2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Kev siv cov pa roj carbon steel yog dav hauv kev tsim kho thiab kev lag luam. Cov pab pawg hu ua technical hlau muaj ntau yam zoo uas ua rau kom muaj kev ua tau zoo ntawm cov khoom kawg thiab cov qauv. Nrog rau qhov zoo tshaj plaws yam ntxwv ntawm lub zog thiab tsis kam mus rau kev nyuaj siab, cov alloys kuj txawv los ntawm saj zawg zog dynamic zog. Hauv particular, hypoeutecoid steel, uas tseem muaj cov feem pua ntawm cov pa roj carbon sib tov, muaj nuj nqis rau nws cov ductility siab. Tab sis qhov no tsis yog txhua qhov zoo ntawm ntau hom hlau muaj zog.

Cov ntaub ntawv dav dav txog cov hlau

Ib qho tshwj xeeb ntawm cov hlau yog qhov muaj qhov tshwj xeeb alloyed impurities thiab carbon hauv cov qauv. Qhov tseeb, cov hlau hypoeutectoid yog txiav txim siab los ntawm cov ntsiab lus carbon. Ntawm no nws yog ib qho tseem ceeb kom paub qhov txawv ntawm classical eutectoid thiab ledeburite steels, uas muaj ntau yam sib xws nrog ntau yam kev piav qhia ntawm cov hlau. Yog tias peb xav txog cov txheej txheem ntawm cov hlau, ces cov hlau nplaum hypoeutectoid yuav xa mus rau eutectoids, tab sis muaj cov alloyed ferrites thiab pearlites. Qhov tseem ceeb sib txawv ntawm hypereutectoids yog cov pa roj carbon qis dua 0.8%. Tshaj qhov noqhov taw qhia tso cai rau peb los faib cov hlau ua cov eutectoids tag nrho. Hauv qee txoj kev, qhov ntxeev ntawm hypoeutectoid yog cov hlau hypereutectoid, uas, ntxiv rau pearlite, kuj muaj cov impurities thib ob ntawm carbides. Yog li, muaj ob yam tseem ceeb uas ua rau nws muaj peev xwm paub qhov txawv ntawm hypoeutectoid alloys los ntawm cov pab pawg neeg ntawm eutectoids. Ua ntej, qhov no yog cov ntsiab lus me me, thiab qhov thib ob, qhov no yog ib qho tshwj xeeb ntawm impurities, lub hauv paus ntawm uas yog ferrite.

Tsev tsim khoom

Cov txheej txheem thev naus laus zis dav dav rau kev tsim cov hlau hypoeutectoid zoo ib yam li kev tsim khoom ntawm lwm cov hlau. Ntawd yog, kwv yees li tib txoj kev siv, tab sis nyob rau hauv ntau configurations. Hypoeutectoid steel xav tau kev saib xyuas tshwj xeeb ntawm kev tau txais nws cov qauv tshwj xeeb. Rau qhov no, ib lub tshuab siv los xyuas kom meej lub decomposition ntawm austenite tiv thaiv keeb kwm ntawm txias. Nyob rau hauv lem, austenite yog ib tug sib tov sib xyaw, nrog rau tib ferrite thiab pearlite. Los ntawm kev tswj hwm qhov kev siv ntawm cov cua sov thiab cua txias, cov kws tshaj lij tuaj yeem tswj cov kev sib cais ntawm cov khoom ntxiv no, uas thaum kawg cuam tshuam rau kev tsim ntawm qee yam kev ua tau zoo ntawm cov khoom.

Txawm li cas los xij, cov pa roj carbon muab los ntawm perlite tseem zoo li qub. Txawm hais tias tom qab annealing tuaj yeem kho qhov tsim ntawm microstructure, cov ntsiab lus carbon yuav nyob hauv thaj tsam ntawm 0.8%. Ib theem obligatory nyob rau hauv cov txheej txheem ntawm steel qauv tsim yog normalization. Cov txheej txheem no yog xav tau rau fractional optimization ntawm cov nplej ntawm tib yamaustenite. Nyob rau hauv lwm yam lus, ferrite thiab pearlite hais raug txo kom pom qhov ntau thiab tsawg, uas ntxiv txhim kho cov txuj ci thiab lub cev ua haujlwm ntawm cov hlau. Qhov no yog ib tug complex txheej txheem nyob rau hauv uas ntau nyob ntawm qhov zoo ntawm cov cua kub kev cai. Yog tias qhov ntsuas kub tau dhau lawm, ces qhov kev cuam tshuam rov qab tuaj yeem muab tau zoo - qhov nce ntawm austenite nplej.

Steel annealing

Kev siv ntau txoj hauv kev annealing yog xyaum. Muaj qhov sib txawv ntawm cov txheej txheem puv thiab ib nrab annealing. Nyob rau hauv thawj rooj plaub, lub austenite yog intensive rhuab mus rau ib tug tseem ceeb kub, tom qab uas normalization yog nqa tawm los ntawm kev txias. Qhov no yog qhov uas decomposition ntawm austenite tshwm sim. Raws li txoj cai, tag nrho annealing ntawm steels yog nqa tawm nyob rau hauv hom ntawm 700-800 ° C. Kev kho cua sov ntawm qib no tsuas yog ua kom cov txheej txheem ntawm kev lwj ntawm ferrite ntsiab. Cov cua txias kuj tuaj yeem hloov kho, piv txwv li, cov neeg ua haujlwm qhov cub tuaj yeem ua haujlwm ntawm lub qhov rooj los ntawm kev kaw lossis qhib nws. Cov qauv tshiab kawg ntawm isothermal ncu hauv hom tsis siv neeg tuaj yeem ua kom txias qeeb raws li qhov kev pab cuam muab.

Raws li qhov tsis tiav annealing, nws yog tsim los ntawm cua sov nrog kub siab tshaj 800 ° C. Txawm li cas los xij, muaj cov kev txwv loj rau lub sijhawm tuav cov txiaj ntsig kub tseem ceeb. Vim li no, tsis tiav annealing tshwm sim, raws li qhov tshwm sim ntawm cov ferrite tsis ploj. Yog li ntawd, ntau yam tsis zoo hauv cov qauv ntawm cov khoom siv yav tom ntej tsis raug tshem tawm. Vim li cas thiaj li annealing ntawm steels tsim nyog yog tias nws tsis txhim kho lub cevzoo? Qhov tseeb, nws yog kev kho cua sov tsis tiav uas tso cai rau koj kom muaj cov qauv muag muag. Cov khoom siv kawg yuav tsis tas yuav tsum muaj nyob rau hauv txhua daim ntawv thov tshwj xeeb rau carbon steels ib se, tab sis yuav cia machining yooj yim. Cov mos pro-eutectoid alloy yog yooj yim los txiav thiab tsis tshua kim los tsim.

Alloy normalization

Tom qab tua hluav taws los ntawm cov txheej txheem ntawm kev kho cua sov ntxiv. Muaj kev ua haujlwm ntawm normalization thiab cua sov. Hauv ob qho tib si, peb tab tom tham txog qhov cuam tshuam thermal ntawm lub workpiece, uas qhov kub tuaj yeem tshaj 1000 ° C. Tab sis nyob rau hauv nws tus kheej, normalization ntawm hypoeutectoid steels tshwm sim tom qab ua tiav ntawm kev kho cua sov. Nyob rau theem no, txias pib nyob rau hauv tej yam kev mob ntawm tseem huab cua, thaum lub sij hawm uas raug tshwm sim mus txog rau thaum tag nrho cov tsim ntawm nplua-grained austenite. Ntawd yog, cua sov yog ib hom kev npaj ua haujlwm ua ntej nqa cov hlau mus rau hauv lub xeev normalized. Yog tias peb tham txog cov kev hloov pauv tshwj xeeb, feem ntau lawv tau nthuav tawm hauv qhov txo qis ntawm ferrite thiab pearlite, nrog rau kev nce hauv lawv cov hardness. Lub zog zoo ntawm cov khoom yog nce nyob rau hauv cov nqe lus piv rau cov ua tiav los ntawm cov txheej txheem annealing.

Tom qab normalization, lwm cov txheej txheem cua sov ntev yuav ua raws. Tom qab ntawd lub workpiece yog txias, thiab cov kauj ruam no tuaj yeem ua tau ntau yam. Qhov kawg hypoeutectoid steel yog tau nyob rau hauv huab cua los yog nyob rau hauvqeeb-txias qhov cub. Raws li kev xyaum qhia, qhov zoo tshaj plaws alloy yog tsim los ntawm tag nrho cov thev naus laus zis ntawm normalization.

Qhov cuam tshuam ntawm qhov kub ntawm cov qauv ntawm cov hlau

Kev cuam tshuam ntawm qhov kub thiab txias hauv cov txheej txheem ntawm kev tsim cov qauv hlau pib los ntawm lub sijhawm hloov pauv ntawm ferritic-cementite loj rau hauv austenite. Hauv lwm lo lus, perlite dhau mus rau hauv lub xeev ntawm kev sib xyaw ua haujlwm, uas ib feem dhau los ua lub hauv paus rau kev tsim cov hlau muaj zog. Nyob rau theem tom ntej ntawm kev kho cua sov, cov hlau tawv tawv tau tshem tawm ntau tshaj ferrite. Raws li twb tau sau tseg, nws tsis yog ib txwm tshem tawm tag nrho, xws li nyob rau hauv cov ntaub ntawv ntawm tsis tiav annealing. Tab sis cov classic hypoeutectoid alloy tseem cuam tshuam nrog kev tshem tawm ntawm cov khoom siv austenite. Nyob rau theem tom ntej, qhov muaj pes tsawg leeg uas twb muaj lawm yog optimized nrog kev cia siab ntawm kev tsim cov qauv zoo. Ntawd yog, muaj qhov txo qis hauv cov khoom ntawm cov hlau nrog qhov tau txais cov khoom muaj zog ntxiv.

Isothermal transformation nrog supercooled sib tov ntawm austenites tuaj yeem ua tau nyob rau hauv ntau hom thiab qhov kub thiab txias yog ib qho ntawm cov kev txwv tswj los ntawm tus kws tshaj lij. Peak intervals ntawm thermal exposure, txias npaum li cas, thiab lwm yam kuj txawv. Nyob ntawm xaiv normalization hom, hardened steel yog tau nrog tej yam kev thiab lub cev yam ntxwv. Nws yog nyob rau theem no uas nws tseem tuaj yeem teeb tsa cov haujlwm tshwj xeeb. Ib qho piv txwv zoo tshaj yog cov hlau alloy nrog cov qauv mos, tau txais nrog lub hom phiaj ntawm kev ua haujlwm zoo ntxiv. Tab sis feem ntaumanufacturers tseem tsom ntsoov rau cov kev xav tau ntawm cov neeg siv khoom kawg thiab nws cov kev xav tau rau lub ntsiab kev thiab kev ua haujlwm zoo ntawm cov hlau.

qauv steel

hom normalization ntawm qhov kub ntawm 700 ° C ua rau tsim cov qauv uas cov nplej ntawm ferrites thiab pearlites yuav tsim lub hauv paus. Los ntawm txoj kev, hypereutectoid steels muaj cementite nyob rau hauv lawv cov qauv es tsis txhob ferrite. Nyob rau hauv chav tsev kub, nyob rau hauv ib txwm lub xeev, cov ntsiab lus ntawm ntau tshaj ferrite kuj tau sau tseg, txawm hais tias qhov no yog qhov tsawg kawg nkaus raws li cov pa roj carbon ntau. Nws yog ib qho tseem ceeb kom paub meej tias cov qauv ntawm cov hlau nyob ntawm qhov me me ntawm cov ntsiab lus carbon. Nws xyaum tsis cuam tshuam rau tus cwj pwm ntawm cov khoom tseem ceeb thaum lub sij hawm tib lub cua sov, thiab yuav luag tag nrho nws yog concentrated nyob rau hauv perlite. Qhov tseeb, perlite tuaj yeem siv los txiav txim siab qib ntawm cov ntsiab lus carbon sib xyaw - raws li txoj cai, qhov no yog qhov tsis tseem ceeb.

Lwm tus qauv nuance kuj nthuav. Qhov tseeb yog tias pearlite thiab ferrite hais muaj tib lub ntiajteb txawj nqus. Qhov no txhais tau hais tias los ntawm tus nqi ntawm ib qho ntawm cov khoom no hauv tag nrho cov huab hwm coj, koj tuaj yeem pom tias tag nrho cheeb tsam nws nyob li cas. Yog li, microsection nto tau kawm. Nyob ntawm hom uas cov hlau hypoeutectoid tau rhuab, cov fractional tsis ntawm austenite hais kuj tsim. Tab sis qhov no tshwm sim yuav luag nyob rau hauv ib tug neeg hom ntawv nrog rau cov tsim ntawm tshwj xeeb qhov tseem ceeb - lwm yam yog hais tias cov kev txwv rau ntau yam indicators, As tus qauv.

Khoom ntawm hypoeutectoid steel

Cov hlau no yograu cov hlau tsis muaj carbon tsawg, yog li koj yuav tsum tsis txhob cia siab tias qhov kev ua haujlwm tshwj xeeb los ntawm nws. Suffice nws hais tias nyob rau hauv cov nqe lus ntawm lub zog yam ntxwv, no alloy yog ho inferior rau eutectoids. Qhov no yog vim qhov sib txawv ntawm cov qauv. Qhov tseeb yog tias cov chav kawm hypoeutectoid ntawm cov hlau nrog cov ntsiab lus ntawm ntau tshaj ferrites yog qhov qis dua hauv lub zog rau cov analogues uas muaj cementite hauv cov txheej txheem. Ib feem yog vim li no, cov kws tshaj lij pom zoo kom siv cov alloys rau kev tsim kho kev lag luam, hauv kev tsim cov khoom siv hluav taws xob nrog kev hloov pauv ntawm ferrites tau siv rau qhov siab tshaj plaws.

Yog tias peb tham txog qhov zoo tshwj xeeb ntawm cov khoom siv no, ces lawv yog plasticity, tsis kam rau cov txheej txheem lom neeg ntawm kev puas tsuaj, thiab lwm yam. Nyob rau tib lub sijhawm, hardening ntawm hypoeutectoid steels tuaj yeem ntxiv ntau yam zoo rau cov khoom siv. hlau. Piv txwv li, nws tuaj yeem ua tau ob qho tib si ua kom muaj cua sov thiab tsis muaj qhov cuam tshuam rau cov txheej txheem corrosion, nrog rau tag nrho cov khoom tiv thaiv uas muaj nyob rau hauv cov pa roj carbon tsawg.

thaj chaw thov

Txawm tias muaj zog me ntsis ntawm cov khoom siv vim qhov tseeb tias cov hlau yog nyob rau hauv chav kawm ntawm ferritic steels, cov khoom no muaj ntau nyob rau hauv ntau qhov chaw. Piv txwv li, nyob rau hauv mechanical engineering, qhov chaw ua los ntawm hypoeutecoid steels yog siv. Lwm qhov yog tias cov qib siab ntawm cov alloys tau siv, hauv kev tsim cov thev naus laus zis ntawm kev tua hluav taws thiab normalization tau siv. Tsis tas li ntawd, cov qauv ntawm cov hlau hypoeutecoid nrog txo cov ntsiab lus ferrite yog heevtso cai rau kev siv hlau hauv kev tsim cov qauv tsim. Ntxiv mus, tus nqi pheej yig ntawm qee cov qib steel ntawm hom no tso cai rau koj suav nrog kev txuag nyiaj tseem ceeb. Qee zaum, hauv kev tsim cov khoom siv hauv tsev thiab cov qauv hlau, tsis tas yuav muaj zog ntxiv, tab sis kev hnav tsis kam thiab elasticity yog qhov tsim nyog. Nyob rau hauv tas li ntawd, kev siv ntawm hypoeutecoid alloys yog tsim nyog.

Production

Ntau lub tuam txhab tau koom nrog hauv kev tsim khoom, kev npaj thiab tsim cov hlau hypoeutecoid hauv Russia. Piv txwv li, Ural Non-Ferrous Metals Plant (UZTSM) tsim ntau qib steel ntawm hom no ib zaug, muab cov neeg siv khoom sib txawv ntawm cov khoom siv thiab lub cev. Lub Ural Steel Plant tsim cov ferritic steels, uas suav nrog cov khoom zoo alloyed. Tsis tas li ntawd, kev hloov kho tshwj xeeb alloy muaj nyob rau hauv ntau hom, suav nrog cov cua sov-resistant, high-chromium thiab stainless hlau.

Metalloinvest tseem tuaj yeem raug cais tawm ntawm cov neeg tsim khoom loj tshaj plaws. Ntawm cov chaw ntawm lub tuam txhab no, cov qauv hlau nrog cov qauv hypoeutectoid yog tsim, tsim los siv rau hauv kev tsim kho. Tam sim no, cov nroj tsuag steel ntawm lub tuam txhab ua haujlwm raws li cov qauv tshiab, uas tso cai rau kev txhim kho qhov tsis muaj zog ntawm ferrite alloys - qhov taw qhia lub zog. Tshwj xeeb, cov tuam txhab thev naus laus zis tau ua haujlwm txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhav Qhov no tso cai rau peb muab yuav luag universal alloys.

Zaj lus

Muaj ntau yam txuj ci thiab kev ua haujlwm ntawm kev lag luam thiab tsim cov hlau uas suav tias yog qhov yooj yim thiab txhim kho tsis tu ncua. Txawm li cas los xij, raws li kev tsim qauv thiab cov txheej txheem thev naus laus zis dhau los ua nyuaj, cov kev xav tau tshiab rau lub hauv paus tseem tshwm sim. Nyob rau hauv no hais txog, hypoeutecoid steel kom meej meej manifests nws tus kheej, nyob rau hauv uas txawv kev ua tau zoo qualities yog concentrated. Kev siv cov hlau no yog qhov tsim nyog tsis yog nyob rau hauv cov xwm txheej uas xav tau ib feem nrog ntau qhov kev ua haujlwm siab, tab sis nyob rau hauv cov xwm txheej tshwj xeeb atypical cov khoom sib txawv yuav tsum tau ua. Nyob rau hauv rooj plaub no, cov hlau ua piv txwv ntawm kev sib xyaw ua ke ntawm kev ua kom yooj yim thiab ductility nrog kev ua haujlwm zoo tshaj plaws thiab kev tiv thaiv yooj yim pom muaj nyob rau hauv feem ntau carbon alloys.

Pom zoo:

Cov ntaub ntawv xa tuaj: tus kheej xaj, daim ntawv them nqi, daim ntawv xaj, cov ntaub ntawv xa khoom thiab cov chaw xa khoom xa tuaj

Kev ua haujlwm hauv kev xa khoom yog nrov heev niaj hnub no, tshwj xeeb tshaj yog cov tub ntxhais hluas muaj siab nyiam. Tus neeg xa xov tsis yog ib tus neeg xa khoom xwb, tab sis yog tus kws tshaj lij uas muaj kev txawj ntse thiab tuaj yeem nqa parcel los yog xa mus rau qhov chaw nyob uas tau teev tseg nrog cov khoom zoo thiab sai

Tooj liab phaj, ntawv ci, daim kab xev: ntau lawm, yam ntxwv, daim ntawv thov

Tooj liab yog ib qho ntawm cov hlau nrov tshaj plaws nyob rau hauv lub ntiaj teb niaj hnub no, nws yog siv nyob rau hauv ntau qhov chaw ntawm ntau lawm

Hluav taws xob steel: ntau lawm thiab daim ntawv thov

Kev tsim cov hlau no ua haujlwm ua haujlwm ntawm lwm cov khoom sib nqus. Hluav taws xob cov hlau yog ib qho hlau hlau nrog silicon, qhov feem pua ntawm 0.5% mus rau 5%

Duralumin yog lub zog muaj zog aluminium-raws li alloy nrog ntxiv ntawm tooj liab, magnesium thiab manganese: cov khoom, ntau lawm thiab daim ntawv thov

Duralumin yog dab tsi? Dab tsi yog cov yam ntxwv ntawm duralumin alloy? Technical thiab zoo ntsuas ntawm lub alloy. Ntau yam khoom siv los ntawm cov hlau no thiab lawv cov peev txheej

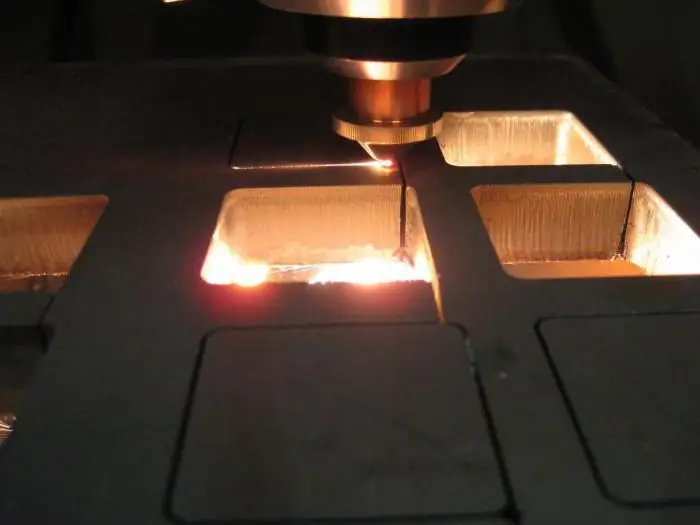

Ytterbium fiber ntau laser: ntaus ntawv, kev khiav hauj lwm hauv paus ntsiab lus, lub zog, ntau lawm, daim ntawv thov

Fiber lasers yog compact thiab rugged, taw tes precisely thiab dissipate thermal zog yooj yim. Lawv tuaj hauv ntau hom thiab, muaj ntau yam sib xws nrog lwm hom optical quantum generators, muaj lawv tus kheej zoo