2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Nyob rau theem tam sim no ntawm kev tsim kho kev lag luam, muaj ob lub ntsiab lus ntawm lub koom haum ntawm cov txheej txheem tsim khoom, uas npog cov chaw tsim khoom los ntawm cov cwj mem ballpoint mus rau cov neeg caij dav hlau. Nyob ntawm seb cov khoom lag luam, qhov ntim ntau lawm, qhov nyuaj ntawm cov thev naus laus zis thiab ntau qhov ntsuas ntawm kev lag luam, kev ruaj ntseg lossis hauv kab ntawm kev tsim khoom lossis kho cov khoom siv.

Qhov txawv ntawm txoj kev

Qhov sib txawv tseem ceeb ntawm ob daim ntawv no yog nyob rau hauv cov txheej txheem ntawm kev txav khoom lossis kev kho thaum ua tiav cov txheej txheem thev naus laus zis. Nrog rau txoj kev nyob ruaj ruaj, ib yam khoom (lub cev muaj zog, lub tsheb, thiab lwm yam) yog rigidly tsau nyob rau hauv ib txoj hauj lwm thaum lub sij hawm tag nrho cov voj voog. Cov neeg ua haujlwm ua cov txheej txheem tsim nyog raws li kev xav tau ntau lawm.

Nrog rau txoj hauv kev ntawm kev teeb tsa kev tsim khoom, ntawm qhov tsis sib xws, cov neeg ua haujlwm tau ruaj khov hauv qhov chaw, thiab cov khoom tsim khoom(kho) txav ntawm txoj haujlwm nrog cov kev xaiv ntau lawm. Qhov no ua kom cov khoom tsim tau zoo tshaj plaws thiab txo cov sij hawm poob.

keeb kwm kev tsim kho

Kev txhim kho ntawm ceg kev lag luam yog txiav txim siab los ntawm cov tuam txhab tsim khoom loj, uas, vim muaj cov ntim ntau thiab cov nqi ntawm cov khoom siv, siv cov thev naus laus zis siab tshaj plaws thiab txoj hauv kev. Nws tsis yog qhov xav tsis thoob tias thawj qhov xwm txheej loj ntawm kev siv cov txheej txheem ntws ntawm kev tsim khoom tau sau tseg hauv Asmeskas kev lag luam tsheb thaum pib ntawm lub xyoo pua 20th. Tus kws tshaj lij Henry Ford raug hu ua leej txiv ntawm cov ntaub ntawv hauv-kab ntawm lub koom haum. Tom qab tag nrho, nws yog nrog nws cov tswv yim uas qhia txog cov hauv paus ntsiab lus ntawm kev tsim khoom tshiab pib.

Yam yuavtsum tau kawm uantej rau kev tsim

Txoj kev ntws ntawm kev tsim cov khoom lag luam suav tias qhov kev kawm ua tau. Yog li ntawd, nyob rau theem pib, nws yog ib qho tsim nyog yuav tsum tau soj ntsuam kev tsim khoom kom ua tau raws li cov xwm txheej rau kev hloov mus rau ntau hom kev koom tes. Cov no suav nrog:

- muaj peev xwm thauj khoom tag nrho ntawm cov cuab yeej siv thev naus laus zis, uas yog txiav txim siab los ntawm tus lej txaus ntawm cov khoom lag luam homogeneous;

- nthuav dav thev naus laus zis sib txawv;

- kev khi ntev ntawm kev ua haujlwm hauv lub sijhawm thiab qhov chaw;

- kev tshwj xeeb hauv kev ua haujlwm tsawg nrog lawv cov tshuab siab tshaj plaws;

- muaj peev xwm los tsim kom muaj kev tsim khoom (kev tso npe ua ntu zus ntawm txoj haujlwm), uas ua rau nws ua tau kom tau txais kev pom zoocov khoom ntws cov qauv;

- siv ib zaug parameter (kev ua suab nrov);

- muaj peev xwm ntawm kev siv cov tog thauj khoom (kev sib luag thiab kev sib xyaw ntawm ntau lawm);

- muaj kev thauj tshwj xeeb rau cov khoom txav.

Kev ua tau zoo ntawm kev siv

yam ntxwv zoo ntawm txoj kev tsim khoom hauv kab:

- siv cov cuab yeej ua haujlwm siab (tshwj xeeb);

- mechanization of transport technology units,

- kev siv cov peev txheej tsim nyog.

Kev ua tau zoo ntawm cov ntawv thov yog ua raws li kev ua kom zoo ntawm ntau qhov ntsuas kev tsim khoom (kev ua haujlwm tsim khoom, kev tsim khoom, lub sijhawm ntawm lub voj voog ntau lawm, thaj chaw ua haujlwm thiab cov nqi tsim khoom).

Kev ua tau zoo tag nrho yog cuam tshuam los ntawm:

- txo qhov sib koom ntawm lub cev ua haujlwm (txo cov neeg ua haujlwm) ntawm cov theem thauj los ntawm kev siv cov cuab yeej tshwj xeeb (cov khoom thauj, thauj, cov menyuam conveyors);

- txo cov neeg ua haujlwm poob haujlwm vim kev hloov khoom siv, kev thauj khoom tsis sib xws thiab ntau lub peev xwm faib;

- qhov tshwj xeeb tshaj plaws ntawm txoj haujlwm (ntau txoj haujlwm sib txawv ntawm ib tus neeg ua haujlwm);

- txo qis kev siv zog tag nrho ntawm kev tsim khoom raws li kev qhia txog kev siv thev naus laus zis tshiab.

Ntaus ntau lawm

Lub ntsiab tseem ceeb ntawm kev tsim khoom hauv kab yog nyob rau hauv-kab (txheej txheem)kab. Nws muaj cov haujlwm tshwj xeeb lossis cov haujlwm uas muaj feem xyuam nrog thev naus laus zis.

Cov kab ntau lawm yog cais raws li tus lej ntawm cov yam ntxwv:

- ntawm qhov sib txawv ntawm cov khoom ntawm cov dej ntws - ntawm txoj kab nrog cov khoom sib xws thiab cov kab nrog cov khoom muaj qhov sib txawv thiab cov qauv tsim;

- raws li cov qauv ntawm cov txheej txheem - kev ua tsis tu ncua hauv lub sijhawm (nruam) thiab ua ntu zus;

- los ntawm hom kev sib dhos - nrog kev nruj (tswj) kev sib dhos thiab nrog kev hloov pauv (dawb) rhiab;

- rau kev thauj khoom ntawm cov khoom - nrog thiab tsis muaj cov ntsiab lus conveyor;

- los ntawm kev siv ntsuas - nyob rau theem ntawm qhov chaw (chaw haujlwm), rhiav (tsev), Hoobkas (ntau qhov txuas nrog lub voj voog ntau lawm);

- on mechanization thiab automation - non-mechanized (tsis muaj kev txav mus los ntawm cov khoom loj), nrog ib feem mechanization (tsav tsheb nrog cov qauv tsheb), nrog rau kev siv tshuab (siv siv txoj siv hlua lossis saw conveyor), automated los yog tsis siv neeg;

- raws li kev teeb tsa spatial - rectilinear, ellipsoidal, thiab lwm yam.

Txoj kev ntws ntawm kev tsim cov khoom tsim ua tus yam ntxwv ntawm kev lag luam. Kev siv cov kab sib txawv ntawm cov kab ntau lawm tsim ib theem tshwj xeeb ntawm cov tuam tsev thiab cuam tshuam rau tag nrho cov kev ua haujlwm ntawm qhov system.

Txoj kev ntws system tsim

Nco ntsoov tias txoj hauv kevlub koom haum txiav txim siab txog hom kev tsim khoom. Kev taw qhia ntawm lub tshuab ua qauv zoo ntawm lub kaw lus nyob rau hauv lub xub ntiag ntawm qhov yuav tsum tau ntim ntau lawm tso cai rau lub lag luam los tsa lub bar ntawm kev ua tau zoo tshaj plaws.

Lub hauv paus tsim rau kev tsim cov dej ntws yog cov txheej txheem tsim nyog ntawm cov txheej txheem ua haujlwm, uas yog nyob ntawm ntau qhov chaw:

- Kev tsim ua ntej yuav tsum qhia tib hom qauv, sib hloov ntawm cov ntsiab lus thiab lawv cov qauv.

- Cov thev naus laus zis tso cai rau kev sib cais siab tshaj plaws ntawm cov khoom siv thev naus laus zis rau hauv cov khoom siv, uas ua rau nws muaj peev xwm ua kom paub cov txheej txheem sib sib zog nqus.

- Txoj kev koom tes yog raws li kev tsim khoom txaus, kev siv nyiaj tag nrho thiab qib siab tshwj xeeb.

- Cov khoom siv yog raws li kev txhim kho ntawm cov khoom siv txhawb nqa rau tag nrho cov kab ke (MRP, "Maximum-Minimum") thiab muab cov haujlwm (Kanban, FEED, thiab lwm yam).

qauv rau txoj kev ntws ntawm kev tsim khoom

Muaj ntau txoj kev xaiv rau kev tsim khoom. Qhov ntim ntawm mechanization, spatial configuration, uniformity ntawm cov qauv yog nyob rau hauv dav dav. Txhawm rau tsim kom muaj txiaj ntsig zoo hauv kab, ntau cov txheej txheem tsim khoom, paub zoo dua li cov khoom siv hauv kab, raug siv.

Raws li txoj cai, lawv tau muab faib ua ib pawg hauv qab no:

- parameters characterizing lub sijhawm ua haujlwm (ntsuas, kev sib dhos);

- parameters uas txiav txim siab txoj haujlwm hauv qhov chaw (ntev, dav, tus lej ntawm txoj haujlwm,cheeb tsam chaw ua haujlwm, thiab lwm yam);

- parameters uas qhia cov khoom tsim tau ntawm cov kab ntau lawm (flow rate, productivity per unit time).

Scope of application

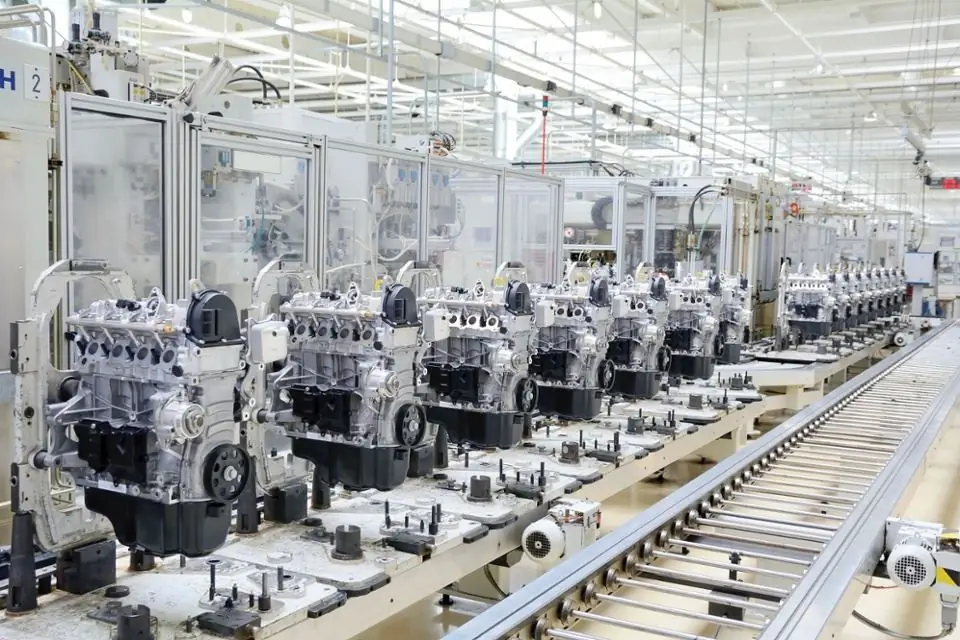

Cov txheej txheem ntws ntau tshaj plaws ntawm kev tsim cov khoom siv yog siv hauv kev tsim kho tshuab. Kev siv ntawm kev lag luam ntawm kev lag luam tsheb, kev tsheb ciav hlau thauj mus los, cov khoom siv hluav taws xob hauv tsev yog qhov nkag siab zoo los ntawm qhov pom ntawm cov khoom sib xws, muaj peev xwm tsim cov tog neeg thauj, nthuav dav ntawm cov cuab yeej technology thiab lwm yam. Nyob rau tib lub sijhawm, txoj kev ntws ntawm kev tsim khoom kuj tseem qhia txog hom kev tsim khoom.

Txawm li cas los xij, kev siv thev naus laus zis yog ib txoj hauv kev rau lub koom haum, kev tswj hwm thiab kev ua haujlwm ntawm ntau yam txheej txheem. Yog li ntawd, kev siv cov ntsiab cai ntws yog ua tau nyob rau hauv txhua lub tshuab uas muaj cov txheej txheem saum toj no. Xav txog kev siv cov thev naus laus zis ntws los ntawm qhov piv txwv ntawm kev tsim kho kev lag luam.

Txoj kev siv hauv kev tsim kho

Kev tsim kho ntawm ntau yam khoom yog tib txoj kev tsim khoom raws li kev tsim cov khoom lag luam. Hauv ob qho tib si thawj thiab thib ob, peb tsuas yog cuam tshuam nrog cov khoom sib txawv (tsim cov khoom siv hauv tsev, ua lub tsev) thiab technologies (sembling lub hwj chim mov, tsim lub hauv paus).

Lub hom phiaj ntawm kev tsim kho yog cov khoom (cov tsev, cov qauv) tau txais kev ua haujlwm, tau txais los ntawm kev siv cov txheej txheem nyuaj ntawm qhov chaw tsim kho. Thaum lub sij hawm tsim kho, serial thiab parallel hom yog siv.ntau lawm voj voog. Kev tsim tawm hauv kab tsis tau hla dhau ib qho.

Txoj kev ntws ntawm kev txhim kho kev tsim khoom muaj nyob rau hauv kev faib cov txheej txheem kev tsim kho rau ntau theem - tso lub hauv paus ntawm lub tsev nyob, txhim kho cov plag tsev, kev ua haujlwm sab hauv uas pab pawg ua haujlwm ua raws li kev sib dhos ntawm cov txheej txheem ntau lawm. Nyob rau tib lub sijhawm, lawv siv zog los tsim cov chaw ua haujlwm nrog kev siv zog ntawm kev sib npaug sib npaug. Cov txheej txheem ntau lawm ntawm cov ntsiab lus sib txawv yog ua tib yam, uas txuag cov peev txheej thiab txo lub sij hawm ntau lawm.

Qhov tsis txaus ntawm cov txheej txheem ntws ntawm kev tsim kho kev tsim khoom tsim cov yam ntxwv ntawm cov dej ntws raws li kev suav nyiaj thiab kev tshuaj xyuas ntawm thev naus laus zis, spatial thiab lub cev nqaij daim tawv. Cov no suav nrog cov qauv ntws, qhov kev ua haujlwm, kev siv zog ua haujlwm, cov kauj ruam ntws, cyclicity module, thiab lwm yam.

Nyob hauv kaw

Qhov kev tshuaj ntsuam qhia tau hais tias kev siv cov txheej txheem hauv-kab ntawm kev tsim khoom yog qhov tsim nyog rau kev tsim cov tuam txhab high-tech niaj hnub. Cov thev naus laus zis hauv kab tuaj yeem siv rau ntau yam kev tsim khoom, ua kom cov qauv tsim tau zoo thiab cov khoom zoo.

Pom zoo:

Yog qhov yuav tsum tau foob rau tus neeg ua lag luam: cov yam ntxwv ntawm kev cai lij choj ntawm Lavxias Federation, cov xwm txheej uas tus neeg ua lag luam yuav tsum muaj lub foob, tsab ntawv lees paub txog qhov tsis muaj foob, cov qauv sau, qhov zoo thiab cons ntawm kev ua haujlwm nrog lub foob

Qhov xav tau siv luam ntawv yog txiav txim siab los ntawm hom kev ua haujlwm uas tus neeg ua lag luam ua. Feem ntau, thaum ua haujlwm nrog cov neeg siv khoom loj, lub xub ntiag ntawm lub thwj yuav yog qhov tsim nyog rau kev koom tes, txawm tias tsis tas yuav tsum tau ua los ntawm txoj cai. Tab sis thaum ua hauj lwm nrog tsoom fwv txiav txim, luam ntawv yog tsim nyog

Ua haujlwm ua tus kws tshaj lij kev tsim khoom noj khoom haus: xav tau kev kawm, kev nkag mus kawm, lub luag haujlwm thiab cov yam ntxwv ntawm kev ua haujlwm

Tus txiv neej tau npaj kom nws xav tau zaub mov txhua hnub. Yog hais tias ua ntej ua noj ua haus tsuas yog ua rau nws tus kheej noj, tam sim no nws yog ib qho kev lag luam loj, tawm tsam ntawm qhov loj me. Muaj ntau lub tsev lag luam. Lawv tau sawv cev los ntawm ntau yam kev lag luam catering, los ntawm cov chaw tsim khoom tsim cov khoom lag luam ib nrab mus rau cov tsev noj mov cov neeg tseem ceeb uas tuaj yeem ua tau raws li qhov xav tau thiab kev thov ntawm cov neeg siv khoom xav tau tshaj plaws thiab cov neeg nyiam

Kev xav tau thiab khoom siv hauv kev ua lag luam. Tsim cov yam ntxwv

Kev xav tau thiab kev xa khoom hauv kev lag luam ua haujlwm raug tsim los ntawm ntau qhov yuav tsum tau ua ua ntej uas tuaj yeem faib ua ob pawg loj. Cia peb saib qhov no hauv kev nthuav dav ntxiv

Txoj kev tsheb ciav hlau yog Txhais, tswvyim, yam ntxwv thiab qhov ntev. Tsheb ciav hlau qhov ntev thiab cov yam ntxwv ntawm cov chaw khiav haujlwm

Kev mus los ntawm tsheb ciav hlau hla lub nroog thiab cov nroog, koj tuaj yeem kawm ntau yam nthuav thiab lom zem txog lub ntiaj teb ntawm txoj kev tsheb ciav hlau. Ntau tshaj ib zaug, cov neeg taug kev tau nug lawv tus kheej cov lus nug txog qhov twg qhov no lossis txoj kev tsheb ciav hlau coj mus? Thiab tus engineer uas tswj lub tsheb ciav hlau xav li cas thaum lub tsheb ciav hlau pib tawm lossis tuaj txog ntawm qhov chaw nres tsheb? Yuav ua li cas thiab los ntawm qhov twg cov tsheb hlau txav thiab txoj hauv kev ntawm cov khoom dov yog dab tsi?

Dab tsi cov khoom lag luam xav tau siab hauv tebchaws Russia? Yam khoom twg yog qhov xav tau tshaj plaws hauv Is Taws Nem?

Yog tias koj txiav txim siab qhib koj tus kheej ua lag luam, los ntawm peb tsab xov xwm koj tuaj yeem pom cov khoom twg yog qhov xav tau ntawm tib neeg. Cov lus qhia tseem ceeb rau kev qhib lub khw hauv online