2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Muaj ntau hom hlau, txhua tus muaj nws tus kheej qhov zoo thiab qhov tsis zoo. Yog li ntawd, koj yuav tsum paub tias cov hlau yuav yuav cov khoom no lossis cov khoom ntawd kom nws kav ntev li ntev tau.

Universal steels

Cov yam ntxwv ntawm cov khoom siv hlau yog nws cov geometry, tab sis ntau dua cov qauv ntawm cov hlau, uas, nyob rau hauv lem, nyob ntawm nws muaj pes tsawg leeg thiab tsim nyog thermal, tshuaj thiab mechanical ua. Nws yog kev sib xyaw ua ke ntawm cov txheej txheem no uas piav qhia txog cov lej loj ntawm cov qib steel thiab cov khoom tiav. Txij li thaum muaj ntau yam tseem ceeb rau cov yam ntxwv ntawm cov khoom hlau (qee zaum tsuas yog xav tau lub zog, thiab qee zaum tsuas yog ductility), steel yog thawj zaug xaiv raws li nws cov tshuaj muaj pes tsawg leeg, thiab tau txais nws cov khoom kawg los ntawm kev ua haujlwm ntxiv.

Kev sib xyaw ntawm cov khoom zoo

Cov qauv ua haujlwm raug xaiv kom raug raws li qhov ua tau rau txhua ntu, thiab yog tias tsim nyog, txawm tias ib feem me me ntawm nws. Lawv nyob ntawm, raws li txoj cai, ntawm qhov chaw qhov chaw nyob hauv cov qauv thiab dab tsi uas nws tau ntsib (kev sib txhuam, dynamic, nro, compression). Raws li qhov no, cov hom phiaj kuj tau teeb tsa: kom ua tiav kev ruaj khov,plasticity los yog kev sib xyaw ua ke ntawm cov khoom zoo. Nws yog ib qho ua tau kom tau txais tib lub hardness, lub zog, ductility rau steels nrog sib txawv tshuaj muaj pes tsawg leeg, tab sis nyob rau tib lub sij hawm lawv yuav muab tsis tau zoo raws li lwm yam kev. Tab sis tib qib hlau tuaj yeem siv rau qhov sib txawv. Yog li, rau pirmer, steel 95x18 tuaj yeem yog lub hauv paus rau kev tsim khoom ntawm ntau qhov chaw, tab sis nrog tib cov kev cai rau tensile lub zog thiab hardness. Cov khoom thiab cov khoom no tuaj yeem ua ntau yam: bushings, axles, bearings, tab sis steel qhia nws cov yam ntxwv zoo tshaj plaws hauv kev tsim cov riam tua tsiaj.

khoom thiab nta

95X18 - yog ib qho zoo tshaj plaws thiab siv tau zoo tshaj plaws steels siv rau kev tsim cov riam nrog kev ua tau zoo tshwj xeeb. Raws li txoj cai, cov no yog cov khoom rau cov neeg yos hav zoov. Cov neeg uas muab lawv nyiam rau riam los ntawm hom no tsis ua rau lawv xaiv los ntawm lub caij nyoog. Txawm tias tsis delving rau hauv intricacies ntawm metallurgy, lawv pab kom paub cov riam ua los ntawm 95x18 steel zoo dua, tshuaj xyuas ntawm lwm tus neeg siv, uas koj yuav nkag siab ntau. Namely: qhov no yog cov khoom siv zoo tshaj plaws rau cov khoom no.

Cov tshuaj muaj pes tsawg leeg thiab cov khoom ntawm cov hlau no tau tshawb pom tsis ntev dhau los. Tab sis nws cov koob meej loj hlob hais ntau txog kev ua haujlwm siab ntawm cov khoom siv no. Feem ntau cov tuam txhab kev tshaj lij ua haujlwm nrog cov hlau no, vim tias nws yog capricious heev, nws yog tus cwj pwm los ntawm qhov tsis xws luag xws li overburning lossis tsis txaus tempering. Qhov no yuav tsum tau cov neeg muaj kev paub zoo ntawm kev lag luam steel thiab cov khoom siv niaj hnub precision, uas tuaj yeem ua tauTsuas yog ib lub tuam txhab ua haujlwm nrog rau kev tsim riam lossis lwm yam khoom siv hlau.

Kev kho mob

Qhov muaj chromium nyob rau hauv nws cov tshuaj muaj pes tsawg leeg tso rau pem hauv ntej lub zog steel nyob rau hauv ib tug xov tooj ntawm corrosion-resistant los yog stainless. Tsis tas li ntawd, steel 95x18 yog npaj rau forging. Rau cov qauv hlau, cov txheej txheem no yog "kev kho mob" rau ntau yam kab mob, feem ntau yog microcracks, sau lub qhov hws nrog cov teeb meem ntawm hydrogen, oxygen, thiab, ntawm chav kawm, qhov chaw ua haujlwm (qhov chaw tsis nyob ntawm lub atom uas tsim. kab noj hniav). Ntxiv nrog rau "kab mob", forging pab kom tshem tau cov tshuaj thiab dendritic cais, kom "pawg" tag nrho cov molecules nruj dua. Nrog xws li ib tug nruj structuring, cov hlau lis yog refined. Qhov no tso cai rau koj kom nce ductility yam tsis tau txo lub zog. Tom qab ntawd, nws muaj steel 95x18 yam ntxwv uas tuaj yeem tiv taus hnyav txawm tias nyob rau hauv dabtsi yog khoov.

riam riam yog ib yam tseem ceeb

Tsim cov yam ntxwv ntawm kev txiav cov khoom ntxiv thiab nce kev ua haujlwm. Lawv faib cov khoom kom zoo thiab ua rau kev siv riam yooj yim thiab xis nyob. Hauv kev tsim cov hniav, qhov tseem ceeb tseem ceeb yog txuas nrog rau cov duab, qhov loj me, txoj hauv kev ntawm kev ua kom zoo nkauj ntawm ntug thiab txoj kev sib txuas ntawm tus kov. Txhua yam ntawm cov khoom no muaj cov ncauj lus kom ntxaws ntxiv. Lawv nce kev yooj yim thiab txhim khu kev kos duab tus nqi ntawm cov khoom. Nws muaj kev vam khom ncaj qha rau lub thickness ntawm cov hniav thiab qhov zoo ntawm kev txiav. Qhov thinner cov hniav, lawv ua tau zoo duaua hauj lwm me me.

Tsev tsim khoom

Steel 95x18, riam los ntawm qhov tau txais nrog lub zog thiab hnav-tiv taus ntug, yuav tsum mus dhau ntau theem ntawm kev ua haujlwm. Kev ua hauj lwm pib nrog kev tau txais ib qho me me casting, uas yog annealed ua ntej forging (lub workpiece yog rhuab mus rau ib tug kub ntawm 885-920 degrees Celsius thiab tuav rau 1-2 teev). Nws tseem ceeb heev kom tsis txhob hlawv cov hlau ntawm no. Yog tias qhov no tshwm sim, tom qab ntawd lub workpiece yuav tsis raug rau kev ua haujlwm ntxiv lawm. Tsuas yog tom qab xws li raug kis yog cov txiv ntseej npaj rau forging. Ib lub phaj ntawm qhov xav tau loj yog tsim los ntawm nws. Ntxiv rau cov nyiaj pab rau machining (sharpening, sib tsoo) tau muab. Tom qab forging tiav, lub workpiece yog txias txias hauv tshuab roj. Qhov no hu ua hardening. Thaum lub sij hawm no, cov hlau muaj ib tug heev brittleness, thiab yog hais tias nws tsis tau tshem tawm, ces cov hlau yuav crumble zoo li iav nrog ib tug me ntsis cuam tshuam. Tej zaum qee zaum muaj kev ua haujlwm ntawm tus kws ua haujlwm tsis muaj kev paub, tab sis qhov tseem ceeb 95x18 steel tau txais kev tshuaj xyuas zoo los ntawm cov neeg siv khoom. Cov txheej txheem tempering yog cua sov lub workpiece, tab sis kom qis kub - tsuas yog mus txog 200-300 degrees Celsius.

Txoj kev ntawm riam tau txais nws cov duab hauv ob qhov kev hla. Thawj qhov kev ua si tso cai rau koj kom tau txais qhov loj me me xwb, qhov thib ob - qhov tseeb dua. Tam sim ntawd tom qab thawj tempering, zaum kawg machining yog nqa tawm. Cov hniav ntawm lub tshuab yog hauv av rau qhov xav tau loj. Hlau 95x18, kev kho cua sov uas tshwm sim nyob rau hauv plaub theem, yuav siv sij hawm nyob rau hauv lub kawg khoom tom qab lub thib ob tempering, nyob rau hauv uastag nrho cov kev ntxhov siab raug tshem tawm - thiab cov hlau ua kom zoo li ua tau. Ua li no, cov hniav tiav lawm yog khaws cia ntawm qhov kub ntawm 150 degrees rau 1-2 teev. Kev txias yuav tshwm sim hauv huab cua. Txhawm rau kho cov hniav nrog cov qauv tshwj xeeb, kua qaub etching tuaj yeem nqa tawm.

Kho riam

Txawm hais tias nws lub zog thiab lub zog, cov hlau yuav ua rau qeeb degradation. Tau kawg, cov txheej txheem no siv sijhawm ntau tshaj li kaum lossis ib puas xyoo, tab sis nws tuaj yeem raug txo kom tsawg los ntawm kev ua kom nrawm nrog kev saib xyuas tsis raug.

Steel 95x18, muaj cov ntsiab lus siab ntawm chromium hauv nws cov muaj pes tsawg leeg, yog qhov txawv los ntawm nws cov kev tiv thaiv corrosion, uas ua rau muaj kev pab cuam lub neej. Cov khoom tsim los ntawm nws kuj muaj qhov tshwj xeeb no, tab sis txawm li cas los xij, ob lub hlau nws tus kheej thiab cov qauv tsim ntawm riam yuav tsum tau ua tib zoo kho.

- Mechanical loads. Cov riam yuav tsum tsis txhob siv rau lwm lub hom phiaj. Loads xam ntawm tus kov, ntug thiab hniav tuaj yeem rhuav tshem ntau cov ntaub ntawv, nrog rau cov muaj zog heev (ntoo, hlau, thiab lwm yam), tab sis lub sharpening thiab curvature ntawm cov hniav yuav raug kev txom nyem ua ntej ntawm tag nrho cov.

- Moisture, dampness, acidic ib puag ncig. Txawm tias muaj tseeb hais tias steel 95x18 yog corrosion resistant, ntev kev sib cuag nrog ib tug tov nrog ib tug siab ntsev cov ntsiab lus adversely cuam tshuam rau saum npoo. Ib yam li nyob hauv qhov chaw ntub dej ntev.

Lub thev naus laus zis ntawm kev tsim riam, zoo li lwm yam khoom siv hlau, yog raws li GOST, daim duab qhia txuj ci thiab cov lus qhia. Hom hlau no muaj nuj nqis heev tsis yog nyob rau hauv Russia xwb. Nws kuj tau yooj yim sib tw nrog txawv teb chaws hom thiab tshaj ntau ntawm lawv nyob rau hauv cov nqe lus ntawm cov tsis yooj yim. Tab sis, txawm li cas los xij, cov khoom ntawm txhua tus tswv muaj lawv tus kheej qhov sib txawv. Qhov no qhia tau hais tias kev ua haujlwm nrog hlau tsis yog tsuas yog cov txheej txheem thev naus laus zis xwb, tab sis thawj zaug nws yog txoj haujlwm.

Pom zoo:

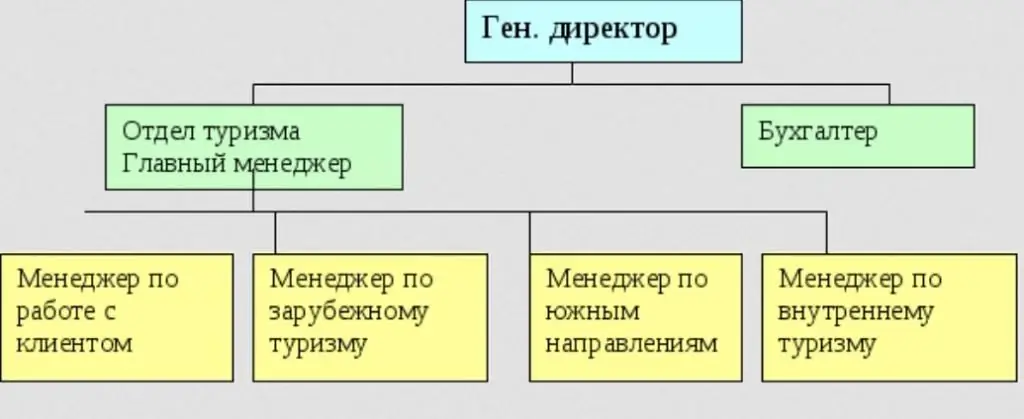

Hom kev ncig xyuas thiab lawv cov yam ntxwv. Kev ua haujlwm thiab cov yam ntxwv ntawm cov haujlwm ntawm cov neeg ncig xyuas ncig xyuas

Tus neeg ncig xyuas muab ntau yam kev pabcuam mus ncig thiab ua kom yooj yim rau kev tshwj tseg cov kev pabcuam hauv lwm lub nroog thiab lub tebchaws, ua haujlwm rau cov haujlwm no. Nyob rau hauv lub tshav pob ntawm tourism kev pab cuam, nws occupies ib tug tshwj xeeb niche. Hauv tsab xov xwm peb yuav txiav txim siab txog hom kev ua ub no ntawm cov neeg ncig xyuas

Hluav taws xob locomotive 2ES6: keeb kwm ntawm kev tsim, kev piav qhia nrog cov duab, cov yam ntxwv tseem ceeb, lub hauv paus ntsiab lus ntawm kev ua haujlwm, cov yam ntxwv ntawm kev ua haujlwm thiab kho

Hnub no, kev sib txuas lus ntawm cov nroog sib txawv, kev thauj neeg caij tsheb, kev xa khoom yog nqa tawm ntau txoj hauv kev. Ib txoj hauv kev no yog txoj kev tsheb ciav hlau. Hluav taws xob locomotive 2ES6 yog ib yam ntawm cov kev thauj mus los uas tam sim no nquag siv

Diesel phom: tshuaj xyuas thiab xaiv cov qauv. Diesel phom ntawm indirect cua sov: cov yam ntxwv kev

Lub tshuab hluav taws xob hluav taws xob yog qhov zoo tshaj plaws rau cua sov sai rau qhov chaw tsim kho, kev ua liaj ua teb, tsev khaws khoom lossis chaw tsim khoom. Txij li thaum nws txoj haujlwm yog ua los ntawm cov roj diesel, nws siv hluav taws xob nkaus xwb rau kev ua haujlwm ntawm automation thiab kiv cua. Cov txiaj ntsig tseem ceeb ntawm cov kev daws teeb meem thev naus laus zis suav nrog lub zog thermal thermal nrog qhov me me

Kev kho cua sov ntawm cov hlau. Hom kev kho cua sov

Kev kho cua sov ntawm cov hlau yog qhov tseem ceeb ntawm cov txheej txheem tsim khoom ntawm ferrous thiab non-ferrous metallurgy. Raws li qhov tshwm sim ntawm cov txheej txheem no, cov hlau muaj peev xwm hloov tau lawv cov yam ntxwv rau qhov yuav tsum tau muaj. Hauv tsab xov xwm no, peb yuav txiav txim siab txog hom kev kho cua sov tseem ceeb uas siv hauv kev lag luam niaj hnub no

Yam ntxwv ntawm steel 65x13: khoom, hardness. Kev tshuaj xyuas txog riam ua los ntawm steel 65x13

Nyob rau hauv niaj hnub metallurgy, ntau cov hlau siv. Lawv cov yam ntxwv, nrog rau ntau yam ntawm nomenclature, yog qhov loj heev