2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Khoov tshuab tso cai rau koj muab cov khoom ua haujlwm raws li qhov xav tau los ntawm kev ncab sab nraud thiab compressing cov txheej sab hauv ntawm qhov. Tsuas yog cov seem nyob rau ntawm axis khaws lawv qhov qub qub. Cov khoom siv tau nthuav tawm ntau yam qauv, sib txawv ntawm hom tsav, cov khoom siv ntxiv, qhov ntev.

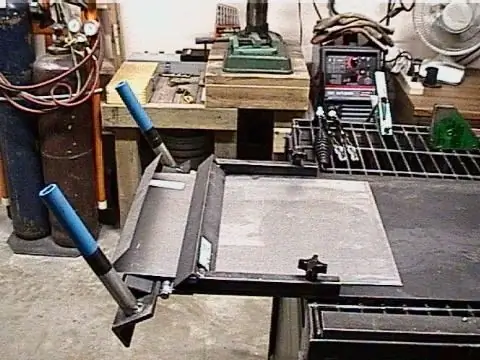

Tsim

Cov tshuab khoov feem ntau muaj cov qauv zoo sib xws. Qhov no suav nrog cov khoom hauv qab no:

- Table for rear sheet fixation. Ib feem yog npaj rau qhov chaw ntawm lub workpiece yuav tsum tau ua, uas yuav txav mus rau saum npoo ntawm qhov xav tau kev taw qhia. Ib lub bender thiab cutter kuj muab rau ntawm lub rooj txhawb nqa.

- Riam cov menyuam hom. Nws muab cov hlau txiav, yuav tsum muaj lub hauv paus muaj zog thiab ntse.

- Pem hauv ntej nres. Tso cai rau koj kho qhov dav ntawm qhov txiav.

- Lub rooj ntoo yog kev txhawb nqa ntxiv.

- Goniometer - tso cai rau koj los teeb tsa lub kaum sab xis kom raug.

- Fasteners nyob rau hauv qhov siab - kho tib yam parameter ntawm cov khoom.

Ntau yam

Cov ntawv hlau dabtsi yog khoov tshuab tuaj ntau hom, thiabyog:

- Phau ntawv qhia yog qhov loj me thiab siv rau kev ua haujlwm nruab nrab. Nws tuaj yeem ua cov tooj liab, txhuas, galvanized thiab cov ntawv hlau. Kev ua haujlwm ntawm cov cuab yeej no tsis tas yuav muaj kev tsim nyog tshwj xeeb.

- Cov cuab yeej siv tshuab ua haujlwm los ntawm kev hloov lub zog los ntawm lub tshuab ua ntej spun flywheel.

- Electro-mechanical versions ua haujlwm nrog lub tshuab hluav taws xob, saw lossis siv tsav thiab gearbox.

- Hydraulic counterparts siv lub tog raj kheej hydraulic hauv lawv tsim.

- Kev hloov kho pneumatic yog siv los ntawm lub tog raj kheej pneumatic, zoo tagnrho rau kev ua cov ntaub ntawv coated nrog cov kua roj vanish lossis xim.

- Electromagnetic tshuab khoov cov nplooj ntawv nrog lub zog hluav taws xob, siv los ua ntu thiab cov thawv.

Hand tools

Ntawm cov khoom siv no muaj kev txwv rau qhov tob ntawm cov khoom noj ntawm cov khoom ua haujlwm, kev ua haujlwm ntev thiab qhov siab tshaj plaws ntawm cov khoom. Phau ntawv ntawv hlau dabtsi yog khoov tshuab ua haujlwm raws li hauv qab no:

- hlau billet yog nias tawm tsam lub rooj los ntawm kab;

- daim ntawv yog khoov nrog lub ntsiab tshwj xeeb rau lub kaum sab xis;

- lub thickness ntawm khoov ntawm xws li ib tug ntaus ntawv yuav tsum yog kwv yees li ob millimeters.

Vim tias phau ntawv qhia yog qhov hnyav, lawv tuaj yeem thauj ncaj qha mus rau qhov chaw tsim kho lossis chaw ua haujlwm.

Hydraulic dabtsi yog khoov tshuabtshuab

Cov cuab yeej zoo li no tau pab txhawb kev ua cov hlau blanks. Nws ua haujlwm raws li txoj cai no:

- lub zog nqa khoom yog cov kua uas thawb lub plunger tawm ntawm lub tog raj kheej nyob rau hauv lub siab, yog li ua kom lub zog ntawm cov khoom txav txav mus los nrog tus ntaus;

- Daim ntawv muab tso rau ntawm lub rooj yog raug rau lub zog tsim nyog, ua rau lub workpiece khoov.

Feem ntau suav tias yog cov khoom siv tau siv los hloov cov nplooj ntawv raws li qhov ntev ntawm lub rooj sab saum toj lossis rau kev sib sib zog nqus ntawm ib feem. Kev ua tau zoo ntawm kev ua haujlwm thiab kev tsim khoom siab tau lees paub los ntawm kev ua haujlwm ntawm cov thooj voos kheej kheej. Koj tuaj yeem tswj tau yooj yim txav, nrawm thiab nres ntawm tus crawler.

Daim ntawv thov ntawm hydraulic hom dabtsi yog khoov tshuab:

- tsim cov paib, cua ducts, ru tsev ntsiab;

- tso tawm cov khoom ntxiv;

- tsim khoom siv rau sab hauv thiab sab nrauv kho kom zoo nkauj ntawm lub tsev;

- npaj cov hlau profiles ntawm ntau yam duab thiab ntau thiab tsawg.

Hydraulic analogues muaj txiaj ntsig ntau dua li phau ntawv qhia, lawv tso cai ua cov haujlwm tuab dua.

Electromechanical hloov kho

Hluav taws xob dabtsi yog khoov tshuab suav nrog hauv nws cov qauv tsim lub zog muaj zog, khoov nqaj, sib sau ua ke nrog lub tshuab hluav taws xob thiab cov ntu ntu tsis siv neeg. Rau kev siv yooj yim, cov cuab yeej nruab nrog ko taw tswj.

bending tshuabelectromechanical hom yog muab faib ua pass-dhau los yog los ntawm kev xaiv, uas ua rau nws muaj peev xwm mus ua hauj lwm uas tsis yog-tus qauv workpieces nyob rau hauv dav, ntev thiab qhov siab. Nws raug tso cai khoov galvanized, txias-dov hlau los xij, tooj liab thiab txhuas blanks ntawm cov khoom siv no. Ua thickness - mus txog 2.5 hli, ntev - mus txog 3 meters. Nyob rau hauv xws li cov cav tov, ebbs, facade cassettes, qhov cua qhov chaw, ru tsev, canopies, skates thiab ntau dua.

Rebar dabtsi yog khoov tshuab

Cov cuab yeej zoo li no tso cai rau koj khoov rods ntawm ntau ntu ntawm lub kaum sab xis xav tau. Lub tshuab yog tswj los ntawm ib tus neeg teb xov tooj, uas teeb tsa hom kev ua haujlwm workpieces. Kev ua haujlwm tas li yog ua los ntawm cov tshuab khoov tshuab ua haujlwm hauv hom tsis siv neeg. Devices yog xav tau nyob rau hauv cov cheeb tsam ntawm zus tau tej cov hlau lug, tsev cov ntaub ntawv, laj kab.

Tsis siv neeg rebar dabtsi yog khoov tshuab yog tsim los ua haujlwm ntev, tsim nyog rau kev khiav lag luam thaum ua haujlwm ntau. Nws ua cov khoom hauv qab no:

- rebar thiab carbon steel;

- hlau kab txaij;

- xov steel tuav;

- txiav-rau-ntev steel.

Chav tsev nyob rau hauv nqe lus nug yuav muab kev ua haujlwm siab thiab ua haujlwm zoo ntawm cov khoom kawg, nrog rau tus nqi siab ntawm qhov raug thiab kev nyab xeeb. Koj tuaj yeem tswj cov khoom siv manually lossis nrog tus tswj ko taw.

Cov khoom siv khoov

Raws li txoj cai ntawm kev ua haujlwm ntawm cov yeeb nkab dabtsi yog khoov tshuabsubdivided zoo ib yam li nplooj variants. Lawv kuj txawv ntawm ib leeg ntawm txoj kev uas lawv khoov. Tus tsim ntawm cov cuab yeej thiab nws cov kev ua tau zoo yog nyob ntawm qhov xwm txheej no. Muaj peb pawg ntawm profile benders.

- Ib chav tsev uas ua haujlwm los ntawm extrusion. Nyob rau hauv cov ntaub ntawv no, lub geometry ntawm cov yeeb nkab profile yog hloov kho siv ib tug deforming cov menyuam mechanism uas ua raws li ib tug punch. Lub matrix ntawm xws li cov cuab yeej tsis yog muab, nws lub luag hauj lwm yog ua si los ntawm ib tug khub ntawm lub zog txhawb mounted rau opposite sab ntawm lub khoov. Xws li cov khoom yog cov khau swivel lossis rollers. Txij li thaum lub zog tsim maj mam thaum ua kom muaj kev sib raug zoo perpendicular rau lub workpiece, txoj kev tso cai rau koj kom tau txais txiaj ntsig zoo kawg. Txoj kev tsim nyog rau kev ua haujlwm me me.

- Qhov kev xaiv thib ob yog nias. Rau kev hloov pauv ntawm cov khoom, lub hauv paus ntsiab lus ntawm locksmith yews yog siv. Ib daim yeeb nkab yog muab tso rau nruab nrab ntawm qhov tuag thiab lub punch. Lawv cov profiles yuav tsum tau rov ua dua cov geometry ntawm lub workpiece kom tau txais kev khoov zoo. Tsis tas li ntawd, nws yog ib qho tsim nyog yuav tsum coj mus rau hauv tus account qhov seem deformation ntawm cov hlau. Lub tshuab dabtsi yog khoov no haum rau kev siv hauv tsev uas tsis tas yuav tsum muaj qhov siab.

- Txoj kev thib peb yog dov cov kav dej. Nws yog universal rau ob qho tib si nyias-walled thiab tuab-walled khoom. Qhov xav tau kev teeb tsa yog tau los ntawm rub qhov nruab nrab ntawm ib qho tig thiab ob qho kev txhawb nqa rollers.

Wire dabtsi yog khoov

Rau cov noLub hom phiaj, ntau yam khoom siv tau muab: los ntawm cov lus qhia yooj yim tshaj plaws rau kev siv tshuab CNC hlau dabtsi yog khoov tshuab.

Cia peb piav me ntsis txog txhua qhov kev hloov kho:

- Homemade version. Chav tsev yog ib tug hlau thav duab nrog ib tug qhia roller, ib tug hlau bar thiab qhov. Cov ntsiab lus saum toj no yog screwed rau nws, thiab daim hlau yog welded rau hauv qab ntawm tus ncej. Tom qab txhim kho cov chais, cov qauv bar txuas nrog rau lub ces kaum.

- Universal CNC dabtsi yog khoov tshuab. Ntawm cov cuab yeej zoo li no, cov ntsiab lus ntawm 2D thiab 3D configurations yog tsim. Kev tswj hwm yog nqa tawm los ntawm lub khoos phis tawj tshwj xeeb uas ua tiav cov haujlwm hauv nws. Cov khoom siv zoo li no muaj kev ua haujlwm siab thiab muaj peev xwm dav.

- Pushing tshuab. Lub hauv paus ntsiab lus ntawm kev ua haujlwm yog ua raws li kev txhais lus txav ntawm cov khoom ua tiav los ntawm qhov profile bender. Rolling rollers muab lub workpiece ua ntej kev teeb tsa. Kev ua haujlwm ntawm cov cuab yeej siv no yuav tsum muaj cov txuj ci siab.

Lwm hom hlau tshuab

Ntawm cov kev hloov kho rau kev ua cov xaim, peb txoj kev xaiv ntxiv tuaj yeem raug sau tseg:

- Breaking machines. Cov cuab yeej ntawm hom no tau tsom mus rau kev tsim khoom ntawm qhov chaw puag ncig. Lub workpiece yog pub rau ntawm tus ncej nrog lub vojvoog pre-set siv cov lus qhia rollers. Thaum tsim cov kev sib hloov ntawm cov ncej, ob peb khoov ntawm cov hlau nyob ib ncig ntawm cov ntiv tes ua haujlwm yog nqa tawm. Cov cuab yeej tshuab no tsuas yog tsim ib hom khoom xwb. Hloov cov configurationcov khoom yuav tsum tau commissioning.

- Ib lub tshuab uas ua cov hlau los ntawm cov hlau bar. Nrog kev pab los ntawm cov cuab yeej no, nws muaj peev xwm nqa tawm stamping thiab carving ntawm workpieces. Ntawm qhov tsis zoo ntawm cov cuab yeej no yog cov khoom tsim tau qis thiab muaj cov khoom siv ntxiv rau kev muab cov khoom, uas muaj cov qauv tsim.

- Bay analogue. Nws ua haujlwm los ntawm unwinding ib coil ntawm hlau. hloov nws mus rau ib tug ncaj pas nrig. Cov zis yog ib yam khoom uas muaj qhov xav tau. Hom khoom siv no yog siv rau kev tsim khoom loj, muaj tus nqi siab ntawm kev tsim khoom.

Yuav ua li cas kho cov benders?

Vim tias cov tshuab feem ntau yog muab faib ua ntu zus, lawv cov kev teeb tsa yuav tsum tau ua raws li qee cov cai. Tom qab txhim kho chav tsev ntawm lub platform ua haujlwm, mus rau nruab cov khoom seem. Xav txog kev teeb tsa lub tshuab dabtsi yog khoov siv qhov piv txwv ntawm phau ntawv qhia rau kev ua cov ntawv.

Kho qhov siab ntawm txoj hlua khoov yog ua los ntawm kev xoob cov bolts kho, thiab tom qab ntawd tig cov ntsia hlau tswj mus rau sab laug lossis sab xis kom txo lossis nce qhov siab. Tom qab kev hloov kho tiav, cov clamps yuav tsum tau nruj. Nws yuav tsum tau muab sau tseg tias kev hloov qhov siab ntawm lub beam ua rau nws muaj peev xwm mus kho qhov khoov vojvoog ntawm lub workpiece, uas yuav tsum tsis txhob yuav tsawg tshaj li lub thickness ntawm daim ntawv.

kho ntug ntawm txoj kev hla thiab cov menyuam

Kho qhov chaw spatial ntawm ntug ntawm lub rotary dabtsi yog khoov traversecuam tshuam qhov zoo ntawm kev ua hauj lwm thaum hloov lub thickness ntawm lub workpiece. Cov txheej txheem yog ua nrog ob-sided roman txiv ntoo, tig nws counterclockwise los yog clockwise.

Txoj kab quab yuam ntawm cov txheej txheem txiav cov menyuam yuav tsum dhau nruj me ntsis raws ntug nias ntawm daim ntawv ua tiav. Qhov siab yuav tsum raug kho los ntawm kev muab cov menyuam yaus txo qis thiab kho los ntawm kev tswj cov ntsia hlau.

Qhov kev tso chaw ntawm cov riam txiav ntawm lub tshuab yuav tsum yog tib yam rau txoj hauj lwm ntawm txoj hlua khoov. Yog tias qhov kev xav tau no tsis tau ua tiav, cov ntsiab lus yuav tsum tau hloov kho siv cov ntsia hlau tswj. Thaum rub tawm cov khoom siv qis qis los ntawm daim ntawv saum npoo thiab rub rab riam mus rau sab, nws raug nquahu kom txo qhov dav ntawm sab laug nqa los ntawm kev nruj lossis xoob cov chais.

Summary

bending tshuab, cov yam ntxwv ntawm cov npe saum toj no, tau siv dav hauv kev lag luam, cov lag luam tshwj xeeb me, nrog rau kev lag luam ntiag tug. Thaum xaiv cov cuab yeej siv, ib tus yuav tsum tau coj mus rau hauv tus account qhov zaus ntawm nws txoj haujlwm, qhov nruab nrab ntawm kev ua haujlwm, nrog rau qib yuav tsum tau ua ntawm kev tsim nyog ntawm cov neeg ua haujlwm. Piv txwv li, rau ib lub tsev lossis qhov chaw tsim kho me me, qhov kev hloov pauv yooj yim tshaj plaws yog tsim, uas yuav luag txhua tus neeg ua haujlwm nrog kev paub txog kev tsim kho tuaj yeem ua haujlwm. Yog tias yuav tsum tau muaj kev ua haujlwm siab, nws yog qhov zoo dua los siv cov cuab yeej tshaj lij (hydraulic, hluav taws xob units lossis CNC tshuab.

Pom zoo:

Quik: teeb tsa, teeb tsa, cov lus qhia ua ntu zus, cov yam ntxwv ntawm kev ua haujlwm

Lub lag luam platform ua lub luag haujlwm tseem ceeb hauv kev lag luam. Txhua qhov kev hloov pauv tau ua rau nws. Hauv kev ua lag luam ntawm kev lag luam nyiaj txiag, muaj cov terminals sib txawv uas muaj lawv tus yam ntxwv thiab cov yam ntxwv. Kab lus no yuav tham hauv kev nthuav dav txog Quick trading platform. Tus nyeem ntawv yuav tau txais cov ntaub ntawv hais txog qhov tseeb Quik chaw rau cov cuab tam sib txawv thiab nws cov kev teeb tsa

Hluav taws xob locomotive 2ES6: keeb kwm ntawm kev tsim, kev piav qhia nrog cov duab, cov yam ntxwv tseem ceeb, lub hauv paus ntsiab lus ntawm kev ua haujlwm, cov yam ntxwv ntawm kev ua haujlwm thiab kho

Hnub no, kev sib txuas lus ntawm cov nroog sib txawv, kev thauj neeg caij tsheb, kev xa khoom yog nqa tawm ntau txoj hauv kev. Ib txoj hauv kev no yog txoj kev tsheb ciav hlau. Hluav taws xob locomotive 2ES6 yog ib yam ntawm cov kev thauj mus los uas tam sim no nquag siv

"Boeing-707" - tus neeg caij dav hlau: tshuaj xyuas, piav qhia, yam ntxwv, keeb kwm ntawm kev tsim thiab kev teeb tsa hauv tsev

Hnub no, Boeing Corporation yog ib qho kev lag luam hauv Asmeskas kev lag luam aviation thiab yog ib lub ntiaj teb ua lag luam dav hlau. Nyob rau tib lub sijhawm, nws yog lub tuam txhab no uas tau tsim lub dav hlau Boeing 707, ua tsaug rau qhov kev mus ncig thoob ntiaj teb huab cua tau txais txiaj ntsig dav

Cov cuab yeej tiv thaiv: lub hom phiaj, hom, kev faib tawm, kev qhia tshwj xeeb, kev teeb tsa, cov yam ntxwv ntawm kev ua haujlwm, teeb tsa thiab kho

Cov cuab yeej tiv thaiv tam sim no ua haujlwm yuav luag txhua qhov chaw. Lawv yog tsim los tiv thaiv ob qho tib si hluav taws xob tes hauj lwm thiab cov khoom siv hluav taws xob, ntau lub tshuab, thiab lwm yam. Nws yog ib qho tseem ceeb heev rau kev txhim kho thiab ua raws li cov kev cai ntawm kev khiav hauj lwm kom cov cuab yeej lawv tus kheej tsis ua rau hluav taws kub, tawg, thiab lwm yam

Lab ntawm Strokach yug: piav qhia ntawm hom, nta ntawm kev saib xyuas, kev yug me nyuam, tus yam ntxwv ntawm tus tsiaj thiab cov cai ntawm kev khaws cia

Yog tias ib tus neeg muaj lub hom phiaj los yug menyuam luav ntawm Strokach yug, ces nws yuav tsum nco ntsoov tias nws yog qhov zoo tshaj plaws kom muaj cov neeg muaj zog thiab zoo tshaj plaws ntawm cov tsiaj German. Thaum loj hlob hauv tsev, ntau tus neeg ua liaj ua teb tsis tas yuav ua tiav ntawm kev yug me nyuam dawb huv, vim qee tus neeg muaj variegated los yog mob