2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Steels yog cov feem ntau ntawm cov hlau siv, thiab lawv cov cim nyob ntawm kev faib pawg.

qib steel yog dab tsi

Deciphering ib hom pib nrog lub ntsiab lus ntawm nws pab pawg neeg los ntawm lub hom phiaj. Cov pawg hauv qab no ntawm cov hlau yog qhov txawv: cov qauv, kev tsim kho, cov cuab yeej, nrog cov khoom tshwj xeeb (kub-resistant, kub-resistant thiab high-strength).

Tshuab qhov chaw, cov khoom dov, cov qauv welded yog tsim los ntawm cov qauv hlau. Toolboxes, raws li lub npe implies, yog siv los tsim ib tug machining cuab tam. Ib hom tshwj xeeb ntawm cov cuab yeej steel - high-speed, lawv yog tsim los rau kev ua haujlwm ntawm cov khoom hnyav dua. Kev tsim kho steels, siv feem ntau rau cov qauv welded, muaj qis (txog li 0.25%) cov ntsiab lus carbon. Cov muaj pes tsawg leeg yog ze rau cov qauv.

Structural steels

Raws li lawv muaj pes tsawg leeg, lawv muab faib ua alloyed thiab carbonaceous, uas yog, nrog thiab tsis muaj impurities tshwj xeeb. Alloy steel yuav tsum muaj tsawg kawg yog 45% hlau. Ib qho cuab yeej tseem ceeb yog qhov muaj cov khoom txawv teb chaws uas tsis yog xim hlau impuritiesnyob rau hauv lub resulting alloy - sulfur, phosphorus thiab lwm yam. Qhov tsawg dua lawv muaj, qhov zoo dua cov hlau raug txiav txim siab. Muaj 4 pawg zoo hauv tag nrho:

| Group | Ntau tshaj plaws ntawm cov teeb meem impurities | Marking |

| Nyob zoo | 0.05 % | "St" thaum pib ntawm kev xaiv |

| Quality | 0.035 % | "Steel" ua ntej xaiv; feem ntau tsis sau |

| High Quality | 0.025 % | "A" tom kawg ntawm kev xaiv |

| Qhib High Quality | 0.015 % | "Ш" kawg ntawm kev xaiv |

Thaum kawg ntawm kev xaiv, hom alloy deoxidation tuaj yeem muab tso rau (deoxidation yog tshem tawm cov pa oxygen los ntawm cov hlau muaj pes tsawg leeg): boiling (KP), semi-quiet (PS), calm (SP). Qhov ntsuas "SP" feem ntau tsis qhia.

Hauv cov ntaub ntawv dav dav, kev txiav txim siab ntawm cov hlau uas koom nrog pawg alloyed tuaj yeem sawv cev raws li hauv qab no:

- [carbon content][alloying elements][deoxidation method][additional features], qhov twg cov ntsiab lus carbon tau sau ntau pua ntawm ib feem pua.

Alloying ntsiab yog qhia raws li ib tug ua ke ntawm lawv tsab ntawv designations thiab feem pua. Yog hais tias cov ntsiab lus hauv cov alloy tsawg dua li ib feem pua, nws qhov ntau yuav tsis qhia. Tam sim noLub sijhawm rau kev suav nrog, cov npe hauv qab no yog siv: H - nickel, X - chromium, C - silicon, titanium - T, manganese - G, Yu - aluminium, thiab lwm yam. Piv txwv li, steel 09G2S muaj 0.09% carbon, 2% manganese thiab silicon nyob rau hauv ib tug npaum li ntawm 1%. Tsis tas li ntawd, muaj qee qhov kev xaiv qib steel ntxiv, lawv qhov kev txiav txim siab yog raws li hauv qab no:

1. "Ш" thaum pib - bearing steel.

2. "L" tom kawg - foundry steel.

3. "A" thaum pib - tsis siv neeg hlau.

4. "E" thaum pib - hluav taws xob hlau.

Cais faib cov qib tsev steel. Kev txiav txim siab zoo li no: thaum pib tsab ntawv "C" tau muab tso rau, tom qab ntawd qhia tias lub zog tawm los. Tsab ntawv "K" txhais tau hais tias ib qho txawv ntawm cov tshuaj muaj pes tsawg leeg, "T" - thermal hardening.

Kev kos cov hlau nrog cov khoom tshwj xeeb zoo ib yam li kev kos cov qauv hlau alloyed.

Tshooj steels

Tsab ntawv "Y" yog muab tso ua ntej lub npe, ua raws li qhov feem ntawm cov pa roj carbon (qhov tsawg kawg nkaus ntawm carbon yuav tsum yog tsawg kawg yog 0.7%). Cov cuab yeej steel, zoo li cov qauv hlau, tau muab faib ua carbon thiab alloy steels, tab sis lawv tsuas muaj 2 pawg zoo - cov khoom zoo thiab cov khoom zoo. Hauv qhov thib ob, tsab ntawv "A" tau muab tso rau hauv lub npe ntawm qhov kawg ntawm kev xaiv. Tsab ntawv "G" qhia txog cov ntsiab lus ntxiv ntawm manganese. Kev txiav txim siab ntawm cov qib steel muaj feem xyuam rau cov cuab yeej high-speed txiav yog qhov txawv me ntsis. Nyob rau hauv thawj qhov chaw yoglub npe ntawm tag nrho cov pab pawg neeg yog tsab ntawv "P" (los ntawm lo lus Askiv "ceev" - ceev), ces tus nqi ntawm lub ntsiab alloying tivthaiv - tungsten yog qhia (nws tsab ntawv xaiv raug tshem tawm).

Qhia txog txoj kev tsim cov hlau

Rau cov khoom zoo siab, cov txheej txheem steel qib ntau lawm yog qhia nyob rau qhov kawg ntawm kev tsim, kev rhuav tshem ntawm cov txheej txheem tsim khoom tau nthuav tawm hauv qab no. Cov lej no tau muab tso rau ntawm qhov kawg ntawm kev xaiv: VD - nqus-arc; Ш - electroslag; EL - electron nqaj; VI - nqus induction.

Pom zoo:

Credit thiab kev koom tes ntawm cov neeg siv khoom: kev tawm tswv yim los ntawm cov neeg tso nyiaj, cov npe, cov lus piav qhia ntawm cov kev pabcuam

Credit-consumer cooperative - ib qho kev xaiv rau cov tsev txhab nyiaj thiab microloans. CCP tau nyob rau hauv kev lag luam nyiaj txiag hauv Lavxias rau ntau tshaj 15 xyoo, tab sis cov pej xeem ceev faj txog lawv cov dej num. Kev tshuaj xyuas cov credit thiab cov neeg siv khoom koom tes, uas nyiam cov neeg Lavxias, yuav tso cai rau cov neeg siv khoom tshiab los kawm txog cov haujlwm ntawm CPC, qhov zoo thiab qhov tsis zoo ntawm kev koom tes hauv kev koom tes hauv Lavxias Federation

Tus kws qhia ntawv qib siab hauv tsev kawm qib siab: hauj lwm piav qhia, lub luag haujlwm thiab cov yam ntxwv ntawm kev ua haujlwm

Rector, Dean, Professor, Associate Professor… Yog koj yog ib tug tub kawm, cov lus no yuav ua rau muaj kev xav thiab xav tsis thoob. Thiab nws nyuaj heev los piav cov ntsiab lus no rau "tus neeg tsis yog menyuam kawm ntawv". Txawm li cas los xij, ntau tus neeg tsis nco qab txog ib txoj haujlwm ntxiv uas nyob hauv txhua lub tsev kawm ntawv - tus kws qhia ntawv laus

Dab tsi yog qhov nyiaj thiab kev pov hwm ib feem ntawm cov nyiaj laus? Lub sij hawm rau kev hloov ntawm cov nyiaj tau los ntawm cov nyiaj laus. Qhov twg ntawm cov nyiaj laus yog kev tuav pov hwm thiab qhov twg yog nyiaj

Hauv tebchaws Russia, kev hloov pauv nyiaj laus tau siv sijhawm ntev, me ntsis dhau kaum xyoo. Txawm li cas los xij, ntau tus pej xeem ua haujlwm tseem tsis tuaj yeem nkag siab tias qhov nyiaj tau los thiab kev pov hwm ntawm cov nyiaj laus yog dab tsi, thiab yog li ntawd, qhov kev nyab xeeb npaum li cas tos lawv thaum laus. Txhawm rau kom nkag siab txog qhov teeb meem no, koj yuav tsum tau nyeem cov lus qhia hauv kab lus

Yuav ua li cas thiaj paub koj qhov kev pov hwm kev pov hwm? Kev tuav pov hwm yog dab tsi thiab nws suav nrog dab tsi? Kev suav ntawm kev pov hwm kev paub

Hauv tebchaws Russia, txhua tus tau siv sijhawm ntev rau cov lus "kev hloov pauv nyiaj laus", tsis ntev los no, yuav luag txhua xyoo, tsoomfwv tau hloov qee yam kev cai lij choj. Cov pej xeem tsis muaj sijhawm los ua raws li txhua qhov kev hloov pauv, tab sis kev paub txog hauv cheeb tsam no yog qhov tseem ceeb, sai lossis tom qab ib tus pej xeem raug yuam kom nug nws tus kheej li cas txhawm rau nrhiav nws cov ntaub ntawv pov hwm thiab thov nyiaj laus

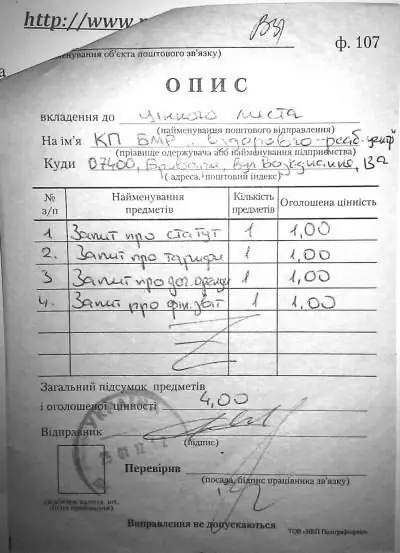

Daim ntawv sau npe nrog cov lus piav qhia txuas ntxiv. Cov txheej txheem xa ib tsab ntawv sau npe nrog cov lus piav qhia ntawm qhov txuas

Nyob hauv lub hnub nyoog ntawm computer technology, tib neeg sau ntawv rau ib leeg tsawg thiab tsawg. Tej zaum nws yuav zoo li tias nyob rau yav tom ntej xws li lub koom haum raws li lub chaw xa ntawv feem ntau yuav dhau los lawm. Tab sis nyob rau hauv kev muaj tiag no yog deb ntawm rooj plaub. Feem ntau, nws yooj yim ua tsis tau yam tsis muaj kev xa ntawv xa mus. Hauv tsab xov xwm no, peb yuav xav txog cov txheej txheem rau xa ib tsab ntawv sau npe nrog cov lus piav qhia txuas ntxiv. Wb kuj tham txog tias tsab ntawv yuav siv sij hawm ntev npaum li cas, thiab tus nqi pabcuam li cas