2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Ib qho hluav taws xob kauj yog ib hom inductive-type resistance rau alternating tam sim no. Yog tias koj qhia txog lub ntsiab lus xws li cov tub ntxhais hlau rau hauv lub kauj, koj tuaj yeem ua kom cov inductance nce. Los ntawm lawv tus kheej, cov khoom siv hluav taws xob tsis txuas, tab sis yog tias koj tseem kaw lawv thiab txuas lub galvanometer, ces nws cov xub yuav txav mus.

Spiral Flat Type Coil

Muaj hom hluav taws xob zoo li lub tiaj tus kauv. Nws yog nthuav nyob rau hauv daim ntawv ntawm ib tug thawj winding ntawm ib tug transformer. Lub kauj yog feem ntau muab tso rau ntawm ib lub disk ntawm txhuas los yog zinc, uas muaj hluav taws xob conductivity siab. Txawm hais tias koj tuaj yeem siv lwm cov khoom siv uas yuav muaj qhov zoo ib yam. Nws yog ib qho tseem ceeb uas cov khoom muaj peev xwm tswj tau qhov zoo ntawm qhov kub siab. Xws li ib tug disk feem ntau yog qhov thib ob winding ntawm tib transformer. Yog hais tias qhov kub thiab txias nyob rau hauv ib txwm txwv, ces tus nqi conductivity yuav khaws cia nyob rau hauv ib txwm txwv rau cov khoom raw uas siv.

Coil processing. Kev tsim txomkhoom siv

Tsawg tus neeg paub tias cov hluav taws xob coils yuav tsum tau impregnated. Impregnation nrog ntau yam varnishes yog nqa tawm, thiab nws yog ib qho tsim nyog los txhim kho kev tiv thaiv kom ya raws, nce thermal conductivity. Nws kuj tseem ua tau los txhim kho cov hluav taws xob thiab cov khoom siv dag zog. Muaj cov chav kawm ntawm hluav taws xob coils xws li A, B lossis E. Kev faib tawm yog nqa tawm raws li kev tiv thaiv tshav kub. Glossy thiab waterproof txheej yuav tsum tiv taus kub txog 250 degrees Celsius.

Thaum muaj hluav taws xob siv rau lub cuab yeej no, lub bracket tau thim rov qab nrog rau cov tub ntxhais. Lub brace txav mus rau hauv txoj hauj lwm thaum nws pib nias ntawm qia, uas txav nrog rau cov roj hmab membrane. Lub zog ntawm tus pas nrig entails ib tug txo nyob rau hauv lub internal ntim ntawm lub kaw kab noj hniav rau nws yam tsawg kawg nkaus tus nqi. Kev nce hauv lub dav hlau no kuj ua tau. Qhov no tuaj yeem tshwm sim vim qhov kev txiav txim ntawm lub caij nplooj ntoos hlav, nrog rau nws tus kheej qhov loj ntawm tus pas nrig, uas yuav pib rov qab mus rau nws txoj haujlwm qub thaum tam sim no nres thiab lub bracket rov qab mus rau nws qhov qub.

Ferrozond

Ferroprobe yog ib qho hluav taws xob coil nrog cov tub ntxhais, uas tau nthuav tawm hauv daim ntawv ntawm cov hlau nplaum mos ferromagnet. Nws yog powered los ntawm alternating tam sim no. Qhov no yog qhov rhiab heev rau qhov tsis xws li qhov loj thiab cov kev taw qhia ntawm magnetic teb.

Tam sim no, hauv engineering, cov khoom siv thiab cov khoom siv, cov coils tau siv rau hauv hluav taws xob hluav taws xob, uas tej zaum yuav muaj lossis tsis muaj qhov tseem ceeb. Nws yuav tsum tau muab sau tseg tias nyob rau hauv thiaj li yuav cais cov lem ntawm xws licov khoom siv hluav taws xob, ntawv yog siv, uas yog pre-impregnated nrog cov kua roj vanish. Xws li cov khoom siv nrog cov hluav taws xob tam sim no hauv lub kauj yog feem ntau siv hauv kev lag luam hluav taws xob. Feem ntau lawv tau tsim rau hauv cov khoom siv ntsuas. Nyob rau hauv lawv, lub kauj yog nthuav tawm nyob rau hauv daim ntawv ntawm ib tug winding, uas yog nyob rau ntawm ib tug ncej ntawm ib tug tej yam zoo li. Lub hauv paus nws tus kheej kuj muaj flanges, nrog rau lub hau.

Nyob ntawm coils

Hnub no, ntau hom khoom siv tau paub.

Piv txwv li, ib lub cuab yeej nrog lub winding ntawm tus ncej, flanges nrog protrusions. Cov protrusions muaj cov chav me me, uas yog zoo li tsab ntawv T. Nyob rau hauv xws li grooves muaj petals siv rau soldering kawg, lawv muaj cov duab ntawm tsab ntawv G. Ntawm qhov tsis zoo ntawm xws li ib tug coil, complexity ntawm nws tsim, raws li zoo raws li cov duab ntawm tsab ntawv G. zoo li cov complexity hauv cov txheej txheem thev naus laus zis, sawv tawm. Tsis tas li ntawd, rau kev ua haujlwm ruaj khov ntawm lub zog hluav taws xob ntawm lub kauj, nws yog ib qho tsim nyog yuav tsum tau solder cov ua rau cov petals. Cov txheej txheem no yog ua thaum winding. Qhov downside yog vim qhov no, cov khoom tsim tau ntawm tag nrho cov khoom siv sib txuas winding raug txo.

Lwm hom kev paub zoo ntawm cov cuab yeej yog lub thav duab nrog flanges uas nyob rau hauv protrusions, nrog rau cov tuav rau kev sib cuag. Cov protrusions nyob rau hauv cov ntaub ntawv no yog ua nrog ib tug recess. Nyob rau hauv xws li recesses, tus tuav yog nyob rau kev sib cuag nrog U-shaped zawj. Nrog rau cov cuab yeej no, qhov tsis zoo yog tias thaum lub sij hawm winding ntawm lub coil ntawm kev kub ceev, muaj feem ntau ntawm ob qho tib si kev sib cuag thiab lawv poob.tuav.

Coil nrog davhlau ya nyob twg

Ib qho hluav taws xob kauj yog siv, qhov winding uas nyob rau ntawm ib tug ncej nrog flanges. Ntawm ib qho ntawm lawv muaj lub davhlau ya nyob twg tuav, nrog rau cov neeg tawm suab. Lub ntsiab sib txawv los ntawm lwm yam khoom siv ntawm hom no yog tias tus tuav yog ua nyob rau hauv daim ntawv ntawm ib tug muab faib. Muaj ob sab protrusions, uas yog nyob rau hauv symmetrically, raws li zoo raws li ib tug central ib. Nws yog mounted noj mus rau hauv tus account ib tug me me qhov sib txawv, uas yog ntsia nyob rau hauv relation mus rau sab protrusions nyob rau hauv xws li ib tug txoj kev uas qhov tshwm sim yog ib tug U-shaped channel. Cov neeg hu xov tooj yuav muab tso rau hauv cov channel no yav tom ntej. Nws tseem tsim nyog sau cia tias txhua sab protrusion muaj qhov dhau los.

Pom zoo:

Daim ntawv thov rov qab los ntawm kev tuav pov hwm qiv nyiaj: piv txwv, cov cai ntawm daim ntawv thov, lub sijhawm xa tawm

Nyob rau hauv tus txheej txheem ntawm tau txais cov nyiaj qiv, cov tsev txhab nyiaj muaj peev xwm qiv nyiaj los xaus daim ntawv cog lus pov hwm. Yog tias tus neeg siv tsis tuaj yeem them cov nuj nqis, lub luag haujlwm kaw nws mus rau lub txhab nyiaj yog nrog lub tuam txhab pov hwm. Tab sis hauv kev xyaum, qhov xwm txheej tsis sib xws feem ntau tshwm sim, thiab cov neeg them nyiaj siab xav tau xav txog qhov muaj peev xwm rov qab tau txais kev pov hwm qiv nyiaj thaum them rov qab ntxov. Tab sis yuav tau txais ntau npaum li cas? Thiab leej twg yuav tsum muab cov nyiaj - tus tuav pov hwm lossis lub txhab nyiaj?

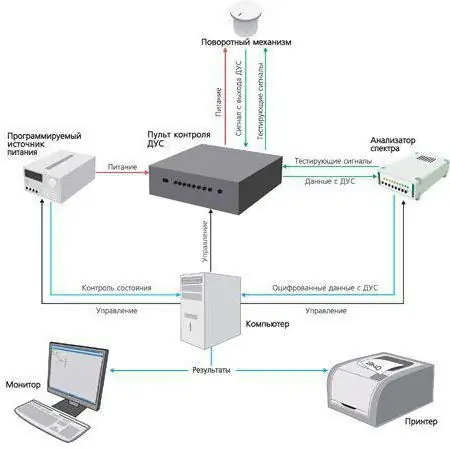

Test bench: piav qhia, daim ntawv thov, daim duab thiab hom

Test bench: views. nta, daim ntawv thov, kev ua haujlwm, schemes. Tswj thiab kuaj sawv ntsug: piav qhia, nta, yam ntxwv, duab

Tshaj tawm ntawm phab ntsa daim ntawv qhia hnub: hom, xaiv cov ntsiab lus ntawm daim ntawv qhia hnub, nuances ntawm kev tsim thiab luam ntawv

Daim ntawv qhia hnub yog ib qho tseem ceeb ntawm txhua qhov chaw ua haujlwm. Thiab txawm tias muaj pes tsawg tus neeg siv khoom thiab cov neeg muag khoom pub dawb rau lawv, lawv tseem ua khawv koob los ntawm lub tuam txhab cov chaw ua haujlwm uas tsis koom nrog kev sib txuas lus nrog cov neeg cog lus. Cias muab, daim ntawv qhia hnub yog qhov tseem ceeb tshaj plaws ntawm cov ntaub ntawv tshaj tawm uas ib txwm mus nrog lub suab nrov

Mi-10 nyoob hoom qav taub: piav qhia nrog cov duab, keeb kwm ntawm kev tsim, kev qhia tshwj xeeb thiab daim ntawv thov

Lub Mi-10 nyoob hoom qav taub yog lub tshuab ya tshwj xeeb, tsim los rau cov tub rog xav tau, tab sis dhau sij hawm, nws tau ua pov thawj tias ua tau zoo hauv kev lag luam hauv tebchaws. Peb yuav tham txog qhov kev ua tiav tiag tiag ntawm kev lag luam hauv Soviet nyoob hoom qav taub hauv ntau npaum li qhov ua tau hauv kab lus

Lub hnab ntawv qhia: piav qhia, xav tau kev teeb tsa, daim ntawv thov, kev siv lub tswv yim

Qhov ntsuas lub hnab ntawv yog cov cuab yeej siv los txiav txim siab qhov txwv sab saud thiab qis ntawm kev ua lag luam. Daim duab qhia txog tus nqi ua haujlwm qhia ob kab, ib qho, ntawm ib qho kev ncua deb ntawm tus tub luam, rov ua qhov nruab nrab txav saum toj no, thiab lwm qhov hauv qab nws. Nrog rau kev lag luam ntau, cov cuab yeej tshuaj ntsuam xyuas no feem ntau yog siv los txheeb xyuas cov khoom lag luam overbought thiab oversold kev lag luam