2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Cov txheej txheem hlau feem ntau cuam tshuam nrog kev txiav qhov khoob kom loj, tsim cov npoo los ntawm khoov ob sab ntawm qee lub kaum ntse ntse. Kev ua haujlwm zoo li no ua rau muaj qhov tseeb tias txhua yam kev ntxhov siab tshwm sim hauv qhov chaw, suav nrog kev sib xyaw ntawm cov kab hauv kev khoov sab hauv thiab nthuav dav rau sab nrauv. Lub ntug dabtsi yog khoov tshuab ua rau nws muaj peev xwm txo tau cov kev tsis zoo no. Nws tsim yog teem nyob rau hauv xws li ib tug txoj kev uas lub dabtsi yog khoov quab yuam yog manifested ib txhij nyob rau hauv tag nrho ntev ntawm lub workpiece. Hauv qhov no, qhov deformation tshwm sim synchronously, thaum cov hlau tsis tawg, tsis muaj qhov chaw uas muaj feem cuam tshuam rau corrosion ntawm nws.

Ntau yam

Flanging tshuab sib txawv ntawm ib leeg los ntawm lub hauv paus ntsiab lus ntawm kev ua haujlwm thiab cov khoom siv. Nrog lawv cov kev pab, khoov ntawm nplooj ntawv thiab cov npoo ntawm ob millimeters yog ua. Cov txheej txheem zoo tshaj plaws yog ua los ntawm kev hloov kho nyob ruaj khov uas ua haujlwm ntawm cov chaw ua haujlwm hlau. Compact thiab mechanical counterparts yog tsom rau kev teeb tsa hauv tsev neeg ntiag tug thiab cov khw kho me me. Kujlawv tau siv ncaj qha rau ntawm kev teeb tsa ntawm lub ru tsev hlau, dej los yog qhov cua.

Cov khoom siv hauv kev txiav txim siab tau muab faib ua hom hauv qab no raws li tus qauv tsim:

- kev hloov pauv hloov;

- xaiv teb;

- xovxwm kev sib tw.

Raws li lub hauv paus ntawm kev ua, lawv yog:

- manual hemming machines;

- cov qauv siv tshuab nrog hom teb flywheel;

- electromagnetic los yog electromechanical specimens;

- pneumatic;

- hydraulic.

Units nrog txhua tus tsav tuaj yeem ua cov hlau dub thiab galvanized, txhuas, tooj liab. Thaum khoov pleev xim rau qhov khoob, cov txheej tiv thaiv tsis puas. Cov kev taw qhia tseem ceeb ntawm kev ua hauj lwm yog kev tsim cov txheej txheem complex thiab qhov chaw (chutes, thawv, stands, bottoms, tshwj xeeb nqaim profiles).

Device

Tus tsim ntawm txhua lub tshuab dabtsi yog khoov suav nrog cov txheej txheem yuav tsum tau ua, nyob ntawm kev ua haujlwm. Piv txwv li, segment-type qauv yog tsom rau kev ua hlau raws cov kab uas tsis sib xws. Qhov no tso cai rau zus tau tej cov triangular, trapezoidal thiab segmental qhov chaw. Pub-los ntawm cov qauv tsuas yog khoov cov khoom nyob rau hauv ib qho kev taw qhia, txij li thaum lub taub hau siab thiab cov nqaj nkhaus tsis txav mus rau qhov ntev axis.

Lub ntsiab lus tseem ceeb ntawm cov khoom hauv nqe lus nug:

- skeleton (txaj);

- rov qab desktop,uas ua haujlwm rau nruab lub workpiece kom ua tiav, txav mus rau hauv kev xav tau thiab ua haujlwm yooj yim;

- flexor thiab cutter;

- kev hloov kho pem hauv ntej txhawb kom teeb tsa qhov dav ntawm qhov chaw ua haujlwm yuav raug txiav;

- riam rau cov menyuam teeb tsa, uas yog siv los tsim cov ntu ntu thiab kho cov npoo;

- angular thiab ntse log;

- flexor nrog goniometers;

- siab beam;

- controllers lub luag haujlwm kho qhov siab ntawm lub rooj tsavxwm;

- tsav thiab tswj.

Txoj Cai Ua Haujlwm

Cov ntawv hlau yog mounted rau ntawm lub rooj ntawm lub tshuab dabtsi yog khoov, nias nrog ib tug nqaj ntawm haum zoo rau saum npoo. Lub ntsiab bending nce, ntes lub workpiece los yog ntug ua tiav. Ib feem yog nias tawm tsam lub log tsheb, uas plays lub luag hauj lwm ntawm ib hom matrix, tom qab uas nws yog khoov rau lub kaum sab xis xav tau.

Hauv cov qauv siv phau ntawv, qhov tsim nyog quab yuam yog siv los ntawm kev tuav tshwj xeeb hauv daim ntawv ntawm lub zog. Thaum ua cov hlau nrog lub thickness txog li ib millimeters, tsis tas yuav raug ntau dhau; tus neeg uas muaj lub cev nruab nrab tuaj yeem tiv taus cov haujlwm no. Ntawm cov cuab yeej tshwj xeeb, ntug yog khoov los ntawm 125-135 degrees, ntxiv kev kho kom zoo (txog 180 °) yog ua los ntawm kev sib txuas eccentric. Rau cov nplooj ntawv ob millimeters lossis ntau dua, cov khoom siv nrog hydraulic lossis lwm yam tsav muaj zog yuav tsum tau.

Kev lag luam xovxwm nres thiab tshuab

Kpawg no suav nrog cov khoom siv hlau ua haujlwm ntau yam. Lawv feem ntau nruab nrog CNC, tuaj yeem siv rau cov khoom lossis cov khoom loj. Xav txog cov yam ntxwv ntawm kev ua haujlwm ntawm cov tshuab xovxwm-bending ntawm qhov piv txwv ntawm lub tshuab IB-1424. Nws yog tsim los ntawm Nelidovo cog rau kev tsim cov hydraulic presses.

Cov khoom siv no tsis yog nyob rau hauv qeb uas muaj zog tshaj plaws, tab sis nws ua tiav tag nrho cov txheej txheem muab tau sai thiab ua tau zoo. Hom ntawm ntug dabtsi yog khoov tshuab muaj peev xwm ua cov nplooj ntawv thiab strips ntawm ntau yam ntaub ntawv, tsim ib tug quab yuam ntawm txog 25 t / s. Cov yam ntxwv tseem ceeb:

- rectilinear dabtsi yog khoov nrog qhov siab kawg ntawm cov hlaws dai ntawm 5 hli;

- txiav blanks;

- qhov ua;

- processing profiles ntawm complex configuration;

- Ntau daim ntev txog 2500mm.

Ntse

txhawm rau ua kom cov ntawv hlau ntawm ntau qhov tuab, cov xovxwm dabtsi yog khoov tau nruab nrog cov xuas nrig sib hloov uas tso cai rau koj los muab lub kaum sab xis uas yuav tsum tau khoov, tsis hais qhov nyuaj ntawm qhov profile. Tsis tas li ntawd, cov cuab yeej yog nruab nrog cov matrices tshwj xeeb uas txawv ntawm qhov dav ntawm ib leeg. Cov ntsiab lus hloov tau raug mounted sai, reconfiguration ntawm pab kiag li lawm rau ib tug ntau yam ntawm cov khoom yog nqa tawm sai li sai tau.

Lub zog ntawm lub tshuab yog kho nyob rau hauv ib qho kev dav dav. Txhawm rau kom tsis txhob muaj qhov tshwm sim ntawm qhov tsis tseem ceeb ua rau deformation ntawm lub workpiece, cov rooj tshwj xeeb quab yuam tau tsim. Lawv muabcov ntaub ntawv uas coj mus rau hauv tus account qhov ntev ntawm txoj kab khoov, thickness ntawm cov khoom thiab lub voj voog ua haujlwm. Lub hydraulic version txawv ntawm lub tshuab rotary bending nyob rau hauv du quab yuam hloov, suab nrov tsawg, ua raws li kev ntsuas siab thoob plaws tag nrho cov txheej txheem thev naus laus zis.

HDS Model

Nov yog lwm qhov nrov hydraulic xovxwm nres. Chav tsev txheej txheem hlau blanks txog li 3.5 millimeters tuab, belongs rau cov chav nruab nrab ntawm kev ua haujlwm. Qhov siab tshaj plaws ntev ntawm qhov txiav yog 3050 hli, thiab khoov ntawm cov npoo yog mus txog 1350 hli. Tsim muaj zog - 16 MPa. Txawm hais tias tsis muaj kev tswj hwm tus lej, cov xovxwm muaj ntau qhov chaw.

LGS-26 version

Kev piav qhia ntawm ntug dabtsi yog khoov tshuab yuav txuas ntxiv nrog phau ntawv qhia kev cog lus, uas yog ib feem ntawm cov khoom siv tsim los ntawm Lipetsk Profile Bending Plant. Chav tsev no yog qhov zoo tshaj plaws rau kev cob qhia me me thiab kev ua haujlwm ncaj qha rau ntawm qhov chaw. Nws yog tsim los ua haujlwm nrog cov hlau, lub thickness ntawm tsis pub tshaj 0.7 millimeters. Lub hom phiaj tseem ceeb yog cov khoom lag luam zoo thiab nrawm ntawm cov khoom zoo li tus, suav nrog cov nqes hav, ebbs, sawv, skates, nqaim strips thiab profiles.

Thaum ua cov khoom, ntug yog khoov los ntawm 15 millimeters ntawm lub kaum sab xis txog li 180 °. Qhov sib npaug ntawm daim ntawv txiav yog lav los ntawm qhov muaj cov chais ua los ntawm cov hlau ruaj khov hauv kev tsim. Cov cuab yeej txheem ntawm chav tsev suav nrog:

- main mechanism nrogclamp;

- beam;

- bender;

- goniometer;

- txiav tshuab;

- frontal nres ceev cov txheej txheem ntawm kev txiav manipulations;

- set riam spare.

Lub tshuab dabtsi yog khoov raws li kev txiav txim siab yog qhov tsim nyog siv tau thiab xav tau. Nws yog qhov tseeb heev los siv nws ua tus qauv tsim los ua-nws-koj tus kheej dabtsi yog khoov tshuab. Nws yog tsim nyog sau cia tias txhua qhov chaw yog tsim los ntawm kev siv cov cuab yeej siv hlau thiab vuam. Hauv ib lub rhiav me me, xws li lub tshuab tuaj yeem ua tau ntawm tus nqi tsawg. Sib dhos los ntawm cov khoom npaj ua tiav, chav tsev yuav raug nqi 2-3 zaug pheej yig dua li yuav hauv daim ntawv tiav.

Result

phaj dabtsi yog khoov tshuab thiab nias ua kom yooj yim ntau ntawm cov hlau tsim thiab kev teeb tsa ua haujlwm. Vim qhov sib txawv ntawm kev tsim thiab lub hom phiaj, nws yuav tsis yooj yim los xaiv cov cuab yeej siv, suav nrog kev siv lub ntsiab thiab tus nqi. Rau kev cob qhia hauv tsev, phau ntawv hloov kho uas koj tuaj yeem ua koj tus kheej yog qhov tsim nyog heev.

Pom zoo:

Kev txhim kho vaj tsev thiab nws lub luag haujlwm hauv kev txhim kho kev lag luam. Lub tswvyim, hom, cov hauv paus ntsiab lus thiab lub hauv paus ntawm txoj kev loj hlob

Nyob rau hauv lub moj khaum ntawm kab lus no, peb yuav txiav txim siab lub koom haum ntawm kev txhim kho vaj tse thiab nws lub luag haujlwm hauv kev txhim kho kev lag luam. Cov ntsiab lus tseem ceeb, hom thiab cov hauv paus ntsiab lus ntawm lub koom haum ntawm txoj kev txhim kho yog txiav txim siab. Cov yam ntxwv nta ntawm lub system nyob rau hauv Lavxias teb sab tej yam kev mob yog xam

Hluav taws xob locomotive 2ES6: keeb kwm ntawm kev tsim, kev piav qhia nrog cov duab, cov yam ntxwv tseem ceeb, lub hauv paus ntsiab lus ntawm kev ua haujlwm, cov yam ntxwv ntawm kev ua haujlwm thiab kho

Hnub no, kev sib txuas lus ntawm cov nroog sib txawv, kev thauj neeg caij tsheb, kev xa khoom yog nqa tawm ntau txoj hauv kev. Ib txoj hauv kev no yog txoj kev tsheb ciav hlau. Hluav taws xob locomotive 2ES6 yog ib yam ntawm cov kev thauj mus los uas tam sim no nquag siv

Lub ntsiab lus ntawm kev qhuab qhia ua haujlwm yog dab tsi? Lub tswv yim, qhov tseem ceeb thiab lub ntsiab lus ntawm kev qhuab qhia ua haujlwm

Nws nyuaj rau kev kwv yees qhov tseem ceeb ntawm kev qhuab qhia ua haujlwm. Tseeb tiag, hauv kev sib raug zoo ntawm kev ua haujlwm, tus tswv ntiav thiab cov neeg ua haujlwm feem ntau ntsib cov xwm txheej uas ob leeg xav txog lawv tus kheej yog, tab sis lawv cov kev xav tsis ua rau kev pom zoo. Kev qhuab qhia kev ua haujlwm raug cai tswj hwm ntau lub ntsiab lus uas kev tsis sib haum xeeb thiab kev tsis txaus siab ntawm cov neeg koom nrog kev sib raug zoo ntawm kev ua haujlwm tsuas yog tsis tshwm sim. Zaj tom ntej no yog hais txog cov ntsiab lus tseem ceeb ntawm kev qhuab qhia ua haujlwm

Titanium ua: thawj lub zog ntawm cov khoom siv, kev nyuaj thiab hom kev ua haujlwm, lub hauv paus ntsiab lus ntawm kev ua haujlwm, cov tswv yim thiab cov lus pom zoo ntawm cov kws tshaj lij

Hnub no, tib neeg tab tom ua ntau yam khoom siv. Titanium processing sawv tawm ntawm cov teeb meem feem ntau ntawm kev ua haujlwm. Cov hlau muaj qhov zoo heev, tab sis vim yog lawv, feem ntau ntawm cov teeb meem tshwm sim

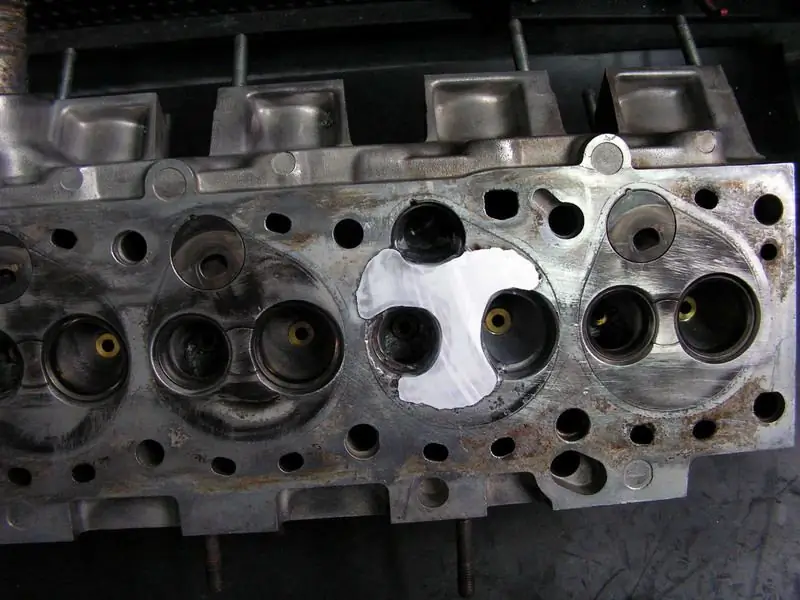

Kho lub cav thaiv: cov lus qhia ua ntu zus nrog cov lus piav qhia, khoom siv, lub hauv paus ntsiab lus ntawm kev ua haujlwm, cov lus qhia los ntawm tus tswv

Lub thaiv yog qhov tseem ceeb ntawm yuav luag txhua lub cav hluav taws xob sab hauv. Nws yog rau lub tog raj kheej thaiv (tom qab no hu ua BC) uas tag nrho lwm qhov txuas nrog, pib ntawm lub crankshaft thiab xaus nrog lub taub hau. BCs tam sim no yog ua los ntawm txhuas, thiab ua ntej, hauv cov qauv tsheb qub, lawv tau cam khwb cia hlau. Lub tog raj kheej thaiv tsis ua haujlwm yog tsis muaj qhov tsis tshua muaj. Yog li ntawd, nws yuav nthuav rau cov tswv tsheb tshiab los kawm txog kev kho chav tsev no