Vuam Machine

Nrog kev pab los ntawm lub pob tw tshwj xeeb vuam tshuab, cov kav dej polyethylene feem ntau yog welded, vim cov khoom ntawm cov khoom no yooj yim amenable rau lub pob tw hom kev sib cuag.

Muaj cov tshuab vuam hauv qab no:

- mobile;

- stationary;

- pendant;

- universal;

- specialized.

Tus tsim ntawm txhua lub tshuab vuam muaj xws li hluav taws xob thiab cov khoom siv sib dhos, nrog rau cov dej txias thiab lub tshuab ua haujlwm pneumatic.

Butt vuam ntawm cov kav dej polyethylene yog qhov txawv me ntsis ntawm kev koom nrog cov khoom hlau. Txij li cov khoom siv yas tsis yog tus neeg xyuas pib ntawm cov hluav taws xob tam sim no, cov cua sov ntawm qhov kawg ntawm cov kav dej yog nqa tawm los ntawm cov cua kub tshwj xeeb. Txwv tsis pub, thev naus laus zis ntawm pob tw vuam ntawm cov kav dej polyethylene zoo ib yam li kev sib txuas ntawm lwm qhov chaw.

Kev siv lub pob tw welding

Hauv tsev, kev siv lub tshuab hu rau vuam yog tsis muaj txiaj ntsig, yog li cov kav dej me me tuaj yeem welded manually. Nyob rau tib lub sijhawm, txhawm rau ua tiav qhov kev sib txuas zoo, nws yog qhov yuav tsum tau txais kev paub hauv kev ua haujlwm los ntawm kev cob qhia.

Cov kauj ruam thev naus laus zis ntawm kev tuav lub pob tw vuam yog raws li hauv qab no:

- Npaj qhov chaw ua haujlwm raws li kev xav tau kev nyab xeeb.

- Ua kom ruaj ntseg ntawm cov khoom ua haujlwm. Fastening tuaj yeem ua tiav siv cov clamps tshwj xeeb, txawm li cas los xij, hauv cov xwm txheej hauv tsev, cov cib lossis cov chaw so hauv av feem ntau yog siv. Qhov tseem ceeb tshaj plaws yog cov khoom nyob twj ywm tsis muaj zog.

- Siv cov ntawv xuab zeb lossis cov ntaub ntawv los ntxuav qhov chaw kom welded.

- Thaum cua sov lub taub qab vuam, lub siab yuav tsum tau siv rau kev sib koom ua ke.

- Lub seam yog txias lawm - hauv huab cua.

Yog tias muaj cua daj cua dub sab nraud, nws raug nquahu kom tsis txhob ua haujlwm kom tsis txhob muaj plua plav lossis xuab zeb nkag mus rau hauv qhov chaw vuam. Nyob rau hauv cov huab cua los nag, ua hauj lwm yuav ua tau nyob rau hauv ib tug tshwj xeeb canopy.

Nyob hauv pob qij txha

Lub sijhawm ua haujlwm ntev ntawm txhua yam khoom siv tshuab feem ntau nyob ntawm qhov zoo ntawm kev pom kev ntawm kev ua haujlwm. Yog li ntawd, txhua tus welder yuav tsum paub thiab muaj peev xwm los ntsuas qhov tsis xws luag uas tuaj yeem tshwm sim thaum lub sijhawm vuam.

Qhov tsis xws luag ntawm lub taub qab vuam muaj xws li:

- Tsis muaj kev nkag mus ntawm qhov vuam, uas tshwm sim nws tus kheej hauv ib feem ntawm cov hlau nplaum. Qhov feem ntau ua rau qhov tsis xws luag yog qhov muajqhov sib txuas ntawm cov yeeb yaj kiab oxide, nrog rau cov cua sov tsis muaj zog ntawm qhov kawg ntawm qhov chaw.

- Cracks thiab delamination ntawm seam, uas tuaj yeem tshwm sim thaum cov khoom siv txias txias tom qab vuam.

- Fiber distortion nyob rau hauv qhov chaw vuam kuj tuaj yeem tshwm sim los ntawm kev ntxhov siab ntau dhau.

- Kev ua qias tuaj ntawm kev sib koom ua ke nrog ntau yam kev suav nrog, cov nplej loj ntawm cov vuam yog cov yam ntxwv tsis xws luag. Cov teeb meem no tshwm sim thaum lub seam yog oxidized los yog overheated.

Butt resistance welding, raws li cov kws tshaj lij, yog txoj hauv kev txhim khu kev qha thiab zoo ntawm kev koom nrog cov khoom sib txawv. Vim muaj peev xwm ua tau cov txheej txheem nyob rau hauv tsis siv neeg hom, nws yog dav siv nyob rau hauv kev lag luam kev lag luam mus cuag complex Cheebtsam ntawm ntau yam khoom siv.

Pom zoo:

Kev tsim cov khoom siv roj: cov txheej txheem thev naus laus zis, khoom siv thiab khoom siv

Hnub no, muaj ntau yam khoom siv hauv tsev uas nrov. Ib qho kev tsim kho tshiab yog kev tsim cov khoom siv roj av, uas yog cov pob zeb ntawm tes. Ntawm cov no, nws muaj txiaj ntsig tsis yog los tsim ib lub tsev ntiag tug xwb, tab sis kuj tsim khoom muag

Kev khaws nyuj: txoj hauv kev, kev siv thev naus laus zis, kev noj haus thiab kev tsim khoom

Tsov ua liaj ua teb hauv tebchaws Russia tuaj yeem siv cov thev naus laus zis sib txawv rau kev khaws nyuj. Cov nyuj tuaj yeem raug tsav tawm mus rau pastures thaum lub caij ntuj sov los yog nyob hauv tsev txhua xyoo puag ncig. Ntawm cov liaj teb lawv tus kheej, nyuj tuaj yeem khaws cia tethered lossis xoob

Kev tsim cov plywood: thev naus laus zis, theem tseem ceeb ntawm cov txheej txheem thiab thaj chaw ntawm kev siv cov khoom siv

Plywood yog ib qho ntawm cov khoom siv pheej yig tshaj plaws thiab siv tau tshaj plaws. Txawm hais tias muaj ntau txheej txheej, nws yooj yim rau nruab thiab tuaj yeem ua tiav hauv tsev yam tsis muaj cov cuab yeej tshwj xeeb. Txuj kev tsim cov plywood suav nrog kev siv cov ntoo lamellas, nrog rau kev ua kom zoo uas koj tuaj yeem tau txais cov khoom tiav uas tiv taus ntau yam kev hem thawj

Vuam hauv qhov chaw tiv thaiv roj: ua haujlwm thev naus laus zis, txheej txheem piav qhia, cov txheej txheem ua tiav, cov khoom tsim nyog thiab cov cuab yeej, cov lus qhia ua haujlwm ib ntus thiab cov lus qhia kws tshaj lij

Vuam thev naus laus zis yog siv hauv ntau ceg ntawm tib neeg kev ua haujlwm. Versatility tau ua vuam nyob rau hauv ib puag ncig tiv thaiv roj ib qho tseem ceeb ntawm kev tsim khoom. Qhov ntau yam no ua rau nws yooj yim los txuas cov hlau nrog lub thickness ntawm 1 hli mus rau ob peb centimeters nyob rau hauv txhua txoj hauj lwm nyob rau hauv qhov chaw. Vuam nyob rau hauv ib puag ncig tiv thaiv yog maj mam hloov cov tsoos electrode vuam

Kev kho dua tshiab ntawm qhov chaw los ntawm vuam thiab ntog: cov txheej txheem thiab cov txheej txheem ntawm kev kho dua tshiab, nta, txheej txheem thev naus laus zis

Vuam thiab surfacing thev naus laus zis ua rau nws ua tau zoo los kho cov hlau seem, muab cov qib siab ntawm kev ntseeg siab thiab ua haujlwm ntev ntawm cov khoom. Qhov no tau lees paub los ntawm kev xyaum siv cov txheej txheem no thaum ua haujlwm kho hauv ntau qhov chaw - los ntawm kev kho tsheb mus rau kev tsim cov hlau dov. Hauv tag nrho cov nyiaj ua haujlwm ntawm kev kho cov qauv hlau, kev kho dua tshiab ntawm qhov chaw los ntawm kev vuam thiab surfacing yuav siv li 60-70%