2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Casting nyob rau hauv plhaub pwm kuj hu ua plhaub casting. Thiab txawv teb chaws, txoj haujlwm no hu ua Plhaub.

cov ntaub ntawv dav dav

Nyob rau hauv kev lag luam niaj hnub no, ntau ntau txoj kev casting yog siv. Ntxiv rau lub plhaub casting, peev casting kuj tseem siv, nrog rau hauv cov pwm hlau thiab ntau lwm txoj hauv kev. Tag nrho qhov zoo ntawm cov txheej txheem casting no, piv rau cov xuab zeb molding, yog tias lawv ua rau cov ntaub ntawv tseeb dua nyob rau hauv cov ntsiab lus ntawm cov duab thiab qhov ntev. Tsis tas li ntawd, tus naj npawb ntawm roughnesses ntawm qhov chaw ntawm cov khoom zoo li no raug txo. Muaj tsawg zaus, tab sis nws tseem tshwm sim tias qhov kev xav tau ntawm kev siv tshuab tom qab smelting raug tshem tawm. Ntxiv rau txhua yam, kev siv casting hauv plhaub pwm thiab lwm txoj hauv kev pab txhawb rau qhov tseeb tias cov txheej txheem no tuaj yeem hloov kho ntau li ntau tau, vim tias nws cov automation kuj nce ntxiv. Thiab qhov no, tau kawg, ua kom cov khoom tsim tau zoo ntawm txhua qhov chaw ua haujlwm.

Shell casting

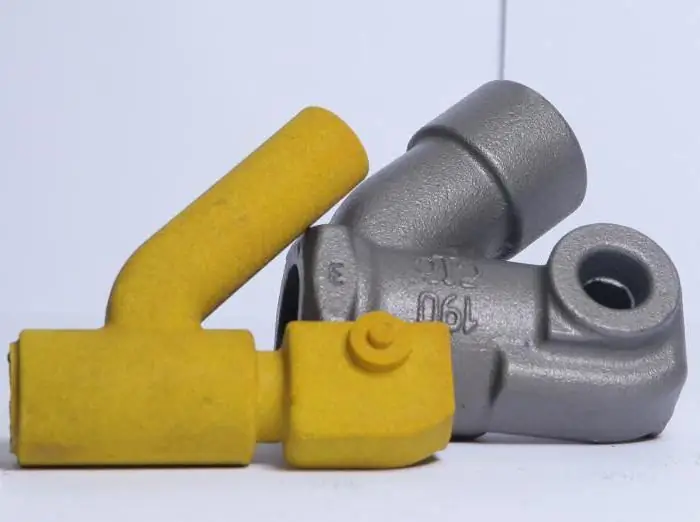

Yog peb tham txog qhov notxoj kev, nws yog thawj zaug qhia ntawm factories rov qab rau hauv 1953. Tam sim no, txoj kev yog siv dav heev. Nws yog casting hauv plhaub pwm, piv txwv li, uas ua rau feem ntau ntawm cov khoom rau Kirovets tsheb laij teb. Txhua qhov chaw uas tsim los siv txoj kev no yog qhov zoo tshaj plaws los ntawm cov hlau los yog cov hlau cam khwb cia. Plhaub casting yog ib txoj hauv kev uas qhov kawg tshwm sim ntawm casting muaj ib tug zoo li ntawm ob xuab zeb-resin plhaub. Tsis tas li ntawd, txoj kev tsim cov khoom siv no tsuas yog siv rau hauv cov xwm txheej uas tsim nyog los tsim ib feem nrog me me lossis nruab nrab qhov ntev, tab sis tib lub sijhawm nrog cov neeg siab. Piv txwv ntawm daim ntawv thov rau txoj kev casting no yog lub cav qhov chaw lossis cov phab ntsa nyias nyias.

Qhov tseem ceeb ntawm txoj kev

Nrog rau txoj kev ua haujlwm no, koj tuaj yeem tau txais ntau yam rau cov kiv cua, lub cev muaj zog, twj lossis tshuab textile. Txawm li cas los xij, qhov ntev tshaj plaws ntawm cov khoom tau txais tsis tuaj yeem tshaj 1 meter, thiab nws tsis tuaj yeem hnyav dua 200 kg.

Lub ntsiab lus ntawm casting rau hauv plhaub pwm yog raws li qee yam khoom ntawm thermosetting resins, uas yog ib feem ntawm cov xuab zeb-resin sib tov. Qhov kom zoo dua ntawm kev siv cov khoom no yog cov resins zoo li sai thiab ruaj khov thaum kho nrog kub ntawm 200-250 degrees Celsius.

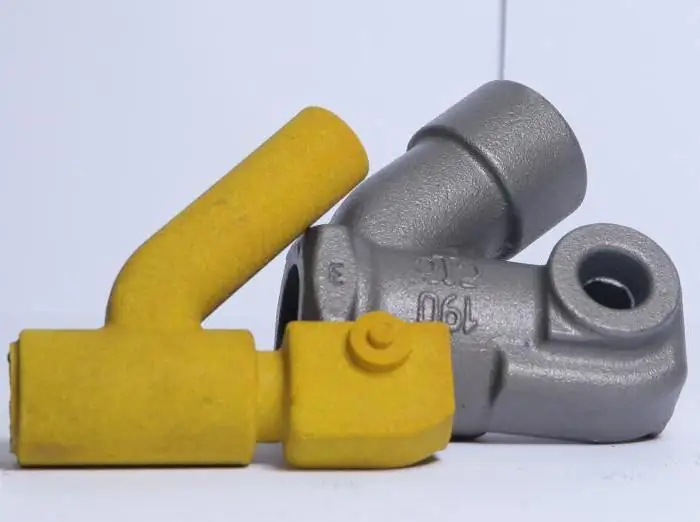

Kev ua lub plhaub pwm rau casting

Yuav ua li cas los ua pwm rau tom ntej casting, nws yog ib qho tsim nyog yuav tsum muaj cov xuab zeb zoo-grained quartz, uas los nrog kev sib ntxiv ntawm cov thermosetting resin, uas yog nws cov khoom sib txuas kom tau lub plhaub pwm puv puv. Cov ntaub ntawv no, tshwj xeeb tshaj yog cov resin, raug xaiv vim lawv tawv thaum lawv dhau ib qho kev ntsuas kub. Cov txheej txheem tsim khoom yog raws li nram no. Ua ntej, cov resin yog rhuab mus rau 140-160 degrees Celsius. Raws li kev cuam tshuam ntawm ib puag ncig zoo li no, nws hloov mus rau hauv cov kua nplaum ua kua nplaum uas ua kom tag nrho cov quartz xuab zeb pwm.

Cov peev txheej ntawm casting hauv plhaub pwm yog qhov dav, thiab yog li cov txheej txheem ntawm kev ua pwm yog coj mus rau qhov tsis siv neeg lossis automated.

Tom qab cov pwm tau npog tag nrho nrog cov resin, qhov kub tau nce mus rau 200-250 degrees Celsius. Qhov ntsuas kub no yog qhov txaus txaus rau cov nplaum nplaum rau irreversibly harden thiab tsim ib qho duab. Tsis tas li ntawd, thaum cov txheej txheem ntawm casting qhov chaw pib, uas yog, thaum cov hlau molten nkag mus rau hauv pwm, qhov kub ntawm nws mus txog 600 degrees. Hom no txaus los xyuas kom meej tias cov resin tsis yaj, tab sis kub hnyiab tawm, thaum tawm hauv qhov hws ntawm pwm nws tus kheej, yooj yim rau kev khiav tawm ntawm gases.

Qhov zoo thiab qhov tsis zoo ntawm plhaub pwm casting

Zoo li lwm yam kev tsim khoom, qhov no muaj nws qhov zoo thiab qhov tsis zoo. Yog hais tias peb piv no txoj kev ntawm casting, piv txwv li, nrog casting nyob rau hauvzoo tib yam xuab zeb pwm, muaj ntau yam zoo:

- Qhov sib txawv ntawm thawj thiab qhov tseem ceeb yog chav kawm raug, uas yog 7-9. Tsis tas li ntawd, qhov chaw tiav ntawm qhov tau txais yog txhim kho mus txog 3-6. Tsis tas li ntawd, cov nyiaj pab txo qis, uas tau tso cai rau kev ua haujlwm tom ntej ntawm qhov tshwm sim tom qab casting.

- Ib qho ntawm cov pluses loj yog qhov txo qis hauv cov nqi zog rau kev tsim cov castings.

- Txoj kev casting no txo qhov kev siv cov khoom molding, nrog rau cov hlau vim qhov loj ntawm lub rooj vag channel raug txo.

- Tshuaj txo tau tus nqi ntawm kev sib yuav.

Txawm li cas los xij, muaj qee qhov tsis zoo ntawm casting hauv plhaub pwm. Cov no suav nrog:

- Shell pwm lub neej - 1 casting.

- Tus nqi ntawm cov xuab zeb mould yog siab heev.

- Feem pua ntawm cov pa phem.

Corpus forming process

Cov txheej txheem tsim lub cev yog ua tiav rau theem:

- Thawj kauj ruam yog cov txheej txheem ntawm cov dej sib tov rau hauv cov qauv hlau kub, nrog rau cov txheej txheem ntawm kev khaws cia rau ob peb lub vib nas this kom txog thaum nyias nyias, muaj zog crusts nyob ib ncig ntawm ib feem. Feem ntau, cov qauv yog ua los ntawm cam khwb cia hlau, thiab lawv cov cua sov yog nqa mus txog 230-315 degrees.

- Tom qab ntawd, nws yuav tsum ua haujlwm kom tshem tawm cov xuab zeb ntau dhau. Lub thickness ntawm lub crust yuav tsum yog los ntawm 10 mus rau 20mm. Nws nyob ntawm lub sijhawm nyob ntawm qhov sib tov ntawm tus qauv, nrog rau qhov kub thiab txias.

- Tom qab ntawd, nws yog qhov yuav tsum tau hloov cov qauv phaj ua ke nrog cov pwm mus rau qhov cub, qhov chaw lawv yuav mus txog thaum kawg ntawm kev kho. Thaum kawg ntawm cov txheej txheem no, lub zog ntawm lub plhaub yuav tsum nyob nruab nrab ntawm 2.4 thiab 3.1 MPa.

- Tom qab raug tshem tawm ntawm lub qhov cub, lub plhaub tawv tawv raug tshem tawm ntawm lub phaj. Ib tug tshwj xeeb pusher yog siv rau cov txheej txheem no.

- Tom qab ntawd, ob lossis ntau tus qauv raug txuas ua ke siv qee yam clamp lossis los ntawm gluing. Cov pwm no tuaj yeem siv los ua cov pwm hauv plhaub pwm lossis khaws cia yooj yim. Yuav luag unlimited txee lub neej.

- Ua ntej pib txheej txheem casting hauv pwm tiav, txhaj tshuaj yog nchuav rau hauv lawv, uas pab tiv thaiv lossis rhuav tshem cov pwm thaum lub sijhawm ntxiv ntxiv.

Casting Details

Nws tsim nyog pib nrog qhov tseeb tias qhov kev zam raug tso cai hauv kev tsim cov cuab yeej tuaj yeem yog 0.5 hli. Deg roughness tau tso cai nyob rau hauv thaj tsam ntawm 0.3 txog 0.4 microns. Cov kev txwv zoo li no tau raug lees paub los ntawm qhov tseeb tias siv cov xuab zeb zoo. Tsis tas li ntawd tsim nyog sau cia: kev siv cov resin pab txhawb rau qhov tseeb tias qhov chaw du heev.

YProduction volumes

Yuav kom koom nrog hauv kev tsim cov pwm thiab qhov chaw, nws yog ib qho tsim nyog yuav tsum tau koom nrog kev teeb tsa ntawm tus qauv pwm. Lub sij hawm yuav tsum tau rau installation yog tsawg tshaj li ib lub lim tiam. Tom qab kev teeb tsa tiav, cov zis ntau tuaj yeem ua tauncav cuag los ntawm 5 mus rau 50 daim ib teev. Xws li cov khoom ntim ib teev yog qhov tiag tiag, txawm li cas los xij, rau qhov no nws yog ib qho tsim nyog los npaj cov txheej txheem casting raws li. Cov ntaub ntawv tseem ceeb uas yuav tsum tau ua rau casting yog cam khwb cia hlau, aluminium, tooj liab, thiab cov alloys ntawm cov hom hlau no. Lwm cov khoom tsim nyog yuav yog cov hlau uas siv txhuas thiab magnesium.

Pom zoo:

Yuav ua li cas hloov mus rau qhov yooj yim se system: cov lus qhia ib kauj ruam. Hloov mus rau qhov yooj yim se system: VAT rov qab

Kev hloov pauv ntawm IP mus rau cov txheej txheem se yooj yim yog ua raws li txoj cai lij choj. Cov neeg ua lag luam yuav tsum tau thov rau cov cai se ntawm qhov chaw nyob

Yuav xa ib pob - sai, yooj yim, yooj yim

Txhua tus neeg tsawg kawg ib zaug, tab sis ntsib qhov xav tau xa ib pob. Tom qab tag nrho, koj xav pamper koj tsev neeg thiab cov phooj ywg nrog khoom plig me me. Tom qab cov kev nthuav qhia raug xaiv, cov lus nug tshwm sim ntawm yuav ua li cas xa cov pob?

Yuav ua li cas txuas Internet tsis txwv ntawm Tele2? Yooj yim, yooj yim, pheej yig

Cov cuab yeej sib txuas lus niaj hnub muab lub sijhawm zoo rau kev nkag mus hauv Is Taws Nem txhua lub sijhawm thiab los ntawm txhua qhov chaw hauv ntiaj teb. Rau cov neeg uas tsis muaj PC, qhov no tsuas yog txoj hauv kev siv lub ntiaj teb network. Yog li ntawd, qhov nrov ntawm cov kev pabcuam uas muab los ntawm Tele2 tau loj hlob txhua hnub

Casting hauv silicone pwm: khoom siv. Nqus casting nyob rau hauv silicone pwm

Rau qhov tsim cov yas me me, lub tshuab nqus tsev rau hauv silicone pwm feem ntau yog siv. Txoj kev no yog kev lag luam heev (ua cov pwm hlau yuav tsum tau siv sijhawm thiab nyiaj txiag ntau). Tsis tas li ntawd, silicone pwm yog siv ntau zaus, thiab qhov no kuj txo cov nqi ntawm cov khoom

Tus nqi se tsawg kawg nkaus raws li kev sau se yooj yim (kev ua se yooj yim)

Txhua tus neeg pib ua lag luam uas tau xaiv cov txheej txheem sau se yooj yim tau ntsib nrog lub tswv yim xws li se tsawg kawg nkaus. Thiab tsis yog txhua tus paub dab tsi nyob tom qab nws. Yog li ntawd, tam sim no lub ntsiab lus no yuav raug txiav txim siab nthuav dav, thiab yuav muaj cov lus teb rau txhua nqe lus nug uas cuam tshuam txog kev lag luam