2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Delayed coking units yog cov khoom siv kho vajtse uas siv ntau tshaj plaws rau kev kho cov roj hnyav. Lawv cov cuab yeej muaj xws li 2 lub ntsiab modules - reactor, qhov twg cov khoom siv raw yog rhuab thiab coked, thiab mechanical processing. Kev tsim cov nroj tsuag yog nqa tawm nyob rau hauv theem thiab suav nrog kev suav thiab xaiv cov txheej txheem cov cuab yeej, kev txiav txim siab ntawm kev ntsuas thiab kev lag luam.

Destination

Technological txheej txheem ntawm coking yog ib txoj kev ntawm cov roj refining. Nws lub hom phiaj tseem ceeb yog kom tau txais cov roj av coke loj. Muaj 3 txoj hauv kev siv coking hauv kev lag luam:

- Lub Sijhawm, cubed. Cov khoom siv raw yog thauj mus rau hauv kab rov tav apparatus, rhuab nrog lub firebox hauv qab nws, ces calcined rau 2-3 teev. Tom qab ntawd, lub cub tawg yog txias thiab cov khoom tiav yog unloaded. Txoj kev no yog qhov yooj yim tshaj plaws thiab ua haujlwm tsawg kawg nkaus.

- Txuas ntxiv. Txoj kev no tseem nyob rau theem ntawm kev tsim kho kev lag luam.

- Semi-nruab nrab, tam sim no tau txaistshaj plaws.

Ultra-delayed coking units yog hom khoom siv txheej txheem tshiab kawg. Nyob rau hauv lawv, cov khoom siv raw yog preheated nyob rau hauv ib lub qhov cub, thiab ces pauv mus rau unheated tshuaj tiv thaiv chamber, uas muaj ib tug thermal rwb thaiv tsev txheej los tswj qhov kub thiab txias. Tus naj npawb thiab qhov loj ntawm cov reactors, lub zog ntawm lub cub tawg cuam tshuam rau kev ua haujlwm ntawm tag nrho cov nroj tsuag.

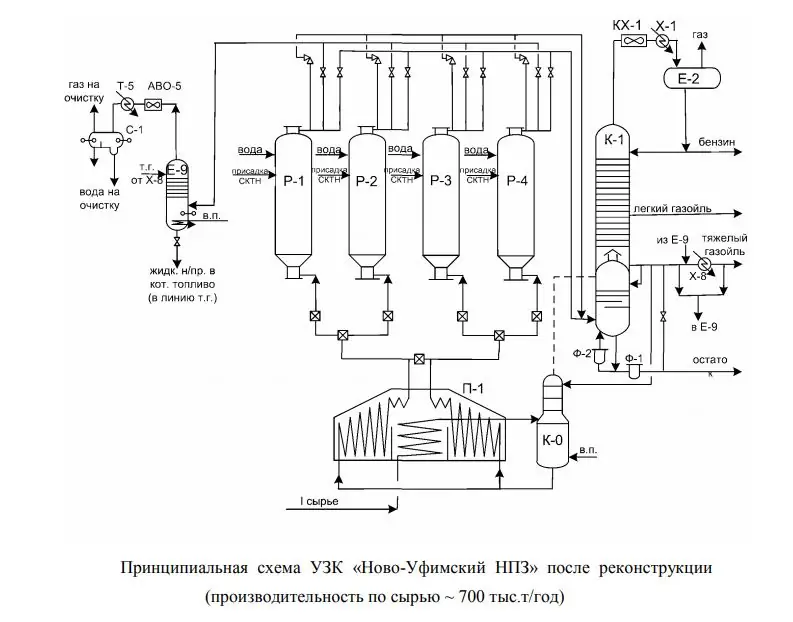

Kev ua haujlwm ntawm thawj DCU hauv tebchaws Russia tau pib xyoo 1965 ntawm Ufaneftekhim. Cov nroj tsuag qeeb coker tseem ua haujlwm niaj hnub no. Tom qab kev tsim kho dua tshiab hauv xyoo 2007, nws cov khoom tsim tau yog li 700-750 txhiab tons / xyoo raws li qhov loj ntawm cov khoom siv raw.

Cov khoom kawg

Cov tshuaj hauv qab no tau txais ntawm kev kuaj ultrasonic, tshwj tsis yog rau coke:

- coking gases (siv ua cov roj txheej txheem lossis ua tiav kom tau cov propane-butane feem);

- gasoline;

- coke distillates (roj, tawg feedstock).

Ntawm cov tshuab kuaj ultrasonic hauv tsev, cov txiaj ntsig coke yog 20-30% los ntawm qhov hnyav. Qhov ntsuas no feem ntau nyob ntawm qhov zoo ntawm cov khoom siv raw. Kev lag luam metallurgical muaj kev xav tau ntau tshaj plaws rau cov khoom no (tsim anodes thiab electrodes, aluminium, abrasives, carbides, carbon-graphite cov ntaub ntawv, ferroalloys). Ntxiv rau thawj Ufa DCU, lwm cov chav coker qeeb kuj tau tsim nyob rau hauv Russia: ntawm Omsk Refinery, Novokuibyshevsk Refinery, LLC LUKOIL-Volgogradneftepererabotka, LUKOIL-Permnefteorgsintez, LUKOIL-Permnefteorgsintez, ntawm Angarsk Petrochemical Company, NOVOIL OJSC (Ufa), TANECO PJSC (Nizhnekamsk).

Raw khoom

Cov khoom noj khoom haus rau coking tau muab faib ua 2 pawg: cov khoom ntawm kev ua thawj thiab theem nrab. Cov tshuaj hauv qab no yog siv los ua cov ntaub ntawv raw hauv ncua sijhawm coking units:

- roj;

- ib nrab-tar;

- tar;

- coal-tar suab;

- asph alt thiab lwm yam khoom siv roj;

- liquid coal residue;

- hnyav pyrolysis thiab shale tar;

- thermal cracking residue;

- roj av bitumen thiab roj hnyav.

Cov roj uas muaj ntxhiab tsw qab heev yog cov khoom noj uas muaj ntau tshaj plaws tam sim no.

Influence on technological parameters

Cov kev txwv hauv qab no ntawm cov nroj tsuag coking nyob ntawm cov khoom ntawm cov khoom noj:

- efficiency ntawm cov tshuaj tiv thaiv chamber;

- zoo ntawm cov khoom tau txais;

- coke qhov hluav taws xob;

- xov xwm rau txheej txheem.

Qhov tseem ceeb tshaj plaws raw khoom tsis yog:

- Coking, nyob ntawm cov ntsiab lus ntawm asph alt-resinous tshuaj. Tus nqi coking yuav tsum nyob rau hauv thaj tsam ntawm 10-20%. Nrog rau tus nqi me me, cov txiaj ntsig coke txo qis, thiab nrog rau qhov loj dua, cov nyiaj tso cia hauv cov coils hauv qhov cub. Lub peev xwm coking yog txiav txim siab los ntawm qhov loj ntawm cov khoom seem hauv lub crucible tom qab cua sov cov khoom siv roj hauv nws.

- Density.

- Tshuaj muaj pes tsawg leeg. Los ntawmteeb meem impurities uas muaj kev cuam tshuam loj tshaj plaws rau qhov zoo ntawm coke emit sulfur (nws yuav tsum tsis pub tshaj 1.5% ntawm qhov hnyav). Nyob ntawm lub hom phiaj ntawm coke nyob rau hauv cov txheej txheem thev naus laus zis, nws yog qhov zoo dua los siv ntau hom khoom siv raw. Yog li, kom tau txais cov qauv fibrous ntawm cov khoom kawg, cov khoom siv nrog paraffin puag yog siv.

Coke tawm los yog proportional rau pub ceev thiab asph altene cov ntsiab lus.

Cov txheej txheem thev naus laus zis hauv cov chav coking qeeb yog ntev thiab tsis tu ncua, los ntawm cov khoom siv raw mus rau kev tshem tawm cov khoom tiav. Conventionally, nws muab faib ua 3 theem:

- Decomposition reactions, tsim ntawm distillate fractions, intermediates, condensation.

- Kev txo qis hauv cov ntsiab lus ntawm unsaturated hydrocarbons hauv cov pa roj, qhov nce hauv qhov hnyav ntawm cov khoom seem, cov tshuaj tiv thaiv cyclization.

- nce hauv cov ntsiab lus ntawm asph altene nyob rau hauv qhov seem mus txog 26%, txo qis ntawm cov resins thiab roj. Hloov ua kua residue mus ua coke.

Kev faib tawm

Muaj 2 hom tseem ceeb ntawm kev ncua sijhawm coking raws li lawv qhov layout: ib leeg-thaiv thiab ob-thaiv.

Ntawm cov nroj tsuag ob-thaiv, muaj 4 hom, uas yog tus cwj pwm los ntawm cov qauv hauv qab no thiab cov yam ntxwv:

- Internal txoj kab uas hla ntawm coking chambers - 4.6 m. Tsev pheebsuab cua sov rauv, plaub chav ua hauj lwm ua khub. Cov roj kerosene thiab roj tau txais thaum lub sijhawm coking yog siv rau cua sov.

- CokeChambers Ø 5.5 m. Feedstock - ncaj-khiav roj roj nrog cov kev taw qhia ntawm cov muaj ntxhiab hydrocarbons, uas ua rau kom cov yield ntawm cov khoom zoo.

- Reactors ua los ntawm alloyed steel Ø 5.5 m, qhov siab 27.6 m, tubular furnaces nrog ib tug volumetric-ntev taws, nyiaj siv ua haujlwm li qub ntawm nce cross-section, radioactive qib ntsuas uas tso cai rau sau npe qhov chaw ntawm lub coke-foam theem sib cais.. Qhov kev hloov tshiab tshiab kawg no pab kom zoo dua siv lub ntim muaj txiaj ntsig ntawm lub reactor. Kev muab cov turbulators nrog cov tshuaj detergent kom txo cov coking ntawm coils, cov roj cua txias hauv lub taub hau raj.

- Reaction chambers Ø 7 m, qhov siab 29.3 m. Axial input ntawm raw khoom mus rau hauv reactors, hydraulic system rau discharging coke nrog tej thaj chaw deb tswj, hluav taws xob cranes, warehouses nrog pem teb hom cia.

Khoom siv siv

Khoom siv, uas tau nruab nrog kev teeb tsa ntawm hom no, muab faib ua pawg hauv qab no nyob ntawm lub hom phiaj:

- Technological, koom ncaj qha rau hauv cov txheej txheem coking (kub, cov khoom siv hauv tsev, cov khoom siv hluav taws xob, cov khoom siv hluav taws xob, cov khoom siv hluav taws xob, cov ntsuas hluav taws xob, cov tub yees, cov twj tso kua mis, cov kav dej, cov twj tso kua mis, cov twj tso kua mis, cov twj tso kua mis, cov twj tso kua mis, thiab lwm yam.

- Cov dej khib nyiab - sau thiab kho cov dej kom rov qab mus rau lub voj voog ua haujlwm (kev ua haujlwm txias thiab coke extraction).

- Khoom siv rau kev tshem tawm coke los ntawm chav tsev (cubes). Hauv kev tsim kho tshuab niaj hnub no, nws tuaj yeem yog hom tshuab thiab hydraulic (slings, winches, combs, cutters, rods, towers, rubber sleeves).

- Cov khoom siv thauj khoom thiab ua tiav cov khoom tiav (tau txais chutes thiab ramps, cranes, conveyors, feeders, crushers, warehouses).

- Tshuab thiab khoom siv rau kev siv tshuab ua haujlwm.

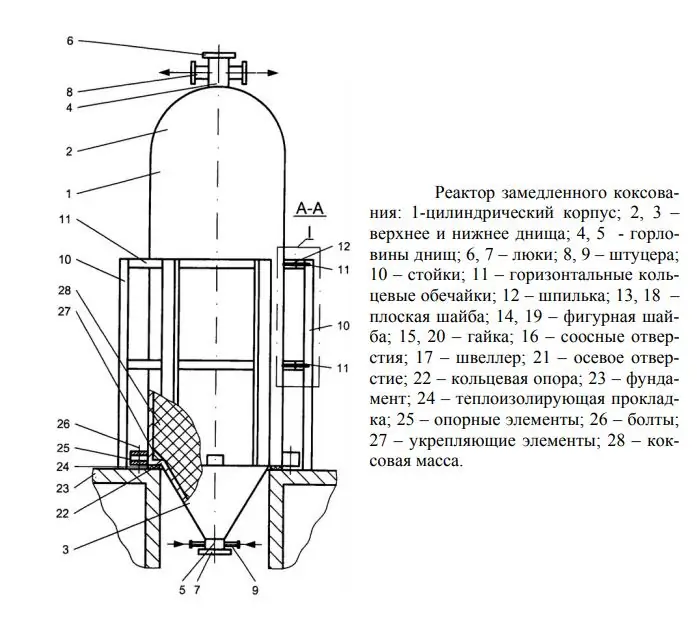

Thaum tsim cov nroj tsuag qeeb qeeb, nws yuav tsum ua tib zoo xav txog qhov tsim ntawm cov tshuaj tiv thaiv chav thiab qhov cub, vim tias lub sijhawm ua haujlwm yog nyob ntawm qhov kev ntseeg tau ntawm lawv txoj haujlwm.

txheej txheem parameters

Qhov tseem ceeb ntawm cov tshuab coking yog:

- Recirculation ratio, txhais raws li qhov piv ntawm tag nrho cov load ntawm cov tshuaj tiv thaiv coils ntawm lub cub tawg rau lub load ntawm tag nrho cov nroj tsuag nyob rau hauv cov nqe lus ntawm raw cov ntaub ntawv. Nrog rau qhov nce hauv nws cov nqi, cov txiaj ntsig ntawm cov coke zoo, roj thiab roj av nce, tab sis cov roj roj hnyav txo.

- Txoj hauv kev tawm tsam chamber. Nws qhov kev txo qis ua rau muaj kev nce hauv cov txiaj ntsig ntawm cov roj roj, txo cov txiaj ntsig ntawm coke thiab roj, thiab nce hauv foaming.

- txheej txheem kub. Qhov loj dua nws yog, qhov siab dua qhov zoo ntawm coke nyob rau hauv cov nqe lus ntawm tus nqi ntawm cov khoom volatile, nws lub zog thiab ntom. Tus nqi siab tshaj plaws yog txwv los ntawm kev pheej hmoo ntawm coking ntawm lub cub tawg thiab cov kav dej, txo cov kav ntev ntawm cov coils. Txhua yam ntawm cov khoom siv raw muaj nws qhov kub thiab txias.

Kev tsim kho cov chav coking qeeb yog txuam nrog cov nqi peev. Yog li ntawd, feem ntau lub reconstruction ntawm ib tug twb ua hauj lwm complex ntawm cov cuab yeej yog nqa tawm. Qhov no yog ua tiav los ntawm kev txo lub voj voogcoking, qhia tshiab cov tshuaj tiv thaiv chav los yog txo cov recirculation ratio.

Txoj Cai Ua Haujlwm

Nqe coking units muaj ib lossis ntau pawg ua ke ntawm cov chav, nyob rau hauv uas ib chav ua haujlwm nyob rau theem ntawm coke ntau lawm, thiab lwm yam ntawm unloading los yog nyob rau hauv ib nrab lub xeev. Cov txheej txheem ntawm decomposition ntawm cov khoom siv pib nyob rau hauv ib lub raj rauv, qhov twg nws yog rhuab mus rau 470-510 ° C. Tom qab ntawd, cov khoom siv raw nkag mus rau hauv cov chav uas tsis muaj cua sov, qhov chaw uas nws yog coked heev vim cua sov uas tuaj nrog nws.

Gaseous thiab kua hydrocarbons raug tso tawm rau fractional sib cais hauv kab distillation. Coke nkag mus rau hauv lub chaw ua haujlwm kho tshuab, qhov twg nws yog unloaded, sorted thiab thauj. Lub qhov dej yog drilled nyob rau hauv txheej ntawm cov khoom tiav, thiab ib tug hydraulic cutter yog muab tso rau hauv nws. Nws cov nozzles ua haujlwm nyob rau hauv siab txog 20 MPa. Cov khoom sib cais ntawm coke poob mus rau hauv lub qhov dej ntws uas cov dej ntws tawm. Cov khoom yog ces crushed rau hauv me me pieces thiab sib cais rau hauv feem. Tom ntej no, lub coke raug tsiv mus rau lub warehouse.

Daim duab qhia txog lub hauv paus ntsiab lus ntawm ultrasound yog qhia hauv daim duab hauv qab no.

Coke chambers

Cov chav yog lub reactor, uas yog lub hauv paus ntawm tag nrho cov installation. Lub voj voog ntawm kev ua haujlwm ntawm lub chamber feem ntau yog 48 teev, txawm li cas los xij, nyob rau xyoo tas los no, cov khoom siv ultrasonic ua haujlwm hauv 18- thiab 36-teev hom tau tsim.

Ib lub voj voog ua haujlwm reactor muaj cov haujlwm hauv qab no:

- thauj khoom raw, txheej txheem coking (1 hnub);

- tawm (1/2 teev);

- kev kho dej dej (2.5 teev);

- dej txias ntawm cov khoom, tshem tawm dej (4 teev);

- unload khoom (5 teev);

- sealing manholes, ntsuas siab nrog chav kub (2 teev);

- cua sov nrog cov roj vapors, hloov mus rau lub voj voog ua haujlwm (3 teev).

Tsim

Qhov kev ncua sijhawm coking unit tau tsim nyob rau hauv kev txiav txim hauv qab no:

- kev txiav txim siab ntawm cov khoom tsim nyog, t / xyoo;

- resourcebase analysis;

- kos cov khoom siv theoretical sib npaug ntawm cov txheej txheem coking rau ntau hom raw khoom;

- kev txiav txim siab ntawm cov khoom tseem ceeb ntws;

- txhim kho lub tswv yim kev teeb tsa;

- kev ncaj ncees rau qhov loj thiab tus naj npawb ntawm cov reactors;

- txiav txim siab lub sijhawm ntawm kev sau ib chav nrog coke thiab nws cov lej hydraulic, kos ib lub sijhawm rau kev ua haujlwm ntawm lub reactor;

- xam qhov ntsuas kub ntawm lub chamber;

- xam ntawm convection thiab hluav taws xob chambers;

- txhim kho cov kab ntau lawm;

- thev naus laus zis suav nrog lwm yam khoom siv tseem ceeb (kem distillation, furnaces, tub yees, thiab lwm yam);

- txhim kho kev saib xyuas thiab tswj qhov system, xaiv cov cuab yeej automation;

- piav qhia txog kev tiv thaiv xwm txheej ceev;

- txhim kho ib puag ncig thiab ntsuas kev nyab xeeb;

- kev txiav txim siab ntawm cov ntsuas kev lag luam (tus nqi peev, tus naj npawb ntawm cov neeg ua haujlwm, them nyiaj,Cov nqi tsim khoom rau cov khoom siv raw thiab cov khoom siv pabcuam, cov txiaj ntsig kev lag luam txhua xyoo, cov khoom lag luam tus nqi).

Xaiv ntawm lub peev xwm ntawm chav tsev coking ncua sij hawm txhua xyoo yog ua raws li cov qauv:

N=P x t, qhov twg P yog lub peev xwm ntawm cov nroj tsuag, t / hnub;

t yog cov hnub ua haujlwm hauv ib xyoos.

Cov khoom tso tawm hauv lub cev raws li lub hauv paus thiab kev xaiv tsim yog txiav txim siab raws li cov khoom sib npaug ntawm kev teeb tsa.

Pom zoo:

Kev ntsuas kev nqis peev zoo ntawm kev lag luam: cov ntsiab lus yooj yim, txoj hauv kev, cov hauv paus ntsiab lus, txoj hauv kev txhim kho

Kev nqis peev tsim khoom yog lub hauv paus ntawm txhua lub lag luam. Kev nqis peev loj loj yuav tso cai rau kev tsim lossis hloov kho cov khoom siv thiab cov txheej txheem uas twb muaj lawm, hloov lub cev lossis kev coj ncaj ncees los ntawm cov cuab yeej cuab tam, nce ntim ntawm cov dej num, mastering cov khoom tshiab, nthuav kev muag khoom, thiab lwm yam

Kev txhim kho vaj tsev thiab nws lub luag haujlwm hauv kev txhim kho kev lag luam. Lub tswvyim, hom, cov hauv paus ntsiab lus thiab lub hauv paus ntawm txoj kev loj hlob

Nyob rau hauv lub moj khaum ntawm kab lus no, peb yuav txiav txim siab lub koom haum ntawm kev txhim kho vaj tse thiab nws lub luag haujlwm hauv kev txhim kho kev lag luam. Cov ntsiab lus tseem ceeb, hom thiab cov hauv paus ntsiab lus ntawm lub koom haum ntawm txoj kev txhim kho yog txiav txim siab. Cov yam ntxwv nta ntawm lub system nyob rau hauv Lavxias teb sab tej yam kev mob yog xam

Nuclear fais fab nroj tsuag. Nuclear fais fab nroj tsuag ntawm Ukraine. Nuclear fais fab nroj tsuag hauv Russia

Kev xav tau lub zog niaj hnub ntawm noob neej tau loj hlob ntawm qhov loj heev. Nws noj rau lub nroog teeb pom kev zoo, rau kev lag luam thiab lwm yam kev xav tau ntawm lub teb chaws kev lag luam yog nce. Yog li ntawd, ntau thiab ntau soot los ntawm hlawv thee thiab roj roj yog emissions mus rau hauv cov huab cua, thiab lub tsev xog paj tshwm sim. Tsis tas li ntawd, muaj ntau thiab ntau tham nyob rau hauv lub xyoo tsis ntev los no hais txog cov kev taw qhia ntawm hluav taws xob tsheb, uas yuav ua rau kom nce nyob rau hauv hluav taws xob noj

Lub chaw fais fab loj tshaj plaws hauv tebchaws Russia: npe, hom thiab nta. Geothermal fais fab nroj tsuag nyob rau hauv Russia

Russia lub zog hluav taws xob tau tawg nyob hauv ntau lub nroog. Lawv lub peev xwm tag nrho yog txaus los muab lub zog rau tag nrho lub tebchaws

Gas piston fais fab nroj tsuag: lub hauv paus ntsiab lus ntawm kev ua haujlwm. Kev ua haujlwm thiab kev saib xyuas cov pa roj piston fais fab nroj tsuag

Gas piston fais fab nroj tsuag yog siv los ua lub ntsiab lossis lub zog thaub qab. Cov cuab yeej xav tau kev nkag mus rau txhua hom roj hluav taws xob los ua haujlwm. Ntau tus qauv GPES tuaj yeem tsim kom muaj cua sov rau cua sov thiab txias rau qhov cua tshuab, warehouses, industrial chaw