2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Qhov ua tau zoo thiab teeb meem ntawm plasma surfacing yog qhov mob hnyav heev rau cov kws tsim khoom siv. Ua tsaug rau cov thev naus laus zis no, nws tuaj yeem ua tsis tau tsuas yog ua kom muaj kev pabcuam lub neej thiab kev ntseeg siab ntawm cov khoom thauj khoom thiab cov khoom sib dhos, tab sis kuj tseem yuav rov qab los, nws yuav zoo li, ib puas feem pua cov khoom hnav thiab rhuav tshem.

Kev taw qhia ntawm plasma surfacing rau hauv cov txheej txheem thev naus laus zis ua rau muaj kev sib tw ntawm cov khoom lag luam engineering. Cov txheej txheem tsis yog qhov tseem ceeb tshiab thiab tau siv rau lub sijhawm ntev. Tab sis nws tab tom txhim kho thiab nthuav dav nws cov peev txheej thev naus laus zis.

khoom siv dav dav

Plasma yog cov roj ionized. Nws ntseeg tau tias cov ntshav tuaj yeem tau txais los ntawm ntau txoj hauv kev los ntawm hluav taws xob, thermal lossis mechanical teebmeem ntawm cov roj molecules. Rau nws txoj kev tsim, nws yog qhov tsim nyog los rhuav tshem cov hluav taws xob tsis zoo los ntawm cov atom zoo.

Nyob hauv qee qhov chaw koj tuaj yeem nrhiav taucov ntaub ntawv hais tias plasma yog plaub lub xeev ntawm kev sib sau ntawm cov teeb meem nrog rau cov khoom, kua thiab gaseous. Ionized roj muaj ib tug xov tooj ntawm pab tau thiab yog siv nyob rau hauv ntau ceg ntawm science thiab technology: plasma surfacing ntawm hlau thiab alloys nyob rau hauv thiaj li yuav restore thiab harden loaded khoom uas muaj cyclic loads, ion-plasma nitriding nyob rau hauv ib tug glow paug rau diffusion saturation. thiab hardening ntawm qhov chaw ntawm qhov chaw, rau kev siv cov txheej txheem tshuaj. pickling (siv nyob rau hauv electronics manufacturing technology).

Npaj ua haujlwm

Ua ntej koj pib ntog, koj yuav tsum teeb tsa cov khoom siv. Raws li cov ntaub ntawv siv, nws yog ib qho tsim nyog los xaiv thiab teeb tsa lub kaum sab xis ntawm inclination ntawm lub qhov hluav taws xob rau ntawm qhov chaw ntawm cov khoom, kho qhov kev ncua deb ntawm qhov kawg ntawm lub qhov cub mus rau ib feem (nws yuav tsum yog los ntawm 5 mus rau 8. millimeters) thiab ntxig cov xaim (yog tias cov khoom siv hlau yog surfacing).

Yog tias surfacing yuav ua tiav los ntawm kev hloov pauv ntawm lub nozzle nyob rau hauv cov lus qhia hla, ces nws yuav tsum tau teem lub taub hau nyob rau hauv xws li ib txoj kev uas lub weld yog raws nraim nyob rau hauv nruab nrab ntawm cov huab ntsiab lus ntawm lub fluctuation amplitudes. taub hau. Nws kuj tseem tsim nyog los kho cov txheej txheem uas teeb tsa qhov zaus thiab qhov loj ntawm cov oscillatory txav ntawm lub taub hau.

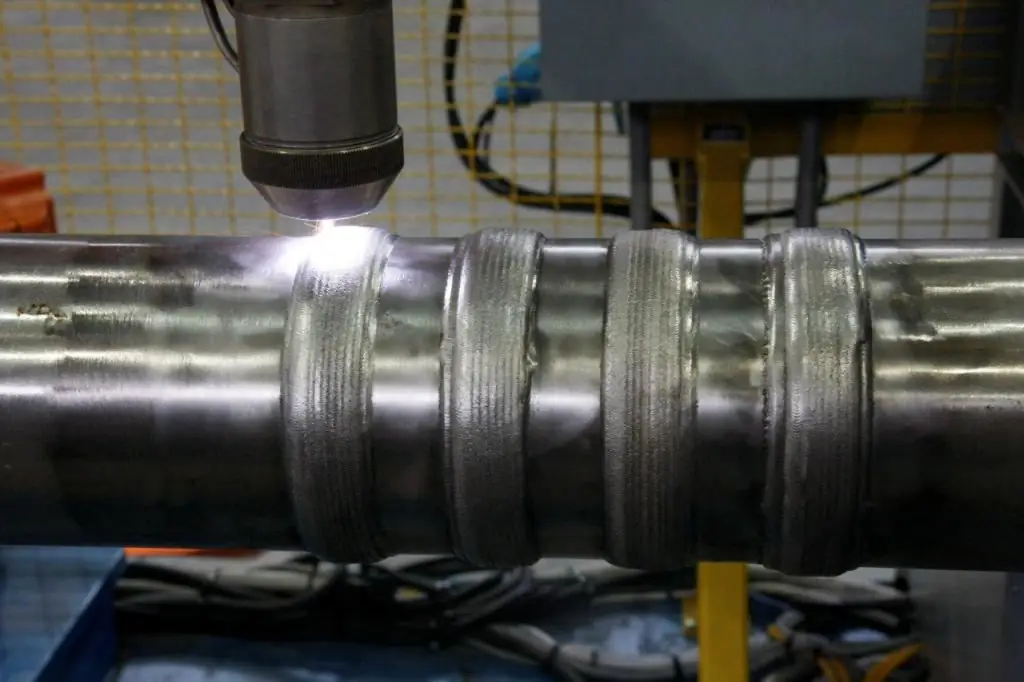

Plasma arc surfacing thev naus laus zis

Cov txheej txheem surfacing yog qhov yooj yim heev thiab tuaj yeem ua tiav los ntawm ib tus neeg paub txog kev siv vuam. Txawm li cas los xij, nws xav tauua yeeb yam ntawm qhov siab tshaj plaws concentration thiab mloog. Txwv tsis pub, koj tuaj yeem rhuav tshem cov khoom ua haujlwm tau yooj yim.

Ib lub zog arc tawm yog siv los ionize cov roj ua haujlwm. Lub detachment ntawm tsis zoo electrons los ntawm zoo them atoms yog nqa tawm vim lub thermal nyhuv ntawm hluav taws xob arc ntawm lub dav hlau ntawm cov ua hauj lwm roj sib tov. Txawm li cas los xij, nyob rau hauv ntau qhov xwm txheej, qhov ntws tuaj yeem ua tsis tau tsuas yog nyob rau hauv kev cuam tshuam ntawm thermal ionization, tab sis kuj vim yog lub zog ntawm lub zog hluav taws xob.

Gas yog nkag rau hauv siab ntawm 20-25 cua. Rau nws cov ionization, qhov hluav taws xob ntawm 120-160 volts yuav tsum muaj tam sim no ntawm 500 amperes. Qhov zoo ions raug ntes los ntawm qhov chaw sib nqus thiab maj mus rau cathode. Qhov ceev thiab lub zog kinetic ntawm lub hauv paus ntsiab lus yog qhov zoo heev uas thaum lawv sib tsoo nrog hlau, lawv tuaj yeem muab qhov kub thiab txias - los ntawm +10 … +18,000 degrees Celsius. Nyob rau hauv cov ntaub ntawv no, cov ions txav ntawm ib tug ceev txog li 15 kilometers ib ob (!). Plasma surfacing installation yog nruab nrog ib tug tshwj xeeb ntaus ntawv hu ua "plasma torch". Nws yog lub node uas yog lub luag hauj lwm rau lub ionization ntawm cov roj thiab tau txais ib tug ncaj qha ntws ntawm elementary hais.

Lub zog ntawm lub arc yuav tsum yog xws li tiv thaiv melting ntawm cov khoom hauv paus. Nyob rau tib lub sijhawm, cov khoom kub yuav tsum siab npaum li qhov ua tau txhawm rau txhawm rau qhib cov txheej txheem diffusion. Yog li, qhov kub thiab txias yuav tsum ze rau cov kab kua dej ntawm daim duab hlau-cementite.

Cov hmoov zoo ntawm ib qho tshwj xeeb muaj pes tsawg leeg lossis electrode xaim yog pub rau hauv lub dav hlau ntawm cov ntshav plasma, uas cov khoom sivyaj. Nyob rau hauv lub xeev ua kua, lub surfacing ntog rau ntawm hardened nto.

Plasma txau

Yuav kom siv cov tshuaj plasma, nws yog ib qho tsim nyog yuav tsum tau ua kom cov ntshav ntws nce ntxiv. Qhov no tuaj yeem ua tiav los ntawm kev kho qhov voltage thiab tam sim no. Parameters raug xaiv empirically.

Cov khoom siv rau kev txau cov ntshav yog cov hlau refractory thiab tshuaj lom neeg: tungsten, tantalum, titanium, borides, silicides, magnesium oxide thiab aluminium oxide.

Qhov txiaj ntsig tsis txaus ntseeg ntawm kev txau piv rau vuam yog lub peev xwm kom tau cov txheej nyias nyias, ntawm qhov kev txiav txim ntawm ob peb micrometers.

Cov thev naus laus zis no yog siv rau kev ua kom tawv tawv txiav thiab milling hloov tau carbide inserts, nrog rau cov kais dej, xyaum, cov txee, cov khoom siv thiab lwm yam cuab yeej.

Tau txais lub dav hlau qhib plasma

Nyob rau hauv cov ntaub ntawv no, lub workpiece nws tus kheej ua raws li ib tug anode, uas cov khoom yog deposited los ntawm plasma. Qhov pom tseeb qhov tsis zoo ntawm txoj kev ua haujlwm no yog cua sov ntawm qhov chaw thiab tag nrho cov ntim ntawm cov khoom, uas tuaj yeem ua rau kev hloov pauv ntawm cov qauv thiab qhov tshwm sim tsis zoo: softening, nce brittleness, thiab lwm yam.

Closed plasma dav hlau

Nyob rau hauv cov ntaub ntawv no, cov roj burner, ntau precisely, nws nozzle, ua raws li ib tug anode. Txoj kev no yog siv rau plasma-powder surfacing txhawm rau kho thiab txhim kho kev ua haujlwm ntawm qhov chaw thiabtshuab nodes. Cov thev naus laus zis no tau txais txiaj ntsig tshwj xeeb hauv kev ua liaj ua teb engineering.

Qhov zoo ntawm Plasma Hardfacing

Ib qho ntawm qhov zoo tshaj plaws yog qhov concentration ntawm thermal zog nyob rau hauv ib cheeb tsam me me, uas txo cov nyhuv ntawm qhov kub thiab txias ntawm cov khoom qub.

txheej txheem yog tswj tau zoo. Yog tias xav tau, thiab nrog cov cuab yeej tsim nyog, txheej txheej saum npoo tuaj yeem sib txawv ntawm ob peb feem kaum ntawm ib millimeter mus rau ob millimeters. Qhov muaj peev xwm tau txais cov txheej txheem tswj hwm yog qhov tshwj xeeb tshaj plaws nyob rau lub sijhawm no, vim nws tso cai rau kev txhim kho kev lag luam ntawm kev ua haujlwm thiab tau txais cov khoom zoo (hardness, corrosion resistance, hnav tsis kam thiab ntau lwm yam) ntawm cov khoom steel.

Lwm yam tsis muaj qhov tseem ceeb tsawg dua yog qhov muaj peev xwm ua cov plasma welding thiab surfacing ntawm ntau yam ntaub ntawv: tooj liab, tooj dag, bronze, precious hlau, thiab tsis yog hlau. Cov txheej txheem vuam ib txwm nyob deb ntawm ib txwm muaj peev xwm ua qhov no.

khoom siv tawv tawv

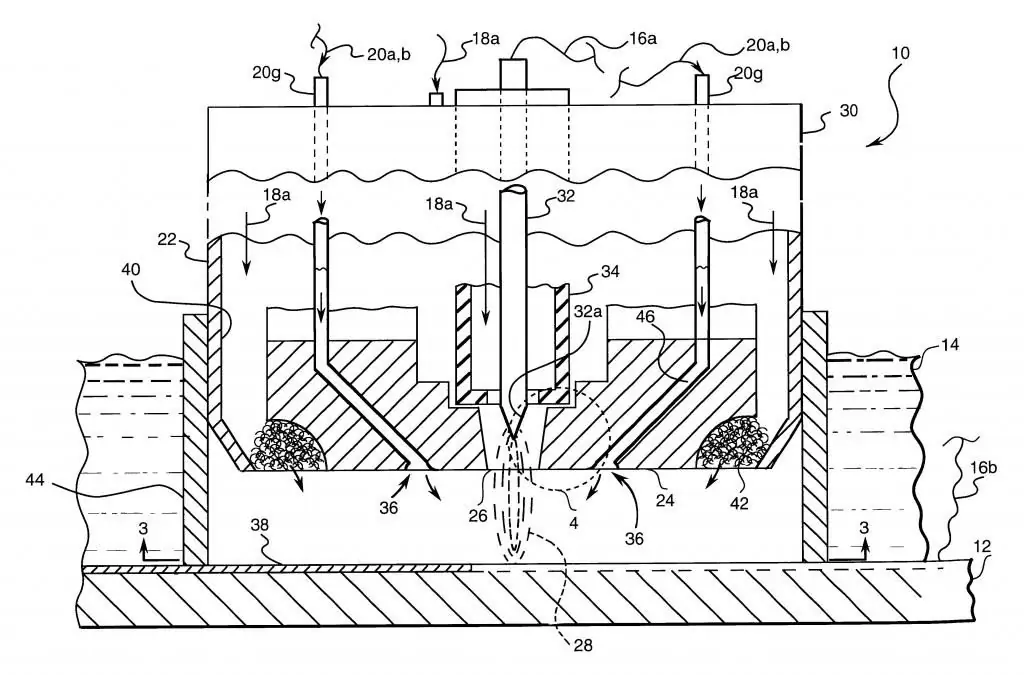

Kev teeb tsa rau plasma-powder surfacing suav nrog choke, oscillator, plasma torch thiab cov khoom siv hluav taws xob. Tsis tas li ntawd, nws yuav tsum tau nruab nrog ib lub cuab yeej rau kev cia li pub hlau hmoov granules rau hauv qhov chaw ua haujlwm thiab lub tshuab ua kom txias nrog cov dej tsis tu ncua.

Cov peev txheej fais fab rau plasma hardfacing yuav tsum ua tau raws li cov kev cai nrujtsis tu ncua thiab kev ntseeg tau. Vuam transformers ua txoj haujlwm zoo tshaj plaws nrog lub luag haujlwm no.

Thaum surfacing hmoov cov ntaub ntawv ntawm ib tug hlau nto, lub thiaj li hu ua ua ke arc yog siv. Ob lub dav hlau qhib thiab kaw plasma yog siv ib txhij. Los ntawm kev kho lub zog ntawm cov arcs, nws muaj peev xwm hloov qhov tob ntawm qhov nkag ntawm lub workpiece. Nyob rau hauv cov xwm txheej zoo, warpage ntawm cov khoom yuav tsis tshwm sim. Qhov no yog qhov tseem ceeb hauv kev tsim cov khoom thiab sib dhos ntawm precision engineering.

Khoom noj khoom haus

Hlau hmoov yog dosed los ntawm ib tug tshwj xeeb ntaus ntawv thiab pub rau hauv lub melting cheeb tsam. Lub tshuab los yog lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm lub feeder yog raws li nram no: lub rotor hniav thawb cov hmoov mus rau hauv cov pa roj, cov khoom yog rhuab thiab lo rau qhov chaw kho. Cov hmoov yog pub los ntawm ib lub nozzle cais. Nyob rau hauv tag nrho, peb lub nozzles raug ntsia rau hauv cov roj burner: rau muab plasma, muab cov hmoov ua hauj lwm thiab rau shielding roj.

Yog tias koj siv cov xaim, nws raug nquahu kom siv cov txheej txheem pub mis ntawm lub tshuab nqus dej arc vuam.

kev npaj nto

Plasma surfacing thiab txau cov ntaub ntawv yuav tsum tau ua ntej los ntawm kev tu kom huv ntawm qhov chaw los ntawm cov roj stains thiab lwm yam kab mob. Yog hais tias thaum lub sij hawm cov pa welding nws yog tso cai rau ua tsuas yog ntxhib, nto ntxuav cov pob qij txha los ntawm xeb thiab nplai, ces thaum ua hauj lwm nrog roj plasma, qhov chaw ntawm lub workpiece yuav tsum tau zoo tagnrho (kom deb li deb tau) huv si, tsis muaj txawv teb chaws inclusions. Lub thinnest oxide zaj duab xis muaj peev xwmUa kom tsis muaj zog ntawm cov nplaum sib cuam tshuam ntawm hardfacing thiab lub hauv paus hlau.

Txhawm rau npaj qhov chaw rau saum npoo, nws raug nquahu kom tshem tawm cov txheej txheem tsis tseem ceeb ntawm cov hlau los ntawm kev ua haujlwm los ntawm kev txiav, ua raws li degreasing. Yog tias qhov ntev ntawm qhov tso cai, nws raug nquahu kom ntxuav thiab ntxuav qhov chaw hauv chav da dej ultrasonic.

Cov yam ntxwv tseem ceeb ntawm cov hlau ntog

Muaj ntau ntau txoj kev xaiv thiab txoj hauv kev rau kev tshem cov ntshav plasma. Kev siv cov xaim ua cov khoom siv rau saum npoo ua rau muaj txiaj ntsig zoo ntawm cov txheej txheem piv rau cov hmoov. Qhov no yog vim lub fact tias cov electrode (hlau) ua raws li ib tug anode, uas ua rau kom lub cua sov sai npaum li cas ntawm cov khoom deposited, uas txhais tau hais tias nws tso cai rau koj mus kho cov kev ua hom upwards.

Txawm li cas los xij, qhov zoo ntawm cov txheej txheem thiab cov khoom adhesion yog kom meej meej nyob rau sab ntawm cov hmoov additives. Kev siv cov khoom zoo hlau ua rau nws ua tau kom tau ib txheej txheej ntawm cov thickness ntawm qhov chaw.

Ntawm hmoov

Kev siv cov hmoov surfacing yog qhov zoo dua nyob rau hauv cov nqe lus ntawm qhov zoo ntawm qhov tshwm sim thiab hnav tsis kam, yog li cov hmoov sib tov tau siv ntau dua hauv kev tsim khoom. Cov tshuaj muaj pes tsawg leeg ntawm cov hmoov sib tov yog cob alt thiab nickel hais. Cov hlau ntawm cov hlau no muaj cov khoom siv zoo. Tom qab ua tiav nrog xws li ib tug muaj pes tsawg leeg, qhov saum npoo ntawm ib feem tseem zoo kawg nkaus du thiab tsis muaj kev xav tau rau nws txhua yam tiav thiab tshem tawm ntawm irregularities. Cov feem ntawm cov hmoov nplej tsuas yog ob peb micrometers xwb.

Pom zoo:

Kev tsim cov khoom siv roj: cov txheej txheem thev naus laus zis, khoom siv thiab khoom siv

Hnub no, muaj ntau yam khoom siv hauv tsev uas nrov. Ib qho kev tsim kho tshiab yog kev tsim cov khoom siv roj av, uas yog cov pob zeb ntawm tes. Ntawm cov no, nws muaj txiaj ntsig tsis yog los tsim ib lub tsev ntiag tug xwb, tab sis kuj tsim khoom muag

Kev tsim cov plywood: thev naus laus zis, theem tseem ceeb ntawm cov txheej txheem thiab thaj chaw ntawm kev siv cov khoom siv

Plywood yog ib qho ntawm cov khoom siv pheej yig tshaj plaws thiab siv tau tshaj plaws. Txawm hais tias muaj ntau txheej txheej, nws yooj yim rau nruab thiab tuaj yeem ua tiav hauv tsev yam tsis muaj cov cuab yeej tshwj xeeb. Txuj kev tsim cov plywood suav nrog kev siv cov ntoo lamellas, nrog rau kev ua kom zoo uas koj tuaj yeem tau txais cov khoom tiav uas tiv taus ntau yam kev hem thawj

Inline ntau lawm yog Lub tswv yim, txhais, cov txheej txheem ntawm lub koom haum thiab cov txheej txheem thev naus laus zis

Cov txheej txheem tsim khoom yog qhov kev ua haujlwm thev naus laus zis uas tuaj yeem txhim kho ntau txoj hauv kev thiab txhais tau tias. Kev ua haujlwm ntawm kev lag luam nyob rau hauv cov xwm txheej ntawm kev tsim cov khoom lag luam niaj hnub no suav tias yog qhov ua tau zoo tshaj plaws, tab sis tib lub sijhawm xav tau ntawm kev ua haujlwm, kev tsim khoom thiab cov nqi khoom siv. Hauv kev txiav txim siab dav dav, kev tsim khoom hauv kab yog ib hom kev ua haujlwm ntau lawm uas cov hauv paus ntsiab lus ntawm kev sib dhos thiab rov ua haujlwm ntawm kev ua haujlwm tau los ua ntej

Vuam hauv qhov chaw tiv thaiv roj: ua haujlwm thev naus laus zis, txheej txheem piav qhia, cov txheej txheem ua tiav, cov khoom tsim nyog thiab cov cuab yeej, cov lus qhia ua haujlwm ib ntus thiab cov lus qhia kws tshaj lij

Vuam thev naus laus zis yog siv hauv ntau ceg ntawm tib neeg kev ua haujlwm. Versatility tau ua vuam nyob rau hauv ib puag ncig tiv thaiv roj ib qho tseem ceeb ntawm kev tsim khoom. Qhov ntau yam no ua rau nws yooj yim los txuas cov hlau nrog lub thickness ntawm 1 hli mus rau ob peb centimeters nyob rau hauv txhua txoj hauj lwm nyob rau hauv qhov chaw. Vuam nyob rau hauv ib puag ncig tiv thaiv yog maj mam hloov cov tsoos electrode vuam

Kev kho dua tshiab ntawm qhov chaw los ntawm vuam thiab ntog: cov txheej txheem thiab cov txheej txheem ntawm kev kho dua tshiab, nta, txheej txheem thev naus laus zis

Vuam thiab surfacing thev naus laus zis ua rau nws ua tau zoo los kho cov hlau seem, muab cov qib siab ntawm kev ntseeg siab thiab ua haujlwm ntev ntawm cov khoom. Qhov no tau lees paub los ntawm kev xyaum siv cov txheej txheem no thaum ua haujlwm kho hauv ntau qhov chaw - los ntawm kev kho tsheb mus rau kev tsim cov hlau dov. Hauv tag nrho cov nyiaj ua haujlwm ntawm kev kho cov qauv hlau, kev kho dua tshiab ntawm qhov chaw los ntawm kev vuam thiab surfacing yuav siv li 60-70%