2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

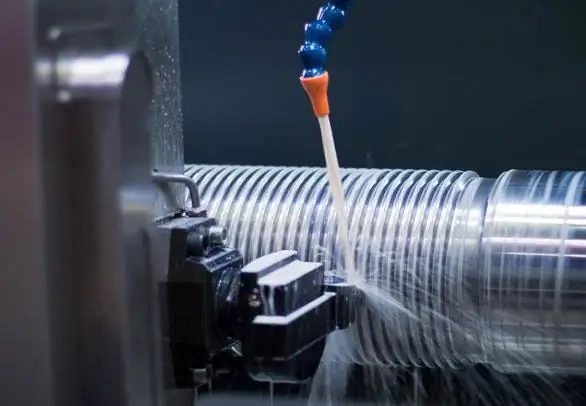

Yog tsis muaj cov roj nplua nyeem, kev ua haujlwm ntawm cov cuab yeej siv hlau niaj hnub no ua tsis tau. Nyob rau tib lub sijhawm, cov ntsiab lus hlau lawv tus kheej, uas yog siv hauv tshuab, tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua yam tsis muaj kev saib xyuas tsim nyog nrog cov tshuaj tshwj xeeb. Txog niaj hnub no, txiav cov kua (coolants) muaj nyob rau hauv kev ua lag luam hauv ntau tshaj 600 yam khoom. Ntawm lawv koj tuaj yeem nrhiav cov khoom siv rau hauv chav tsev fais fab, rau kev siv hlau ua haujlwm, nrog rau kev kho mob, insulating, shape-sparating, biological and anti-corrosion oils. Feem ntau ntawm cov kua dej no yog siv los ntawm cov chaw tsim khoom thiab kev tsim kho kev lag luam.

txiav cov kua dej yog dab tsi?

Feem ntau, cov roj nplua nyeem tau nkag mus rau hauv qhov chaw ua haujlwm ntawm cov khoom siv txhawm rau txhawm rau txo qis hnav hauv cov txheej txheem. Feem ntau qhov kev ua haujlwm no yog ntxiv los ntawm kev nce hauv kev ua haujlwm. Tab sis qhov no siv rau cov tshuaj ib txwm muaj ntawm hom no, txawm li cas los xij, cov ntaub ntawv txias kuj tseem tsim nyog los tiv thaiv cov khoom siv thiab cov khoom ua haujlwm los ntawm kev kub dhau. Piv txwv li, lubricantcoolants rau hlau ua hauj lwm tso cai rau koj mus optimize lub kub tswj thiab txo lub siab. Yog li ntawd, xws li kev them nyiaj tsis tsuas yog tso cai rau koj kom tswj tau qhov kev ua tau zoo ntawm cov cutters, tab sis kuj txhim kho cov yam ntxwv ntawm cov khoom tsim. Kuj tseem muaj cov khoom tiv thaiv tshwj xeeb, uas qhov tseem ceeb tshaj plaws yog muab los tiv thaiv corrosion, insulating thiab sealing zog. Cov khoom siv no feem ntau yog siv hauv kev tsim kho.

Coolant composition

Txhua lub roj nplua nyeem yog ua raws li daim ntawv qhia tshwj xeeb. Muaj cov txheej txheem tswj hwm yooj yim, nrog rau kev hloov kho uas tau txais los txhawm rau muab kev ua haujlwm tshwj xeeb. Feem ntau, lub hauv paus yog cov roj viscosity tsawg. Lubricating kua yog tsim los ntawm nws, cov muaj pes tsawg leeg yog hloov nrog chlorinated paraffin, zinc dialkyldithiophosphates, multi-ash calcium sulfonate thiab lwm yam additives. Xws li cov khoom siv feem ntau yog siv los txiav cov hlau kub kub thiab cov hlau tsis muaj hlau. Ib tug feature ntawm qhov kev txiav txim ntawm qhov muaj pes tsawg leeg yog tiv thaiv kom txhob lo ntawm cov khoom rau lub cuab tam. Kev siv cov viscosity qis-hydrogenated feem ntawm qaub roj raws li lub hauv paus kuj yog dav. Cov kua dej ua haujlwm ntawm lub hauv paus no yog siv rau hauv cov tshuab electroerosive ntawm ntau qib ntawm lub zog, hauv kev ua tiav thiab xa cov haujlwm ntawm cov tshuab sib dhos ntau lawm.

yam ntxwv tseem ceeb ntawm cov kua

Cov yam ntxwv ntawm cov kua dej no txawv heev nyob ntawm cov khoom siv ntxiv. Raws li txoj cai, nws yog cov kua xim av loj, qhov ntxoov ntxoo uas yuav txawv. Los ntawm qhov pom ntawm kev ua haujlwm, ib qho ntawm cov yam ntxwv tseem ceeb tshaj plaws yog qhov ceev. Cov txheej txheem txias txias lubricant muaj qhov ceev ntawm 1100 txog 1200 kg / m 3. Txawm li cas los xij, qhov ntsuas no tuaj yeem sib txawv hauv kev tsim cov concentrate. Tsis tas li ntawd, txiav cov kua hauv qee cov qauv muaj cov ions nquag. Rau 1% aqueous tov, tus nqi no tuaj yeem nyob ntawm qhov kev txiav txim ntawm 10 pH. Cov neeg tsim khoom feem ntau pom zoo kom siv cov tshuaj sib xyaw ua ke nrog qhov zoo ntawm 1-3%. Tab sis nyob ntawm qhov chaw ntawm qhov chaw ua haujlwm thiab cov khoom siv lub hom phiaj, tus nqi no yuav nce ntxiv. Yog li, txhawm rau xyuas kom muaj kev sib tsoo, nws raug nquahu kom siv 4% mloog zoo, thiab rau kev ua haujlwm hlau nyuaj, qhov taw qhia nce mus rau 7%.

yam ntxwv ntawm cov khoom siv coolant

Muaj ntau txoj hauv kev rau kev muab, thov thiab faib cov kua roj lubricating rau qhov chaw ua haujlwm. Tsis yog txhua tus ntawm lawv yuam kev tshwj xeeb ntawm cov roj nplua nyeem nyob rau hauv cov nqe lus ntawm lub cev, tab sis qee zaum lawv tseem ceeb heev vim tias lawv txiav txim siab qhov xwm txheej ntawm kev cuam tshuam nrog kev ua haujlwm. Thaum kawg, qhov no cuam tshuam rau kev ua haujlwm ntawm cov khoom nws tus kheej. Piv txwv li, yog hais tias ib tug txiav kua rau metalworking tshuab yog siv, ces ceev los mus rau lub hauv ntejlub dav hlau muab. Raws li, qhov sib zog ntawm cov khoom, qhov zoo dua lub lubrication ntawm cov khoom txiav thaum lub sijhawm ua haujlwm. Cov feem ntawm ib tug neeg hais nyob rau hauv cov muaj pes tsawg leeg ntawm cov kua kuj muab rau hauv tus account. Ntawm cov khoom noj siab, lawv tuaj yeem cuam tshuam rau cov khoom ntawm qhov chaw, deforming nws. Tsis tas li ntawd, cov neeg ua haujlwm tshuab yuav tsum ntsuas lub dav hlau kub rau hauv tus account thiab tso cai rau kev hloov pauv tau rau tus nqi no rau qhov chaw nyob.

Technical and operation properties

Cov yam ntxwv tseem ceeb xa mus rau kev muab cov roj lubrication zoo thiab ua kom txias. Tsis tas li ntawd, nyob rau hauv qee qhov chaw, cov kev xav tau siab tau muab tso rau ntawm kev ua haujlwm ntxhua, uas tso cai rau kev tu lub sijhawm ntawm qhov chaw ntawm qhov chaw thaum lub sijhawm ua haujlwm ntawm lub tshuab. Cov khoom zoo ntxiv uas niaj hnub txiav cov kua dej tau txais txiaj ntsig suav nrog cov kab mob bactericidal, ib puag ncig tus phooj ywg, kev nyiam huv, tshuaj lom neeg thiab kub tsis kam. Nws yog ib qho tseem ceeb uas yuav tau txiav txim siab tias cov khoom siv lubricating lawv tus kheej muaj cov tshuaj muaj txiaj ntsig zoo rau ntau yam ntaub ntawv, yog li ntawd, thaum xaiv cov khoom, koj yuav tsum sib piv cov kua dej zoo nrog cov khoom siv.

Ntau yam ntawm cov khoom txias

Qhov kev faib tawm tseem ceeb ntawm cov roj nplua nyeem nrog cov txiaj ntsig txias yog nyob ntawm lub hauv paus ntawm cov khoom. Cov roj ntau tshaj plaws uas siv rau hauv kev lag luam thiab kev tsim khoom lag luam. Feem ntau cov no yog cov kua roj av ntxiv nrog cov hloov pauv. Ib qho nrovntau yam ntawm xws li additives kuj yog ntxhib emulsions ntawm roj av khoom, uas yog tsim nyob rau hauv cov dej ib puag ncig. Stable microemulsion hom ntawm cov kua txiav tso cai tsim cov semi-synthetic los yog hluavtaws tebchaw raws li cov organics. Tsawg-boiling, evaporating mixs raws li halogen derivatives ntawm hydrocarbons nrog additives kuj tau dhau mus.

Daim ntawv thov kom txias

Lubricants feem ntau siv dav hauv kev tsim cov hlau, nrog rau lawv cov kev ua haujlwm. Lawv tsis tsuas yog tiv thaiv cov cuab yeej ua haujlwm los ntawm kev hnav ntxov ntxov, tab sis kuj txhim kho cov khoom tsim tau zoo. Qhov chaw thib ob hauv kev thov rau cov khoom siv no tuaj yeem raug ntaus nqi rau kev tsim kho kev lag luam. Hauv kev lag luam no, kev siv cov kua dej txiav yog vim muaj lub siab xav muab kev tiv thaiv zoo rau cov khoom siv hauv tsev, insulating thiab cov txheej txheem zoo nkauj.

Chaw tsim tshuaj xyuas

Proma, Univeco thiab Messer tuaj yeem raug cais tawm ntawm cov chaw tsim khoom loj tshaj plaws. Thawj hom tau nto moo vim kev tso tawm cov cuab yeej siv tau zoo uas tso cai rau koj kom ntseeg tau cov txheej txheem hlau siv cov txheej txheem txias thiab kub. Cov lus tawm tswv yim los ntawm cov neeg siv cov kua dej no sau tseg tias thaum lub sijhawm tsim khoom nws muaj peev xwm txo qis kev tsis lees paub, ua kom cov khoom tsim tau thiab ua kom raug. Kev tsim cov kua roj lubricating ntawm lub tuam txhab Univeco kuj tau tsim nyob rau theem niaj hnub no. Cov pab pawg no ntawm kev sib tov yog tsim los ntawm lub hauv paus ntawmcorrosion inhibitors thiab activated dej ib puag ncig, uas tshwj xeeb tshaj yog txaus siab los ntawm cov neeg siv khoom hauv kev tsim kho. Raws li rau lub npe Messer, nws cov khoom tau siv ntau dua hauv kev ua haujlwm siab precision machining. Cov neeg siv khoom muaj txiaj ntsig zoo los tiv thaiv corrosion, tiv thaiv micro-fermentation, nrog rau ib puag ncig tus phooj ywg rau qhov zoo ntawm cov kua dej.

Zaj lus

Cov thev naus laus zis niaj hnub rau kev ua cov khoom hlau yog maj mam txav deb ntawm cov txheej txheem kev siv tshuab ntawm kev cuam tshuam. Tawm tsam keeb kwm yav dhau los no, kev noj cov khoom tiv thaiv thiab kev ruaj ntseg-txhim kho cov khoom kuj tseem txo qis. Txawm li cas los xij, muaj kev lag luam uas txiav cov kua dej tseem cuam tshuam. Qhov no feem ntau yog kev tsim kho, mechanical engineering, tshuaj thiab hluav taws xob engineering. Lwm qhov yog tias nyob rau hauv cov chaw tshwj xeeb, cov ntaub ntawv uas muaj ntau dua thiab zoo tshaj plaws ntawm lawv cov txuj ci thiab kev ua haujlwm yuav tsum tau ua, yuav tsum tau siv cov khoom siv high-tech additives thiab modifiers.

Pom zoo:

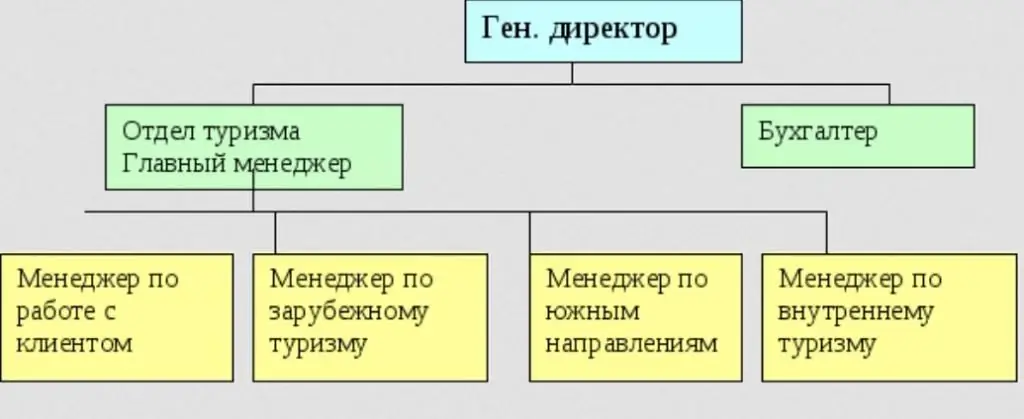

Hom kev ncig xyuas thiab lawv cov yam ntxwv. Kev ua haujlwm thiab cov yam ntxwv ntawm cov haujlwm ntawm cov neeg ncig xyuas ncig xyuas

Tus neeg ncig xyuas muab ntau yam kev pabcuam mus ncig thiab ua kom yooj yim rau kev tshwj tseg cov kev pabcuam hauv lwm lub nroog thiab lub tebchaws, ua haujlwm rau cov haujlwm no. Nyob rau hauv lub tshav pob ntawm tourism kev pab cuam, nws occupies ib tug tshwj xeeb niche. Hauv tsab xov xwm peb yuav txiav txim siab txog hom kev ua ub no ntawm cov neeg ncig xyuas

Stoeger X50 cua phom: tshuaj xyuas, piav qhia, specifications thiab tshuaj xyuas

Lub ntsiab lus ntawm tsab xov xwm no yog Stoeger X50 pneumatics, tsim los ntawm Italian gunsmiths thiab nthuav tawm rau pej xeem raws li kev daws teeb meem pheej yig rau kev ua si tua phom

Crawler roj av snow blower: tshuaj xyuas, specifications thiab tshuaj xyuas

Cov kab lus yog hais txog kab ntsig roj av daus tshuab. Cov yam ntxwv, kev tshuaj xyuas thiab nuances ntawm kev xaiv cov khoom siv no suav nrog

Cov cai thiab cov tswv yim rau kev pub nees, lawv cov khoom noj txhua hnub thiab kev saib xyuas, kev saib xyuas thiab yug tsiaj

Nees yog cov tsiaj zoo, tab sis lawv xav tau kev saib xyuas kom raug. Txhawm rau khaws cov tsiaj no, tus tswv tsev yav tom ntej yuav tsum tsim lub tsev rau nws, txhim kho kev noj zaub mov zoo thiab teem caij nrog kws kho tsiaj. Nrog kev saib xyuas kom zoo, nees yuav muab rau tus tswv nkaus xwb cov kev xav zoo nkauj

I-Nyiaj ntsuab hauv kev them nyiaj: kev tshuaj xyuas lub tuam txhab, kev tshuaj xyuas kev tsheb thiab kev txheeb xyuas

Ib tsab xov xwm hais txog I-Nyiaj Ntsig hauv kev pabcuam them nyiaj: kev tshuaj xyuas lub tuam txhab, kev tshuaj xyuas tsheb thiab kev txheeb xyuas