2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Polyamides tau nyob ib puag ncig ntev, tab sis iav-filled polyamides yog ib tiam tshiab ntawm cov khoom siv no. Lawv qhov sib txawv ntawm cov pa ib txwm nyob rau hauv qhov tseeb hais tias qhov kev taw qhia ntawm xws li ib tug muab tub lim li fiberglass ua kom tau ib yam khoom uas yog yus muaj los ntawm siab zog, rigidity, tsis kam mus rau tshav kub, raws li zoo raws li tsawg tawg, uas manifests nws tus kheej nyob rau hauv tej yam kev mob. siab thiab tsis kub.

Kev piav qhia thiab daim ntawv thov

Txawm hais tias lub iav ntim polyamide tau txhim kho yuav luag tag nrho nws cov yam ntxwv, muaj qee qhov uas tau dhau los ua phem me ntsis. Qhov no siv rau kev tiv thaiv ntawm cov khoom rau nws puas, nrog rau nws elasticity. Nyob rau hauv ib yam khoom uas tsis tau sau, cov qualities yog siab dua.

Hais txog kev siv iav-filled polyamide, qhov chaw rau cov cuab yeej precision yog tsim los ntawm nws. Tsis tas li ntawd, nws kuj yog siv rau kev tsim cov cam discs rau cov cuab yeej hluav taws xob. Txhawm rau txhim kho kev ua haujlwm ntawm cov iav ntim polyamide, cov tshuaj xws li graphite thiab molybdenum disulfide kuj tau ntxiv rau cov khoom xyaw. Cov tshuaj ntxiv no txhim khocoefficient ntawm kev sib txhuam, thiab yog li hnav tsis kam. Koj tuaj yeem siv talc ua ib qho ntxiv. Nws yog siv kom tau txais warp-like tags.

Type of polyamide

Hnub no, xws li PA thiab PA66 yog nrov heev. Cov iav uas muaj polyamides no yog cov yam ntxwv los ntawm kev nruj, lub zog thiab toughness. Kev tiv thaiv zoo rau ntau qhov chaw nruj heev tau pom.

Raws li cov txiaj ntsig ntawm kev siv cov polyamide, lawv muaj raws li hauv qab no:

- Viscosity, hardness thiab siab tiv thaiv cov teebmeem xws li thermal warping.

- Cov coefficient ntawm kev sib txhuam thiab hnav kuj yog qhov siab heev.

- Cov hom polyamides no tuaj yeem siv rau qhov kub ntawm -60 txog +150 degrees Celsius.

- Cov khoom ntawm cov iav uas muaj polyamide tso cai rau nws ua haujlwm ntev heev txawm tias nyob rau hauv cov xwm txheej ntawm ib txhij raug rau yam xws li kub siab, siab mechanical stress, nrog rau raug rau cov khoom xws li roj, roj thiab lwm yam aggressive compounds.

hom polyamide no nws tus kheej yog cov khoom sib xyaw uas muaj cov polyamide hom resin ntim nrog cov iav filaments.

Kev piav qhia ntawm cam khwb cia polyamides

Nws yog ib qho tsim nyog sau cia tias muaj ib pab pawg ntawm cov iav ntim thermoplastic polyamides, uas tau txais thaum lub sij hawm casting txheej txheem. Lawv muaj ib tug xov tooj tseem ceebua tsis tau. Ntawm lawv, tsis tshua muaj coefficient ntawm elasticity, qis coefficient ntawm kev cuam tshuam lub zog sawv tawm feem ntau ntawm tag nrho cov. Tsis tas li ntawd, kev ua haujlwm ntawm cov khoom siv no yog nrog kev sib tsoo muaj zog ntawm fibers ntawm hom reinforcing. Thaum lub sijhawm txheej txheem no, kuj tseem muaj cov khoom siv abrasive muaj zog.

Lwm yam khoom ntawm fiberglass ua cov muab tub lim yog nws qhov ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom. Vim yog cov yam ntxwv no, nws hloov tawm tias cov khoom tiav yog qhov hnyav hnyav, thiab tseem muaj kev siv tsis tiav ntawm kev nyab xeeb ntawm cov fibers. Cov khoom no kuj qhia tau tias tsis muaj dej noo tsis kam thiab delamination hnyav.

GOST iav-filled polyamide

GOST 17648-83 tswj cov kev xav tau zoo ntawm cov khoom tiav, cov txheej txheem thev naus laus zis ntawm nws cov khoom tsim, nrog rau cov kev cai nyab xeeb, kev lees paub thiab kev sim rau kev tswj kom zoo.

Raws li kev nyab xeeb yog kev txhawj xeeb, polyamides ntawm hom no yog cov pab pawg ntawm cov khoom siv hluav taws xob thiab hluav taws xob. Cov khoom no tsuas tuaj yeem ua tiav yam nyab xeeb ntawm qhov kub txog 270 degrees Celsius. Hauv qhov no, cov pa phem yuav tsis raug tso tawm, thiab cov khoom nws tus kheej yuav tsis raug decomposition. Tsis muaj kev hem thawj rau tib neeg noj qab haus huv.

Yog tias lub hauv paus cim 66 siv hauv polyamide, tom qab ntawd ntawm qhov kub siab tshaj 275 degrees Celsius, cov khoom yuav pib decompose. Lub sijhawm no, carbon monoxide, ammonia thiab carbon dioxide yuav raug tso tawm. Cov noCov tshuaj twb muaj kev phom sij rau tib neeg noj qab haus huv. Yog tias polyamide cim 6 lossis 610 siv los ua lub hauv paus, qhov siab tshaj plaws ua haujlwm kub yuav nce mus rau 300 degrees ua ntej cov khoom pib decompose.

Pom zoo:

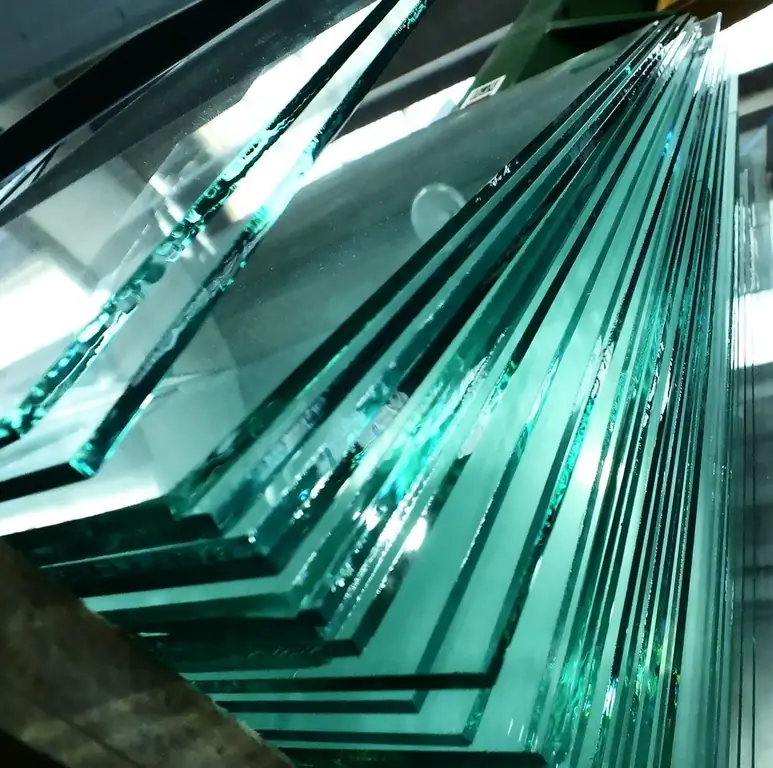

Yuav ua li cas iav? iav ntau lawm technology. iav khoom

Iav yog paub rau sawv daws. Tab sis cov txheej txheem ntawm kev ua nws yog qhov zoo siab heev. Txhua theem yog qhov tseem ceeb thiab cuam tshuam rau qhov zoo ntawm cov khoom kawg. Lub hauv paus yog xuab zeb, dej qab zib, txiv qaub. Cov txheej txheem yog yuav luag tag nrho automated. Kuj ceeb tias, iav tuaj yeem ua tau hauv tsev

Iav sandblasting: iav ua cov lus piav qhia, khoom siv, daim ntawv thov, duab

Ntawm ntau qhov kev hloov pauv ntawm kev kho kom zoo nkauj sab hauv, sandblasting ntawm iav los yog iav nto occupies ib qho chaw tshwj xeeb. Cov cuab yeej no suav nrog kev nthuav tawm cov ntaub ntawv rau cov xuab zeb lossis lwm yam abrasive nrog lub dav hlau ntawm cov cua compressed tso rau hauv siab. Raws li qhov tshwm sim, qhov chaw hloov pauv thiab ua matte, ntxhib, velvety lossis pleev xim nrog cov qauv. Nyob rau hauv tsab xov xwm peb yuav xav txog dab tsi yog sandblasting iav

Italian geese: piav qhia ntawm hom, nta ntawm kev saib xyuas, kev yug me nyuam, yam ntxwv nta, kev cai ntawm kev khaws cia thiab cov txiaj ntsig

Qhia kev yug me nyuam yog ib txoj hauv kev zoo kom tau nyiaj rau tus neeg ua liaj ua teb. Lawv yog unpretentious nyob rau hauv kev saib xyuas, sai sai nce qhov hnyav thiab nyob rau hauv kev thov ntawm cov pejxeem. Dawb Italian geese yuav tsis tsuas yog coj cov nyiaj tau los zoo, tab sis kuj kho lub tshav puam nrog lawv cov tsos. Cov noog yoog tau zoo rau cov xwm txheej sib txawv ntawm kev kaw, lawv tuaj yeem raug bred nyob rau hauv txhua qhov chaw huab cua. Italian geese - ib tug godsend rau ib tug neeg ua liaj ua teb ua lag luam

Iav shaping tshuab: piav qhia, yam ntxwv, hom thiab hom kev ua haujlwm

Gear shaping machines: specifications, settings, operation, features, purpose. Iav shaping tshuab: piav qhia, lub hauv paus ntsiab lus ntawm kev ua haujlwm, duab

JSC "Bor iav cog" (BSZ): piav qhia, cov khoom lag luam thiab cov yam ntxwv ntau lawm

JSC "Bor iav cog" yog lub chaw tsim khoom ntawm nws pib iav hauv Russia. Txij li thaum xyoo 1997 nws tau los ntawm AGC Europe pawg tuam txhab. Lub tuam txhab kuj tsim: tais diav, iav, polished iav thiab lwm yam khoom