2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Metallurgy yog ib ceg tseem ceeb ntawm kev tsim khoom niaj hnub no. Nws yog ua tsaug rau nws tias colossal nyiaj txiag cov nyiaj tau los mus rau lub xeev pob nyiaj siv, vim steel thiab hlau cov khoom, raws li ib tug txoj cai, yog exported thiab tsim lub txawv teb chaws cov nyiaj khwv tau los ntawm cov nroj tsuag los yog cog nws tus kheej thiab lub teb chaws. Muaj ntau yam kev lag luam metallurgical, lub voj voog ua haujlwm uas tuaj yeem ua tiav tag nrho thiab tsis tiav. Tab sis nyob rau hauv txhua rooj plaub, theem kawg ntawm lub voj voog metallurgical yuav yog qhov dov ntawm cov hlau thiaj li yuav tau txais qhov profile xav tau rau cov neeg siv khoom. Nws yog nyob rau hauv lub khw dov uas kab teeb, raws, rails thiab thiaj li nyob. Rolls yog cov ntsiab lus tseem ceeb ntawm txhua lub tshuab dov. Cov nroj tsuag ntawm cov metallurgical complex yog yooj yim unthinkable yam tsis muaj lawv, yog li peb yuav tham txog rolls kom meej nyob rau hauv tsab xov xwm no.

Kev piav qhia dav dav

Hlau dov yog qhov nyuaj, lub zog siv zog ua haujlwm uas yuav tsum muaj kev txawj tshwj xeeb thiab kev paub los ntawm cov neeg ua haujlwm. Compression ntawm cov khoom, uas ua rau ib tug yob yob, tso cai rau koj mus cuag tej qhov ntev ntawm cov txheej txheem profile. Nws yog ib qho tseem ceeb kom paub tias cov yob nyob rau hauv cov txheej txheem ntawm lawv cov hauj lwm coj ib tug impressive quab yuam uas tshwm sim ncaj qha nyob rau hauv tus txheej txheem ntawm tag nrho cov dov kab. Yog vim li casRolling yob yog qhov hnav tshaj plaws ntawm txhua lub tshuab dov.

Txuas thiab Nta

Txhua yob muaj peb lub ntsiab, suav nrog:

- Barrel yob. Nws yog nws uas yog nyob rau hauv kev sib cuag ncaj qha nrog kub thiab tiav hlau. Lub thoob muaj ob lub ntsiab linear tsis - ntev (L) thiab txoj kab uas hla (ØD).

- Necks (cov kabmob qhov chaw) - nyob rau ntawm ob sab ntawm lub thoob thiab so ntawm cov yob bearings. Kuj muaj qhov ntev thiab txoj kab uas hla.

- Drive kawg.

Rau lub tshuab dov, cov ntsuas tseem ceeb yog: nominal txoj kab uas hla, caj dab txoj kab uas hla thiab txoj kab uas hla ua haujlwm. Qhov twg cov yob yuav tsum tau tig los ntawm ib tug universal hom spindle, nws tsav kawg yuav nyob rau hauv daim ntawv ntawm ib tug hniav los yog ib lub tog raj kheej. Qhov kawg tsav yuav muaj hom ntoo khaub lig yog tias yob tig nrog lub club (yuav tsum tau sib txuas nruab nrab).

yob rau daim hlau

Daim ntawv dov yob, kev tsim khoom uas yog cov txheej txheem ua haujlwm nyuaj, ua dov ntawm strips thiab strips. Lub thoob ntawm cov yob no yog du, ua nyob rau hauv ib tug cylindrical zoo.

Section yob yog siv los tsim cov khoom zoo li tus, uas tuaj yeem muaj ob qho tib si puag ncig thiab square seem (I-beams, fab).

Cov yob ntawm cov yob yob yog ua rau me ntsis convex yog tias lawv npaj rau txias dov ntawm cov ntawv nyias. ATHauv lwm qhov xwm txheej, rau qhov kub dov, lub thawv yob tau muab cov duab concave. Qhov no yog ua tiav vim hais tias thaum lub sij hawm cov hlau txav raws lub yob, lub chim yuav sov thiab ncaj.

yob rau cov khoom ntev

Lub thoob ntawm cov yob no muaj qhov tshwj xeeb recesses (kwj), uas rov ua cov profile ntawm cov hlau tom qab dov. Cov kwj ntawm ib khub yob, thaum txuas rau ib leeg, tsim ib lub caliber. Lub chim ntev ntawm cov yob profiled nyob ntawm qhov dav ntawm lub dov workpiece thiab qhov loj me.

Cov yob mos yog tus cwj pwm los ntawm nominal txoj kab uas hla thiab chim ntev. Yog hais tias lub zeb muaj ntau qhov sawv ntsug thiab yob ntawm cov kab sib txawv, ces txoj kab uas hla ntawm cov dov sawv ntsug yuav yog qhov tseem ceeb.

Raws li lub hom phiaj, ntau yam yob tau muab faib raws li hauv qab no:

- Rau qhov hnyav swaging mills.

- Rau qhov hnyav thiab cov kab hluav taws xob rail.

- Rau qhov nruab nrab.

- Rau qhov me me.

- Rau hlau mills.

- rau sawb mills.

Centrifugal casting

Niaj hnub tsim cov yob raws li ib txoj hauv kev tseem ceeb suav nrog txoj hauv kev ntawm centrifugal casting. Txoj kev no yog kim heev, tab sis nws tag nrho tso cai rau compact mus rau qhov siab tshaj plaws ntawm cov qauv ntawm cov hlau ntawm lub sab nrauv, uas yog ib tug ua hauj lwm ntawm lub yob. Txoj hauv kev no tuaj yeem ua kom lub neej kev pab cuam ntawm cov khoom lag luam nce ntxiv.

Rau txoj kev no, siv lub tshuab tshwj xeeb, uas muaj kab rov tav axis ntawm kev sib hloov ntawm daim ntawvcentrifugal casting. Daim ntawv nws tus kheej yog mounted ntawm kev txhawb nqa rollers. Cov tsav chais yog mounted nyob rau hauv xws li ib txoj kev uas lawv tag nrho kom lub synchronization ntawm cov txheej txheem kev sib hloov. Cov menyuam kev nyab xeeb nyob rau saum toj kawg nkaus muaj qhov sib txawv ntawm qhov sib txawv ntawm qhov dov rim ntawm daim ntawv nws tus kheej. Muaj damping pads nruab nrab ntawm cov menyuam thiab lub hub kom nqus tau kev co. Kev txo qis ntawm kev co thiab kev hloov pauv ntawm cov duab yuav txo tau txoj kev sib yuav mus rau xoom.

Casting rolls los ntawm txoj kev centrifugal yog ua los ntawm high-alloy cam khwb cia hlau. Hlau yog nchuav rau hauv pwm rotating nyob ib ncig ntawm nws ntsug axis, lub ntim ntawm uas yog nyob rau hauv 95% ntawm tag nrho cov ntim ntawm cov ua hauj lwm txheej ntawm dov yob.

Qhov zoo tsis txaus ntseeg ntawm centrifugal casting yog:

- Saib kom siab swath ceev.

- Txhim kho yob hnav tsis kam.

- Tsis muaj plhaub, voids, non-metallic inclusions, slag.

Forging method

Qhov no yog txoj kev kim tshaj plaws ntawm kev tsim cov yob, uas txawm li cas los xij ua rau nws muaj peev xwm ntxiv dag zog rau tag nrho lub cev ntawm yob ntau li ntau tau. Qhov no txhim kho kev ntseeg tau thiab kav ntev.

Forging nws tus kheej yog ua los ntawm tshwj xeeb automated complexes tsim thiab manufactured siv advanced technologies. Lub peev xwm ntawm cov chav no tuaj yeem ncav cuag 150 MN.

Cov yob tau txais los ntawm txoj kev no feem ntau yog siv rau hauv kev tawg paj thiab slabbing, nrog rau seem mills. Cov hlau yob no muaj cov coefficient nce ntxivkev sib txhuam thaum lub sij hawm sib cuag nrog cov dov workpiece. Qhov nuance no yog ib qho tseem ceeb heev rau kev txo qis qis.

Forging nws tus kheej suav nrog cov haujlwm hauv qab no:

- Nkauj tawm tshiab.

- Draft.

- Broach.

- Forging rau qhov loj ntawm forging.

Kev ua cov yob tom qab forging suav nrog kev kho cua sov, theem kawg ntawm qhov uas yog qhov tawv tawv thiab tempering.

Titanium ntau lawm

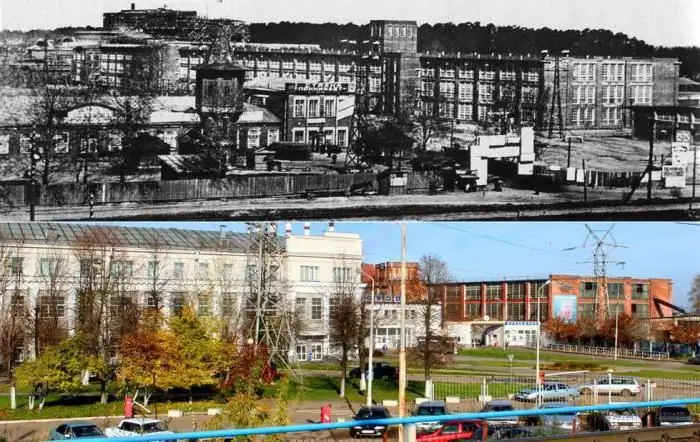

Hnub no Russia yog ib lub tebchaws uas tswj hwm lub ntiaj teb kev lag luam ntawm cov hlau thiab hlau. Yog li ntawd, qhov ze tshaj plaws yog them nyiaj rau kev tsim cov khoom siv thiab cov khoom siv rau metallurgy hauv lub tebchaws. Tshwj xeeb, Magnitogorsk Rolls Plant yog ib tus thawj coj hauv kev tsim cov khoom no.

Lub Xya hli ntuj 2016, tshiab high-performance crucible induction furnaces twb launched nyob rau hauv lub enterprise. Cov cuab yeej siv high-tech no yuav ua rau nws muaj peev xwm tsim cov alloys nyuaj thiab txo cov nqi ntawm cov khoom siv ferroalloys thiab nqi. Nyob rau tib lub sijhawm, qhov txo qis ntawm kev siv hluav taws xob yuav yog li 10%. Lub melting hom yuav ua tau nrog ib tug zaus ntawm 250 Hz, thiab ua tiav thiab sib tov - nrog ib tug zaus ntawm 125 Hz. Kev ua raws li cov kev cai ib puag ncig kuj tseem ceeb: cov cua sov no yuav txo qis emissions los ntawm 2.6 npaug.

Feem ntau, lub tuam txhab Ural tsis tu ncua muab cov yob ua lag luam nrog nws cov khoom thiab yog ib qho kev txhim kho kev lag luam.

Sverdlovsk giant

Koj tsis tuaj yeem tsis quav ntsej Kushvinsky cog ntawm dov yob. Nws cov khoom yog txhua hom yob, ntaub qhwv rau lawv. Ntawm cov nroj tsuag, dov zeb yob yog tsim los ntawm kev siv cov ntaub ntawv ua haujlwm xws li:

- Indefinite.

- Indefinite txhim kho nrog tshwj xeeb carbides.

- High Chrome Iron.

- High Chrome steel.

- HSS.

Lub caj dab thiab lub hauv paus ntawm lub phaj dov yob yog tsim los ntawm cov hlau cam muaj zog ntxiv.

Rolls rau ntu dov mills yog tsim los ntawm bainitic thiab pearlitic alloy cam khwb cia hlau nrog nodular lossis lamellar graphite.

Ukrainian producers

Muaj peb lub ntsiab yob mills hauv Ukraine: Dnepropetrovsk, Lutuginsky thiab Novokramatorsk yob mills.

Dneprovsk cog muaj ntau yam ntawm cov yob ntau lawm, tsis yog rau metallurgy xwb, tab sis kuj rau lwm yam lag luam. Feem ntau, lub tuam txhab ua haujlwm rau ib tus neeg siv khoom tshwj xeeb, koom nrog nws cov kws tshaj lij uas tsim nyog los ntawm lub tuam txhab kev lag luam los tsim ntau yam duab kos thiab cov qauv tshiab ntawm yob.

Ua ntej muaj kev tawm tsam ntawm Donbass hauv 2014, Lutugino Rolls Cog yog qhov zoo tshaj plaws. Nws cov khoom tau muab tsis tau tsuas yog rau tag nrho cov metallurgical lag luam ntawm Ukraine, tab sis kuj rau ntau lub teb chaws nyob sib ze thiab cov teb chaws Europe. Txawm li cas los xij, kev ua tub rog tsis sib haum xeeb tau ua rau qhov tseeb tias cov nroj tsuag raug tso tseg. raug kev txom nyem thiabtsau cov cuab tam ntawm lub lag luam. Tab sis tseem, xyoo 2015, lub tuam txhab tau tswj hwm rov qhib lub lag luam, thiab hnub no nws tau pib tau txais kev txiav txim los ntawm Lavxias Federation.

Kev tswj hwm ntawm swaths

Thaum cov txheej txheem tsim khoom, kiag li txhua qhov yob yob tsis ua haujlwm dhau los ntawm cov txheej txheem kev tswj xyuas zoo ntawm nws cov khoom siv. Kev saib xyuas tshwj xeeb yog them rau:

- Cov tshuaj muaj pes tsawg leeg ntawm cov khoom siv.

- Kev tshuaj xyuas cov qauv ntawm cov khoom siv (yob).

- Kev tsom xam ntawm centricity thiab geometric qhov ntev.

- Controlling the degree of hardness of the work layer of the yob.

- Control the degree of roughness of the work deg.

- Kev tshuaj xyuas cov qauv hlau ntawm txheej txheej.

Packaging

Txhua cov yob yob (cov chaw tsim khoom uas tsim lawv muaj daim ntawv pov thawj zoo) raug xa mus rau cov neeg siv khoom hauv pob tshwj xeeb. Lub thawv no feem ntau muaj cov thawv ntoo nrog cov khoom sib faib, sab hauv uas yob tau nteg thiab ruaj ntseg nrog cov ntsiab lus khi. Cov neeg tsim khoom tseem ua tib zoo mloog rau lub thawv ntim khoom, vim tias qhov tsis zoo ntawm cov yob thiab tsis muaj kev tiv thaiv zoo ntawm kev ua haujlwm thiab qhov chaw zaum ntawm cov khoom lag luam tuaj yeem ua rau muaj qhov tsis zoo ntawm qhov zoo ntawm cov yob.

Zaj lus

Rolls, cov cuab yeej tsim khoom uas tau tham hauv cov ncauj lus kom ntxaws saum toj no, muaj kev cuam tshuam loj rau cov khoom tau txais nrog lawv cov kev pab. Yog li ntawd, lub ntiaj teb no ua manufacturerskev xauj tsev them nyiaj tshwj xeeb rau lub caij no. Txhua lub taub hau ntawm lub tuam txhab metallurgical paub zoo tias qhov kawg profitability ntawm tag nrho cov ntau lawm yuav loj nyob ntawm seb cov kev mob ntawm lub dov zeb tag nrho thiab dov yob nyob rau hauv particular.

Pom zoo:

"Kanban", ntau lawm system: piav qhia, essence, functions thiab xyuas

Kanban yog qhov paub zoo tshaj plaws kev lag luam kev tswj hwm kev lag luam hauv lub tswv yim Just-in-Time. Nrog rau cov nqi koom nrog tsawg, nws tuaj yeem txo lub sijhawm ua haujlwm thiab tus nqi ntawm cov khoom siv

JSC "Yaroslavl Tire Plant": piav qhia, khoom lag luam, ntau lawm thiab tshuaj xyuas

JSC Yaroslavl Tyre Cog yam tsis muaj kev tshaj tawm yog tus thawj coj ntawm lub teb chaws kev lag luam log tsheb. Txhua xyoo, lub tuam txhab tsim tawm txog 3 lab units ntawm cov khoom zoo rau ntau yam khoom siv. Lub tuam txhab yog ib feem ntawm tuav "Cordiant"

Tawv ntau lawm: keeb kwm, piav qhia thiab siv thev naus laus zis

Tawv ntau lawm niaj hnub no tau tsim zoo ob qho tib si hauv Russia thiab hauv ntiaj teb. Cov khoom ntawm cov chaw tsim khoom zoo li no tau muab rau cov lag luam teeb pom kev lag luam, qhov twg cov khaub ncaws, khau thiab cov khoom siv yog tsim los ntawm nws, uas yog nrov heev ntawm cov pejxeem

Roj ntau lawm hauv ntiaj teb. Roj ntau lawm nyob rau hauv lub ntiaj teb no ( rooj)

Lub ntiaj teb li peb paub nws yuav txawv heev yog tias tsis muaj roj. Nws yog ib qho nyuaj rau xav txog tias muaj pes tsawg yam khoom txhua hnub yog tsim los ntawm cov roj. Synthetic fibers uas ua rau cov khaub ncaws, tag nrho cov yas siv nyob rau hauv lub neej txhua hnub thiab kev lag luam, tshuaj, tshuaj pleev ib ce - tag nrho cov no yog tsim los ntawm cov roj. Yuav luag ib nrab ntawm lub zog siv los ntawm noob neej yog tsim los ntawm roj. Nws yog siv los ntawm aircraft xyaw, nrog rau yuav luag tag nrho cov tsheb nyob rau hauv lub ntiaj teb no

Pob kws yield: qhov nruab nrab, ntau lawm technology thiab ntau yam

Pob kws yog cov qoob loo muaj txiaj ntsig uas tau cog rau ntau thaj tsam ntawm peb lub tebchaws. Hauv 2018, piv txwv li, kwv yees li 2.5 lab hectares ntawm thaj av tau nyob rau hauv Russia. Cov qoob loo ntawm pob kws nyob ntawm ntau yam. Txawm li cas los xij, kev cog qoob loo ntawm cov qoob loo no tuaj yeem tsim nyog tsuas yog yog tias cov txheej txheem kev saib xyuas yuav tsum tau ua nruj me ntsis thiab xaiv ntau yam kom raug