2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Kev txhim kho raug txheeb xyuas nrog kev txhim kho. Kev txhim kho kev lag luam thiab kev muaj peev xwm hauv tsev yog ua los ntawm kev siv cov khoom siv nrog cov yam ntxwv zoo zuj zus. Cov no yog, tshwj xeeb, alloyed hlau. Lawv qhov kev sib txawv yog txiav txim siab los ntawm qhov muaj peev xwm kho qhov ntau thiab qhov zoo ntawm cov hlau alloying.

Natural Alloy Steel

Thawj smelted hlau, uas txawv ntawm nws cov txheeb ze nyob rau hauv nws cov khoom, yog lawm alloyed. Smelted prehistoric meteoric hlau muaj ntau ntxiv ntawm nickel. Nws tau pom nyob rau hauv ancient Egyptian burials ntawm 4-5 txhiab xyoo BC. e., architectural monument ntawm Qutab Minar hauv Delhi (5th caug xyoo) tau tsim los ntawm tib yam. Japanese damask swords yog ua los ntawm hlau saturated molybdenum, thiab Damascus steel muaj tungsten, yam ntxwv ntawm niaj hnub high-ceev txiav. Cov no yog hlau, cov ore uas tau mined los ntawm tej qhov chaw.

Cov khoom siv niaj hnub no tuaj yeem muaj cov khoom siv hlau thiabCov keeb kwm tsis yog xim hlau, uas tau tshwm sim hauv lawv cov yam ntxwv thiab cov khoom.

keeb kwm

Lub hauv paus rau txoj kev loj hlob ntawm alloying tau nteg los ntawm kev ncaj ncees ntawm txoj kev crucible ntawm melting hlau nyob rau hauv cov teb chaws Europe nyob rau hauv lub xyoo pua 18th. Nyob rau hauv ib qho tseem ceeb tshaj version, crucibles tau siv nyob rau hauv ancient sij hawm, nrog rau smelting damask thiab Damascus hlau. Thaum pib ntawm lub xyoo pua 18th, cov thev naus laus zis no tau txhim kho ntawm kev lag luam thiab ua kom nws tuaj yeem kho qhov muaj pes tsawg leeg thiab zoo ntawm cov khoom siv.

- Qhov kev tshawb pom ib txhij ntawm ntau thiab ntau cov tshuaj tshiab tau thawb cov kws tshawb fawb mus rau qhov kev sim smelting.

- Cov txiaj ntsig tsis zoo ntawm tooj liab rau qhov zoo ntawm cov hlau tau tsim.

- Brass muaj 6% hlau nrhiav tau.

Kev sim tau ua tiav raws li cov txiaj ntsig zoo thiab muaj txiaj ntsig ntawm cov hlau alloy ntawm tungsten, manganese, titanium, molybdenum, cob alt, chromium, platinum, npib tsib xee, txhuas thiab lwm yam.

Thawj qhov kev lag luam ntawm cov hlau alloyed nrog manganese tau tsim nyob rau thaum pib ntawm lub xyoo pua 19th. Nws tau tsim txij li xyoo 1856 los ua ib feem ntawm cov txheej txheem smelting Bessemer.

yam ntxwv ntawm doping

Kev muaj peev xwm niaj hnub ua rau nws ua tau rau smelt hlau alloyed ntawm txhua yam muaj pes tsawg leeg. Lub hauv paus ntsiab lus ntawm kev siv tshuab hauv nqe lus nug:

- Cov ntsiab lus raug suav tias yog alloying nkaus xwb yog tias lawv tau qhia lub hom phiaj thiab cov ntsiab lus ntawm txhua qhov siab tshaj 1%.

- Sulfur, hydrogen, phosphorus yog suav tias yog impurities. raws li non-metallicsuav nrog, boron, nitrogen, silicon yog siv, tsis tshua muaj - phosphorus.

- Kev sib xyaw ua ke ntau yog kev taw qhia ntawm cov khoom siv rau hauv cov khoom molten nyob rau hauv lub moj khaum ntawm metallurgical ntau lawm. Nto yog ib txoj hauv kev ntawm diffusion saturation ntawm txheej txheej nrog cov khoom tsim nyog tshuaj nyob rau hauv lub siab kub.

- Thaum tus txheej txheem, cov khoom ntxiv hloov pauv cov qauv siv lead ua ntawm "tus ntxhais" cov khoom. Lawv tuaj yeem tsim kev nkag mus lossis tshem tawm cov kev daws teeb meem, nrog rau muab tso rau ntawm thaj tsam ntawm cov hlau thiab cov hlau tsis yog hlau, tsim kom muaj kev sib xyaw ntawm cov nplej. Qib ntawm solubility ntawm cov ntsiab lus nyob rau hauv ib leeg plays lub luag hauj lwm loj ntawm no.

Alloying Cheebtsam

Raws li kev faib tawm dav dav, tag nrho cov hlau tau muab faib ua ferrous thiab non-ferrous. Dub muaj xws li hlau, chromium thiab manganese. Non-ferrous muab faib ua lub teeb (txhuas, magnesium, potassium), hnyav (nickel, zinc, tooj liab), noble (platinum, nyiaj, kub), refractory (tungsten, molybdenum, vanadium, titanium), lub teeb, tsis tshua muaj ntiaj teb thiab radioactive.. Alloy hlau muaj xws li ntau yam ntawm lub teeb, hnyav, noble thiab refractory non-ferrous hlau, nrog rau tag nrho cov ferrous sawv daws yuav.

Raws li qhov sib piv ntawm cov ntsiab lus thiab qhov loj ntawm cov hlau, cov tom kawg tau muab faib ua qis-alloyed (3%), nruab nrab-alloyed (3-10%) thiab high-alloyed (ntau tshaj 10). %).

Alloy steels

Technologically, cov txheej txheem tsis ua teeb meem. Qhov ntau yog dav heev. Lub hom phiaj tseem ceeb rausteels yog raws li nram no:

- Txhawb zog.

- Txhim kho cov txiaj ntsig kho cua sov.

- Kev txhim kho corrosion, tiv thaiv tshav kub, tiv thaiv tshav kub, tiv thaiv tshav kub, tiv thaiv kev ua haujlwm hnyav, kev pabcuam lub neej.

Cov khoom tseem ceeb yog ferrous alloying thiab refractory hlau, uas suav nrog Cr, Mn, W, V, Ti, Mo, thiab tsis-ferrous Al, Ni, Cu.

Chromium thiab npib tsib xee yog cov khoom tseem ceeb uas txhais cov hlau tsis muaj steel (X18H9T), nrog rau cov hlau tsis muaj cua sov, kev ua haujlwm ntawm cov yam ntxwv ntawm qhov kub thiab txias thiab poob siab (15X5). Txog li 1.5% yog siv rau cov kabmob thiab kev sib txhuam (15HF, SHKH15SG)

Manganese yog ib qho tseem ceeb ntawm cov hlau tsis muaj zog (110G13L). Hauv qhov me me, nws pab txhawb rau deoxidation, txo cov concentration ntawm phosphorus thiab sulfur.

Silicon thiab vanadium yog cov khoom ua kom elasticity hauv qee qhov nyiaj thiab siv los ua cov springs thiab springs (55C2, 50HFA).

Aluminium siv tau rau hlau nrog hluav taws xob siab (X13Y4).

Cov ntsiab lus tseem ceeb ntawm tungsten yog qhov zoo rau cov cuab yeej siv siab ceev (R9, R18K5F2). Kev xyaum hlau alloyed ua los ntawm cov khoom siv no yog qhov ua tau zoo dua thiab tiv thaiv kom tsis txhob cuam tshuam ntau dua li tib lub cuab yeej ua los ntawm cov hlau.

Alloy steels tau nkag mus siv txhua hnub. Nyob rau tib lub sij hawm, lub thiaj li hu ua alloys nrog amazing zog, kuj tau los ntawm alloying txoj kev, paub. Yog li "ntoo steel" muaj 1% chromiumthiab 35% npib tsib xee, uas txiav txim siab nws cov thermal conductivity, yam ntxwv ntawm ntoo. Pob zeb diamond kuj suav nrog 1.5% carbon, 0.5% chromium thiab 5% tungsten, uas qhia nws tshwj xeeb tshaj yog nyuaj, zoo li pob zeb diamond.

alloying cam khwb cia hlau

Cam khwb cia hlau txawv ntawm cov hlau los ntawm cov ntsiab lus tseem ceeb ntawm carbon (los ntawm 2.14 txog 6.67%), siab hardness thiab corrosion kuj, tab sis tsis muaj zog. Txhawm rau nthuav dav ntau yam ntawm cov khoom tseem ceeb thiab kev siv, nws yog alloyed nrog chromium, manganese, aluminium, silicon, npib tsib xee, tooj liab, tungsten, vanadium.

Vim yog cov yam ntxwv tshwj xeeb ntawm cov khoom siv hlau-carbon, nws cov alloying yog txheej txheem nyuaj dua li cov hlau. Txhua yam ntawm cov khoom cuam tshuam rau kev hloov pauv ntawm cov ntawv carbon hauv nws. Yog li manganese pab tsim cov graphite "yog" uas ua rau kom muaj zog. Kev taw qhia ntawm lwm tus ua rau kev hloov pauv ntawm cov pa roj carbon monoxide mus rau lub xeev dawb, tshuaj dawb ntawm cov hlau cam thiab txo qis hauv nws cov khoom siv kho tshuab.

Cov thev naus laus zis yog qhov nyuaj los ntawm qhov qis melting kub (qhov nruab nrab, txog li 1000 ˚C), thaum rau feem ntau alloying ntsiab nws ho ntau tshaj qhov theem no.

Complex alloying yog qhov zoo tshaj plaws rau cov hlau cam khwb cia. Nyob rau tib lub sijhawm, ib tus yuav tsum tau coj mus rau hauv tus account qhov muaj feem ntau ntawm kev sib cais ntawm cov castings, qhov kev pheej hmoo ntawm kev tawg, thiab qhov tsis xws luag. Nws yog qhov tsim nyog ntau dua los ua cov txheej txheem thev naus laus zis hauv electromagnetic thiab induction furnaces. Ib kauj ruam uas yuav tsum tau ua raws yog kev kho cua sov zoo.

Chromium cam khwb cia hlau yog tus cwj pwm los ntawm kev hnav tsis kam, lub zog, kub tsis kam, tiv thaiv kev laus thiab corrosion (CH3, CH16). Lawv siv nyob rau hauv chemical engineering thiab hauv kev tsim cov khoom siv metallurgical.

Cov hlau nrum alloyed nrog silicon yog qhov txawv los ntawm kev tiv thaiv corrosion siab thiab tsis kam mus rau cov tshuaj lom neeg ua phem, txawm hais tias lawv muaj cov khoom siv zoo (ChS13, ChS17). Lawv tsim cov khoom siv tshuaj lom neeg, cov kav dej thiab cov twj.

Cov cam khwb cia kub-resistant yog ib qho piv txwv ntawm kev ua haujlwm zoo heev. Lawv muaj ferrous thiab alloying hlau xws li chromium, manganese, nickel. Lawv yog cov yam ntxwv los ntawm kev ua haujlwm siab corrosion, hnav tsis kam thiab tsis kam rau siab loads nyob rau hauv qhov kub thiab txias - qhov chaw ntawm turbines, twj, cav, cov cuab yeej siv tshuaj (ChN15D3Sh, ChN19Kh3Sh).

Ib qho tseem ceeb yog tooj liab, uas yog siv ua ke nrog lwm cov hlau, thaum ua kom cov yam ntxwv ntawm cov hlau.

alloy tooj liab

Siv hauv daim ntawv ntshiab thiab ua ib feem ntawm tooj liab alloys, uas muaj ntau yam nyob ntawm qhov piv ntawm cov ntsiab lus thiab cov alloying: tooj dag, bronze, cupronickel, npib tsib xee nyiaj thiab lwm yam.

Ntshiab tooj dag - ib qho hlau nrog zinc - tsis yog alloyed. Yog hais tias nws muaj alloying non-ferrous hlau nyob rau hauv ib tug npaum li cas, nws yog xam tau tias yog multicomponent. Bronzes yog cov alloys nrog lwm cov khoom siv hlau,tuaj yeem ua tin thiab tsis muaj tin, yog alloyed nyob rau hauv txhua rooj plaub. Lawv qhov zoo yog txhim kho nrog kev pab ntawm Mn, Fe, Zn, Ni, Sn, Pb, Be, Al, P, Si.

Silicon cov ntsiab lus hauv cov khoom siv tooj liab nce lawv cov kev tiv thaiv corrosion, lub zog thiab elasticity; tin thiab txhuas - txiav txim siab qhov zoo ntawm kev sib txhuam thiab cov yam ntxwv zoo ntawm machinability; npib tsib xee thiab manganese - cov khoom ntawm qhov hu ua wrought alloys, uas tseem muaj txiaj ntsig zoo rau kev tiv thaiv corrosion; hlau txhim kho cov khoom siv dag zog, thaum zinc txhim kho cov cuab yeej technology.

Siv hauv hluav taws xob engineering ua cov khoom siv tseem ceeb rau kev tsim khoom ntawm ntau cov xov hlau, cov khoom siv rau kev tsim cov khoom tseem ceeb rau cov khoom siv tshuaj, hauv kev siv tshuab thiab ntsuas ntsuas, hauv cov kav dej thiab cov khoom siv hluav taws xob.

Aluminium alloying

Siv raws li wrought lossis cam khwb cia hlau. Alloyed hlau raws li nws yog cov tebchaw nrog tooj liab, manganese lossis magnesium (duralumins thiab lwm yam), tom kawg yog cov tebchaw nrog silicon, hu ua silumins, thaum tag nrho lawv cov kev hloov pauv tau yog alloyed nrog Cr, Mg, Zn, Co, Cu, Si.

tooj liab nce nws cov ductility; silicon - fluidity thiab zoo casting zog; chromium, manganese, magnesium - txhim kho lub zog, thev naus laus zis ntawm kev ua haujlwm los ntawm kev siab thiab corrosion kuj. Thiab, B, Pb, Zr,Ti, Bi.

Hlau yog ib qho khoom tsis zoo, tab sis nws yog siv me me hauv kev tsim cov ntawv txhuas. Silumins yog siv rau casting qhov tseem ceeb thiab vaj tse nyob rau hauv mechanical engineering. Duralumins thiab aluminium-raws li stamping alloys yog ib qho tseem ceeb raw khoom rau kev tsim cov khoom hull, suav nrog cov qauv thauj khoom, hauv kev lag luam dav hlau, nkoj tsim thiab tshuab engineering.

Alloyed hlau yog siv nyob rau hauv tag nrho cov cheeb tsam ntawm kev lag luam raws li cov uas tau txhim kho cov neeg kho tshuab thiab thev naus laus zis yam ntxwv piv rau cov khoom qub. Qhov ntau ntawm cov ntsiab lus alloying thiab lub peev xwm ntawm cov thev naus laus zis niaj hnub tso cai rau ntau yam kev hloov kho uas nthuav dav qhov muaj peev xwm hauv kev tshawb fawb thiab thev naus laus zis.

Pom zoo:

Alloy cam khwb cia hlau: qib, khoom thiab daim ntawv thov

Alloyed hlau yog ib yam khoom uas yog tsim los ntawm smelting nyob rau hauv blast furnaces. Nws tuaj yeem muaj cov pa roj carbon ntau sib txawv. Nyob ntawm seb muaj pes tsawg cov ntsiab lus ntawm cov khoom no, ob hom cam khwb cia hlau yog qhov txawv. Thawj yog hu ua hloov dua siab tshiab, los yog dawb, thiab lub thib ob yog grey, los yog foundry

Indium hlau: piav qhia, khoom thiab daim ntawv thov

Indium muaj ntau yam khoom muaj txiaj ntsig vim nws tuaj yeem siv rau hauv aerospace, engineering, electronics, nuclear kev lag luam thiab lwm yam lag luam

Perforated hlau yeeb nkab: hom, piav qhia thiab daim ntawv thov nta

Cov kab lus no mob siab rau cov kav hlau perforated. Cov yam ntxwv ntawm cov khoom zoo li no, ntau yam thiab thaj tsam ntawm daim ntawv thov raug txiav txim siab

Tshaj tawm ntawm phab ntsa daim ntawv qhia hnub: hom, xaiv cov ntsiab lus ntawm daim ntawv qhia hnub, nuances ntawm kev tsim thiab luam ntawv

Daim ntawv qhia hnub yog ib qho tseem ceeb ntawm txhua qhov chaw ua haujlwm. Thiab txawm tias muaj pes tsawg tus neeg siv khoom thiab cov neeg muag khoom pub dawb rau lawv, lawv tseem ua khawv koob los ntawm lub tuam txhab cov chaw ua haujlwm uas tsis koom nrog kev sib txuas lus nrog cov neeg cog lus. Cias muab, daim ntawv qhia hnub yog qhov tseem ceeb tshaj plaws ntawm cov ntaub ntawv tshaj tawm uas ib txwm mus nrog lub suab nrov

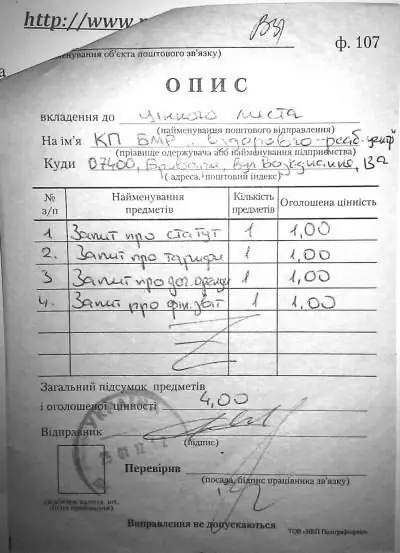

Daim ntawv sau npe nrog cov lus piav qhia txuas ntxiv. Cov txheej txheem xa ib tsab ntawv sau npe nrog cov lus piav qhia ntawm qhov txuas

Nyob hauv lub hnub nyoog ntawm computer technology, tib neeg sau ntawv rau ib leeg tsawg thiab tsawg. Tej zaum nws yuav zoo li tias nyob rau yav tom ntej xws li lub koom haum raws li lub chaw xa ntawv feem ntau yuav dhau los lawm. Tab sis nyob rau hauv kev muaj tiag no yog deb ntawm rooj plaub. Feem ntau, nws yooj yim ua tsis tau yam tsis muaj kev xa ntawv xa mus. Hauv tsab xov xwm no, peb yuav xav txog cov txheej txheem rau xa ib tsab ntawv sau npe nrog cov lus piav qhia txuas ntxiv. Wb kuj tham txog tias tsab ntawv yuav siv sij hawm ntev npaum li cas, thiab tus nqi pabcuam li cas