2024 Tus sau: Howard Calhoun | [email protected]. Kawg hloov kho: 2023-12-17 10:28

Nyob rau hauv cov txheej txheem ntawm vuam, ntau yam kev sib txuas tau txais. Vuam seams tuaj yeem txuas tsis tau tsuas yog hlau, tab sis kuj muaj lwm yam khoom sib txawv. Cov ntsiab lus docked rau hauv ib qho kev sib koom ua ke sawv cev rau kev sib txuas uas tuaj yeem txiav mus rau ntau ntu.

Weld zones

Kev sib koom ua ke tau txais thaum lub sijhawm vuam tau muab faib ua cov cheeb tsam hauv qab no:

- Qhov chaw ntawm fusion yog ciam teb ntawm lub hauv paus hlau thiab cov hlau ntawm qhov tshwm sim weld. Nyob rau hauv cheeb tsam no muaj cov nplej uas txawv ntawm lawv cov qauv los ntawm lub xeev ntawm lub hauv paus hlau. Qhov no yog vim ib nrab melting thaum lub sij hawm vuam txheej txheem.

- thaj chaw muaj kev kub ntxhov yog thaj tsam ntawm lub hauv paus hlau uas tsis tau yaj, txawm hais tias nws cov qauv tau hloov pauv thaum lub cua sov ntawm cov hlau.

- vuam seam - ib seem uas tau tsim thaum lub sij hawm crystallization nyob rau hauv cov txheej txheem ntawm txias cov hlau.

Yam vuam sib txuas

Nyob ntawm qhov chaw ntawm cov khoom sib koom ua ke, cov kev sib txuas tau muab faib ua hom hauv qab no:

- Tub. Docking ntawm cov txheej txheem yog nqa tawm nyob rau hauv tib lub dav hlau nrog xaus rau ib leeg. Nyob ntawm qhov sib txawv thicknesses ntawm qhov yuav tsum tau koom nrog, qhov kawg yuav hloov vertically txheeb ze rau ib leeg.

- Txoj kev sib txuas. Nyob rau hauv rooj plaub no, qhov kawg yog aligned ntawm ib lub kaum sab xis. Cov txheej txheem vuam yog ua los ntawm cov npoo uas nyob ib sab.

- Kev sib txuas. Yam yuav tsum tau welded yog parallel nrog ib nrab overlap.

- End txuas. Cov ntsiab lus yuav tsum tau welded yog dlhos thaum uas tig mus rau ib leeg thiab koom rau ntawm qhov kawg.

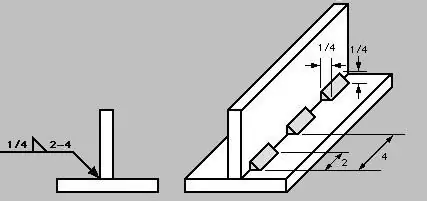

- T-kev sib txuas. Hauv qhov no, qhov kawg ntawm ib feem txuas rau sab ntawm lwm qhov ntawm lub kaum sab xis.

Vuam pob qij txha kuj qhia cov hom welds, uas tuaj yeem tsim nyog raws li qee cov qauv.

ntsuas ntsuas

Muaj ntau qhov ntsuas uas txhua qhov welds tau tuaj yeem ua tus yam ntxwv:

- dav yog qhov loj ntawm cov seam ciam teb, uas tau kos los ntawm cov kab fusion pom;

- lub hauv paus ntawm seam yog nws sab nraub qaum, uas nyob ntawm qhov siab tshaj plaws ntawm sab xub ntiag;

- convexity - yog txiav txim siab nyob rau hauv feem ntau convex ib feem ntawm lub seam thiab qhia los ntawm qhov deb ntawm lub dav hlau ntawm lub hauv paus hlau mus rau ciam teb ntawm qhov loj tshaj plaws protrusion;

- concavity - qhov ntsuas no cuam tshuam yog tias nws tshwm sim hauv qhov vuam, vim qhov tseeb, nws yog qhov tsis xws luag; qhov kev ntsuas no tau txiav txim siab nyob rau hauv qhov chaw uas lub seam muaj qhov loj tshaj deflection - los ntawm nws mus rau lub dav hlaulub hauv paus hlau yog ntsuas los ntawm qhov loj ntawm lub concavity;

- ceg ntawm seam - nws tsuas yog nyob rau hauv lub ces kaum thiab tee pob qij txha; Qhov ntsuas no yog ntsuas los ntawm qhov tsawg tshaj plaws nyob deb ntawm sab saum npoo ntawm ib feem welded mus rau ciam teb kab ntawm lub seam nyob rau saum npoo ntawm qhov thib ob.

Nyob ntawm seams raws li txoj kev ua

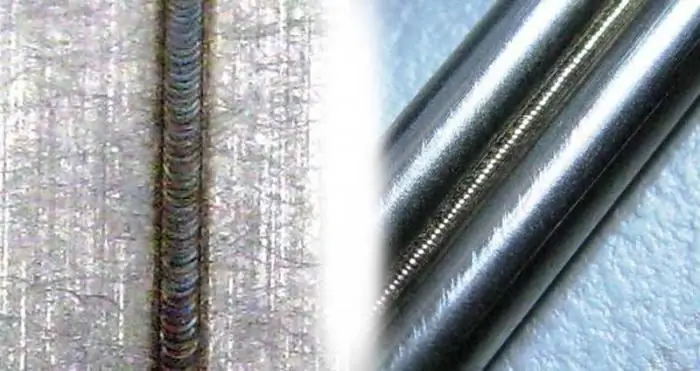

- Ib sab vuam seams. Lawv tau ua tiav nrog kev nkag mus ntawm cov hlau tag nrho ntev.

- Kev ua ob sab. Raws li thev naus laus zis, tom qab vuam ib sab, lub hauv paus ntawm lub seam raug tshem tawm, thiab tsuas yog tom qab ntawd vuam yog ua nyob rau sab nraud.

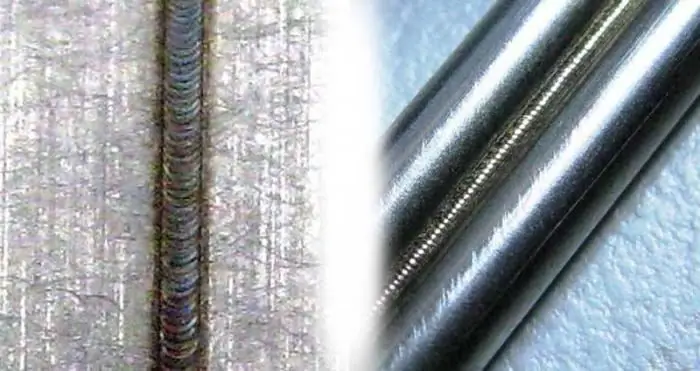

- Ib txheej seams. Ua los ntawm ib leeg-pass welding nrog ib tug deposited hlaws.

- Multilayer seams. Lawv siv yog pom zoo nrog ib tug loj thickness ntawm cov hlau, uas yog, thaum nws tsis muaj peev xwm ua welding nyob rau hauv ib tug pass raws li lub tshuab. Lub seam txheej yuav muaj ob peb chais (txoj kev). Qhov no yuav txwv tsis pub sib kis ntawm thaj chaw uas muaj kev kub ntxhov thiab tau txais cov vuam zoo thiab muaj zog.

Hom welds los ntawm qhov chaw thiab qhov ntev

Cov haujlwm vuam hauv qab no yog qhov txawv:

- qis dua, thaum lub welded seam nyob rau hauv qis kab rov tav dav hlau, piv txwv li ntawm lub kaum sab xis ntawm 0º txheeb ze rau hauv av;

- kab rov tav, vuam kev taw qhia yog kab rov tav, thiab qhov tuaj yeem nyob ntawm lub kaum sab xis ntawm 0º txog 60º;

- ntsug, nyob rau hauv txoj hauj lwm no qhov chaw yuav tsum tau weldedyog nyob rau hauv lub dav hlau los ntawm 60º mus rau 120º, thiab vuam yog nqa tawm nyob rau hauv txoj kev ntsug;

- ceiling, thaum ua haujlwm ntawm lub kaum sab xis ntawm 120-180º, uas yog, cov welds nyob saum tus tswv;

- "rau hauv lub nkoj", qhov kev qhia no tsuas yog siv rau lub kaum lossis tee pob qij txha, ib feem yog teem rau ntawm lub kaum sab xis, thiab vuam yog nqa tawm "hauv kaum".

Kev sib cais los ntawm qhov ntev:

- txuas ntxiv, qhov no yuav luag tag nrho cov seams tau ua, tab sis muaj qhov zam;

- sib quas ntus seams, lawv tsuas yog tshwm sim hauv kaum pob qij txha; ob-sided seams ntawm hom no tuaj yeem ua tau ob qho tib si hauv cov qauv checkerboard thiab hauv cov qauv saw.

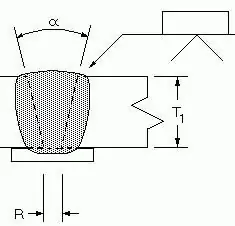

Tus qauv tsim no yog siv thaum lub thickness ntawm cov hlau siv rau vuam yog loj dua 7 hli. Grooving yog tshem tawm cov hlau los ntawm cov npoo hauv ib qho duab tshwj xeeb. Cov txheej txheem no yog ua nrog ib leeg-pass taub qab vuam. Qhov no yog qhov tsim nyog thiaj li tau txais qhov tseeb vuam. Raws li cov ntaub ntawv tuab, qhov zawj yog qhov tsim nyog txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau nws, nws yog qhov yuav tsum tau ua cov txheej txheem sib xyaw nrog cov hlaws dai, sib sau ua ke cov kab noj hniav, txuas cov hlau los ntawm tag nrho cov thickness.

Edging tuaj yeem ua tau yog tias lub thickness ntawm cov hlau tsis tsawg dua 3 hli. Vim tias tus nqi qis dua yuav ua rau kub hnyiab. Txiav yog tus cwj pwm los ntawm cov qauv tsim hauv qab no: clearance - R; ntug txiav kaum - α; siab tawv - p. Qhov chaw ntawm cov kev txwv no qhia tau hais tias kev kos duab ntawm vuamseam.

Beveling nce tus nqi ntawm cov khoom siv. Yog li ntawd, tus nqi no tau sim hauv txhua txoj hauv kev kom txo qis. Nws muab faib ua ob peb hom raws li tus tsim:

- V-shaped;

- X-puab;

- Y-zoo li;

- U-shaped;

- slit.

Txoj kev txiav ntug

Rau cov tuab me me ntawm cov khoom siv welded los ntawm 3 mus rau 25 hli, ib sab V-groove feem ntau yog siv. Lub bevel tuaj yeem ua tau ntawm ob qho kawg lossis ntawm ib qho ntawm lawv. Nws yog ib advisable mus welding hlau nrog ib tug tuab ntawm 12-60 hli nrog ib tug ob-sided X-shaped zawj. Lub kaum sab xis α thaum txiav hauv X, V zoo li 60º, yog tias lub bevel ua tiav ntawm ib ntug xwb, ces tus nqi ntawm α yuav yog 50º. Rau ib lub thickness ntawm 20-60 hli, qhov kev lag luam tshaj plaws yuav yog kev siv cov hlau txuas nrog U-shaped zawj. Lub bevel kuj tuaj yeem ua rau ntawm ib lossis ob qho kawg. Lub blunting yuav yog 1-2 hli, thiab tus nqi sib txawv yuav yog 2 hli. Rau ib tug loj thickness ntawm hlau (tshaj 60 hli), txoj kev zoo tshaj plaws yog qhov txiav. Rau kev sib koom ua ke, cov txheej txheem no tseem ceeb heev, nws cuam tshuam ntau yam ntawm cov seam:

- kev sib txuas kev noj qab haus huv;

- lub zog thiab qhov zoo ntawm qhov vuam;

- Nyob zoo.

qauv thiab GOSTs

- Kev tuav arc vuam. Vuam seams thiab pob qij txha raws li GOST 5264-80 muaj xws li hom, tsim qhov ntev rau vuam, them nrog electrodes nyob rau hauv tag nrho cov spatial txoj hauj lwm. Qhov no tsis suav nrog cov kav dej.steel.

- Vuam ntawm cov kav dej steel. GOST 16037-80 - Txhais lub ntsiab hom, txiav npoo, qhov ntev ntawm cov cuab yeej siv vuam.

- Vuam ntawm cov kav dej ua los ntawm tooj liab thiab tooj liab-nickel alloys. GOST 16038-80.

- Arc vuam ntawm aluminium. Seams yog welded. GOST 14806-80 - Cov duab, qhov ntev, ntug kev npaj rau phau ntawv thiab tshuab vuam ntawm txhuas thiab nws cov alloys, txheej txheem yog ua nyob rau hauv ib puag ncig tiv thaiv.

- Submerged arc. GOST 8713-79 - Vuam seams thiab pob qij txha yog ua los ntawm kev siv tsis siv neeg lossis kev siv tshuab vuam ntawm qhov hnyav, ntawm lub ncoo flux. Siv rau hlau thickness ntawm 1.5mm mus rau 160mm.

- Vuam aluminium hauv inert gases. GOST 27580-88 - tus qauv rau phau ntawv, semi-automatic thiab tsis siv neeg vuam. Nws yog ua los ntawm cov khoom siv tsis siv hluav taws xob hauv inert gases nrog cov khoom muab tub lim thiab txuas mus rau txhuas thickness ntawm 0.8 mus rau 60 hli.

weld mark

Raws li cov ntaub ntawv tswj hwm, qhov muaj cov welds tau pom ntawm cov duab kos los yog ntawm qhov pom dav dav. Welds tau pom raws li cov kab khoom yog tias lawv pom. Thiab yog hais tias vice versa - ces dashed ntu. Cov thawj coj nrog ib-txoj kev xub yog kos los ntawm cov kab no. Lub cim rau vuam seams yog nqa tawm ntawm lub txee los ntawm tus thawj coj. Cov ntawv sau yog ua rau saum lub txee yog tias lub seam nyob rau sab pem hauv ntej. Txwv tsis pub, lub npe yuav nyob hauv qab txee. Qhov no suav nrog cov ntaub ntawv seam hauv qab no:

Cov paib pab. Ntawm kev sib tshuam ntawm tus thawj coj nrog lub txee tuaj yeem ua taupaib:

○ - kaw seam;

┐ - lub seam yog welded thaum lub sij hawm installation.

- Kev tsim cov welds, lawv cov qauv tsim thiab GOST kev sib txuas.

- Lub npe ntawm seam raws li tus qauv.

- Vuam txoj kev raws li cov qauv kev cai.

- Cov ceg qhia, cov khoom no tsuas yog siv rau cov pob qij txha xwb.

- Seam discontinuity, yog tias muaj. Ntawm no cov kauj ruam thiab qhov chaw ntawm vuam ntu yog qhia.

- Ntxiv tus nqi pabcuam ntxiv icons. Cia peb xav txog lawv ua ib yam khoom cais.

Pab cov cim

Cov cim no kuj tseem siv rau saum lub txee yog tias qhov vuam hauv daim duab pom, thiab hauv qab nws thaum pom tsis pom:

- tshem tawm cov hlua khi;

- kho qhov chaw uas yuav muab kev hloov pauv mus rau lub hauv paus hlau, tshem tawm sags thiab pob;

- lub seam yog ua raws ib txoj kab qhib; Cov cim no tsuas yog siv rau cov welds pom hauv daim duab;

- kev huv ntawm qhov chaw ntawm qhov sib koom ua ke.

Txhawm rau kom yooj yim, yog tias tag nrho cov seams ntawm cov qauv tau ua raws li tib GOST, muaj tib qhov grooves thiab cov qauv qhov ntev, kev tsim thiab cov qauv rau vuam yog qhia hauv cov kev cai. Tus tsim yuav tsis yog tag nrho, tab sis ib tug loj tus naj npawb ntawm zoo tib yam seams. Tom qab ntawd lawv muab faib ua pab pawg thiab muab rau lawv cov lej hauv txhua pab pawg sib cais. Ntawm ib lub seam qhia tag nrho cov npe. Tus so yog suav xwb. Tus naj npawb ntawm pawg thiab tus lej ntawm cov stitches hauv txhuauas yuav tsum tau teev nyob rau hauv cov ntaub ntawv tswj.

Pom zoo:

Ultrasonic kuaj ntawm cov pob qij txha welded, txoj kev thiab thev naus laus zis ntawm kev sim

Ultrasonic kuaj - cov cuab yeej siv siab tshaj plaws rau kev kawm ntawm vuam pob qij txha thiab cov seams. Nws yuav tau tham hauv kab lus no

Welded pob qij txha: nta, hom thiab thev naus laus zis

Ntawm thiab hom vuam. Kev faib tawm ntawm cov pob qij txha welded raws li ntau yam tsis muaj kev sib tw. Technology tsim ib lub pob tw, nyob ntawm seb cov khoom siv. Kev ntsuas kev nyab xeeb thaum ua haujlwm vuam

Flux rau vuam: lub hom phiaj, hom vuam, flux muaj pes tsawg leeg, cov cai ntawm kev siv, GOST cov cai, qhov zoo thiab qhov tsis zoo ntawm daim ntawv thov

Qhov zoo ntawm cov vuam yog txiav txim siab tsis yog los ntawm lub peev xwm ntawm tus tswv los npaj lub arc kom raug, tab sis kuj los ntawm kev tiv thaiv tshwj xeeb ntawm thaj chaw ua haujlwm los ntawm kev cuam tshuam sab nraud. Tus yeeb ncuab tseem ceeb ntawm txoj hauv kev los tsim kom muaj kev sib txuas ntawm cov hlau uas muaj zog thiab ruaj khov yog cov huab cua puag ncig ntuj. Lub vuam yog cais tawm los ntawm cov pa oxygen los ntawm cov flux rau vuam, tab sis qhov no tsis yog nws txoj haujlwm xwb

Kev sib txhuam cov pob qij txha ntawm cov ntsia hlau muaj zog

Kev sib txhuam cov pob qij txha ntawm lub zog muaj zog bolts: tsim nta, tsim khoom thiab sib dhos yuav tsum tau ua. Cov txheej txheem kom tau txais qhov tsim nyog roughness ntawm mating nto. Kev suav ntawm qhov tseem ceeb ntawm kev sib txuas. Kev tswj kom zoo

Tsis muaj kev puas tsuaj ntawm cov pob qij txha welded: khoom siv, GOST

Cov kab lus no tau mob siab rau txoj hauv kev tsis muaj kev puas tsuaj ntawm cov pob qij txha welded. Cov txheej txheem tswj tau tso cai los ntawm GOST thiab cov cuab yeej siv tau piav qhia