2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Hauv kev lag luam thiab hauv lub neej niaj hnub, cov khoom siv hlau txuas rau hauv ib qho qauv los ntawm kev vuam. Txoj kev no yog suav tias yog qhov feem ntau txhim khu kev qha thiab pheej yig. Cov cuab yeej siv tsis sib xws (lub tshuab vuam, electrodes, cov cuab yeej tiv thaiv) ua rau nws tuaj yeem tsim thiab kho ntau cov qauv hlau hauv lub sijhawm luv luv thiab muaj txiaj ntsig zoo.

Yuav kom tsim tau cov khoom siv hlau ruaj khov, cov neeg siv khoom tshiab yuav tsum paub meej cov yam ntxwv thiab hom pob tw welds, nrog rau cov thev naus laus zis ntawm kev ua haujlwm.

Weld sib koom txhais

Vuam ntawm cov hlau yog lawv cov kev sib txuas los ntawm melting cov npoo ntawm cov khoom thiab lawv cov crystallization tom ntej thaum txias. Cov txheej txheem vuam yog nrog rau cov txheej txheem ntawm lub cev thiab tshuaj lom neeg. Cov ntau yam no yuav tsum tau coj mus rau hauv tus account los ntawm welder thaum lub sijhawm ua haujlwm ntawm kev ua haujlwm. Ntxiv mus, tag nrho cov txheej txheem ntawm lub cev thiab tshuaj lom neeg muaj kev sib txuas hauv lub sijhawm thiab qhov chaw.

Thaum lub sijhawm vuam, muaj ntau qhov chaw tshwj xeeb uas qhia txog kev sib koom ua ke:

- qhov chaw ntawm fusion (weld pas dej), qhov twg muaj molten nplej ntawm hlau thiab electrode ntawm ciam teb ntawm lub hauv paus hlau thiab cov weld;

- weld tsim tom qab txias thiab solidification ntawm lub pas dej ua ke;

- Thaj chaw muaj kev kub ntxhov yog txhais los ntawm ib daim hlau uas tsis tau yaj, tab sis tau hloov nws cov muaj pes tsawg leeg thiab cov qauv los ntawm cov cua sov;

- puag hlau uas tuaj yeem welded yam tsis hloov nws cov khoom.

Yam welded joints

Muab faib cov kev sib txuas ntawm ob qhov hlau raws li lawv qhov chaw txheeb ze txheeb ze rau ib leeg. Hom kev sib txuas thaum lub sij hawm vuam yog xaiv los ntawm tus welder, coj mus rau hauv tus account cov yam ntxwv ntawm cov hlau thiab muaj peev xwm ua tiav cov txiaj ntsig zoo.

Nyob ntawm kev tso cov khoom hauv qhov chaw, kev sib txuas tau muab faib ua hom hauv qab no:

- pob tw;

- pob sib koom;

- T-bond;

- lap joint;

- end view.

Butt Fusion

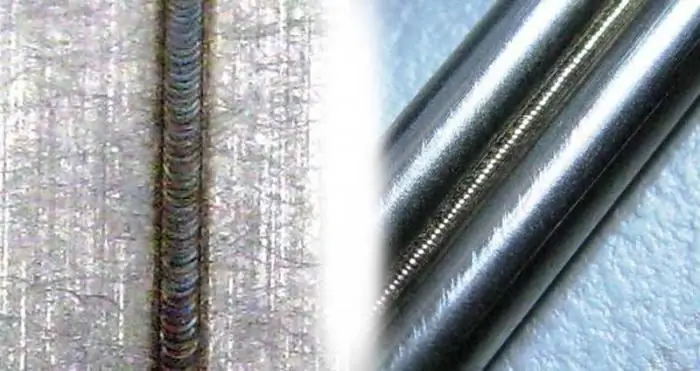

hom vuam ntau tshaj plaws yog lub pob tw. Nrog xws li vuam, ob qhov chaw yuav tsum tau koom nyob rau hauv tib lub dav hlau, yog li cov nto ntawm ib lub caij yog ib tug continuation ntawm lwm yam.

Cov ntsiab lus thaum lub pob tw vuam yog nyob ib sab ntawm txhua qhov kawg. Qhov kawg ntawm cov npoo yuav tsum tau welded tuaj yeem nrog lossis tsis muaj bevel. Ntxiv mus, tsis muaj bevel, vuam seam ntawm cov ntawv hlau txog li 4 hli tuab yog tau nrog qhov zoo tshaj plaws. Ob chav sided taub qab weldtsis muaj beveling qhov kawg ntawm cov hlau tso cai rau koj kom ua tiav cov txiaj ntsig zoo nrog lub thickness ntawm cov khoom mus txog 8 hli. Txhawm rau txhim kho qhov zoo ntawm kev sib txuas, nws yog ib qho tsim nyog yuav tsum ua kom muaj qhov sib txawv txog li ob millimeters ntawm cov phiaj.

Ib sab vuam ntawm qhov chaw nrog lub thickness ntawm 4 mus rau 25 millimeters, nws yog ntshaw kom ua nrog ib tug ua ntej bevel ntawm cov npoo. Qhov nrov tshaj plaws ntawm cov welders yog V-shaped bevel ntawm qhov kawg nto. Cov nplooj ntawv nrog lub thickness ntawm 12 hli los yog ntau tshaj yog pom zoo kom welded nyob rau hauv ob-sided X-txiav.

Kev faib tawm ntawm txoj haujlwm seam

Qhov zoo ntawm cov vuam yog nyob ntawm txoj haujlwm ntawm cov khoom hauv qhov chaw. Muaj plaub txoj hauv kev tseem ceeb los ua lub pob tw ntawm welds:

- Txoj kev sib txuas hauv qab yog siv thaum lub welder nyob rau sab saum toj ntawm qhov chaw ua haujlwm yuav tsum tau welded. Txoj kev no yog qhov yooj yim tshaj plaws, txij li cov hlau molten tsis ntws los ntawm ob sab, tab sis ntog ncaj qha rau hauv lub qhov dej. Nyob rau hauv rooj plaub no, slag thiab roj raug tshem tawm ntawm lub pas dej ua ke yam tsis muaj kev cuam tshuam thiab tawm mus rau saum npoo.

- Kab rov tav seams yog tsim los ntawm vertically teem daim hlau, thaum lub electrode yog coj los ntawm sab laug mus rau sab xis los yog ntawm sab xis mus rau sab laug. Kev ua haujlwm zoo ntawm kab rov tav seam muaj nyob rau hauv kev tswj nruj ntawm cov hlau molten, tiv thaiv nws los ntawm ntws, yog li nws yuav tsum raug xaiv kom raug xaiv cov electrode txav ceev thiab lub zog tam sim no.

- Vertical method siv rau ntawm qhov chawnyob vertically, thaum lub seam ntawm lub pob tw yog nqa tawm los ntawm sab saum toj mus rau hauv qab los yog vice versa. Qhov nyuaj ntawm kev vuam zoo li no yog cov hlau molten ntws, yog li ua txhaum cov tsos thiab qhov zoo ntawm kev sib txuas. Feem ntau, welders sim zam kev ua haujlwm hauv txoj haujlwm no. Tsuas yog cov kws ua haujlwm paub txog kev siv txoj kev no, tso siab rau lawv qhov kev paub theoretical thiab cov tswv yim.

- Nrog rau txoj kev qab nthab, cov khoom yuav tsum tau welded yog saum lub welder lub taub hau. Thaum siv txoj kev no, koj yuav tsum ua raws li cov txheej txheem thev naus laus zis thiab kev nyab xeeb, raws li cov hlau molten drips.

Kev koom tes ntawm cov seams los ntawm hom vuam

pob qij txha tuaj yeem raug cais raws li hom kev cuam tshuam ntawm cov khoom siv vuam. Nws yog kev siv cov cuab yeej tsim nyog thiab cov khoom siv uas ua rau nws tuaj yeem tau txais cov qauv hauv qab no:

- Kev siv hluav taws xob arc vuam txhawb kev tsim cov vuam siv lub tshuab hluav taws xob tshwj xeeb thiab tso cai rau koj kom tau txais kev txhim khu kev ruaj ntseg ntawm cov hlau txuas nrog lub thickness ntawm 0.1 txog 100 hli.

- Arc vuam siv cov roj inert tso cai rau koj kom muaj zog thiab zoo nkauj seams, txij li tag nrho cov txheej txheem vuam siv nyob rau hauv kev tiv thaiv ntawm huab cua.

- Tsis siv neeg vuam ua lub pob tw vuam ntawm cov hlau hauv hom kev ua haujlwm ywj pheej ntawm lub inverter, ntawm no tus welder tswj cov txheej txheem tom qab teeb tsa cov cuab yeej.

- Thaum roj welding, tsim cov vuam tshwm simvim qhov kub kub ntawm cov roj sib tov.

- Nrog cov hlau nplaum nws tuaj yeem tsim cov seams.

weld profile

Yog tias koj txiav lub pob tw, nws yooj yim los txiav txim siab qhov xwm txheej ntawm nws cov tsos:

- Cov concave weld tsis muaj zog, yog li nws yog tsuas yog siv rau vuam nyias, rau cov qauv nrog me me dynamic load.

- Convex seams yog suav tias yog qhov muaj zog ntxiv, yog li lawv tau siv dav hauv cov qauv nrog cov khoom zoo li qub, kev tsim cov seam yuav tsum tau siv ntau dua ntawm electrodes.

Ib txwm welds yog siv rau dynamic loads, nyob rau hauv cov ntaub ntawv no tsis muaj ntau qhov sib txawv ntawm lub hauv paus hlau thiab qhov siab ntawm lub weld

Nyob seams by length

Lwm qhov tseem ceeb hauv kev tau txais kev sib txuas zoo ntawm ob lub hlau yog qhov ntev ntawm qhov vuam. Kev suav cov pob qij txha yuav siv sij hawm rau hauv tus account hom thiab ntev ntawm lub vuam.

Los ntawm qhov ntev, cov pob qij txha raug cais raws li txuas ntxiv lossis cuam tshuam:

- Tshuaj welds tsis muaj qhov khoob khoob los ntawm kev vuam raws tag nrho ntev ntawm kev sib txuas ntawm ob qhov hlau. Hom vuam no tso cai rau koj kom tau txais qhov zoo tshaj plaws thiab ruaj khov kev sib txuas ntawm txhua yam qauv. Qhov tsis zoo ntawm kev taw qhia txuas ntxiv electrode yog cov khoom siv siab thiab kev ua haujlwm qeeb.

- Txoj kev sib cuam tshuamNws yog siv nyob rau hauv rooj plaub thaum nws tsis tas yuav tsim kom muaj kev sib txuas tshwj xeeb. Xws li cov seams feem ntau yog ua los ntawm qee qhov ntev nrog lub sijhawm nruj synchronous. Kev sib tshuam welding tuaj yeem staggered lossis saw khiav.

Vuam Kev Tiv Thaiv Kev Nyab Xeeb

Cov txheej txheem vuam yog nrog los ntawm ntau yam uas tuaj yeem cuam tshuam kev nyab xeeb ntawm tib neeg kev noj qab haus huv. Lub ntsiab ua puas tsuaj yog suav hais tias yog cov muaj hluav taws xob uas cuam tshuam rau lub qhov muag, qhov cuam tshuam ntawm cov roj tso tawm, nrog rau cov nyhuv ntawm cov hlau molten.

Yog li ntawd, ntawm txhua qhov kev lag luam niaj hnub no, kev saib xyuas tshwj xeeb yog them rau cov khaub ncaws tiv thaiv ntawm cov welder:

- canvas suit;

- khau lossis khau khiab nrog kaw;

- vuam daim npog qhov ncauj lossis tsom iav;

- respirator tiv thaiv kab mob ua pa;

- canvas mittens.

Txhua yam khoom yuav tsum huv si, tsis muaj cov kua roj stains.

Rau tus pib welder kom tau txais kev txawj vuam, nws yog qhov zoo dua los pib nrog cov khoom yooj yim, vim tias qhov kev ntseeg siab thiab lub zog ntawm cov qauv hlau nyob ntawm qhov kev sib txuas zoo. Kev ua kom zoo ntawm cov txheej txheem vuam yog lub ntsiab lav ntawm kev ua haujlwm zoo.

Pom zoo:

Vuam seams: hom seams thiab pob qij txha

Nyob rau hauv cov txheej txheem ntawm vuam, ntau yam kev sib txuas tau txais. Vuam seams tuaj yeem txuas tsis tau tsuas yog hlau, tab sis kuj muaj lwm yam khoom sib txawv. Lawv raug cais raws li ntau yam: txoj kev ua tiav, spatial txoj hauj lwm, ntev, thiab lwm yam

Ultrasonic kuaj ntawm cov pob qij txha welded, txoj kev thiab thev naus laus zis ntawm kev sim

Ultrasonic kuaj - cov cuab yeej siv siab tshaj plaws rau kev kawm ntawm vuam pob qij txha thiab cov seams. Nws yuav tau tham hauv kab lus no

Teem sijhawm ntawm kev kho pob zeb: nta, hom, thev naus laus zis thiab cov ntsuas tseem ceeb

Cov kuab ua kua rau ib lub sijhawm tom qab nchuav yuav tau txais cov khoom ua tau zoo. Lub sijhawm no yog hu ua lub sijhawm tuav, tom qab uas cov txheej txheem tiv thaiv tuaj yeem siv tau

Kev tswj hwm hauv kev siv thev naus laus zis: lub tswv yim, lub hom phiaj thiab lub hom phiaj

Cov kab lus tham txog kev tswj hwm hauv cov ntaub ntawv thev naus laus zis, saib xyuas nws ntau yam thiab cov yam ntxwv ntawm kev siv tswv yim

Tsis muaj kev puas tsuaj ntawm cov pob qij txha welded: khoom siv, GOST

Cov kab lus no tau mob siab rau txoj hauv kev tsis muaj kev puas tsuaj ntawm cov pob qij txha welded. Cov txheej txheem tswj tau tso cai los ntawm GOST thiab cov cuab yeej siv tau piav qhia