2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Raws li kev xyaum qhia, cov kab ke sib xyaw ua ke hauv cov qauv tsim niaj hnub tso cai rau qhov kawg shaping ntawm cov khoom tiav nrog cov contours meej. Qee zaum, cov qauv tsim tshwj xeeb yog siv thaum cov hlau hla dhau qhov kev hloov pauv ntev thiab nyuaj. Cov chav tsev no tau nruab nrog lub voj voog ncig los txhim kho cov kev mob filling.

Sib hloov kho

Sab rooj vag nruab nrog cov khoom noj uas nyob ntawm lub kaum sab xis ntawm lub rooj vag. Hom no feem ntau siv rau hauv ib qho thiab ntau qhov pwm.

Thaum mus txog qhov ua haujlwm kab noj hniav, cov khoom noj muaj qhov txo qis, sib sau ua ke nrog cov khoom nkag, qhov hla ntawm qhov cuam tshuam rau cov hlau uas dhau los ntawm pwm kab noj hniav. Nyob rau hauv feeders ntawm lub lateral hom, cov khoom siv raw txav mus raws lub dav hlau parting nrog tom qab txhaws ntawm qhov qis ntawm lub chamber ua haujlwm. Nyob rau hauv rooj plaub no, lub qhov cua ducts raug thaiv, uas ua rau nws nyuaj rau tshem tawm cua. Raws li qhov tshwm sim, sab rooj vag tshuab tau zoo tshaj plaws rau cov khoom ntiav ntiav.

Yog tias koj txav cov kab noj hniav mus rau hauv qhov txav ntawm chav tsev, cov hlau los hauv siab kuj tseem yuav tiv thaiv kev tshem tawm.cua npuas los ntawm qhov tob. Nws yog ib nqi sau cia hais tias thaum casting qhov chaw nrog loj central rods nyob perpendicularly, ib tug xov tooj ntawm tsis xws luag yuav tshwm sim.

Txoj kev ntawm sab sprue

Qhov kev tso kawm ntawm sab feeder raws txoj kab tangent tso cai rau koj los ntsuas qhov cuam tshuam rau pem hauv ntej thiab turbulence. Lub casting muaj ib tug dav lub caij uas yog teem rau perpendicular mus rau lub hauv paus, thiab kuj muaj cov huab cua loj sib txuas. Raws li qhov tshwm sim, tsis muaj huab cua porosity thiab cov dav hlau tuaj.

Nrog tangential sprues, annular casting yog tau nrog qhov zoo tshaj plaws, muab hais tias qhov dav ntawm ib feem yog commensurate nrog cov khoom ua hauj lwm. Nws yog irrational siv xws li ib tug mechanism thaum casting nplhaib blanks nrog ib tug stepped txoj kab uas hla thiab khoom seem. Qhov no yog vim lub fact tias thaum cov hlau tig, nws swirls, thiab qhov no tsis zoo rau lub filling ntawm lub hauv paus ib feem, tsim qhov khoob hauv nws. Txhawm rau daws qhov teeb meem, siv lub sprue nrog txoj kab uas hla dav dua.

Kev suav ntawm lub rooj vag system yuav tsum tau coj mus rau hauv tus account qhov dav ntawm cov khoom noj khoom haus thiab nws qhov chaw. Cov yam ntxwv no cuam tshuam rau qhov zoo ntawm qhov casting. Nws yuav tsum tau muab sau tseg tias thaum lub sprue nyob ze ntawm qhov dav ntawm lub workpiece, cov hlau yuav ntws nyob rau hauv ib tug dav kwj, swirling thiab prematurely sau lub qhov cua qhov slots. Yog hais tias lub kaw lus yog mounted rau ntawm qhov nqaim ntawm ib feem, cov khoom yuav ntws raws phab ntsa yam tsis muaj teeb meem loj.

Central runner systems

Central variations yog siv rau casting slabs nrogpub dawb hauv nruab nrab (thav duab, rings) yog muab. Lawv kuj tau siv los tsim lub thawv-zoo li tus thiab cylindrical qhov chaw nrog qhib qhov chaw kab noj hniav.

Qhov kev tsim qauv no tso cai rau koj los txhim kho lub sprue nyob rau hauv nruab nrab ntawm lub axis ntawm sab pem hauv ntej. Hauv qhov no, ntau lub feeders tuaj yeem siv tau. Lub qhov nruab nrab yog siv rau hauv kev tsim cov khoom siv nrog cov kab noj hniav, hauv qab uas muaj lub qhov. Ib tug pas nrig yog dhau los ntawm nws, transforming mus rau hauv ib tug divider. Cov khoom no tuaj yeem dhau nruj me ntsis hauv qhov chaw lossis nrog kev sib txawv, uas ua rau nws tuaj yeem tso pwm rau hauv kab noj hniav asymmetrically rau lub caij khiav.

Ntawm cov txiaj ntsig ntawm qhov chaw khiav haujlwm rau kev txhaj tshuaj molding yog cov hauv qab no:

- Nws tuaj yeem ua rau cov kab noj hniav ua haujlwm nrog ob peb lub tshuab pub khoom yam tsis muaj kev tsim cov hlau dav hlau tuaj.

- Tus qauv tsim muaj tib qhov ntsuas kub ntawm txhua qhov chaw ua haujlwm, uas ua kom tsis muaj kev cuam tshuam ntawm deformations.

- Guaranteed ib tug tseem ceeb txo nyob rau hauv txoj kev ntawm cov hlau tsis muaj ntxiv dav hlau los ntawm lub compression chamber.

- Muab kev sib npaug ntawm cov hlau nkag thiab cua rho tawm.

Rau qhov ua haujlwm kom raug ntawm chav tsev thiab tshem tawm qhov kev kub ntxhov, lub dav hlau yuav tsum tau coj mus rau qhov sib npaug ntawm cov pas nrig nruab nrab thiab cov phab ntsa pwm.

siv sprues

Cov khoom siv hauv kev txiav txim siab yog siv tshwj xeeb hauv cov ntawv nrog ib lub qhov (socket) ua haujlwm. Casting nyias-walled blanks yuav tsum tau lub installation ntawm ob pebfeeders. Txhawm rau ua hauj lwm nrog ib feem tuab-walled thiab tsis muaj zog streamlining, ib lub caij yuav txaus. Nws yog ntsia tangentially nrog lub inlet compartment, uas tso cai rau koj tshem tawm cov huab cua impurities ntau npaum li sai tau thaum hlau nkag los ntawm ib sab.

Kev ua haujlwm ntawm cov khoom loj ntawm lub thawv-zoo li tus thiab lub cev teeb tsa yog ua los ntawm kev siv ob peb lub hauv paus feeders. Qhov no tso cai rau koj los muab lub zog rau txhua qhov chaw nyob deb ntawm cov kab noj hniav ua haujlwm, nrog rau kev tshem tawm qhov tshwm sim ntawm lub dav hlau txuas ntxiv uas ua rau delamination ntawm cov khoom siv raw. Tag nrho cov nqi ntawm cov feeders nce, thiab qhov zoo ntawm lub hauv paus casting pwm tshwm sim yog hais tias tus ntoo khaub lig seem ntawm lub input lub ntsiab yog ntau tshaj li muab lub hwj chim rau lub chaw ua hauj lwm kab noj hniav yam tsis muaj kev cuam tshuam nyob rau hauv cov kua hlau dav hlau ntawm txhua feeder.

Direct Feeders

Central feeders tsis muaj qhov sib faib yog siv rau cov qauv casting, qhov kev teeb tsa uas tsis tso cai rau kev teeb tsa ntawm cov khoom sib txuas. Nyob rau hauv cov ntaub ntawv no, lub ntsiab ntawm lub rooj vag system yog mounted ncaj qha rau ntawm ib feem, lawv kuj ua hauj lwm raws li ib tug feeder. Nws yog qhov tsim nyog los siv cov kev hloov pauv ncaj qha rau kev ua cov tuab-walled compact blanks, uas tau ua tiav ntawm qhov qis qis los ntawm qhov loj-section feeders.

Sau thaum ua haujlwm hauv cov xwm txheej zoo li no tsis nyuaj tshwj xeeb. Lub ntsiab tseem ceeb yog sealing cov hlau nrog lub siab kawg. Cov txiaj ntsig zoo tshaj plaws hauv cov txheej txheem tau txais thaum lub sijhawm thauj khoom ntawm cov khoom siv raw tsis raug tshem tawm ua ntej lub sijhawm qhib ntawm cov pwm ua haujlwm (chamber ntawm niastype).

Vim cov qauv sau

Zoo sib xws lub rooj vag rau cov hlau castings yog siv thaum nws tsis tuaj yeem muab cov khoom ntim txaus ntawm txhua qhov chaw taws teeb ntawm chav ua haujlwm nrog ib qho khoom noj. Lub hom phiaj tseem ceeb ntawm chav tsev yog synchronously muab hlau rau tag nrho cov peripheral compartments, tom qab uas cov khoom siv raw nkag mus rau cov ntsiab lus nyuaj-rau-noj siv ob peb lub ntsiab lus inlet.

Qhov kev tsim no tsim nyog nyob rau hauv lub xub ntiag ntawm tej thaj chaw deb ntawm lub sprue uas tsis haum rau hauv tus qauv tag nrho qhov ntev. Tsis tas li ntawd, xws li ib tug configuration yog haum rau casting lattice blanks, uas yog hampered nyob rau hauv manufacturing vim lub nyias-walled qauv. Qhov no yog qhov tseem ceeb tshwj xeeb yog tias cov pas nrig tau teeb tsa ze ze ntawm cov chaw taws teeb. Thaum lub grating ebbs, lub rooj sib tham ntawm ob lub dav hlau nyob rau hauv nqaim hnab tshos xyaum tsis muaj vortex obstacles, nyob rau hauv sib piv rau ib tug zoo xws li cov txheej txheem nyob rau hauv loj-ntim kab noj hniav.

Kev ua haujlwm

Circular commutator casting systems yog siv los tshuab me me, nyias-walled iav log uas muaj lub suab dav thiab tribok. Feeders nrog ib tug me me hlaws thiab ib tug tuab ntawm txog 0.5 hli yog muab rau txhua tus hniav los ntawm cov collector.

Kev siv cov khoom siv coj los ua kom nws muaj peev xwm tshem tawm cov huab cua los ntawm cov hlau txawm tias nyob rau hauv qhov nyuaj mus txog thiab qhov chaw tsis zoo. Lawv zoo haum rau smelting ntawm blanks nyob rau hauv lub thawv thiab lub plhaub configurations. Tus tsim zamua rau muaj kev cuam tshuam rau pem hauv ntej thiab ntau dhau swirl.

nias daim ntawv

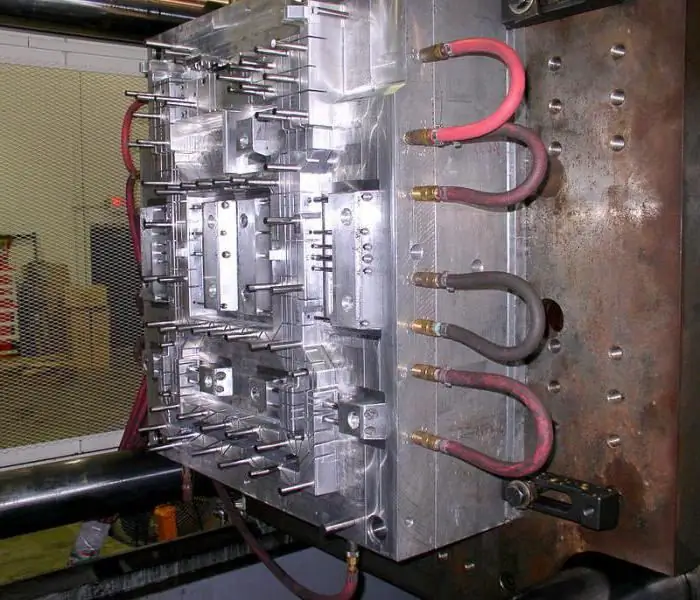

Cov khoom tsim no yog cov cuab yeej siv los ua cov khoom hlau, polymer thiab roj hmab ntawm ntau yam duab. Chav tsev yog siv rau casting ntau yam khoom nyob rau hauv siab los ntawm kev txhaj tshuaj molding tshuab. Cov pwm tuaj yeem ua tau ntau yam:

- Mechanical yam.

- Semi-automatic lossis tsis siv neeg.

- Kho thiab tshem tau mounting.

- Nrog kab rov tav thiab ntsug sib cais.

Lub rooj sib txoos suav nrog cov matrix ruaj khov thiab ib feem ua haujlwm. Cov kab noj hniav ntawm cov khoom no yog tsim nyob rau hauv ib txoj kev thim rov qab, uas ua rau nws muaj peev xwm muab qhov yuav tsum tau imprint ntawm lub workpiece. Cov ntaub ntawv raw yog muab los ntawm lub rooj vag, thiab qhov kub thiab txias yog tswj los ntawm cov dej ntws hauv qhov cua txias.

Pom zoo:

Kev tsim cov khoom siv roj: cov txheej txheem thev naus laus zis, khoom siv thiab khoom siv

Hnub no, muaj ntau yam khoom siv hauv tsev uas nrov. Ib qho kev tsim kho tshiab yog kev tsim cov khoom siv roj av, uas yog cov pob zeb ntawm tes. Ntawm cov no, nws muaj txiaj ntsig tsis yog los tsim ib lub tsev ntiag tug xwb, tab sis kuj tsim khoom muag

Cov neeg siv khoom lag luam. Sberbank rau cov neeg siv khoom lag luam. MTS rau cov neeg siv khoom lag luam

Txhua tus neeg nyiam cov neeg siv khoom loj yog suav tias yog qhov ua tiav rau cov tsev txhab nyiaj, tuam txhab pov hwm, cov neeg siv xov tooj. Rau nws, lawv muab cov ntsiab lus tshwj xeeb, cov kev pab cuam tshwj xeeb, nyiaj tshwj xeeb rau kev pabcuam tas li, sim nyiam thiab ua rau nws tag nrho nws lub zog

Casting hauv silicone pwm: khoom siv. Nqus casting nyob rau hauv silicone pwm

Rau qhov tsim cov yas me me, lub tshuab nqus tsev rau hauv silicone pwm feem ntau yog siv. Txoj kev no yog kev lag luam heev (ua cov pwm hlau yuav tsum tau siv sijhawm thiab nyiaj txiag ntau). Tsis tas li ntawd, silicone pwm yog siv ntau zaus, thiab qhov no kuj txo cov nqi ntawm cov khoom

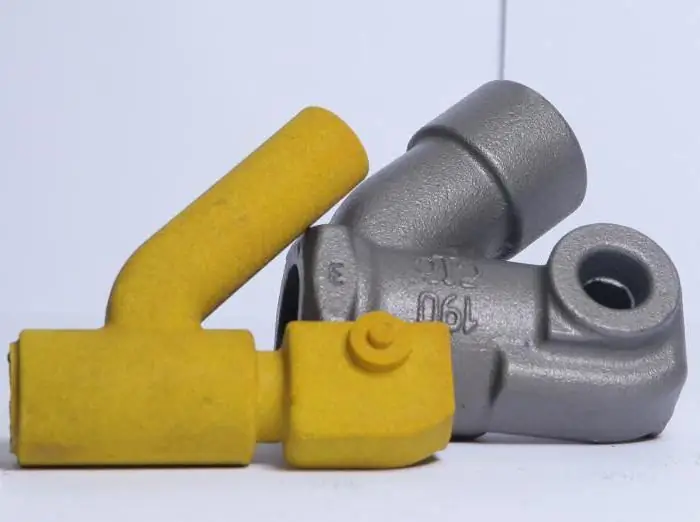

Casting pwm: nta, thev naus laus zis, hom

Ib qho ntawm cov txheej txheem tseem ceeb tshaj plaws hauv kev lag luam yog cov txheej txheem ntawm casting ntau yam, raw khoom thiab lwm yam. Txawm li cas los xij, txhawm rau ua tiav cov khoom xav tau, nws yog qhov yuav tsum tau ua cov pwm rau nws, uas feem ntau txiav txim siab qhov txiaj ntsig kawg

Plhaub pwm casting: yooj yim pwm ua haujlwm

Tam sim no, kev lag luam tau tsim kho thiab ntau txoj hauv kev tau siv los ua cov casting. Ib txoj kev zoo li no yog plhaub casting