2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Rau qhov tsim cov yas me me, lub tshuab nqus tsev rau hauv silicone pwm feem ntau yog siv. Txoj kev no yog kev lag luam heev (ua cov pwm hlau yuav tsum tau siv sijhawm thiab nyiaj txiag ntau). Tsis tas li ntawd, cov pwm silicone tuaj yeem rov qab siv tau, thiab qhov no kuj txo cov nqi tsim khoom.

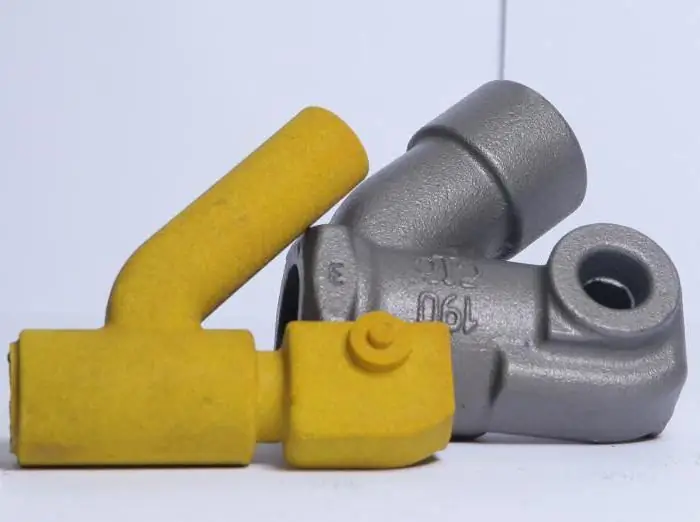

YPlastic molding

Lub ntsiab lus ntawm cov txheej txheem ntawm cov yas casting yog raws li hauv qab no. Cov khoom siv molten yog nyob rau hauv cov ntsia hlau ntawm chav tsev (cov cuab yeej tshwj xeeb rau casting rau hauv silicone pwm). Raws li kev cuam tshuam ntawm lub piston, cov huab hwm coj txav mus raws li lub rooj vag channel, tom qab ntawd sau cov pwm qhov chaw. Nyob rau hauv no txoj kev, ib tug casting yuav tau. Thaum cov yas yog rhuab, cov atoms uas ua rau nws pib txav mus los randomly thiab randomly. Txawm li cas los xij, thaum txias, crystallization chaw pib tsim. Nyob rau ntawm phab ntsa ntawm daim ntawv, crystals loj hlob, ces xws licov txheej txheem kuj tshwm sim nyob rau hauv lub casting. Nyob rau theem no, nws yog ib qho tseem ceeb heev uas yuav tau soj ntsuam qhov kub thiab txias, xaiv lub sij hawm raug. Txwv tsis pub, molding plastics rau hauv silicone pwm yuav tsis zoo, nrog rau pom kev sib yuav. Tab sis, ua ntej ntawm tag nrho cov, nws yog ib qho tsim nyog yuav tau ua cov pwm lawv tus kheej, uas lub loj rau crystallization yuav poured.

Technology rau tsim cov pwm

Muaj ntau txoj hauv kev los tsim cov pwm silicone. Thawj qhov yog ib qho khoom ntim. Cov qauv no yog tsim rau cov qauv yooj yim: nyem, souvenirs, ob sab. Cov qauv yog muab tso rau hauv formwork, ntim nrog silicone. Split pwm yog tsim zoo ib yam li yav dhau los, siv rau cov duab ntau dua. Ob daim ntawv yog tsim nyob rau hauv ob peb theem. Ua ntej, thawj ib nrab ntawm lub workpiece yog poured, tom qab lub silicone tau hardened, lub pwm yog tig dua thiab qhov thib ob yog ua nyob rau hauv tib txoj kev. Nws yog ib qho tseem ceeb heev rau txoj kev no los xaiv cov xauv tshwj xeeb ntawm lub hauv paus (casting hauv silicone pwm ntawm hom no yuav tsum tshwm sim yam tsis muaj kev txav chaw). Feem ntau yog rov ua dua tag nrho cov ntsiab lus ntawm daim ntawv workpiece "hauv kis". Ib qho yooj yim silicone yog siv rau ib feem nrog txhuam. Cov txheej txheem yuav siv sij hawm qhov chaw nyob rau hauv ob peb theem, qhov no yog tsim nyog rau ua kom tiav repetition ntawm tag nrho cov me me nuances ntawm cov khoom. Nyob rau tib lub sij hawm, daim ntawv nws tus kheej yog heev nyias - los ntawm 3 hli. Txhawm rau kom nws tuav nws cov duab, lub plhaub sab nraud yog tsim nyob rau theem kawg.

Silicon rau ua pwm

Nqus casting hauvsilicone pwm koom nrog kev siv ntau yam ntaub ntawv los tsim matrices. Ib tug ntawm lawv yog Mould Star hom silicone. Nws yog siv rau nruam filling, es muaj zog thiab saj zawg zog. Hardening tshwm sim nyob rau hauv chav tsev kub. Rau cov txheej txheem "kev sib kis", Rebound series feem ntau yog siv. Cov silicone no muaj viscosity siab, uas tuaj yeem tswj tau siv lub thickener. Casting nyob rau hauv silicone pwm ntawm hom no tso cai rau koj kom tau ib tug high-zoo, check matrix, thiab, raws li, ib tug ultra-precise feem. Kuj tseem muaj cov silicones translucent uas zoo tagnrho rau cov duab txiav.

Cov khoom siv Casting

Raws li txoj cai, polyurethane yog siv los ua cov khoom lawv tus kheej. Cov khoom muaj kev cuam tshuam lub zog, hardness, elasticity. Polyurethane roj hmab muaj zog tensile ntau dua, tsim kua muag. Lawv yog siv nyob rau hauv kev tsim ntawm ntau yam tapes, cylinders, tuag, gaskets, bushings. Tsis tas li ntawd, pob tshab yas yog siv rau casting. Nws yog heev tiv taus UV rays thiab khaws nws cov pob tshab txawm tias stained. Scope - lo ntsiab muag rau ntau yam kev ntsuam xyuas, prototypes nyob rau hauv cov tshuaj, kev tsim khoom ntawm souvenirs, thiab lwm yam. Raws li txoj cai, molding nyob rau hauv ib tug silicone pwm yuav tsum tau siv ob-tivthaiv mixs, uas muaj xws li ncaj qha yas thiab ib tug catalyst.

Moulding yas rau hauv silicone pwm. Khoom siv

Small batch productioncam khwb cia blanks yog txheej txheem thev naus laus zis uas tso cai rau koj kom tau txais ib pawg ntawm cov ntawv luam ntawm ib feem ntawm qhov nyuaj. Feem ntau, cov txheej txheem yog siv kom tau txais cov qauv uas tau sim ua ntej pib ntau lawm, ua haujlwm tawm qhov zoo li, tsim.

Kev lag luam molding ntawm cov yas rau hauv cov khoom siv silicone pwm suav nrog cov hauv qab no: lub tshuab nqus tsev (txhaj tshuaj molding tshuab), cua sov txee, lub tshuab nqus tsev tov khoom (sib tov). Silicone yog thawj zaug npaj nyob rau hauv lub tshuab nqus tsev chamber, qhov twg cov txheej txheem ntawm degassing cov khoom siv qhov chaw. Qhov no yog qhov tsim nyog los tiv thaiv kev tsim cov npuas ntawm daim ntawv. Tom qab cov pwm tau ua thiab preheated, cov polyurethanes (los yog resins rau qhov kawg) yog tov ncaj qha. Cov txheej txheem no tshwm sim hauv lub tshuab nqus tsev vacuum. Los ntawm sprue, qhov sib tov yog poured rau hauv pwm. Rau kev ua tiav kawg, nws yog ib qho tsim nyog yuav tsum tau muab cov khoom tso rau hauv qhov cub tshwj xeeb, qhov kawg ntawm cov khoom tawv tawv yuav tshwm sim ntawm qhov kub ntawm 70 ° C.

Nqus Chamber. Cov yam ntxwv tseem ceeb

Feem ntau, cov nplai ntau lawm siv tsis siv neeg silicone pwm casting. Cov khoom siv, uas yog lub tshuab nqus tsev chamber, tso cai rau koj los tswj qhov kub thiab txias thiab qhov nrawm nrawm. Tus neeg teb xov tooj tsis xav tau kev txawj tshwj xeeb thiab kev paub, txij li txhua qhov kev tswj hwm los ntawm kev ua haujlwm, uas muaj ob qho tib si tsis siv neeg thiab phau ntawv hloov pauv. Kuj tseem muaj peev xwm kho qhov kev pab cuam. Ntau yam kev hloov kho lub koob yees duab muaj peev xwm ua tauworkpieces txog li 5 kg (piv txwv li, ST-02 lub koob yees duab). Chav tsev yog nruab nrog lub elevator rau nqa cov pwm silicone. Nws yuav tsum raug sau tseg tias ST-02 system tso cai rau siv ob qho tib si me me thiab hnyav matrices.

Lwm qhov kev xaiv yog lub koob yees duab MCP. Cov khoom siv silicone pwm no tuaj yeem tsim cov khoom nrog cov phab ntsa nyias thiab cov txheej txheem nyuaj. Cov txheej txheem no yog ua los ntawm kev sib txawv siab. Tom qab ntawd lub resulting casting raug tshem tawm, thiab ces nws hardens nyob rau hauv huab cua. Nqus casting rau hauv silicone pwm rau qee hom yas yog ua tiav hauv cov khoom cua sov, uas muab cov cua sov tsis sib xws, thiab, raws li, cov khoom ua haujlwm.

Tom qab cov yas loj yog ua tiav, nws tau ua tib zoo tshem tawm ntawm pwm. Qhov saum npoo yog machined, lub protrusions raug tshem tawm thiab ntxuav, cov irregularities yog polished. Yog tias tsim nyog, lub workpiece yog them nrog cov xim lossis lwm yam khoom siv tiv thaiv. Nws tseem yog ib qho tsim nyog los ntxuav cov pwm silicone, tshem tawm cov seem ntawm cov yas. Tom qab ntawd nws yog ntxuav, npaj rau kev siv tom ntej. Nws yog ib nqi sau cia hais tias molding yas rau hauv silicone pwm yuav tsum tau rov siv cov matrices (los ntawm 20 mus rau 80 zaug).

Qhov tseem ceeb ntawm txoj kev

Cov khoom me me tab tom txhim kho dynamically, nws tso cai rau koj los soj ntsuam cov khoom lag luam zoo, sim cov khoom lag luam, tsim cov ntawv tshwj xeeb cov haujlwm me me. Siliconecov pwm uas siv rau hauv kev txhaj tshuaj ntawm cov yas ua rau nws muaj peev xwm luam tawm tag nrho cov kev ntxhib los mos, zoo li, thiab tsim ntawm lub workpiece. Ib feem yog yooj yim tso tawm ntawm lub matrix, uas, ntxiv mus, yuav siv tau ntau zaus. Castings muaj qhov tsawg kawg nkaus ntawm qhov tsis xws luag, pom lub cev thiab cov khoom siv kho tshuab. Tsis tas li ntawd, qee zaum, txawm tias hlau tuaj yeem nchuav rau hauv cov pwm silicone.

Tab sis lub ntsiab kom zoo dua uas silicone pwm casting muaj yog tus nqi. Cov neeg muab kev pabcuam no qhia tias tus nqi kawg ntawm qhov khoob yuav nyob ntawm ob qho tib si ntawm cov khoom siv ntawm cov yas thiab ntawm qhov ntsuas qhov ntsuas ntawm qhov (piv txwv li, qhov khoob ntsuas 101010 cm tuaj yeem raug nqi 1,500 rubles). Silicone nws tus kheej tuaj yeem yuav los ntawm 500 rubles ib kg, yas - los ntawm 700 rubles. Tus nqi ntawm cov ntaub ntawv hlau yog qhov siab heev, qee zaum lawv siv tsuas yog tsis muaj txiaj ntsig (yog tias kev ncig yog ob peb units). Thiab silicone matrices kuj tsim nyog rau kev siv hauv tsev, nws tsis yog qhov tsim nyog yuav khoom kim heev. Ib tug tsuas yog yuav tsum tau ua ib tug layout ntawm lawv tus kheej, coj mus rau hauv tus account lub neej ntawm polyurethanes (lub sij hawm thaum lawv nyob twj ywm kua thiab haum rau pouring), saib xyuas tag nrho cov technological nuances - thiab casting nyob rau hauv ib tug silicone pwm yuav ua tau txawm nyob rau hauv tsev. Raws li kev xam, tus nqi ntawm ib qho dawb paug nyob rau hauv cov ntaub ntawv no yog hais txog 70-140 rubles.

Pom zoo:

Cov neeg siv khoom lag luam. Sberbank rau cov neeg siv khoom lag luam. MTS rau cov neeg siv khoom lag luam

Txhua tus neeg nyiam cov neeg siv khoom loj yog suav tias yog qhov ua tiav rau cov tsev txhab nyiaj, tuam txhab pov hwm, cov neeg siv xov tooj. Rau nws, lawv muab cov ntsiab lus tshwj xeeb, cov kev pab cuam tshwj xeeb, nyiaj tshwj xeeb rau kev pabcuam tas li, sim nyiam thiab ua rau nws tag nrho nws lub zog

Cov khoom ib puag ncig ntawm zaub mov. Cov kev cai rau cov khoom nyob ib puag ncig ntawm cov khoom nyob rau hauv pej xeem catering thiab nyob rau hauv lub khw

Cov neeg ua haujlwm ntawm ib lub lag luam ncaj qha ntsig txog cov khoom noj khoom haus yuav tsum ua raws li cov cai ntawm cov khoom hauv zej zog. Qhov no yuav ua rau kom ntev lub neej txee ntawm cov khoom thiab tsis lwj nws qhov zoo. Tom qab tag nrho, ob peb tus neeg yuav zoo siab thaum lawv yuav ib lub ncuav mog qab zib nyob rau hauv ib lub khw muag khoom uas muaj ntxhiab tsw ntawm cov hnyuv ntxwm los yog herring

Cov ntsiab lus pabcuam rau cov neeg siv khoom. Kev Pabcuam Cov Neeg Siv Khoom. Kev pabcuam neeg siv khoom yog

Cov txheej txheem tsis sib haum xeeb uas qee zaum tshwm sim ntawm cov neeg siv khoom thiab cov tuam txhab tsim kho tuaj yeem ua rau lub neej ntawm ob tog mus ntev. Qhov ntawd yog qhov kev pabcuam rau cov neeg siv khoom. Nws yog nws lub luag haujlwm ncaj qha los xyuas kom muaj kev sib raug zoo thiab muaj peev xwm koom tes

Plhaub pwm casting: yooj yim pwm ua haujlwm

Tam sim no, kev lag luam tau tsim kho thiab ntau txoj hauv kev tau siv los ua cov casting. Ib txoj kev zoo li no yog plhaub casting

Qhov twg tau txais txiaj ntsig kom tau txais qiv nyiaj rau cov neeg siv khoom xav tau? Cov xwm txheej zoo tshaj plaws rau cov neeg siv khoom siv credit

Cov nyiaj qiv siv tam sim no muaj rau yuav luag txhua tus. Lub hom phiaj ntawm cov neeg qiv nyiaj yog xaiv qhov kev pom zoo. Cov tsev txhab nyiaj muab nyiaj qiv nrog ntau yam xwm txheej. Qhov twg nws tau txais txiaj ntsig los qiv nyiaj rau cov neeg siv khoom xav tau yuav tau tham hauv kab lus