2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

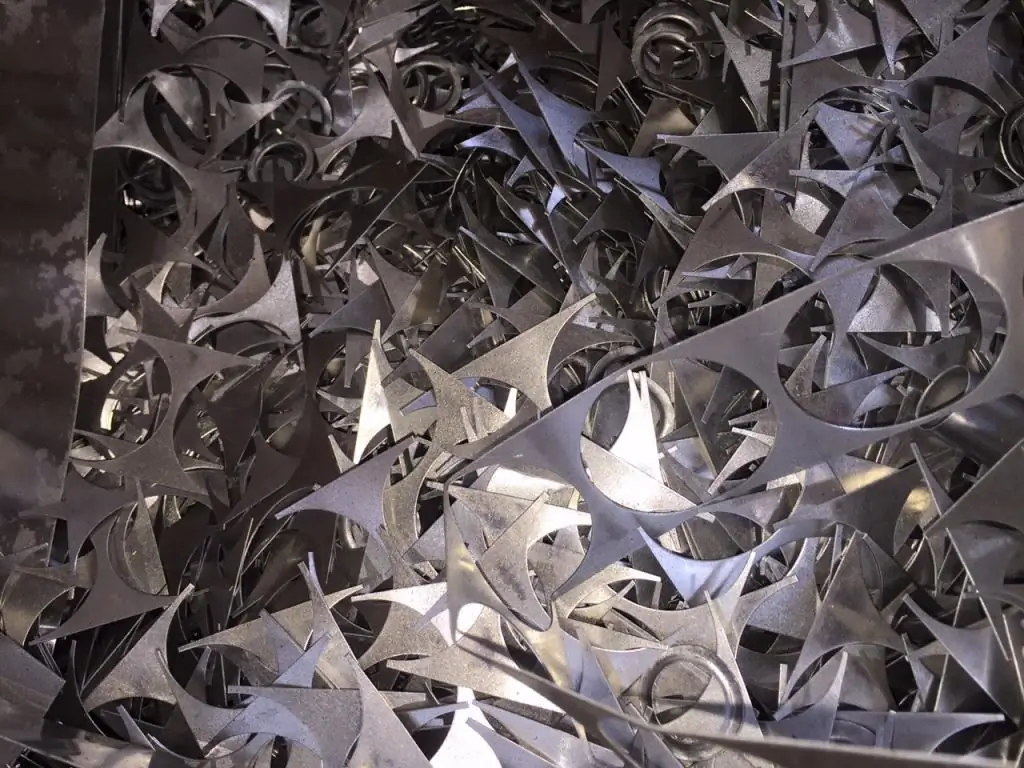

Kev siv cov txhuas ua cov khoom siv tau nyob ib puag ncig ntev heev. Txawm li cas los xij, nws tsuas yog qhov txawv ntawm nws qhov tsis tshua muaj lub ntiajteb txawj nqus, zoo ductility thiab siab corrosion kuj. Lub zog thiab hardness ntawm cov khoom no yog tsawg heev. Qhov teeb meem tau raug tshem tawm ib nrab los ntawm cov kws tshawb fawb Soviet, uas ntxiv magnesium rau cov khoom xyaw. Yog li, AMG alloys tau txais thawj zaug.

Kev piav qhia dav dav

Hnub no, muaj ntau ntau yam ntawm hom alloy no. Tag nrho cov ntawm lawv txawv ntawm ib leeg nyob rau hauv lawv cov yam ntxwv thiab scope. Piv txwv li, koj tuaj yeem xav txog cov khoom ntawm pawg thib ob thiab thib peb, uas yog, AMg-2 thiab AMg-3. Cov muaj pes tsawg leeg ntawm AMG alloy nyob rau hauv cov ntaub ntawv no yog supplemented nrog cov ntsiab lus xws li Si thiab Mn. Corrosion kuj tseem nyob rau theem siab, zoo weldability tshwm sim thaum siv hom vuam xws li chaw, cov menyuam, roj. Tsis tas li ntawd, cov khoom siv ob pawg no yog cov yam ntxwv ntawm qhov txias txias thiab kub deformation.

Interval kubdeformation, piv txwv li, yog nyob rau hauv cheeb tsam ntawm 340 mus rau 430 ° C. Txias tom qab hom deformation no yog nqa tawm hauv huab cua qhib. Nws tseem tsim nyog ntxiv tias AMG alloys ntawm hom no tsis yog hardened los ntawm kev kho cua sov. Profiles feem ntau yog tsim los ntawm cov khoom siv no. Hauv lawv qhov chaw tsim khoom, siv ob hom annealing: qis ntawm qhov kub ntawm 270-300 ° C thiab siab ntawm qhov kub ntawm 360-420 ° C.

Kev piav qhia ntawm AMG-6

Hnub no, tag nrho AMG-alloys yog nyob rau hauv qeb ntawm deformable tshuaj. Nws yog ib qho tsim nyog ntxiv tias tus naj npawb ntawm cov ntsiab lus uas siv rau alloying, nrog rau cov khoom siv kho tshuab, tau tswj hwm los ntawm GOST 4784-97. Raws li cov ntaub ntawv no, ntxiv rau AMg alloy - txhuas thiab manganese, lwm yam tshuaj muaj nyob rau hauv cov muaj pes tsawg leeg.

tshuaj muaj pes tsawg leeg

Nws tsim nyog xav txog cov tshuaj muaj pes tsawg leeg ntawm AMg-6, vim nws suav tias yog qhov zoo tshaj plaws ntawm txhua yam khoom zoo sib xws.

- Ib txwm, thawj lub ntsiab lus ntawm daim ntawv teev npe yog magnesium, xws li 5.8% txog 6.8%. Cov khoom no yog lub ntsiab hardener ntawm aluminium. Yog hais tias tsuas yog 1% magnesium ntawm tag nrho cov khoom ntawm txhuas yog ntxiv rau qhov muaj pes tsawg leeg, ces qhov kev nce hauv lub zog ntawm li 35 MPa tuaj yeem ua tiav yam tsis muaj kev cuam tshuam ductility. Txawm li cas los xij, nws yuav tsum tau muab sau tseg tias magnesium txo lub ntuj tiv thaiv corrosion. Qhov no yuav tshwm sim tshwj xeeb tshaj yog tias nws cov nyiaj pib ntau dua 6%, thiab qhov ua los ntawm txhuas alloy AMg-6 yog nyob rau hauv static load.

- Manganese kuj ntxiv rautus nqi ntawm 0.5 mus rau 0.8%. Qhov no yog qhov tsim nyog rau kev sib tsoo cov nplej loj ntawm txhuas, uas yuav cuam tshuam zoo rau cov khoom siv kho tshuab. Tsis tas li ntawd, lub ntsiab lus no txo qis qhov kev pheej hmoo ntawm kev sib cais - kev faib tsis sib xws ntawm cov tshuaj muaj pes tsawg leeg hla cov txhuas nto.

- Qhia 0.06% titanium los txhim kho kev ua haujlwm. Feem ntau ntawm tag nrho cov, qhov no cuam tshuam qhov weldability ntawm cov khoom. Titanium muaj peev xwm txo tau cov qauv ntawm cov alloy mus rau ib tug finer grain, raws li zoo raws li txo tus nyiam mus cracking. Tag nrho cov no ua rau lub fact tias lub zog ntawm cov welds nyob rau hauv cov khoom ntawm cov alloy AMg-6 nce heev.

- Sodium hauv tus nqi ntawm 0.01%. Ntawm no nws yuav tsum tau hais tias lub ntsiab lus no tsis ntxiv rau qhov muaj pes tsawg leeg ntawm lub hom phiaj, txij li qhov no yog qhov tsis xav tau, nws tshwm sim hauv nws vim yog melting ntawm cryolite-muaj fluxes. Lub melting point ntawm sodium tsuas yog 96 ° C, uas yog qis dua li ntawm txhuas nws tus kheej. Vim li no, nws tuaj yeem hais tau tias cov yam ntxwv ntawm hom AMG alloy no tau ua tiav los ntawm kev nce liab brittleness vim sodium.

- Copper hauv tus nqi ntawm 0.01%. Cov tshuaj no belongs rau qeb ntawm teeb meem impurities rau txhuas. Lub xub ntiag ntawm tooj liab ho txo cov corrosion kuj ntawm cov khoom no. Tsis tas li ntawd, nws degrades lub ductility ntawm alloy. Txawm li cas los xij, nws yuav tsum tau ntxiv ntawm no tias txawm tias me me ntawm tooj liab ua rau muaj kev ua tau zoo ntawm cov tshuab, uas yog, lub zog thiab hardness.

Qhov tsis zoo ntawm AMG-6

Txawm hais tias tag nrho cov khoom ntxiv, cov hlau no tseem muaj qee qhov tsis zoo.

- Yield zog ntawm alloyqis txaus. Txhawm rau kom zam dhau los yog txo cov txiaj ntsig ntawm qhov tsis zoo no, txog li 0.8% zinc tuaj yeem ntxiv rau hauv cov muaj pes tsawg leeg lossis saum npoo tuaj yeem ua kom tawv.

- Lwm qhov tsis zoo yog qhov tsis muaj peev xwm ua kom tawv nqaij raws li kev kho cua sov. Tag nrho cov alloys qis dua 8% magnesium tsis tuaj yeem ua kom tawv.

zoo ntawm aluminium alloys

Kev qhia txog ntau yam tshuaj lom neeg tau coj mus rau qhov tseeb tias qee yam yam ntxwv tau txhim kho tau zoo.

- Cov khoom siv tshuab tau raug coj mus rau qib txaus siab. Tom qab annealing, lub zog tensile yog 340 MPa, tib yam li cov pa steels. Hardness kuj tseem txhim kho. Alloy AMg-6 muaj qhov ntsuas siab tshaj plaws ntawm lwm tus.

- Tseem tshuav tsawg. Qhov no txhais tau hais tias kev siv cov ntsiab lus los ntawm cov hlau no tseem ceeb heev, tshwj xeeb tshaj yog nyob rau hauv cov qauv tsim uas muaj cov kev cai nruj rau qhov loj ntawm cov khoom.

- Corrosion kuj. Yog hais tias ua ntej nws siab txaus, ces cov hlau yuav ua rau invulnerable kiag li rau cov teebmeem ntawm atmospheric huab cua, dej, raws li zoo raws li ib pab pawg neeg ntawm qaug zog acids thiab alkalis. Txawm li cas los xij, kom tau txais tag nrho cov khoom zoo no, kev sib tsoo yuav tsum tau ua thiab tsuas yog nyob rau qhov kub thiab txias xwb.

- Qhov kev vibration tsis kam ntawm aluminium-magnesium alloy yog qhov siab heev thiab muaj li 130 MPa.

- High technology. Qhov no txhais tau hais tias lub weldability ntawm cov alloy belongs rau thawj qeb, uas yog, qhov ceev thiablub zog ntawm cov vuam yog yuav luag sib npaug ntawm cov khoom siv. Tsis tas li ntawd, ductility yog siab heev, thiab compressive elongation yog 20%.

khoom siv

Nws yog AMg-6 alloy uas tau dhau los ua ntau tshaj. Nws yog muab rau cov khoom siv hauv tsev ua lag luam nyob rau hauv daim ntawv tuav, raws, nplooj ntawv, cov ces kaum nrog ntau qhov ntev. Cov khoom no feem ntau yog siv thaum tsim nyog los tsim cov qauv welded nrog kev txwv ntawm qhov loj ntawm cov khoom. Cov khoom siv no tseem tuaj yeem siv tau zoo los tsim cov tawv nqaij sab hauv thiab sab nraud rau ntau yam ntawm lub cev muaj zog. Tsis tas li ntawd, tso tsheb hlau luam tuaj yeem tsim los ntawm nws, uas tsim nyog rau kev thauj cov roj, piv txwv li.

Pom zoo:

Usinskoye teb: cov yam ntxwv tseem ceeb thiab cov yam ntxwv ntawm thev naus laus zis

Usinskoye teb: thaj chaw thaj chaw, piav qhia, kwv yees hydrocarbon reserves. Nta ntawm cov roj thiab geological qauv ntawm cov deposit. Keeb kwm ntawm discovery thiab kev tshawb fawb ntawm cov deposit. Roj ntau lawm technology

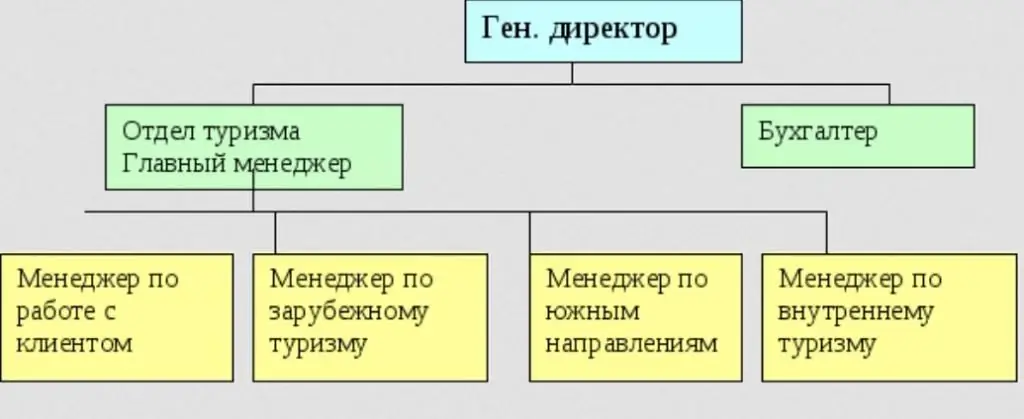

Hom kev ncig xyuas thiab lawv cov yam ntxwv. Kev ua haujlwm thiab cov yam ntxwv ntawm cov haujlwm ntawm cov neeg ncig xyuas ncig xyuas

Tus neeg ncig xyuas muab ntau yam kev pabcuam mus ncig thiab ua kom yooj yim rau kev tshwj tseg cov kev pabcuam hauv lwm lub nroog thiab lub tebchaws, ua haujlwm rau cov haujlwm no. Nyob rau hauv lub tshav pob ntawm tourism kev pab cuam, nws occupies ib tug tshwj xeeb niche. Hauv tsab xov xwm peb yuav txiav txim siab txog hom kev ua ub no ntawm cov neeg ncig xyuas

Txoj kev tsheb ciav hlau yog Txhais, tswvyim, yam ntxwv thiab qhov ntev. Tsheb ciav hlau qhov ntev thiab cov yam ntxwv ntawm cov chaw khiav haujlwm

Kev mus los ntawm tsheb ciav hlau hla lub nroog thiab cov nroog, koj tuaj yeem kawm ntau yam nthuav thiab lom zem txog lub ntiaj teb ntawm txoj kev tsheb ciav hlau. Ntau tshaj ib zaug, cov neeg taug kev tau nug lawv tus kheej cov lus nug txog qhov twg qhov no lossis txoj kev tsheb ciav hlau coj mus? Thiab tus engineer uas tswj lub tsheb ciav hlau xav li cas thaum lub tsheb ciav hlau pib tawm lossis tuaj txog ntawm qhov chaw nres tsheb? Yuav ua li cas thiab los ntawm qhov twg cov tsheb hlau txav thiab txoj hauv kev ntawm cov khoom dov yog dab tsi?

Cov yam ntxwv thiab cov yam ntxwv ntawm cov kev pabcuam hauv tsev so, tshwj xeeb thiab cov ntsiab lus

Kev lag luam tsev so yog ib ceg ntawm kev tos txais qhua. Cov ntsiab lus thiab cov yam ntxwv ntawm cov kev pabcuam hauv tsev so raws li cov khoom lag luam ntawm lub tsev so yog vim muaj kev lag luam zoo ntawm cov lag luam kev lag luam uas xav tau ntawm cov neeg siv khoom uas xav tau cov xwm txheej tsim nyog rau kev pab thiab khoom noj

Yam koj yuav tsum tau ua haujlwm hauv tsheb tavxij: cov ntaub ntawv tsim nyog thiab cov cai, cov cai thiab kev cai lij choj. Cov lus teb thiab cov lus qhia los ntawm cov neeg tsav tsheb tavxij, cov neeg siv khoom thiab cov neeg xa khoom

Raws li ntau tus neeg caij tsheb, txoj haujlwm ntawm tus tsav tsheb tavxij yog qhov yooj yim tshaj plaws. Koj zaum, mloog suab paj nruag zoo nkauj thiab tsav tsheb rov qab los. Thiab lawv muab nyiaj rau koj. Tab sis qhov no tsuas yog sab nraud ntawm lub npib. Qhov rov qab yog ntau dua rosy. Peb yuav tham txog nws hauv kab lus no. Thiab peb tseem yuav qhia txog yam koj xav tau ua haujlwm hauv tsheb tavxij