2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Tej zaum, txhua tus neeg, txawm tias nyob deb tshaj plaws ntawm kev lag luam, tsawg kawg ntawm lub kaum ntawm nws pob ntseg hnov txog cov khoom zoo ntawm high-speed steel P18. Nws yog rumored los ua ib tug super-nyuaj alloy muaj peev xwm ntawm kev txiav, drilling los yog lwm yam ua hauj lwm lwm yam qib ntawm steel. Ntxiv nrog rau cov yam ntxwv ntawm lub zog, kev kub ceev 18th steel muaj nuj nqis heev los ntawm cov kws ua hlau, cov tuam txhab riam hauv tsev thiab riam phom edged. Puas yog P18 steel tsim nyog tus cwj pwm zoo li no, lossis puas yog txhua yam peb paub txog nws tsuas yog kev tshaj tawm, uas yog, yog li hais, lus dab neeg pej xeem? Kab lus yuav teb lo lus nug no.

GOST

Ua ntej, koj yuav tsum xa mus rau cov ntaub ntawv qhia kev muaj. Hauv qhov no, nws yuav yog GOST raws li tus lej 19265-73. Nyob rau hauv nws, peb feem ntau nyiam nyob rau hauv cov npe ntawm tag nrho cov alloying ntsiab muaj nyob rau hauv lub alloy, thiab lawv loj feem, ntawm chav kawm, nyob rau hauv feem pua.

P18 steelmuaj cov tshuaj lom neeg hauv qab no.

- Carbon, uas muab nws hardness thiab lub zog - los ntawm 0.7 mus rau 0.8 feem pua.

- Manganese thiab silicon, uas ua rau kom hnav tsis kam thiab lub zog ntawm cov hlau tsis txo cov tawv nqaij - los ntawm 0.2 txog 0.5 feem pua.

- Chromium, uas txhim kho corrosion kuj thiab tag nrho lub zog, yog tam sim no ntawm 3.8-4.4 feem pua ntawm tag nrho qhov hnyav.

- Tungsten yog lub ntsiab alloying tivthaiv rau txhua qhov kev kub ceev steel, ua kom muaj zog, txiav cov khoom thiab kub ua haujlwm. Cov alloy muaj 17 mus rau 18.5 feem pua.

- Vanadium, uas ua rau kom muaj zog ntawm cov hlau, muaj li ntawm 1-1.4 feem pua.

- Qhov sib ntxiv ntawm cob alt hauv qhov nyiaj ntawm 0.5 feem pua ntawm tag nrho cov huab hwm coj kuj muaj txiaj ntsig zoo rau kev txiav cov khoom thiab lub zog ntawm cov hlau.

- Ntawm lwm yam, ib feem pua molybdenum tau ntxiv rau cov khoom sib xyaw ntawm cov hlau, uas pab kom nws ua nyuaj dua thiab tib lub sijhawm ua kom nws cov cua sov ua haujlwm thiab txiav cov khoom.

- Nickel nyob rau hauv tus nqi ntawm 0.6 feem pua nyob rau hauv lub ligature muaj pes tsawg leeg yog tam sim no nyob rau hauv thiaj li yuav sib npaug cov hlau, muab nws ductility thiab elasticity, raws li zoo raws li nce hardenability.

Txawm li cas los xij, txawm tias nyob rau hauv cov hlau tsis txaus nrog cov hlau alloying, muaj "cov kab tsuag" nyob rau hauv daim ntawv ntawm cov impurities me ntawm tooj liab - 0.25 feem pua, phosphorus thiab sulfur - 0.3 feem pua.

P18 steel: khoom yam ntxwv

Tom tau kawm tag nrho cov npe ntawm cov hlau alloying, nws yooj yim dua rau peb kom nkag siab txog qhov txwv ntawm nws lub peev xwm. Thiab, raws li nws muab tawm, steel qib R18muaj peev xwm heev. Vim muaj cov ntsiab lus siab ntawm tungsten nrog ntxiv ntawm cob alt, molybdenum thiab vanadium, cov alloy yog endowed nrog siab ceev, zuag qhia tag nrho hardness, thiab tshav kub kuj. Txawm li cas los xij, ntau tus neeg paub tias cov alloys nyuaj yog qhov ua rau tsis ua haujlwm hauv kev ntxhov siab dua li lwm tus. Hauv qhov no, P18 steel tau txais kev cawmdim los ntawm manganese, silicon, npib tsib xee thiab cov pa roj carbon tsawg. Yog li, nws dhau los ua kom sib npaug thiab tiv taus kev puas tsuaj thiab hnav. Nws yog cov khoom zoo uas yog qhov tseem ceeb rau cov hlau siv hauv kev tsim cov cuab yeej txiav rau kev ua hlau.

Daim ntawv thov

Peb twb tau pom zoo tias P18 steel yog siv rau kev tsim cov cuab yeej txiav, tab sis nws yuav tsim nyog dua los muab koj cov npe ntawm cov khoom tsim los ntawm cov hlau no, txawm tias tsis yog ib qho tiav. Cov npe muaj:

- drills (tsuas yog rau hlau);

- sweep;

- kab rau hauv xov;

- Dies rau lwm threading;

- cutters rau hlau lathes;

- sinks;

- broaches;

Txawm li cas los xij, koj yuav tsum ceev faj heev, vim P18 yog cov hlau kim, thiab nws tsis tas siv. Yog li saib cov cim ib zaug ntxiv.

Kev

P18 steel, tus yam ntxwv thiab daim ntawv thov uas peb twb tau tham hauv cov ncauj lus kom ntxaws saum toj no, kuj tseem tuaj yeem txaus siab ua cov khoom siv raukev tsim khoom ntawm ntau yam khoom siv hauv tsev, tshwj xeeb yog riam, chisels, chisels, chisels, feem ntau, txhua yam uas yog yam tsawg kawg yog npaj rau kev txiav ua haujlwm. Thiab txhawm rau ua kom lub neej yooj yim dua rau cov kws ntaus hlau thiab cov kws tsim riam, peb yuav txiav txim siab nthuav dav tag nrho cov txheej txheem thev naus laus zis hauv kev tsim cov khoom zoo li no.

- Kub txoj hauv kev rau forging khoom - 1 280-900 ° C. Txawm li cas los xij, vim yog thawj qhov ntom ntawm cov khoom, forging steel yog teeb meem heev. Nws yuav siv sijhawm thiab siv zog ua qhov no.

- Hardening yuav xav kom cov hniav yuav tsum tau preheated rau 800 ° C, ua raws li lub ntsiab cua sov mus rau ib tug tempering kub ntawm 1280 ° C. P18 yog hardened nkaus xwb nyob rau hauv cov roj rhuab mus rau 200 ° C, tom qab ntawd nws txias nyob rau hauv huab cua.

- Hnub so yog ua ntawm qhov kub ntawm 400 ° C rau ib teev, tab sis peb zaug. Qhov kawg hardness ntawm cov khoom yuav nyob ib ncig ntawm 62 units ntawm Rockwell scale.

Analogues hom

Kuv xav tso ob peb lo lus kawg yog tias koj dheev pom koj tus kheej sab nraum ciam teb ntawm peb lub teb chaws loj, thiab koj xav tau ib yam dab tsi sai sai. Hauv qhov no, nws yog qhov zoo dua kom paub koj tus kheej nrog cov analogues ntawm P18 hauv kev lag luam txawv teb chaws.

- United States - T1.

- Europe - 1, 3355 lossis HS18-0-1.

- Japan – SKH2.

- England - BT1.

- Tuam Tshoj - W18Cr4V.

daim ntawv teev npe no tsuas muaj ib feem me me ntawm cov paub analogues ntawm P18 steel. Tab sis txawm nws yuav txaus los nrhiav qhov koj xav tau yog tias tsim nyog.

Pom zoo:

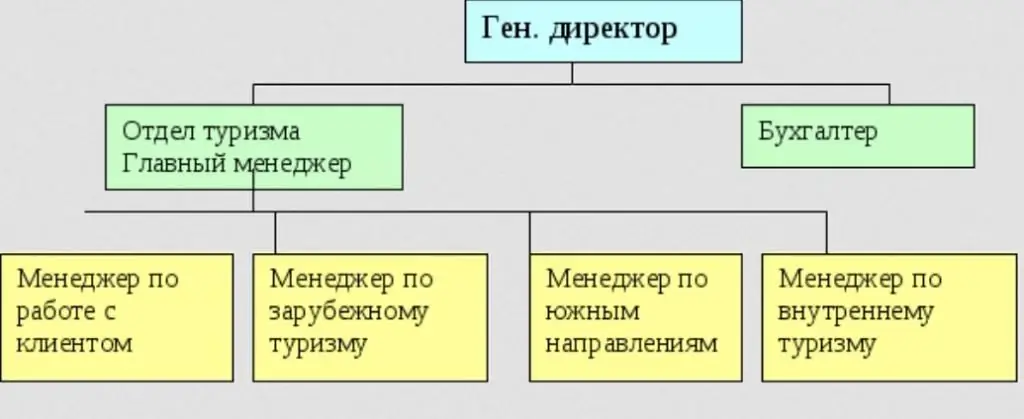

Hom kev ncig xyuas thiab lawv cov yam ntxwv. Kev ua haujlwm thiab cov yam ntxwv ntawm cov haujlwm ntawm cov neeg ncig xyuas ncig xyuas

Tus neeg ncig xyuas muab ntau yam kev pabcuam mus ncig thiab ua kom yooj yim rau kev tshwj tseg cov kev pabcuam hauv lwm lub nroog thiab lub tebchaws, ua haujlwm rau cov haujlwm no. Nyob rau hauv lub tshav pob ntawm tourism kev pab cuam, nws occupies ib tug tshwj xeeb niche. Hauv tsab xov xwm peb yuav txiav txim siab txog hom kev ua ub no ntawm cov neeg ncig xyuas

Txoj kev tsheb ciav hlau yog Txhais, tswvyim, yam ntxwv thiab qhov ntev. Tsheb ciav hlau qhov ntev thiab cov yam ntxwv ntawm cov chaw khiav haujlwm

Kev mus los ntawm tsheb ciav hlau hla lub nroog thiab cov nroog, koj tuaj yeem kawm ntau yam nthuav thiab lom zem txog lub ntiaj teb ntawm txoj kev tsheb ciav hlau. Ntau tshaj ib zaug, cov neeg taug kev tau nug lawv tus kheej cov lus nug txog qhov twg qhov no lossis txoj kev tsheb ciav hlau coj mus? Thiab tus engineer uas tswj lub tsheb ciav hlau xav li cas thaum lub tsheb ciav hlau pib tawm lossis tuaj txog ntawm qhov chaw nres tsheb? Yuav ua li cas thiab los ntawm qhov twg cov tsheb hlau txav thiab txoj hauv kev ntawm cov khoom dov yog dab tsi?

Hlau 40ХН: yam ntxwv, GOST thiab analogues

Hmoov tsis zoo, tshawb txog Is Taws Nem loj hauv kev tshawb nrhiav cov ntsiab lus yooj yim thiab nkag siab ntawm cov ntsiab lus ntawm cov qauv hlau thiab cov hlau hauv cov ntsiab lus, qhov zoo tshaj plaws, koj yuav pom ob peb nqe lus uas tsis muaj kev nkag siab ntau. Hauv lwm qhov xwm txheej, cov ntaub ntawv tau muab rau hauv daim ntawv yooj yim clippings los ntawm cov ntaub ntawv tswj hwm, qhov twg tag nrho cov ntaub ntawv yuav raug muab rau hauv daim ntawv ntawm kev tsis paub txog kev tshawb fawb thiab kev sau ntawv thiab cov npe

Cov yam ntxwv thiab cov yam ntxwv ntawm cov kev pabcuam hauv tsev so, tshwj xeeb thiab cov ntsiab lus

Kev lag luam tsev so yog ib ceg ntawm kev tos txais qhua. Cov ntsiab lus thiab cov yam ntxwv ntawm cov kev pabcuam hauv tsev so raws li cov khoom lag luam ntawm lub tsev so yog vim muaj kev lag luam zoo ntawm cov lag luam kev lag luam uas xav tau ntawm cov neeg siv khoom uas xav tau cov xwm txheej tsim nyog rau kev pab thiab khoom noj

Steel 20X13: yam ntxwv, daim ntawv thov thiab analogues

Kab lus no yog cov lus piav qhia luv luv ntawm tag nrho cov yam ntxwv ntawm cov hlau 20X13: cov yam ntxwv, daim ntawv thov, cov khoom, hloov pauv thiab txawv teb chaws analogues. Kab lus no yuav muaj txiaj ntsig zoo rau cov neeg uas xav paub txog cov ntaub ntawv tseem ceeb tshaj plaws ntawm cov ncauj lus no hauv lub sijhawm luv luv yam tsis muaj sijhawm nkim sijhawm