2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2024-01-02 13:55

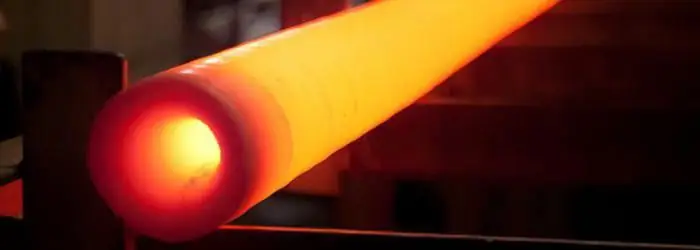

Tsim cov ntaub ntawv tshiab thiab tswj lawv cov khoom yog kos duab ntawm cov cuab yeej hlau. Ib qho ntawm nws cov cuab yeej yog kev kho cua sov. Cov txheej txheem no ua rau nws muaj peev xwm hloov tau cov yam ntxwv thiab, raws li, thaj chaw ntawm kev siv cov alloys. Steel annealing yog ib qho kev xaiv dav siv los tshem tawm cov khoom tsis xws luag hauv cov khoom, ua kom lawv lub zog thiab kev ntseeg tau.

Txoj haujlwm ua haujlwm thiab nws ntau yam

Kev ua haujlwm Annealing yog ua nrog lub hom phiaj ntawm:

- kev ua kom zoo ntawm cov qauv intracrystalline, xaj ntawm cov ntsiab lus alloying;

- txo qis kev cuam tshuam sab hauv thiab kev ntxhov siab vim cov txheej txheem kub hloov pauv sai;

- nce ntxiv ntawm cov khoom siv rau kev txiav tom ntej.

Lub lag luam classic hu ua "tag nrho annealing", txawm li cas los xij, muaj ntau yam ntawm nws ntau yam, nyob ntawm seb cov khoom thiab cov yam ntxwv ntawm cov dej num: ua tsis tiav, qis, diffusion (homogenization),isothermal, recrystallization, normalization. Tag nrho cov ntawm lawv zoo ib yam, txawm li cas los xij, hom kev kho cua sov ntawm cov hlau sib txawv heev.

kho cua sov raws li daim duab

Txhua qhov kev hloov pauv hauv ferrous metallurgy, uas yog raws li qhov kev ua si ntawm qhov kub thiab txias, kom meej meej sib haum rau daim duab ntawm hlau-carbon alloys. Nws yog ib qho kev pab cuam rau kev txiav txim siab microstructure ntawm carbon steels lossis cam khwb cia hlau, nrog rau cov ntsiab lus ntawm kev hloov pauv ntawm cov qauv thiab lawv cov yam ntxwv nyob rau hauv lub zog ntawm cua sov los yog txias.

Hlau tshuab tswj txhua hom kev tshem tawm cov pa roj carbon steel nrog lub sijhawm no. Rau qhov tsis tiav, qis, thiab tseem rau recrystallization, qhov "pib" kub qhov tseem ceeb yog PSK kab, uas yog nws cov ntsiab lus tseem ceeb Ac1. Tag nrho annealing thiab normalization ntawm hlau yog thermally taw qhia rau GSE daim duab kab, nws cov ntsiab lus tseem ceeb Ac3 thiab Acm. Daim duab kos kuj tseem qhia meej txog kev sib txuas ntawm qee yam kev kho cua sov nrog cov khoom siv hauv cov ntsiab lus ntawm cov pa roj carbon monoxide thiab muaj peev xwm sib xws ntawm nws qhov kev siv rau ib qho alloy.

Cov khoom: castings thiab forgings los ntawm hypoeutectoid alloy, thaum cov hlau muaj pes tsawg leeg yuav tsum sau cov pa roj carbon ntau txog 0.8%.

Target:

- qhov kev hloov pauv siab tshaj plaws hauv microstructure tau los ntawm kev casting thiab kub siab, nqa cov inhomogeneous coarse-grained ferrite-pearlite muaj pes tsawg leeg rau hauv homogeneous nplua-grained;

- txo hardness thiab nce ductility rau kev ua haujlwm ntxivtxiav.

Technology. Lub annealing kub ntawm steel yog 30-50˚С siab tshaj qhov tseem ceeb point Ac3. Thaum cov hlau ncav cuag cov yam ntxwv thermal, lawv tau khaws cia ntawm qib no rau qee lub sijhawm, uas tso cai rau ua kom tiav tag nrho cov kev hloov pauv tsim nyog. Loj pearlitic thiab ferritic nplej tag nrho hloov mus rau hauv austenite. Cov theem tom ntej yog qeeb txias ua ke nrog rau lub qhov cub, thaum lub sij hawm uas ferrite thiab pearlite tau rov sib cais los ntawm austenite, uas muaj cov nplej zoo thiab cov qauv zoo sib xws.

Kev ua tiav ntawm cov hlau tso cai rau tshem tawm cov teeb meem sab hauv nyuaj tshaj plaws, txawm li cas los xij, nws ntev heev thiab lub zog siv zog.

Kev tsis tiav

Yam khoom: hypoeutectoid steels yam tsis muaj qhov tsis sib haum xeeb sab hauv.

Lub Hom Phiaj: Sib tsoo thiab muag cov nplej pearlite, tsis hloov lub hauv paus ferritic.

Technology. Cua sov cov hlau kom kub poob hauv lub caij nyoog ntawm cov ntsiab lus tseem ceeb Ac1 thiab Ac3. Kev nthuav tawm ntawm qhov khoob hauv qhov cub nrog cov yam ntxwv ruaj khov pab ua kom tiav cov txheej txheem tsim nyog. Txias yog ua kom maj mam, ua ke nrog lub qhov cub. Ntawm cov zis, tib lub pearlite-ferrite nplua-grained qauv tau txais. Nrog xws li thermal nyhuv, pearlite hloov mus rau hauv nplua-grained, thaum ferrite tseem tsis hloov pauv crystalline, thiab tsuas tuaj yeem hloov cov qauv, kuj sib tsoo.

Tsis tiav annealing ntawm steel tso cai rau koj kom sib npaug ntawm lub xeev sab hauv thiab cov khoom ntawm cov khoom yooj yim, nws tsis tshua muaj zog.

Tsawg annealing(recrystallization)

Cov khoom: txhua hom dov carbon steel, alloy steel nrog cov ntsiab lus carbon nyob rau hauv 0.65% (piv txwv li, pob bearings), qhov chaw thiab qhov khoob ua los ntawm cov hlau tsis muaj hlau uas tsis muaj qhov tsis zoo sab hauv, tab sis xav tau Kev kho lub zog qis.

Target:

- tshem tawm cov kev ntxhov siab sab hauv thiab tawv vim yog qhov cuam tshuam ntawm ob qho tib si txias thiab kub deformation;

- tshem tawm qhov tsis zoo ntawm qhov tsis sib xws ntawm cov qauv welded, ua kom cov yas thiab lub zog ntawm cov seams;

- ua rau microstructure ntawm cov khoom tsis yog hlau metallurgy zoo ib yam;

- spheroidization ntawm lamellar pearlite - muab nws cov duab granular.

Technology.

Cov khoom yog rhuab 50-100˚C hauv qab qhov tseem ceeb Ac1. Raws li kev cuam tshuam ntawm cov kev cuam tshuam no, cov kev hloov me me sab hauv raug tshem tawm. Tag nrho cov txheej txheem thev naus laus zis yuav siv li 1-1.5 teev. Kwv yees qhov ntsuas kub rau qee yam khoom siv:

- Carbon steel thiab tooj liab alloys - 600-700˚C.

- Nickel alloys - 800-1200˚C.

- Aluminium alloys - 300-450˚C.

Cov ua tiav hauv huab cua. Rau martensitic thiab bainitic steels, hlau tshuab muab ib lub npe txawv rau cov txheej txheem no - siab tempering. Nws yog ib txoj hauv kev yooj yim thiab pheej yig los txhim kho cov khoom ntawm cov khoom thiab cov qauv.

YHomogenization (diffusion annealing)

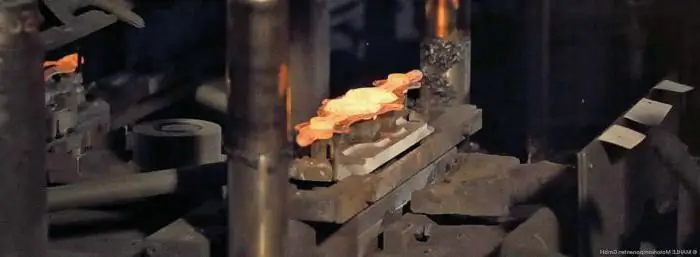

Cov khoom: cov khoom lag luam loj loj, tshwj xeeb tshaj yog castingshlau alloy.

Lub Hom Phiaj: kev faib tawm ntawm cov atoms ntawm cov ntsiab lus alloying hla cov khoom siv lead ua lattices thiab tag nrho cov ntim ntawm cov ingot vim yog qhov kub thiab txias; softening tus qauv ntawm lub workpiece, txo nws hardness ua ntej ua hauj lwm technologies.

Technology. Cov khoom yog rhuab mus rau qhov kub thiab txias ntawm 1000-1200˚С. Cov yam ntxwv ruaj khov thermal yuav tsum tau khaws cia rau lub sijhawm ntev - txog 10-15 teev, nyob ntawm qhov loj thiab qhov nyuaj ntawm cov qauv cam khwb cia. Tom qab ua tiav ntawm txhua theem ntawm kev hloov pauv ntawm qhov kub thiab txias, qeeb txias ua raws li.

Ib lub zog siv zog tab sis cov txheej txheem ua haujlwm tau zoo heev rau kev txhim kho microstructure ntawm cov qauv loj.

Isothermal annealing

Yam khoom: cov ntawv carbon steel, alloy thiab cov khoom siab alloy.

Lub Hom Phiaj: Txhim kho microstructure, tshem tawm cov teeb meem sab hauv nrog lub sijhawm tsawg.

Technology. Cov hlau yog pib rhuab mus rau tag nrho cov annealing kub thiab lub sij hawm yuav tsum tau rau transformation ntawm tag nrho cov uas twb muaj lawm qauv rau hauv austenite yog tswj. Tom qab ntawd maj mam txias los ntawm immersion nyob rau hauv kub ntsev. Thaum ncav cuag qhov cua sov ntawm 50-100˚C hauv qab ntawm Ac1 taw tes, nws tau muab tso rau hauv lub cub tawg txhawm rau tswj nws ntawm qib no rau lub sijhawm tsim nyog rau kev hloov pauv ntawm austenite tiav. nyob rau hauv pearlite thiab cementite. Qhov kawg qhov txias yuav tshwm sim hauv huab cua.

Txoj kev tso cai rau koj kom ua tiav cov khoom tsim nyog ntawm cov hlau tsis muaj hlau, thaum txuag lub sijhawm, piv nrog tag nrhokev lom zem.

Normalization

Cov khoom: castings, forgings thiab qhov chaw ua los ntawm cov pa roj carbon tsawg, cov pa roj carbon nruab nrab thiab cov hlau tsis tshua muaj hlau.

Lub Hom Phiaj: txhawm rau txhim kho lub xeev sab hauv, muab qhov xav tau hardness thiab lub zog, txhim kho lub xeev sab hauv ua ntej cov theem tom ntej ntawm kev kho cua sov thiab txiav.

Technology. Cov hlau yog rhuab mus rau qhov kub thiab txias me ntsis saum GSE kab thiab nws cov ntsiab lus tseem ceeb, tuav thiab txias hauv huab cua. Yog li, qhov ceev ntawm kev ua tiav ntawm cov txheej txheem nce. Txawm li cas los xij, siv cov txheej txheem no, nws tuaj yeem ua tiav cov qauv kev sib haum xeeb tsuas yog thaum cov hlau muaj pes tsawg leeg txiav txim siab los ntawm cov pa roj carbon monoxide tsis ntau tshaj 0.4%. Nrog rau qhov nce ntawm cov pa roj carbon ntau, qhov nce hauv hardness tshwm sim. Tib steel tom qab normalization muaj ib tug ntau dua hardness nrog rau tus sib npaug spaced zoo nplej. Cov txheej txheem tso cai rau ua kom muaj kev tiv thaiv ntawm alloys rau kev puas tsuaj thiab ductility ntawm txiav.

Yuav ua li cas tshem tawm qhov tsis xws luag

Thaum lub sijhawm ua haujlwm ntawm kev kho cua sov, nws yog ib qho tsim nyog yuav tsum tau ua raws li cov qauv teev ntawm cov cua sov thiab cua txias. Nyob rau hauv rooj plaub ntawm kev ua txhaum cai, ntau yam tsis xws luag yuav tshwm sim.

- Oxidation ntawm txheej txheej thiab tsim cov nplai. Thaum lub sijhawm ua haujlwm, cov hlau kub reacts nrog atmospheric oxygen, uas ua rau tsim cov nplai ntawm qhov chaw ntawm lub workpiece. Yuav tsum tau ntxuav mechanically los yog nrogtshuaj tshwj xeeb.

- Cov pa roj carbon hlawv. Nws kuj tshwm sim los ntawm kev cuam tshuam ntawm oxygen ntawm cov hlau kub. Kev txo qis ntawm cov pa roj carbon monoxide hauv txheej txheej ua rau txo qis hauv nws cov khoom siv tshuab thiab thev naus laus zis. Txhawm rau tiv thaiv cov txheej txheem no, steel annealing yuav tsum tau ua nyob rau tib lub sijhawm nrog kev qhia txog kev tiv thaiv roj rau hauv lub qhov cub, lub luag haujlwm tseem ceeb ntawm kev tiv thaiv kev sib cuam tshuam ntawm alloy nrog oxygen.

- Hloov kub. Nws yog qhov tshwm sim ntawm kev raug mob ntev hauv qhov cub ntawm qhov kub siab. Nws ua rau muaj kev loj hlob ntau dhau ntawm cov nplej, qhov tau txais ntawm cov qauv sib xyaw ua ke tsis sib xws, thiab nce hauv brittleness. Yuav kom kho los ntawm lwm cov kauj ruam annealing.

- Kub tawm. tshwm sim los ntawm ntau tshaj qhov tso cai qhov tseem ceeb ntawm cov cua sov thiab raug, ua rau kev puas tsuaj ntawm daim ntawv cog lus ntawm qee cov nplej, ua rau tag nrho cov qauv ntawm cov hlau thiab tsis raug kho.

Txhawm rau tiv thaiv qhov ua tsis tiav, nws yog ib qho tseem ceeb uas yuav tsum ua cov haujlwm kho cua sov kom raug, muaj kev txawj ntse thiab tswj cov txheej txheem nruj me ntsis.

Steel annealing yog cov cuab yeej siv tau zoo rau kev nqa cov microstructure ntawm txhua qhov nyuaj thiab muaj pes tsawg leeg rau cov qauv sab hauv thiab cov xwm txheej zoo, uas yuav tsum tau ua rau cov theem tom ntej ntawm thermal influences, txiav thiab muab cov qauv ua haujlwm.

Pom zoo:

Kev kho cua sov ntawm cov hlau yog txheej txheem tseem ceeb hauv kev tsim cov hlau

Kev kho cua sov ntawm cov hlau muab cov khoom hlau uas xav tau. Cov txheej txheem no yog ib kauj ruam tseem ceeb hauv kev tsim cov hlau alloy

Kev tswj hwm kev ua haujlwm zoo ntawm kev lag luam raws li kev lees paub ntawm kev txhim kho kev vam meej

Kab lus no yuav qhia koj txog qhov txiaj ntsig zoo uas qhia txog kev tswj hwm kev lag luam zoo yuav muaj thiab yuav tsum ua li cas rau qhov no

Kev kho cua sov ntawm cov hlau. Hom kev kho cua sov

Kev kho cua sov ntawm cov hlau yog qhov tseem ceeb ntawm cov txheej txheem tsim khoom ntawm ferrous thiab non-ferrous metallurgy. Raws li qhov tshwm sim ntawm cov txheej txheem no, cov hlau muaj peev xwm hloov tau lawv cov yam ntxwv rau qhov yuav tsum tau muaj. Hauv tsab xov xwm no, peb yuav txiav txim siab txog hom kev kho cua sov tseem ceeb uas siv hauv kev lag luam niaj hnub no

Cov roj cua sov ua lwm txoj hauv kev rau cov cua sov ib txwm muaj

Cov roj cua sov tau dhau los ua qhov xav tau tshaj plaws rau kev tsim hluav taws xob. Nws tsis pom zoo kom siv roj thiab hluav taws xob ua qhov chaw cua sov thiab dej. Ntxiv mus, thaum kub hnyiab, cov roj cua kub tso tawm ntau lub zog ntau dua li cov roj diesel, ua rau nws lub zog tsim nyog tshaj plaws rau cov cua sov hauv tsev

Kev tsim cov khoom cua sov. Ua-nws-koj tus kheej cua sov tiaj tus

Cov cua sov tiaj tus yog cov khoom cua sov ua los ntawm cov phaj ntawm cov khoom sib txawv. Lawv yog tsim los ntawm ib tug tej yam zoo li, txhua yam uas ua hauj lwm rau cua sov qhov chaw. Lub tiaj cua sov caij hauv nws cov qauv tsim zoo ib yam li cov roj hmab xaim txuas rau lub tsev tshwj xeeb. Nws tuaj yeem ua los ntawm hlau, ceramic lossis micanite. Cov cuab yeej no ua haujlwm ntawm qhov yooj yim 220 V mains mov