2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

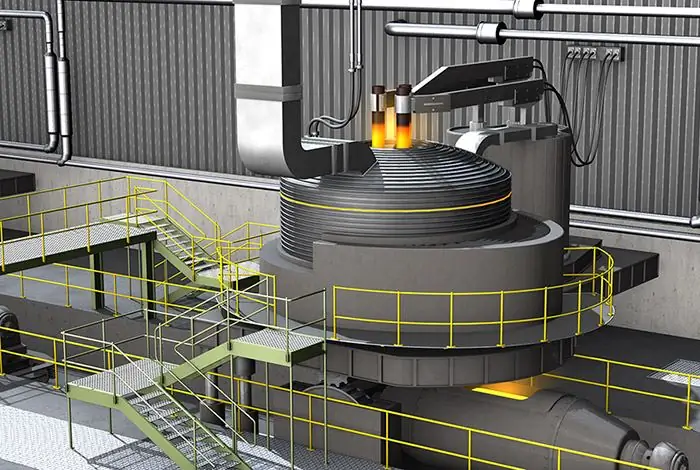

A steel arc rauv (EAF) yog cov khoom siv uas ua kom sov cov khoom siv hluav taws xob khoov.

Cov khoom siv hauv kev lag luam muaj ntau qhov loj los ntawm cov chav me me, kwv yees li ib tuj ntawm lub zog (siv hauv cov chaw tsim khoom los ua cov khoom siv hlau) txog 400 units ib tuj, siv rau cov khoom siv hlau. Arc steel furnaces, EAF, siv nyob rau hauv kev tshawb fawb soj ntsuam tej zaum yuav muaj peev xwm tsuas yog ob peb kaum grams. Qhov kub ntawm cov khoom siv hauv kev lag luam tuaj yeem ncav cuag 1800 ° C (3272 ° F), thaum lub chaw soj nstuam tshaj 3000 ° C (5432 ° F).

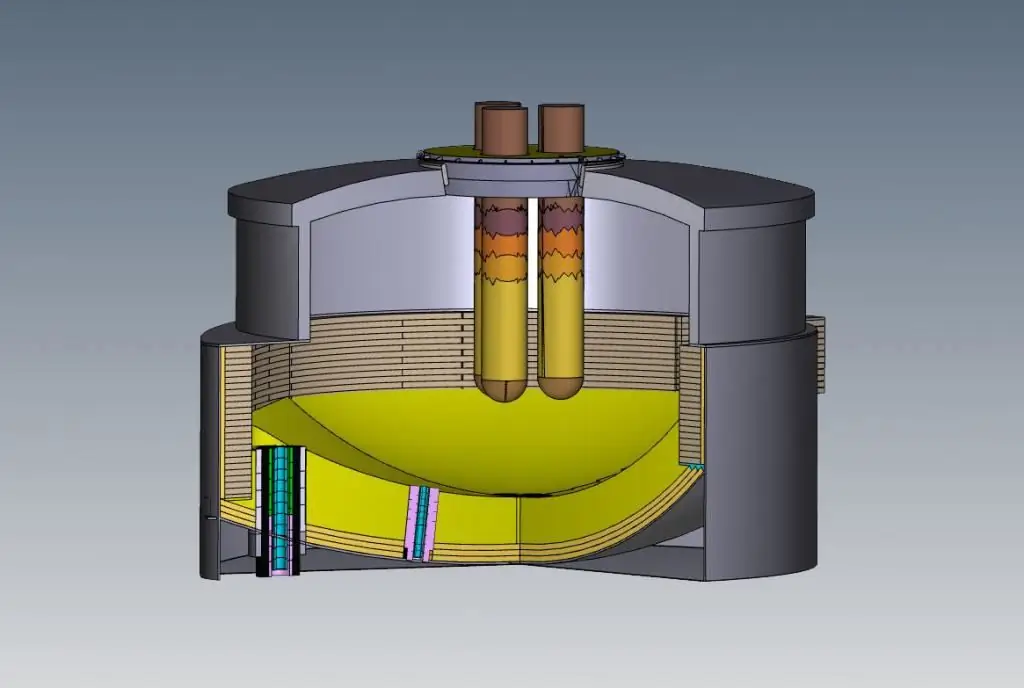

Arc steel furnaces (EAFs) txawv ntawm qhov cub induction nyob rau hauv uas cov khoom raug thauj khoom yog ncaj qha mus rau hluav taws xob dabtsi yog khoov, thiab tam sim no ntawm cov terminals dhau los ntawm cov khoom siv.

Arc steel rauv yog siv rau kev tsim steel thiab yog tsim los ntawm cov hlab ntsha refractory. Feem ntau muab faib ua peb ntu:

- Shell, uas muaj cov phab ntsa sab thiab hauv qab steeltais.

- Pallet uas yog ua los ntawm cov khoom siv refractory.

- Rov. Nws tuaj yeem ua tau nrog cov ntaub ntawv kub-resistant los yog dej-txias. Thiab nws kuj yog ua nyob rau hauv daim ntawv ntawm ib lub pob los yog ib tug truncated cone (conical seem). Lub ru tsev kuj txhawb nqa lub refractory delta ntawm nws qhov chaw los ntawm qhov twg ib lossis ntau dua graphite electrodes nkag.

khoom tus kheej

Lub hearth yuav muaj cov duab hemispherical thiab xav tau nyob rau hauv lub qhov cub eccentric rau kais hauv qab. Hauv kev cob qhia niaj hnub no, lub tshuab hluav taws xob arc hlau - EAF 5 - feem ntau nce siab tshaj hauv pem teb kom cov ladles thiab slag pots tau yooj yim maneuvered nyob rau hauv qhov kawg. Kev sib cais los ntawm cov qauv yog cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob, nrog rau lub platform inclined ntawm qhov ntsuas ntsuas.

Unique tool

Ib yam EAF 3 steel-smelting arc rauv yog siv los ntawm peb theem thiab yog li muaj peb lub electrodes. Lawv muaj ib puag ncig thiab, raws li txoj cai, ntu nrog cov xov sib txuas, yog li thaum lawv hnav, cov ntsiab lus tshiab tuaj yeem ntxiv.

Lub arc yog tsim los ntawm cov khoom siv thiab cov electrode. Tus nqi yog rhuab ob qho tib si los ntawm tam sim no dhau los ntawm nws thiab los ntawm lub zog hluav taws xob tso tawm los ntawm yoj. Qhov kub nce mus txog 3000 ° C (5000 ° F), ua rau cov ntu qis ntawm cov hluav taws xob ua kom ci zoo li cov teeb ci incandescent thaum lub qhov cub arc ua haujlwm.

Cov ntsiab lus tau txais kev tsa thiab txo qis los ntawm qhov chaw ua haujlwm uas tuaj yeem siv hluav taws xobwinch, hoists lossis hydraulic thooj voos kheej kheej. Txoj cai tswj xyuas qhov kwv yees li qhov tam sim no. Lub zog siv hluav taws xob ntawm lub qhov cub arc yog dab tsi? Nws khaws cia tas li thaum lub sij hawm them nyiaj melting, txawm tias cov seem yuav txav mus rau hauv cov electrodes thaum nws melts. Lub tes tsho mast tuav lub caij tuaj yeem nqa cov busbars hnyav (uas tuaj yeem ua dej txias hollow tooj liab xaim tam sim no rau cov clamps) lossis "lub tes tsho kub" qhov twg tag nrho sab saum toj nqa tus nqi, nce efficiency.

hom tom kawg tuaj yeem ua los ntawm tooj liab plated steel lossis aluminium. Cov cables loj dej txias txuas rau busbars lossis brackets rau lub transformer nyob ib sab ntawm qhov cub. Ib qho cuab yeej zoo sib xws tau nruab rau hauv qhov chaw cia thiab txias nrog dej.

Tapping thiab lwm yam haujlwm

Lub EAF 50 steel arc rauv yog ua rau ntawm lub platform inclined kom cov kua hlau tuaj yeem nchuav rau hauv lwm lub thawv rau kev thauj mus los. Kev ua haujlwm tilting kom hloov cov hlau molten yog hu ua tapping. Thaum pib, tag nrho cov hlau ua vaults ntawm lub arc rauv muaj ib tug paug chute them nrog refractory, uas tau ntxuav tawm thaum nws yog tilted.

Tab sis feem ntau cov cuab yeej siv niaj hnub no muaj lub qhov hluav taws xob hauv qab qhov hluav taws xob (EBT) kom txo tau cov kev sib xyaw ntawm nitrogen thiab slag rau hauv cov kua hlau. Cov qhov cub no muaj qhov qhib uas khiav vertically los ntawm lub hearth thiab lub plhaub thiab yog off-center nyob rau hauv ib tug nqaim qe-zoo li "spout". Nws puvrefractory xuab zeb.

Cov nroj tsuag niaj hnub tuaj yeem muaj ob lub plhaub nrog ib txheej ntawm electrodes uas tau dhau los ntawm lawv. Thawj ntu heats cov seem, thaum lwm qhov yog siv rau melting. Lwm cov DC furnaces muaj qhov zoo sib xws tab sis muaj cov khoom siv hluav taws xob rau txhua lub plhaub thiab ib txheej hluav taws xob.

Oxygen element

AC furnaces feem ntau muaj cov qauv kub thiab txias me ntsis raws li ib puag ncig ntawm lub siab, nyob nruab nrab ntawm cov electrodes. Nyob rau hauv niaj hnub sawv daws yuav, oxy-roj burners yog ntsia rau sab phab ntsa. Lawv tau siv los muab tshuaj lom neeg lub zog rau cov cheeb tsam rho tawm, uas ua rau cov cua sov ntawm cov hlau tsis sib xws. Lub zog ntxiv yog muab los ntawm kev muab cov pa oxygen thiab carbon rau lub qhov cub. Keeb kwm qhov no tau ua tiav nrog hmuv (me me steel hollow raj) nyob rau hauv lub qhov rooj slag, tam sim no nws yog feem ntau ua nrog cov phab ntsa mounted txhaj tshuaj uas muab oxy-roj burners thiab cua muab tshuab rau hauv ib lub nkoj.

Ib lub tshuab hluav taws xob nruab nrab niaj hnub no muaj qhov ntsuas ntsuas ntawm 60,000,000 volt-amps (60 MVA), nrog rau qhov nruab nrab ntawm 400 txog 900 thiab tam sim no tshaj li ntawm 44,000. Hauv lub khw niaj hnub, xws li Lub tshuab hluav taws xob xav kom tsim tau 80 metric tons ntawm cov kua hlau hauv li 50 feeb los ntawm cov khoom txias txias rau tapping.

Hauv kev sib piv, cov pa oxygen yooj yim tuaj yeem muaj peev xwm ntawm 150-300 tons ib pob lossis "kub" thiab ua kom sov li 30-40 feeb. Muaj qhov sib txawv loj hauv cov ntsiab lus ntawm qhov cub tsim thiab kev ua haujlwm,nyob ntawm cov khoom kawg thiab cov xwm txheej hauv zos, nrog rau kev tshawb fawb txuas ntxiv txhawm rau txhim kho kev cog qoob loo.

Qhov loj tshaj plaws seem-tsuas yog (raws li qhov ntsuas qhov hnyav thiab qhov ntsuas ntsuas) yog DC cov khoom xa tawm los ntawm Nyij Pooj nrog qhov hnyav ntawm 420 metric tons thiab pub los ntawm yim 32 MVA transformers rau tag nrho lub zog ntawm 256 MBA.

Nws yuav siv sijhawm li 400 kilowatt-teev los tsim ib tuj ntawm cov hlau hauv lub cub hluav taws xob hluav taws xob, lossis txog 440 kWh ib metric. Lub zog theoretical yam tsawg kawg nkaus uas yuav tsum tau yaj cov hlau yog 300 kWh (melting point 1520 ° C / 2768 ° F). Yog li ntawd, 300-tuj EAF nrog lub zog ntawm 300 MVA yuav xav tau txog 132 MWh ntawm lub zog, thiab lub sijhawm tig yog kwv yees li 37 feeb.

Steel ntau lawm siv hluav taws xob arc tsuas yog siv tau yog tias muaj hluav taws xob txaus nrog lub network tsim tau zoo. Hauv ntau qhov chaw mills ua haujlwm thaum lub sijhawm ua haujlwm siab tshaj thaum cov khoom siv hluav taws xob muaj peev xwm ntau lawm thiab tus nqi ib 'meter' qis dua.

Kev ua haujlwm

Lub arc steel rauv nchuav hlau rau hauv lub tshuab me me. Cov hlau nplaum yog xa mus rau qhov chaw so nyob ib sab ntawm lub smelter. Cov khib nyiab tuaj yeem muaj ob hom loj: cov khoom siv dawb (cov khoom dawb, tsheb thiab lwm yam khoom ua los ntawm cov khoom zoo sib xws.lub teeb steel) thiab hnyav yaj (slabs loj thiab kab teeb), nrog rau qee qhov ncaj qha txo hlau (DRI) lossis npua hlau rau cov tshuaj sib npaug. Cov cub tawg sib cais yuav luag 100% DRI.

Next step

Cov khoom seem tau ntim rau hauv cov thoob loj, hu ua pob tawb, nrog lub qhov rooj clamshell rau hauv paus. Kev saib xyuas yuav tsum tau ua kom ntseeg tau tias cov khoom seem nyob hauv lub pob tawb kom ntseeg tau tias lub tshuab ua haujlwm zoo. Lub zog yaj yog pw rau saum nrog lub teeb txheej ntawm kev tiv thaiv shred, nyob rau sab saum toj ntawm lwm qhov lus dag. Tag nrho cov ntawm lawv yuav tsum muaj nyob rau hauv qhov cub tom qab loading. Lub sijhawm no, lub pob tawb tuaj yeem txav mus rau hauv cov khoom seem preheater, uas siv cov kub, cov pa tawm ntawm cov smelter kom rov qab muaj zog, txhim kho kev ua haujlwm.

Nkauj

Tom qab ntawd lub nkoj raug coj mus rau lub khw muag tshuaj, lub ru tsev ntawm lub qhov cub qhib thiab cov khoom ntim rau hauv nws. Kev hloov pauv yog ib qho kev ua haujlwm txaus ntshai tshaj plaws rau cov neeg ua haujlwm. Ntau lub zog muaj peev xwm raug tso tawm los ntawm tons ntawm cov hlau poob. Txhua yam khoom ua kua hauv lub cub tawg feem ntau raug thawb thiab tawm los ntawm cov khoom seem thiab roj. Plua plav ntawm hlau ignites yog lub qhov cub kub, ua rau ib tug fireball.

Nyob hauv qee cov khoom siv ob lub plhaub, cov khoom seem yog thauj mus rau qhov thib ob thaum thawj lub melting, thiab yog preheated los ntawm cov pa tso pa tawm ntawm lub active feem. Lwm yam kev khiav hauj lwm yog: nruam loading thiab ua hauj lwm nrog kub ntawm ib tug conveyor siv, uas ces unloads cov hlau mus rau hauv lub cub tawg nws tus kheej. Lwm yam khoom siv tuaj yeem khau rajCov khoom kub los ntawm lwm cov haujlwm.

Voltage

Tom qab them nyiaj, lub ru tsev leans rov qab rau lub qhov cub thiab pib yaj. Cov electrodes raug txo qis mus rau cov khoom seem, ib qho arc yog tsim, thiab tom qab ntawd lawv tau teeb tsa kom lawv kis tau rau hauv cov txheej txheej ntawm cov khoom siv sab saum toj. Tsawg voltages raug xaiv rau txoj haujlwm no los tiv thaiv lub ru tsev thiab phab ntsa los ntawm kev kub ntxhov thiab arc puas.

Thaum cov electrodes tau mus txog qhov hnyav ntawm lub hauv paus ntawm lub cub tawg thiab cov nthwv dej tau tiv thaiv los ntawm crowbar, qhov hluav taws xob tuaj yeem nce ntxiv thiab cov electrodes tsa me ntsis, lengthening thiab nce lub zog rau yaj. Qhov no tso cai rau lub pas dej molten kom tsim tau sai dua, txo lub sijhawm kais tawm.

Oxygen yog cua tshuab rau hauv cov hlau, hlawv lossis txiav hlau, thiab cov khoom siv hluav taws xob ntxiv yog muab los ntawm phab ntsa burners. Ob txoj kev ua kom lub cev yaj ntawm cov khoom. Supersonic nozzles tso cai rau cov dav hlau oxygen nkag mus rau hauv cov slag foaming thiab ncav cuag cov dej da dej.

Oxidation ntawm impurities

Ib feem tseem ceeb ntawm kev tsim steel yog tsim cov slag uas ntab saum npoo ntawm cov hlau molten. Nws feem ntau yog tsim los ntawm cov hlau oxides thiab tseem ua qhov chaw khaws oxidized impurities, ua ib daim pam thermal (tso tseg kub ntau dhau) thiab tseem yuav pab txo qis kev yaig ntawm cov ntaub ntawv refractory.

Rau lub cub tawg nrog cov refractories yooj yim tsim cov pa roj carbon steel, cov slag qub yog calcium oxide (CaO nyob rau hauv daim ntawv ntawm calcinedtxiv qaub) thiab magnesium (MgO nyob rau hauv daim ntawv ntawm dolomite thiab magnesite.). Cov khoom no yog loaded nrog seem los yog tshuab mus rau hauv lub cub tawg thaum meltdown.

Lwm yam tseem ceeb yog hlau oxide, tsim thaum hlau hlawv nrog oxygen nkag. Tom qab ntawd, thaum rhuab, carbon (nyob rau hauv daim ntawv ntawm thee) yog txhaj rau hauv txheej no, reacting nrog hlau oxide los ua hlau thiab carbon monoxide. Qhov no ua rau foaming ntawm slag, uas ua rau thermal efficiency ntau dua. Cov txheej tiv thaiv kev puas tsuaj rau lub ru tsev thiab sab phab ntsa ntawm qhov cub los ntawm tshav kub.

Combustion ntawm impurities

Thaum cov khoom seem yaj tag thiab lub pas dej tiaj tus mus txog, lwm lub thoob tuaj yeem thauj mus rau hauv qhov cub. Tom qab tus nqi thib ob yog melted tag, refining hauj lwm yog nqa tawm los xyuas thiab kho cov tshuaj muaj pes tsawg leeg ntawm cov hlau thiab superheat lub yaj saum toj no nws freezing point nyob rau hauv kev npaj rau tapping. Ntau cov slag qub tau qhia thiab ntau cov pa nkag mus rau hauv da dej, hlawv cov impurities xws li silicon, sulfur, phosphorus, aluminium, manganese thiab calcium, thiab tshem tawm lawv cov oxides rau hauv slag.

Kev tshem tawm cov pa roj carbon monoxide tshwm sim tom qab cov khoom no hlawv ua ntej, vim tias lawv zoo ib yam li oxygen. Cov hlau uas muaj qis dua li cov hlau, xws li npib tsib xee thiab tooj liab, tsis tuaj yeem raug tshem tawm los ntawm oxidation thiab tsuas yog yuav tsum tau tswj los ntawm chemistry. Qhov no yog, piv txwv li, kev taw qhia txog kev txo cov hlau ncaj qha thiab cam khwb cia hlau tau hais ua ntej.

Famy slagpheej mus thoob plaws thiab feem ntau overflows qhov cub kom dhau los ntawm lub qhov rooj mus rau hauv lub qhov taub npaj. Kev ntsuas kub thiab kev xaiv tshuaj yog ua los ntawm cov hmuv tsis siv neeg. Cov pa thiab cov pa roj carbon monoxide tuaj yeem ntsuas tau los ntawm mechanically nrog kev sojntsuam tshwj xeeb uas tau muab tso rau hauv cov hlau.

Production Benefits

Siv tswj qhov system rau steel-smelting arc furnaces, nws muaj peev xwm tsim steel los ntawm 100% raw khoom - seem hlau. Qhov no txo qis lub zog xav tau los tsim cov tshuaj, piv rau thawj cov khoom lag luam los ntawm ores.

Lwm qhov txiaj ntsig yog qhov yooj yim: thaum lub qhov cub tawg tsis tuaj yeem sib txawv thiab tuaj yeem khiav tau ntau xyoo, qhov no tuaj yeem pib thiab kaw sai. Qhov no tso cai rau cov hlau zeb sib txawv ntau lawm raws li qhov xav tau.

Hom arc steel rauv yog lub hauv paus ntawm cov hlau rau mini zeb, uas tuaj yeem tsim cov khoom lag luam lossis cov khoom lag luam. Mini-smelters tuaj yeem nyob ze rau kev lag luam hlau thiab kev thauj mus los tsawg dua rau cov nroj tsuag sib xyaw, uas feem ntau nyob ze rau ntawm ntug dej rau kev xa khoom nkag.

Arc Steel Rauv Ntaus

Lub schematic hla ntu yog ib qho hluav taws xob uas tau tsa thiab txo qis los ntawm khib thiab pinion tsav. Qhov saum npoo yog lined nrog refractory cib thiab hauv qab cladding. Lub qhov rooj tso cai rau nkag mus rau sab hauvqhov chaw ntawm lub cuab yeej. Lub qhov cub lub cev so ntawm lub caj npab rocker kom nws tuaj yeem tig rau tapping.

Pom zoo:

Kev tswj hwm yog kev tswj hwm. Qhov txawv ntawm kev tswj hwm thiab kev tswj hwm

Kev tswj hwm pab tswj cov haujlwm ntawm cov neeg ua haujlwm zoo tib yam los ntawm tus neeg tshwj xeeb. Tsis muaj lub tuam txhab ua tau yam tsis muaj lub koom haum ntawm cov dej num ntawm qib no

Tus thawj coj txoj kev tswj hwm: kev tswj hwm, kev ywj pheej, kev ywj pheej-tus thawj tswj hwm, tsis sib haum, xwm txheej

Yuav ua li cas thiaj nrhiav tau txoj hauv kev rau tus thawj coj thiab kawm paub tsim kev sib raug zoo nrog nws? Ua ntej koj yuav tsum paub seb hom thawj coj twg nws koom nrog. Nyeem txog hom thawj coj hauv kab lus no

Yuav ua li cas tswj lub tuam txhab kev tswj vaj tsev thiab kev pabcuam hauv zej zog? Daim ntawv tso cai, koom haum thiab kev ua ub no ntawm lub tuam txhab kev tswj hwm hauv thaj chaw ntawm vaj tse thiab kev pabcuam hauv zej zog

Hnub no, tsis muaj kev sib tw hauv kev tswj vaj tsev nyob hauv kev lag luam niaj hnub no. Thiab feem ntau ntawm cov tuam txhab uas muaj nyob no feem ntau tsis muaj kev pib lossis txawm tias muaj teeb meem. Thiab qhov no txawm tias qhov tseeb tias lub tuam txhab tswj hwm, ntawm qhov tsis sib xws, yog tsim los txhim kho thaj chaw no thiab xyuas kom muaj txiaj ntsig ntawm kev siv nyiaj. Nws yog lo lus nug ntawm yuav ua li cas tswj lub tuam txhab kev tswj vaj tsev thiab kev pabcuam hauv zej zog uas tsab xov xwm no tau mob siab rau

Kev tuav pov hwm kev tuav pov hwm yog kev tswj hwm kev pheej hmoo rau kev tuav pov hwm muaj txiaj ntsig. Cov ntsiab lus tseem ceeb ntawm daim ntawv cog lus pov hwm

Kev tuav pov hwm kev tuav pov hwm feem ntau yog kev pabcuam los ntawm cov tuam txhab nyiaj txiag xws li tsev txhab nyiaj thiab tuam txhab pov hwm. Lawv lav qhov tau txais cov nyiaj them poob haujlwm thaum muaj qee yam kev poob nyiaj txiag

Kev tswj hwm xwm txheej yog kev tswj hwm lub koom haum ntawm cov xwm txheej. Kev tswj hwm qhov xwm txheej thiab nws txoj kev loj hlob hauv Russia

Kev tswj hwm qhov xwm txheej yog qhov nyuaj ntawm txhua yam dej num ua los tsim cov xwm txheej loj thiab koom nrog. Nyob rau tib lub sijhawm, tus qub raug hu los muab kev txhawb nqa muaj zog rau cov tuam txhab tshaj tawm, thaum lub sijhawm kawg yog tsom rau kev txhawb nqa tus ntsuj plig hauv kev lag luam