2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Cov ntsia hlau txhuas yog ib qho tseem ceeb uas siv los ua lub suab hloov pauv. Nws hloov cov lus tsa suab mus rau hauv kev txhais lus-rectilinear tsab ntawv tsa suab. Ua li no, nws yog muab nrog ib tug tshwj xeeb txiv ntseej. Tsis tas li ntawd, nws muab kev txav mus los nrog qhov tseeb.

Prop quality indicators

Cov ntsia hlau, yog qhov tseem ceeb heev, yuav tsum ua tau raws li ntau qhov kev xav tau. Nyob rau hauv thiaj li yuav siv tau, piv txwv li, nyob rau hauv ib tug desktop vice, nws yuav tsum haum rau xws li tsis xws li: diametrical loj, profile raug thiab xov pitch raug, piv ntawm cov ntsia hlau xov rau nws lub caj dab txhawb nqa, hnav tsis kam, xov thickness. Nws tseem yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias, nyob ntawm seb qhov kev txav mus los qhov tseeb uas cov ntsia hlau muab, lawv tuaj yeem muab faib ua ob peb qhov tseeb ntawm 0 txog 4. Piv txwv li, cov hlau lead screws ntawm cov cuab yeej siv tshuab yuav tsum sib haum rau cov chav kawm raug ntawm 0. mus rau 3. 4 chav kawm raug tsis haum rau kev siv cov khoom siv zoo li no.

Khoom siv rau cov ntsia hlau tsis muaj

Raws li qhov khoob rau kev tsim cov ntsia hlau, ib qho bar zoo tib yam yog siv, uas yog txiav los ntawm cov hlau zoo. Txawm li cas los xij, nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov ntawm no tias qee qhov yuav tsum tau ua rau cov khoom siv ua ib qho khoob. Cov hlau yuav tsum muaj kev hnav zoo, kev ua haujlwm zoo, thiab tseem muaj lub xeev ruaj khov nyob rau hauv cov xwm txheej ntawm kev ntxhov siab sab hauv uas tshwm sim tom qab ua tiav. Qhov no tseem ceeb heev, vim tias cov cuab yeej no yuav pab kom tsis txhob deformation ntawm cov ntsia hlau txhuas thaum nws siv ntxiv.

Rau qhov tsim ntawm qhov no nrog qhov nruab nrab qhov tseeb hauv chav kawm (thib ob lossis thib 3), uas yuav tsis raug raws li qhov yuav tsum tau ua kom muaj zog tiv thaiv kub, siv A40G steel, uas yog nruab nrab carbon, nrog rau kev sib ntxiv ntawm cov sulfur thiab steel 45 nrog ntxiv ntawm cov hlau lead. Cov hlau no txhim kho lub peev xwm ua haujlwm ntawm cov ntsia hlau thiab kuj txo qhov roughness ntawm cov khoom.

Propeller Profile

Muaj peb cov ntsia hlau uas siv los tsim cov hlau lead ntawm lub tshuab dhos lossis lwm yam. Qhov profile tuaj yeem yog trapezoidal, duab plaub lossis duab peb sab. Feem ntau hom yog cov xov trapezoidal. Nws qhov zoo muaj xws li qhov tseeb tias nws yog siab dua nyob rau hauv qhov tseeb dua ib lub duab plaub. Tsis tas li ntawd, siv cov txiv ntoo slotted, koj tuaj yeem kho cov axial clearances nrog cov ntsia hlau trapezoidal, uas tshwm sim vim cov khoom siv.

Nws tseem ceeb heev uas yuav tsum nco ntsoov ntawm no tias kev txiav, nrog rau kev sib tsoo cov xov trapezoidal rau ntawm cov ntsia hlau, yooj yim dua li lub duab plaub. Tab sis tib lub sijhawm, koj yuav tsum nkag siab tias qhov tseeb ntawm cov duab plaubcov xov yog siab dua cov ntawm cov trapezoidal sawv daws yuav. Qhov no txhais tau hais tias yog tias txoj haujlwm yog los tsim cov ntsia hlau nrog qhov zoo tshaj plaws kev hloov kho kom raug, ces koj tseem yuav tsum tau txiav ib daim duab plaub. Trapezoidal screws tsis haum rau kev ua haujlwm zoo heev.

Txhim kho cov ntsia hlau

Qhov tseem ceeb ntawm cov ntsia hlau yog nyob rau hauv lub tshuab yog lub caj dab txhawb nqa thiab dab tshos. Threaded nto ntawm ib tug ntsia hlau yog suav hais tias yog nws cov xov. Qhov tseeb tshaj plaws nyob rau hauv lub desktop lwm tus thiab lwm lub tshuab nrog xws li cov ntsia hlau yuav tsum tau ua kom ntseeg tau ntawm qhov ua tiav ntawm qhov chaw, nrog rau lub hauv paus loj. Lub hauv paus thev naus laus zis rau kev tsim cov ntsia hlau txhuas yog nws qhov chaw nruab nrab. Vim li no, txhawm rau kom tsis txhob deformation, kev ua haujlwm ntawm tag nrho cov chaw no yog ua los ntawm kev siv lub xov tooj ntawm tes ruaj khov. Daim ntawv thov ntawm ntu no txiav txim siab qhov ua tiav ntawm cov ntsia hlau txhuas.

Ntawm no nws tseem ceeb heev uas yuav tsum nco ntsoov tias lub hau ntswj nrog cov chav kawm raug sib txawv tau ua tiav rau ntau qhov sib txawv. Cov ntsiab lus uas yuav suav nrog 0, 1 thiab 2 cov chav kawm raug raug ua tiav mus txog qib 5. Screws teej tug mus rau 3rd qhov tseeb chav kawm yog ua tiav mus txog 6th zoo. Cov ntsia hlau uas muaj nyob rau hauv qeb 4 kuj tau ua tiav mus txog qib 6, tab sis tib lub sijhawm lawv muaj qhov kam rau ua rau sab nraud.

Yuav kom tau txais cov ntsia hlau ua tau zoo, nws yuav tsum tau ua ob peb txoj haujlwm ntxiv. Ib tug ntawm lawv yog lub centering ntawm ib feem, uas yuav siv sij hawm qhov chaw nyob rau hauv txoj kevtshuab. Cov ntsia hlau txhuas, lossis theej, lub tshuab ua haujlwm rau qhov no, yog nyob rau ntawm cov khoom siv tshwj xeeb thiab qhov kawg raug txiav rau ntawm no. Tsis tas li ntawd, ib qho kev sib tsoo workpiece yog nqa tawm. Txhawm rau ua qhov no, siv lub tshuab tsis muaj nruab nrab lossis cylindrical sib tsoo hauv cov chaw. Nws yog ib qho tseem ceeb uas yuav tau ntxiv ntawm no tias kev sib tsoo hauv cov chaw tsuas yog ua rau cov ntsia hlau ntawm 0, 1 thiab 2 cov chav kawm raug.

Ntxiv mus, ua ntej pib nrog threading, lub workpiece yuav tsum ncaj. Nws yuav tsum raug sau tseg ntawm no tias tsuas yog screws nrog rau chav kawm 3rd thiab 4th raug raug rau cov haujlwm no. Tom qab ntawd, lawv nto yog polished ntxiv. Lub tshuab dhos ntsia hlau yog siv los ua cov cuab yeej txiav cov xov ntawm cov ntsia hlau txhuas.

Prop txiv ntoo piav qhia

Cov ntsia hlau ntsia hlau yog tsim los xyuas kom meej qhov kev teeb tsa raug. Qee qhov tsis tshua muaj, lawv tuaj yeem ua los ntawm cov khoom siv xws li cov hlau tsis muaj kev sib txhuam. Cov khoom no yuav tsum tau muab kev koom tes tas li nrog cov lem ntawm cov ntsia hlau, thiab tseem ua raws li qhov nyiaj tau los. Koj yuav tsum tau them nyiaj rau qhov sib txawv, uas yuav ua rau muaj kev cuam tshuam thaum lub hau ntswj tawm. Piv txwv li, txiv ntseej rau cov hlau lead screws siv hauv tshuab dhos yog ua ob npaug. Qhov no yog qhov tsim nyog txhawm rau txhawm rau tshem tawm qhov sib txawv uas yuav tshwm sim los ntawm kev tsim khoom thiab kev sib dhos ntawm lub tshuab, lossis los ntawm kev hnav ntawm nws qhov chaw.

Qhov feature ntawm ob lub txiv ntoo ntsia hlau yog tias nws muaj qhov ruaj khov thiab txav tauib feem. Qhov txav tau, uas yog, tuaj yeem txav mus raws li qhov axis ntawm qhov ruaj khov. Nws yog qhov kev txav no uas yuav them rau qhov sib txawv. Txiv ntseej ntau lawm yog nqa tawm tsuas yog rau screws ntawm xoom, 1st thiab 2nd raug chav kawm. Lawv yog ua los ntawm tin bronze.

txiv ntseej ua los ntawm thiab hnav dab tsi?

Cov khoom siv ntau tshaj plaws rau kev tsim cov khoom no yog txhuas-hlau bronzes, raws li cov qauv siv tshuab MT 31-2. Ntxiv nrog rau cov khoom siv no, cov hlau tsis sib txhuam kuj tuaj yeem siv los hloov cov ntsia hlau tsis tseem ceeb.

Nws yog ib qho tseem ceeb uas yuav tsum tau ntxiv ntawm no tias cov txiv ntoo hnav tawm sai dua li cov ntsia hlau lead nws tus kheej. Muaj ntau qhov laj thawj rau qhov no:

- cov txiv ntoo xov tsis zoo tiv thaiv los ntawm txhua yam kab mob, thiab nws kuj nyuaj heev los ntxuav nws ntawm cov khoom tsis tsim nyog;

- feem ntau tshwm sim tias cov khoom no pib tsis zoo lubricated thiab qhov no cuam tshuam rau lub neej kev pab cuam;

- thaum cov txiv ntoo koom nrog cov ntsia hlau, nws hloov tawm tias tag nrho cov lem ntawm cov khoom thib ob ua haujlwm ib txhij, tab sis cov ntsia hlau tsuas muaj cov uas koom nrog cov txiv ntoo xwb.

Vim cov laj thawj no, cov txiv ntoo ntsia hlau yuav tsum tau tshuaj xyuas ntau zaus raws li cov txiv ntoo hnav tau nrawm dua.

Pom zoo:

Khoom noj khoom haus stainless hlau: GOST. Yuav ua li cas txheeb xyuas cov zaub mov qib stainless hlau? Dab tsi yog qhov txawv ntawm cov khoom noj stainless hlau thiab technical stainless hlau?

Cov lus hais txog qib ntawm cov zaub mov qib stainless hlau. Nyeem yuav ua li cas paub qhov txawv cov zaub mov stainless hlau los ntawm kev

Tsis siv neeg tshuab dhos thiab nws cov yam ntxwv. Tsis siv neeg tshuab dhos ntau spindle longitudinal tig nrog CNC. Manufacturing thiab processing ntawm qhov chaw ntawm tsis siv neeg lathes

Tsis siv neeg tshuab dhos yog cov cuab yeej siv niaj hnub siv feem ntau hauv kev tsim khoom ntau. Muaj ntau ntau yam ntawm cov tshuab xws li. Ib hom nrov tshaj plaws yog longitudinal tig lathes

Txoj kev tsheb ciav hlau yog Txhais, tswvyim, yam ntxwv thiab qhov ntev. Tsheb ciav hlau qhov ntev thiab cov yam ntxwv ntawm cov chaw khiav haujlwm

Kev mus los ntawm tsheb ciav hlau hla lub nroog thiab cov nroog, koj tuaj yeem kawm ntau yam nthuav thiab lom zem txog lub ntiaj teb ntawm txoj kev tsheb ciav hlau. Ntau tshaj ib zaug, cov neeg taug kev tau nug lawv tus kheej cov lus nug txog qhov twg qhov no lossis txoj kev tsheb ciav hlau coj mus? Thiab tus engineer uas tswj lub tsheb ciav hlau xav li cas thaum lub tsheb ciav hlau pib tawm lossis tuaj txog ntawm qhov chaw nres tsheb? Yuav ua li cas thiab los ntawm qhov twg cov tsheb hlau txav thiab txoj hauv kev ntawm cov khoom dov yog dab tsi?

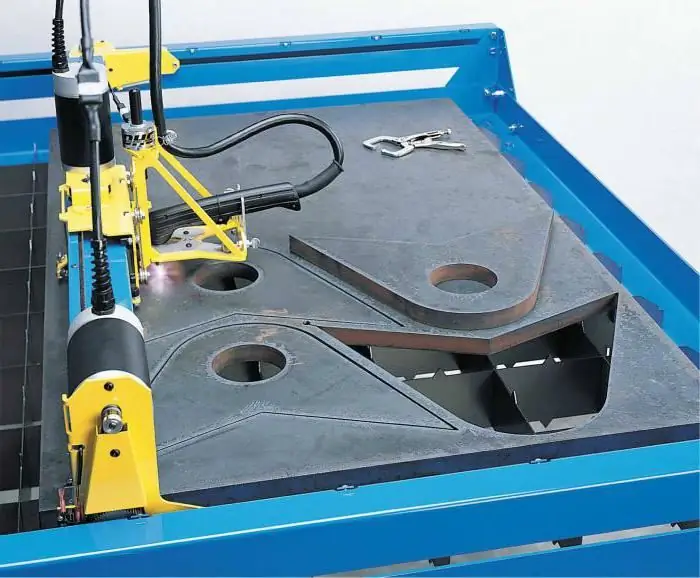

Hlau txiav tshuab. Plasma hlau txiav tshuab

Zaj lus no mob siab rau lub cuab yeej txiav hlau. Kev siv tshuab ntawm plasma txiav, nrog rau cov cuab yeej thiab cov yam ntxwv ntawm cov cuab yeej raug txiav txim siab

Ntsia taub hau ntsia hlau: siv

Kev lag luam niaj hnub tsim ntau yam ntawm cov fasteners. Lub countersunk ntsia hlau yog siv los tsim kev sib txuas muaj zog thiab tsis pom kev. Nws yog siv nyob rau hauv kev tsim kho, mechanical engineering, ntsuas ntsuas thiab lwm yam kev lag luam, nrog rau hauv lub neej txhua hnub