2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Serial ntau lawm ntawm cov khoom siv hauv kev sib dhos ntawm cov khoom siv thiab cov khoom siv cuam tshuam nrog qhov kub thiab txias thiab nias. Raws li cov kev xav tau no, cov thev naus laus zis zoo tshaj plaws rau kev muab cov tshuab ua haujlwm raug xaiv. Piv txwv li, nyob rau hauv zus tau tej cov volumetric thiab tiaj tus nyias-walled ntsiab, kev siv ntawm daim ntawv stamping yog ib txwm muaj. Txoj kev no ua rau nws muaj peev xwm tiv nrog kev tsim khoom ntawm ntau qhov chaw hauv ib qho kev ua haujlwm nrog qhov tsawg kawg nkaus ntawm cov peev txheej ntawm tus nqi qis. Tsis tas li ntawd, kev ua haujlwm ntawm daim ntawv stamping yog qhov txiaj ntsig ntawm qhov zoo ntawm qhov kawg tshwm sim. Qhov tseeb yog tias kev tsim khoom loj ntawm cov khoom siv hlau ntawm cov khoom siv siab tsis tshua muaj qhov ua tau zoo ntawm cov khoom tsim tawm. Nyob rau hauv cov ntaub ntawv no, tshwj xeeb manufacturing tej yam kev mob kuj xyuas kom meej tias cov khoom yog endowed nrog zoo zog rau yav tom ntej siv.

Cov ntaub ntawv dav dav txog txheej txheem stamping

Kom tau txais nyias-walled axisymmetric qhov chaw, niaj hnub txoj kev shaping yog siv. Tshwj xeeb, cov txheej txheem zoo li no ua rau nws muaj peev xwm ua haujlwm nrog cov khoom tapered thiab truncated. Feem ntau, cov txheej txheem noimply siv cov cuab yeej rau yas deformation ntawm nyias-walled workpieces nyob rau hauv tshwj xeeb ib puag ncig. Piv txwv li, cov ntawv hlau stamping tuaj yeem ua tau raws li qhov ntsuas huab cua nruj. Ntawd yog, ntxiv rau kev siv tshuab ua haujlwm, cov kws tshaj lij kuj tseem muab cov txheej txheem physico-chemical uas tau txais txiaj ntsig los ntawm qhov pom ntawm molding, cuam tshuam rau cov khoom siv.

Raws li rau stamping nws tus kheej, cov txheej txheem no tso cai rau koj ua hauj lwm nrog hlau, muab ntau yam shaping ntawm cov zis raws li cov dej num ntawm qhov project. Tiag tiag daim ntawv stamping tsuas yog ntau yam kev siv tshuab ntawm cov yas deformation. Tsis zoo li cov cuab yeej siv rau kev ua cov khoom ntim, cov txheej txheem no suav nrog kev ua haujlwm nrog nyias-walled workpieces, uas kuj txiav txim siab txo nqi zog hauv cov txheej txheem ntawm kev muab cov khoom siv dag zog. Txawm li cas los xij, cov yam ntxwv ntawm txoj kev tsis xaus rau ntawd.

Txoj kev ntawm daim ntawv stamping

Vim tias txoj kev txhais tau tias yog hom kev stamping no tau lees paub koom nrog kev ua haujlwm nrog cov ntawv nyias nyias, qhov tseem ceeb ntawm kev ua haujlwm. Ntawd yog, cov neeg ua haujlwm ua haujlwm ntawm kev khoov, sib ntswg thiab clamping cov khoom, tso cai rau cov khoom tsim los ntawm cov khoom tsim tawm ntawm cov duab uas xav tau. Forging cov cuab yeej yuav tsis tiv nrog cov kev ua no - los yog, tsawg kawg, yuav ua tau xws li kev ua hauj lwm tsis zoo. Muaj lwm qhov tshwj xeeb uas daim ntawv stamping muaj nyob rau hauv cov kev xav ib txwm muaj. Tseem rov,Yog hais tias volumetric processing tsom rau lub zog, ces qhov no nws tsis yog lub ntsiab. Qhov no piav qhia ntau yam ntawm cov ntaub ntawv uas cov txheej txheem stamping ua haujlwm. Yog li, ntxiv rau cov hlau, cov tuam txhab tseem ua cov duab los qhia, ebonite, plastics, tawv, roj hmab, fiber ntau thiab blanks los ntawm lwm cov ntaub ntawv raw.

Cold sheet forming technology

Yuav luag txhua txoj kev stamping lwm txoj kev muab faib ua txoj hauv kev txias thiab kub. Nyob rau hauv cov ntaub ntawv ntawm daim ntawv stamping, nws yog tsuas yog txias ua hauj lwm. Rolled hlau yog siv los ua ib qho chaw ua haujlwm hauv daim kab xev lossis kab xev, uas tuaj yeem pib dov rau hauv yob. Tsis tas li ntawd, los ntawm cov khoom siv tshwj xeeb lossis tsis muaj nws, cov khoom nkag mus rau hauv qhov chaw ua haujlwm, qhov twg cov txheej txheem thev naus laus zis tseem ceeb tau ua tiav. Yog hais tias peb tham txog hlau, ces lub workpiece yuav raug rau cov yas deformation tseem ceeb. Ntawd yog, nws yog qhov xav tau tias cov khoom pib nws tus kheej muaj qhov zoo ntawm plasticity txaus. Ntawm qhov tso zis, txias stamping ntawm cov ntawv hlau tso cai tsim cov khoom zoo spatial thiab tiaj tus. Cov khoom tiav ntawm hom no yog siv rau hauv ntau qhov kev lag luam, suav nrog kev ntsuas thiab kev tsim hluav taws xob.

Daim Ntawv Sau Npe Ua Haujlwm

Txawm tias muaj kev ua haujlwm siab ntawm kev ua haujlwm, lub hauv paus ntawm kev ua haujlwm ntawm cov tuam txhab feem ntau yogmechanical processing los ntawm kev txiav, xuas nrig ntaus thiab xuas nrig ntaus. Tshwj xeeb, nws yog ib qho kev cais ib feem ntawm lub workpiece raws ib txoj kab nkhaus los yog ncaj. Kev txiav yog nqa tawm los ntawm ntau hom kev teeb tsa txiab. Cov txheej txheem no tso cai rau txiav cov txheej hlau kom tau txais cov strips ntawm qhov xav tau loj. Los ntawm txoj kev, yog hais tias volumetric processing ua rau nws muaj peev xwm mus ua hauj lwm nrog nyuaj thiab tuab hlau, ces daim ntawv stamping nyob rau hauv cov nqe lus ntawm mechanical txiav yog heev raug. Hauv kev xyaum, qhov no txhais tau tias tau txais cov khoom lag luam nrog cov kev ntsuas uas tsim nyog rau kev siv hauv kev sib dhos ntxiv. Tib yam siv rau kev txiav thiab xuas nrig ntaus.

Mechanism ntawm txoj kev tsim

Txoj kev tsim cov axisymmetric cov ntsiab lus feem ntau cuam tshuam nrog deformation los ntawm ntu nthuav dav punches. Nyob rau tib lub sijhawm, cov khoom tsim tom qab cov txheej txheem ntawm stamping nyob ib ncig ntawm lub voj voog yuav muaj kev txiav uas tsis tsim nyog los ntawm qhov pom ntawm kev siv cov khoom siv ntxiv. Ntawd yog, thaum ua haujlwm dabtsi yog khoov, twisting thiab compression, tseem muaj txoj haujlwm tsis suav nrog kev kho kom zoo ntxiv kom ntau li ntau tau. Hauv lwm lo lus, ib feem npaj rau kev siv zaum kawg yuav tsum tau tsim nyob rau hauv ib qho kev tsim thiab molding voj voog. Sheet hlau stamping tuag, qhov tsis sib xws ntawm cov kev xav tau ntawm kev tsim cov kev daws teeb meem, pab kom ua tiav cov khoom zoo hauv kev tsim cov khoom. Technically, lub workflow yog nqa tawm siv ib tug matrix, ib tug active punch, zawv zawg sectors thiab auxiliary khoom, los ntawm cov workpiece yog cuam tshuam.

Khoom siv siv

Feem ntau siv yog cov khoom me me, uas yog cov kab ntau yam rau kev ua cov ntawv hlau. Tab sis txawm tias tus tswv ntiav zoo tib yam tuaj yeem npaj cov kab zoo sib xws ntawm cov khoom sib xws hauv chav me. Lub workflow yuav xav tau lub stamp hais, ua los ntawm cov cuab yeej steel. Nws yog ib qho tseem ceeb uas yuav tau siv cov cuab yeej ua los ntawm cov hlau muaj zog, txwv tsis pub nws yuav tsis kav ntev. Lub hauv paus rau kev ua haujlwm yuav yog cov xovxwm, uas yuav muab cov haujlwm yooj yim ntawm kev txiav, txiav thiab sib sau. Qee zaum, txhawm rau txo tus nqi ntawm lub koom haum kev tsim khoom, qee cov khoom ntawm cov kab ntau lawm yog hloov los ntawm cov khoom siv improvised. Piv txwv li, cov ntawv hlau stamping txheej txheem kuj tuaj yeem ua tau siv lub thawv dej los hloov lub qhov punch qhov yooj yim.

yam ntxwv khoom

Txoj kev tso cai rau koj los tsim cov khoom lag luam zoo, uas tau nthuav tawm hauv qhov ntev thiab txawm tias kab geometric. Cov kws tshaj lij tau sau tseg tias tsuas yog cov cuab yeej no ua rau cov hlau tiaj tus, cov tuab ntawm cov uas xyaum tsis hloov pauv piv rau qhov khoob. Cov khoom tsim los ntawm daim ntawv stamping yog qhov txawv ntawm cov hlau nplaum thiab hluav taws xob conductivity. Qhov no txhais tau hais tias cov khoom tuaj yeem siv rau hauv kev lag luam hluav taws xob, ua haujlwm ntawm cov khoom siv tam sim no. Nyob ntawm cov khoom siv, cov tuam ntxhab tuaj yeem muab cov khoom kawg nrog lub zog siab,Qhov zoo tshaj plaws viscosity thiab kub tsis kam.

Txoj kev txiaj ntsig

Ntxiv rau qhov kev ua tau zoo thiab kev ua haujlwm zoo ntawm cov khoom tsim los ntawm cov txheej txheem no, nws raug nquahu kom siv txoj hauv kev no los ua cov ntaub ntawv rau kev lag luam. Qhov tseeb yog tias ntau yam khoom siv uas tuaj yeem raug ua raws li qhov kev txiav txim siab ntau yam ntawm txoj kev. Txawm hais tias muaj kev txwv pom tseeb ntawm kev siv cov khoom thiab cov khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob Nyob rau tib lub sij hawm, stamping ntawm cov ntawv hlau qhov chaw yog ib txwm siv ntawm machining uas tsis xav tau kev nqis peev siab. Nws tsis yog qhov nyuaj rau kev teeb tsa lub cim muaj zog thiab tsim tau yog tias koj muaj kev txawj ntse hauv kev lag luam hlau.

Zaj lus

Thaum ntsuas qhov ua tau zoo ntawm ib lossis lwm txoj hauv kev ntawm kev ua hlau, cov ntsuas kev ua tau zoo ntawm cov khoom tau txais tsawg dua thiab tsawg dua nyob rau pem hauv ntej. Qhov no yog vim plasma, waterjet thiab laser tshuab tau zoo tshem tawm tag nrho cov teeb meem kom ua tiav kev txiav siab. Thiab nws yog tseeb hais tias nyob rau hauv cov nqe lus ntawm zoo ntawm lawv cov khoom, lawv yog noticeably inferior rau ib tug pa metalworking tshuab. Txawm li cas los xij, cov ntawv hlau stamping ntawm qhov chaw txo qis qhov sib txawv, tso cai rau koj khaws qhov zoo ntawm cov khoom siv ib txwm muaj. Cov txiaj ntsig zoo no feem ntau yog qhov tseem ceeb rau kev lag luam, txij li lawv tau nthuav tawm ob qho tib si hauv kev txo nqi nyiaj txiag ntawm kev ua haujlwm thiab ua kom yooj yim rau kev lag luam.ntau lawm lub koom haum txheej txheem. Suffice nws hais tias stamping, tsis zoo li abrasive txiav, tsis xav tau cov khoom ntawm consumables nyob rau hauv daim ntawv ntawm cov xuab zeb thiab dej.

Pom zoo:

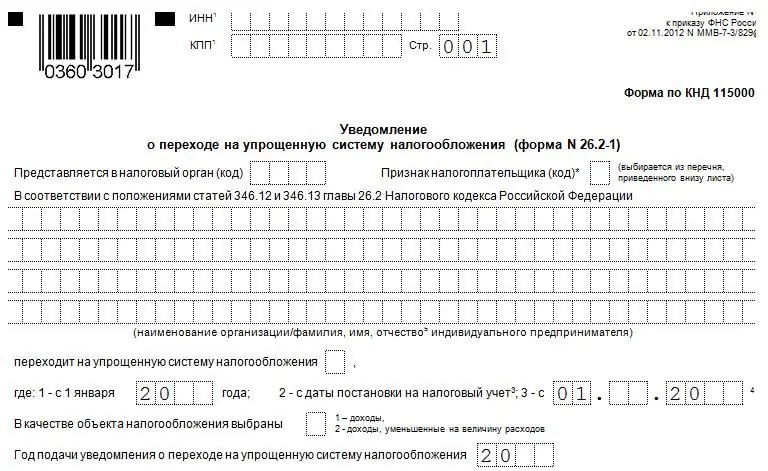

Siv cov txheej txheem se yooj yim: cov yam ntxwv ntawm cov txheej txheem, daim ntawv thov txheej txheem

Kab lus no tshawb txog cov yam ntxwv ntawm kev sau se nrov tshaj plaws - yooj yim. Qhov zoo thiab qhov tsis zoo ntawm qhov system, cov xwm txheej ntawm daim ntawv thov, kev hloov pauv thiab kev tshem tawm tau nthuav tawm. Cov nqi sib txawv raug txiav txim siab rau cov khoom sib txawv ntawm kev them se

Kev tshuaj xyuas cov txheej txheem: kev faib tawm, cov txheej txheem thiab cov txheej txheem, qhov dav

Hnub no, ntawm cov cuab yeej tshuaj ntsuam xyuas kev lag luam, kev sau zoo heev ntawm cov txheej txheem thiab cov txheej txheem ntawm kev txheeb xyuas nyiaj txiag tau sau tseg. Lawv txawv hauv cov hom phiaj, kev xaiv ua pab pawg, xwm txheej lej, sijhawm, thiab lwm yam. Xav txog cov txheej txheem ntawm kev txheeb xyuas nyiaj txiag hauv kab lus

Vuam hauv qhov chaw tiv thaiv roj: ua haujlwm thev naus laus zis, txheej txheem piav qhia, cov txheej txheem ua tiav, cov khoom tsim nyog thiab cov cuab yeej, cov lus qhia ua haujlwm ib ntus thiab cov lus qhia kws tshaj lij

Vuam thev naus laus zis yog siv hauv ntau ceg ntawm tib neeg kev ua haujlwm. Versatility tau ua vuam nyob rau hauv ib puag ncig tiv thaiv roj ib qho tseem ceeb ntawm kev tsim khoom. Qhov ntau yam no ua rau nws yooj yim los txuas cov hlau nrog lub thickness ntawm 1 hli mus rau ob peb centimeters nyob rau hauv txhua txoj hauj lwm nyob rau hauv qhov chaw. Vuam nyob rau hauv ib puag ncig tiv thaiv yog maj mam hloov cov tsoos electrode vuam

Kuv puas xav tau daim ntawv teev nyiaj ntsuab rau cov neeg ua lag luam nrog cov txheej txheem se yooj yim? Yuav ua li cas rau npe thiab siv daim ntawv sau nyiaj ntsuab rau cov neeg ua lag luam nyob rau hauv cov txheej txheem se yooj yim?

Kab lus piav qhia txog cov kev xaiv rau kev ua cov nyiaj tsis muaj kev koom nrog cov ntawv sau nyiaj ntsuab (CCT)

Kev kho dua tshiab ntawm qhov chaw los ntawm vuam thiab ntog: cov txheej txheem thiab cov txheej txheem ntawm kev kho dua tshiab, nta, txheej txheem thev naus laus zis

Vuam thiab surfacing thev naus laus zis ua rau nws ua tau zoo los kho cov hlau seem, muab cov qib siab ntawm kev ntseeg siab thiab ua haujlwm ntev ntawm cov khoom. Qhov no tau lees paub los ntawm kev xyaum siv cov txheej txheem no thaum ua haujlwm kho hauv ntau qhov chaw - los ntawm kev kho tsheb mus rau kev tsim cov hlau dov. Hauv tag nrho cov nyiaj ua haujlwm ntawm kev kho cov qauv hlau, kev kho dua tshiab ntawm qhov chaw los ntawm kev vuam thiab surfacing yuav siv li 60-70%