2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Hauv kev tsim kho thiab kev lag luam, muaj kev hloov pauv ntawm cov ntaub ntawv hlau mus rau cov yas muaj zog thiab cov khoom siv niaj hnub. Qhov no yog vim qhov tseeb tias cov khoom siv hluavtaws yog ze rau cov yam ntxwv ntawm cov hlau alloys, tab sis tib lub sijhawm lawv tsis muaj qhov tsis zoo ntawm cov hlau, ib qho yog corrosion. Nyob rau tib lub sijhawm, kev tsis lees paub tag nrho ntawm cov khoom siv ib txwm nyob deb ntawm qhov ua tau nyob rau hauv txhua qhov kev lag luam, yog li ntawd, txoj kev tshem tawm cov txheej txheem xeb tseem cuam tshuam. Ib txoj hauv kev nrov tshaj plaws ntawm hom no yog kub-dip galvanizing, uas tsim cov txheej txheem ruaj khov thiab txhim khu kev qha ntawm cov khoom.

Zinc tiv thaiv txoj cai

Tom qab dhau los ntawm cov txheej txheem kev npaj, cov khoom lossis cov qauv siv nrog zinc molten. Qhov no feem ntau yog ua los ntawm dipping lub workpiece mus rau hauv cov kua loj nyob rau hauv xws li ib txoj kev uas tag nrho cov pores ntawm cov hlau qauv yog sau. Muaj qee qhov nuances uas yuav tsum tau coj mus rau hauv tus account ua ntej kub-dip galvanizing. Cov thev naus laus zis xav tias qhov siab anodization ntawm zinc nyob rau hauv kev sib raug zoo rau lub hauv paus hlau yuav ua rau muaj kev ywj pheej nkag mus rau zinc rau hauv cov qauv ntawm cov khoom uas twb muaj lawm nyob rau hauv cov txheej txheem.kev ua haujlwm ntawm cov khoom. Kev sau tus nqi ntawm qhov chaw tsis pom qhov nruab nrab yog 2 hli ib xyoos.

Txawm li cas los xij, qhov chaw nrog cov xov thiab cov txiv ntoo tuaj yeem dhau los ua qhov chaw ntawm corrosion. Koj tuaj yeem tiv thaiv cov txheej txheem zoo li no los ntawm kev siv cov khoom siv thawj zaug nrog kev tiv thaiv xeb. Qhov no yog qhov tseem ceeb tshwj xeeb uas yuav tsum tau coj mus rau hauv tus account yog tias kub-dip galvanizing ntawm cov qauv hlau tau ua tiav, cov bolts uas nqa lub zog siab.

Npaj rau kev phais

Nyob rau theem kev npaj, lub luag haujlwm tseem ceeb yog los ntxuav qhov chaw ntawm cov khoom thiab xyuas kom muaj kev sib haum xeeb hauv cov tshuaj tiv thaiv zinc thiab hlau thaum muab tso rau hauv lub thawv nrog cov khoom hnyav. Qhov no tau ua tiav los ntawm ntau cov kauj ruam thev naus laus zis, suav nrog degreasing thiab ntxuav. Kev ua haujlwm ntxiv ntawm etching thiab fluxing yuav ua raws. Degreasing raug txo kom tshem tawm cov khoom ntawm cov av thiab cov roj - qhov no yuav cuam tshuam rau kev nkag mus ntawm zinc rau hauv cov qauv hlau.

Raws li txoj cai, qhov haujlwm no yog ua los ntawm kev degreasing reagents thiaj li tau txais cov khoom kub-dip galvanizing yav tom ntej. Lub tshuab nqus dej yog siv tom qab degreasing. Nyob rau theem no, nws yog ib qho tseem ceeb kom tshem tawm tag nrho cov tshaj uas tau siv los tshem tawm cov kab ntawm cov roj. Tshwj xeeb, ua npuas ncauj raug tshem tawm los ntawm kev daws teeb meem thiab cov tshuaj reagents uas yaj chemistry.

Cov txheej txheem no kuj tuaj yeem raug ntaus nqi rau theem ntawm kev ntxuav cov hlau nto. Tab sis yog nyob rau hauvNyob rau hauv cov ntaub ntawv dhau los, cov khoom tau tshem tawm ntawm cov av thiab cov roj, tab sis lub sij hawm no koj yuav tsum tau nrog cov nplai tsim thaum kho cua sov. Nyob rau hauv cov txheej txheem etching, hydrochloric acid yog siv, tshuaj lom neeg kev ua ntawm uas ua rau nws muaj peev xwm mus tsis tau tsuas yog ib tug huv si, tab sis kuj ib tug ci iab nto. Yuav luag txhua qhov kub dip galvanizing cov nroj tsuag tsim nws tus kheej cov zaub mov txawv rau kev tawm suab, uas nyob rau hauv sib txawv proportions yuav suav nrog cov inhibitors kom tshem tawm hydroxyl thiab oxides. Kev ua raws li qhov tseeb proportions yog tsim nyog rau vim li cas, ntxiv rau qhov ntsuas, cov kev daws teeb meem no kuj cuam tshuam rau cov qauv ntawm lub hauv paus. Yog li ntawd, cov kws tshaj lij thev naus laus zis siv zog los txwv cov txiaj ntsig ntawm chemistry ntau dhau ntawm cov hlau, tiv thaiv kev pheej hmoo ntawm hydrogen saturation.

Muaj ntau txoj haujlwm koom nrog hauv cov txheej txheem fluxing. Lub ntsiab yog ua tiav ntawm kev npaj cov hlau nto rau cov txheej txheem galvanizing tseem ceeb. Tshwj xeeb, muaj kev sib cais ntawm oxides, uas tuaj yeem rov tsim dua thaum ntxuav. Tsis tas li ntawd, fluxing muab cov ntaub ntawv tiv thaiv los ntawm cov yeeb yaj kiab passivated. Cov txheej no nyob rau hauv qee txoj kev pib tsim lub hauv paus tiv thaiv, uas yav tom ntej yuav txuas ntxiv kub-dip galvanizing ntawm cov hlau, thiab tshwj xeeb tshaj yog nws cov qauv sab hauv. Tab sis yog tias zinc tiv thaiv cov khoom los ntawm kev cuam tshuam sab nraud thaum nws siv, tom qab ntawd cov txheej txheem passivated tiv thaiv oxidation thaum lub sij hawm galvanizing, thiab tib lub sij hawm ua rau kom lub wettability ntawm molten mass.

Stagezinc plated

Nyob rau theem no, cov khoom yog muab tso rau hauv ib da dej uas muaj zinc molten. Cov txheej txheem uas tau ua nyob rau theem no yuav sawv cev los ntawm kev puas tsuaj ntawm cov flux thiab kev cuam tshuam ntawm cov qauv ntawm ob lub hlau. Lub sijhawm ntawm kev dhia dej yog nyob ntawm qhov loj ntawm cov qauv. Qhov no feem ntau yuav siv li 5 mus rau 10 feeb. Nws yog qhov tseem ceeb tshaj plaws los txiav txim siab qhov zoo tshaj plaws ntawm immersion thiab extraction ntawm lub workpiece. Piv txwv li, kub dip galvanizing ntawm tus nqi qeeb qeeb yuav pab dawb cov hlau los ntawm pre-passivated txheej.

Ntawm qhov tod tes, kev kub ceev ua rau kev ntes cov ntsev seem ntawm qhov chaw, uas inevitably txo qhov zoo ntawm qhov tshwm sim. Qhov zoo tshaj plaws ceev yog xaiv raws li qhov loj ntawm cov khoom, lub sijhawm ntawm kev dhia dej thiab cov yam ntxwv ntawm qhov chaw.

Kub dip galvanizing zoo tswj

Yeej, qhov ua tau zoo ntawm cov khoom lag luam raug txiav txim los ntawm ob tus yam ntxwv: lub zog thiab txheej tuab. Txhawm rau ntsuas cov kev txwv no, cov kws tshaj lij ua qhov kev soj ntsuam ntawm cov pob qij txha thiab cov welded sib dhos, uas yog suav tias yog qhov chaw tsis muaj zog tshaj plaws los ntawm kev pom. Raws li kev txheeb xyuas qhov tuab, ntawm no ib qho yuav tsum tso siab rau cov kev cai uas GOST imposes. Kub-dip galvanizing raws li cov qauv yuav tsum tau ua nyob rau hauv xws li ib txoj kev uas lub thickness nyob rau hauv tej thaj chaw deb ntawm lub knurling, ces kaum thiab threads los ntawm 5 hli sib haum mus rau lub tsim sawv daws yuav. Cov txiaj ntsig tshwj xeeb ntawm cov txheej txheem tsis raug txiav txim siab raws li qhov yuav tsum tau ua rau cov khoom tshwj xeeb, tab sis cov txheej txheemkev kuaj xyuas yuav tsum tau ua tiav ntawm qhov chaw dawb.

Tus nqi kub dip galvanizing ntau npaum li cas?

Ntawm qhov nruab nrab, tus nqi ntawm kub-dip galvanizing yog 30-35 txhiab rubles. ib 1 tuj tib lub sijhawm, kuj tseem muaj qhov sib txawv ntawm txoj kev hauv tsev no thaum nws los txog rau kev txiav txim tsis raug cai. Muaj feem xyuam rau tus nqi tag thiab qhov xwm txheej ntawm cov khoom. Feem ntau, cov tuam txhab muab kev pabcuam tag nrho, uas suav nrog ntau theem kub-dip galvanizing. Tus nqi ntawm lub voj voog tag nrho, uas yuav suav nrog kev npaj ua haujlwm, tuaj yeem ncav cuag 50 txhiab. Rau qhov nyiaj no, raws li txoj cai, nws tau thov kom siv cov khoom siv zoo, ziab cov khoom ua tiav hauv cov chav tshwj xeeb thiab paub meej tias qhov ua haujlwm zoo. ua tiav nrog cov ntaub ntawv kws tshaj lij.

Qhov zoo thiab qhov tsis zoo ntawm txoj kev

Rau cov lag luam loj uas ua haujlwm nrog cov khoom loj ntawm cov hlau dov, txoj kev tiv thaiv corrosion yog qhov zoo tshaj plaws rau kev lag luam. Tsis tas li ntawd, thev naus laus zis muab kev ruaj ntseg thaiv kev tiv thaiv corrosion thiab tib lub sijhawm tsis txo cov thermal thiab hluav taws xob conductivity ntawm cov khoom. Raws li qhov tsis zoo, kub-dip galvanizing ntawm cov qauv hlau yuav tsum muaj kev noj ntau ntawm cov khoom siv rau cov khoom siv loj thiab ua tib zoo koom tes ntawm cov txheej txheem tag nrho. Qhov tsis zoo ntawm qhov kub-dip galvanizing suav nrog cov kev txwv ntawm nws txoj kev siv nyob rau hauv kev sib raug zoo rau qhov me me - qhov no tsuas yog siv tsis tau rau cov txheej nyias nyias.

Zaj lus

Hlau tiv thaiv tshuabzinc plating tau siv rau ob peb xyoos, thiab rau hnub no tsis muaj lwm txoj hauv kev tsim nyog rau nws. Qhov nthuav dav ntawm txoj kev yog vim lub fact tias kub galvanizing zoo copes nrog lub luag hauj lwm tseem ceeb - tiv thaiv cov tsim ntawm xeb. Txoj kev txhim khu kev qha no tau ua pov thawj nws tus kheej hauv kev lag luam thiab hauv kev tsim kho.

Qhov twg nws yog qhov teeb meem ntawm kev ua tiav lub zog thiab ua haujlwm ntawm cov qauv hlau uas tuaj rau hauv ntej, zinc txheej kuj them tawm.

Pom zoo:

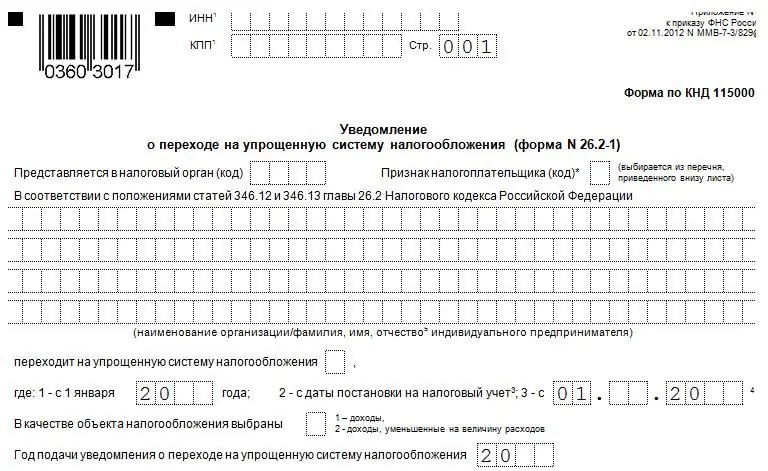

Siv cov txheej txheem se yooj yim: cov yam ntxwv ntawm cov txheej txheem, daim ntawv thov txheej txheem

Kab lus no tshawb txog cov yam ntxwv ntawm kev sau se nrov tshaj plaws - yooj yim. Qhov zoo thiab qhov tsis zoo ntawm qhov system, cov xwm txheej ntawm daim ntawv thov, kev hloov pauv thiab kev tshem tawm tau nthuav tawm. Cov nqi sib txawv raug txiav txim siab rau cov khoom sib txawv ntawm kev them se

Kev tshuaj xyuas cov txheej txheem: kev faib tawm, cov txheej txheem thiab cov txheej txheem, qhov dav

Hnub no, ntawm cov cuab yeej tshuaj ntsuam xyuas kev lag luam, kev sau zoo heev ntawm cov txheej txheem thiab cov txheej txheem ntawm kev txheeb xyuas nyiaj txiag tau sau tseg. Lawv txawv hauv cov hom phiaj, kev xaiv ua pab pawg, xwm txheej lej, sijhawm, thiab lwm yam. Xav txog cov txheej txheem ntawm kev txheeb xyuas nyiaj txiag hauv kab lus

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

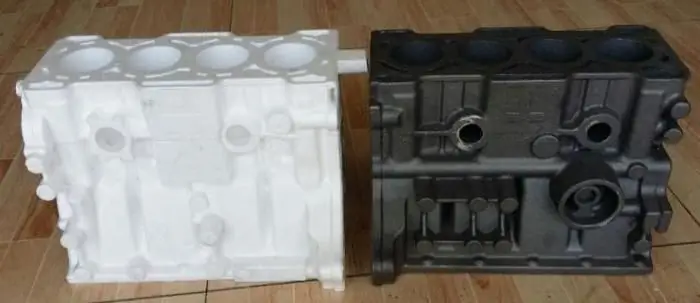

Hlau casting: txheej txheem, txheej txheem, txheej txheem

Hlau yog lub hauv paus ntawm txhua qhov kev vam meej niaj hnub no. Hauv ib xyoos, tib neeg niaj hnub mines thiab cov txheej txheem xws li cov hlau ib leeg ua ntej tag nrho lub ntiaj teb yuav tau khawb nws tsawg kawg ob peb centuries

Kev kho dua tshiab ntawm qhov chaw los ntawm vuam thiab ntog: cov txheej txheem thiab cov txheej txheem ntawm kev kho dua tshiab, nta, txheej txheem thev naus laus zis

Vuam thiab surfacing thev naus laus zis ua rau nws ua tau zoo los kho cov hlau seem, muab cov qib siab ntawm kev ntseeg siab thiab ua haujlwm ntev ntawm cov khoom. Qhov no tau lees paub los ntawm kev xyaum siv cov txheej txheem no thaum ua haujlwm kho hauv ntau qhov chaw - los ntawm kev kho tsheb mus rau kev tsim cov hlau dov. Hauv tag nrho cov nyiaj ua haujlwm ntawm kev kho cov qauv hlau, kev kho dua tshiab ntawm qhov chaw los ntawm kev vuam thiab surfacing yuav siv li 60-70%