2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Ib qho ntawm cov hlau muaj nqis tshaj plaws hauv ntiaj teb yog tooj liab. Nws yog ib qho zoo heev conductor ntawm hluav taws xob thiab cua sov, uas yog thib ob tsuas yog nyiaj nyob rau hauv cov tsis. Thiab tooj liab hlau yog yuav luag cov khoom siv zoo tshaj plaws rau kev ua haujlwm filigree. Tab sis feem ntau ntawm tag nrho nws yog siv nyob rau hauv kev lag luam raws li ib tug conductor ntawm hluav taws xob tam sim no. tooj liab hlau kuj muaj siab ductility. Nws kuj tseem pheej yig thiab thev naus laus zis heev. Nws tuaj yeem khoov thiab txiav, nws qiv nws tus kheej yooj yim rau txhua yam ntawm vuam thiab vuam, tooj liab hlau yog muaj rau kev kos duab thiab dov. Tsis tas li ntawd, nws tsis quav ntsej txog qhov kub thiab txias (ntawm -200 txog +250 degrees), thiab huab cua thiab av noo tsis cuam tshuam rau nws. Tsis tas li ntawd, xws li ib tug hlau yog xyaum tsis muaj teeb meem thiab muaj kev pab lub neej ntev. Thiab ua tsaug rau cov txiaj ntsig zoo, nws tau siv dav heev.

Ib lub xov tooj hluav taws xob tooj liab yog tsim los ntawm tib yam khoom, qib uas tsis qis dua M1, thiab cov tshuaj muaj pes tsawg leeg sib haum rau GOST 859-2001. Qhov no yog ib qho hlau uas txaus siab nrog qhov tsawg kawg nkauscov ntsiab lus impurity (li 0.1%). Thiab tus ntoo khaub lig ntawm M1 hlau yog puag ncig. Nws tseem raug rau annealing, thiab qhov no nce nws cov plasticity, thiab tseem ua rau nws ua tau los ntawm kev txiav. Thiab txias deformation muab nws siab hardness. Thiab rau kev lag luam hluav taws xob, cov qib hlau xws li M1 thiab M2r yog siv. Thiab tsab ntawv ntxiv "E" nyob rau hauv lawv lub npe qhia tias lawv yuav tsum tau kuaj hluav taws xob conductivity. Tsis tas li ntawd, nyob ntawm qhov hardness ntawm cov khoom, nws kuj tau muab faib ua hard MT thiab soft MM. Nyob rau tib lub sijhawm, tooj liab hlau ntawm txhua lub npe ntawm cov khoom no muaj nws tus kheej zoo thiab muaj peev xwm. Thiab raws li nws lub hom phiaj, nws tuaj yeem muab faib ua hluav taws xob, xaim rau rivets thiab rau cov thermocouples uas tsis tshua muaj kub.

Thiab tooj liab hlau yog siv rau hauv kev lag luam fais fab, kev tsim kho, luam ntawv, tshuab engineering thiab lub teeb kev lag luam. Tiv tauj cov xov hlau, cables, rivets, cov khoom zoo nkauj thiab cov khub uas tsis tshua muaj kub yog tsim los ntawm nws. Hauv kev lag luam khau, me me tooj liab rau tes, accessories thiab studs yog tsim los ntawm nws. Thiab nyob rau hauv kev lag luam xws li mechanical engineering, telecommunications thiab shipbuilding, nws yog indispensable. Ntawm no nws yog siv los ua windings rau hluav taws xob motors thiab transformers, spark ignition leads thiab fuses yog tsim los ntawm nws. Nyob rau tib lub sij hawm, nws yog ib qho yooj yim mus ua hauj lwm nrog nws, vim nws muaj siab plasticity. Txawm tias qhov kev tiv thaiv ntawm tooj liab hlau yog tsawg dua qhov uas ua los ntawm txhuas, dua li nws muaj zog dua. Yog li ntawd, nws muaj txiaj ntsig ntau dua los ua cov xaim hluav taws xob los ntawm nws, txij li rau tib yamvoltage thiab tam sim no xav tau ib tug sib zog thiab nyias hlau.

Tsis tas li ntawd, cov xov tooj tooj liab thiab cov kab hluav taws xob yog clad nrog cov hlau xws li npib tsib xee, uas muaj qhov zoo ntawm cov tin thiab nyiaj, tshwj xeeb tshaj yog nyob rau hauv qee qhov kev siv cable. Qhov no yog vim lub fact tias nickel-plated tooj liab hlau yog heev resistant rau corrosion thiab oxidation, raws li zoo raws li rau qhov tseem ceeb kub. Thiab nws yog siv feem ntau hauv kev tsim cov khoom siv hluav taws xob zoo sib xws, uas yog npaj rau kev lag luam aviation, hluav taws xob, chaw, kev sib txuas lus thiab kev tiv thaiv kev lag luam. Copper-nickel hlau kuj tseem siv los ua cov kab hluav taws xob kub, cov hluav taws kub hnyiab, thiab fuses. Nws tuaj yeem tiv taus kub txog li 750 degrees.

Pom zoo:

Kev nthuav dav ntawm thaj chaw pabcuam. Qauv xaj kom nthuav dav thaj chaw pabcuam

Hauv kev lag luam thiab cov koom haum, ib qho feem ntau ntsib qhov tseeb tias cov dej num hauv tib yam lossis lwm txoj haujlwm ntawm lwm tus neeg ua haujlwm tuaj yeem raug ntxiv rau cov haujlwm ntawm tus neeg ua haujlwm. Xav txog nyob rau hauv tsab xov xwm cov kev xaiv rau kev tsim xws li kev ua hauj lwm ntxiv nyob rau hauv ntau zaus

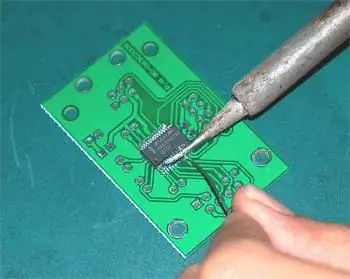

Solder rau soldering tooj liab, txhuas, tooj dag, hlau, stainless hlau. Solder muaj pes tsawg leeg rau soldering. Hom solders rau soldering

Thaum nws yuav tsum tau ua kom ruaj khov ntau yam khoom sib txuas ua ke, soldering feem ntau xaiv rau qhov no. Cov txheej txheem no tau nthuav dav hauv ntau lub lag luam. Peb yuav tsum tau solder thiab tsev craftsmen

Vuam ntawm tooj liab thiab nws cov alloys: txoj kev, thev naus laus zis thiab khoom siv

Tooj liab thiab nws cov alloys yog siv nyob rau hauv ntau yam kev lag luam. Cov hlau no yog nyob rau hauv kev thov vim nws cov khoom physicochemical, uas kuj nyuaj rau kev ua ntawm nws cov qauv. Tshwj xeeb, kev vuam ntawm tooj liab yuav tsum tau tsim cov xwm txheej tshwj xeeb, txawm hais tias cov txheej txheem yog raws li kev siv thev naus laus zis zoo sib xws

Oxygen-dawb tooj liab: nta, txiaj ntsig, kev siv

Tooj liab yog cov ntxhia uas nyob hauv tib neeg lub neej tau ntau txhiab xyoo. Nyob rau hauv ancient sij hawm, nws yog siv tsuas yog kom tau bronze, nyob rau hauv ib tug alloy nrog tin. Hauv Latin, nws lub npe yog Cuprum. Nws tau muab rau nws los ntawm cov kob qub ntawm Cyprus, uas yog ib qho ntawm thawj qhov chaw uas tooj liab raug mined thiab smelted los ntawm mines

Lena thee phiab: thaj chaw thaj chaw, yam ntxwv ntawm kev khaws cia, txoj hauv kev ntawm kev rho tawm

Kab lus no piav qhia txog Lena thee phiab. Nws yog ib qho ntawm cov loj tshaj plaws nyob rau hauv lub ntiaj teb no nyob rau hauv cov nqe lus ntawm lub ntim ntawm thee deposited nyob rau hauv nws. Tab sis tam sim no nws tau siv tsis zoo vim nws qhov chaw deb, tab sis qhov no tsis ua rau nws tsis tshua xav kawm